vi

3-6 Start Binding .............................................................................................................. 62

3-7 Manual Feeding .......................................................................................................... 65

3-8 Saving, Loading and Deleting Jobs ......................................................................... 70

3-8-1 Saving a Job ...................................................................................................... 70

3-8-2 Loading a Job .................................................................................................... 71

3-8-3 Deleting a Job .................................................................................................... 73

3-9 Power Saving Mode ................................................................................................... 74

3-10Reversing the Stitcher Heads ................................................................................... 75

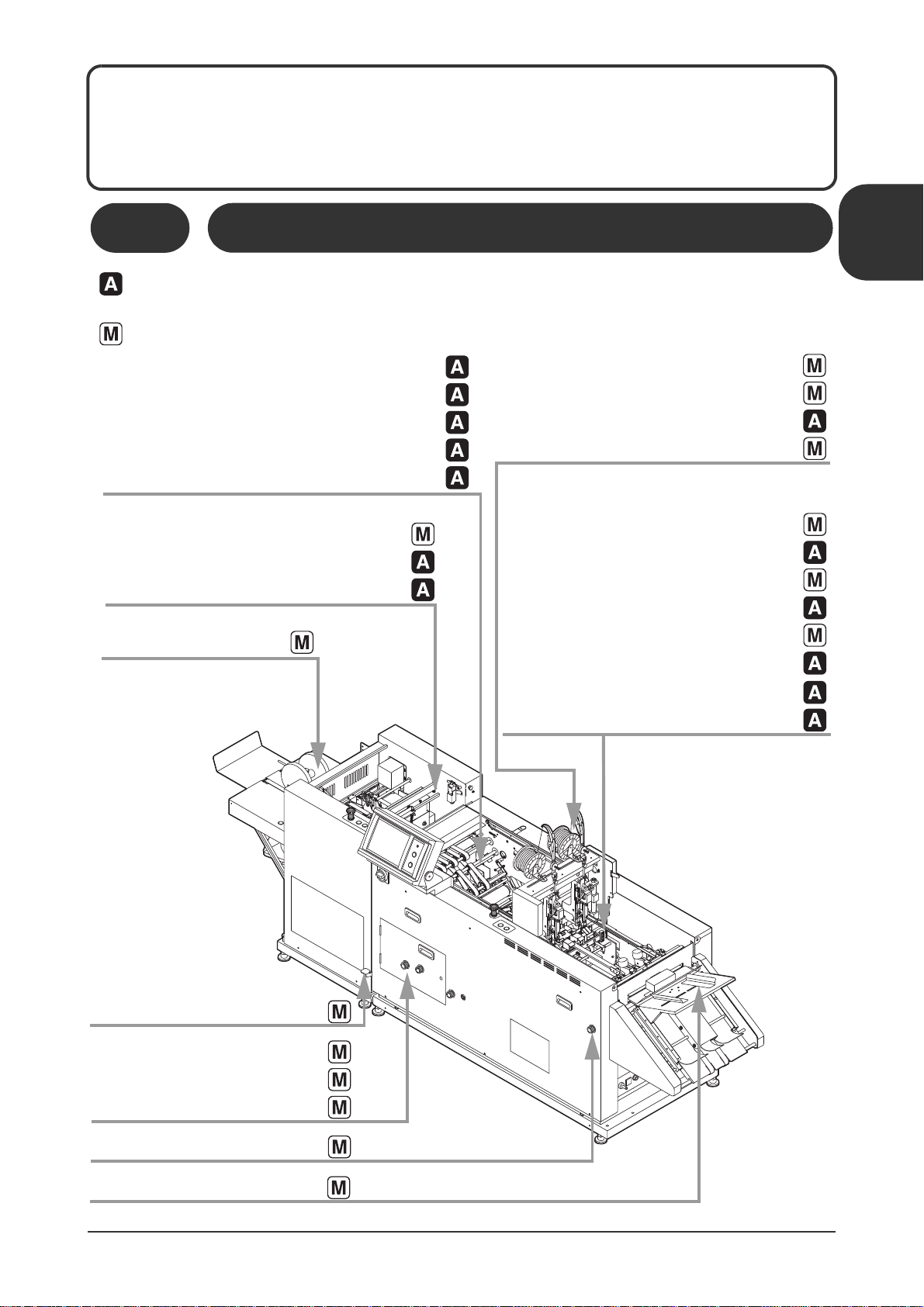

4 Adjustments

4-1 Stitch Adjustments................................................................................................... 77

4-2 Infeed Section Adjustments ...................................................................................... 79

4-3 Jog Section Adjustments .......................................................................................... 81

4-4 Fold Section Adjustments ......................................................................................... 83

4-5 Fore-edge Trim Section Adjustments ...................................................................... 84

5 Troubleshooting

5-1 If an Icon Is Displayed on the Error Screen ............................................................. 87

5-1-1 If An Error Icon Is Displayed .............................................................................. 87

5-1-2 If a System Error Occurs ................................................................................... 90

5-2 Removing Jammed Sheets ....................................................................................... 99

5-3 Stitch-Related Problems ......................................................................................... 101

5-3-1 The Stitches Are Moved Parallel to the Fold Line ........................................... 101

5-3-2 The Distance Is Not Correct........................................................................... 101

5-3-3 The Stitches Are Angled................................................................................. 101

5-3-4 The Stitch Position Varies............................................................................... 102

5-3-5 The Stitches Are Curved................................................................................. 102

5-3-6 There Are Problems With The Stitch Length.................................................. 102

5-3-7 The Sheets Are Not Stitched.......................................................................... 103

5-3-8 The Wire Jams................................................................................................ 103

5-3-9 The Shape of the Stitch is Incorrect................................................................ 104

5-4 Poor Sheet Arrangement ......................................................................................... 107

5-5 Folding-Related Problems ...................................................................................... 109

5-5-1 Fold Skewing.................................................................................................. 109

5-5-2 The Folding Position Varies............................................................................ 109

5-5-3 Failed to Fold at Correct Position................................................................... 110

5-5-4 Jog Error Not Detected................................................................................... 111

5-5-5 The Sheets Are Bent...................................................................................... 111

5-6 Fore-edge Trimming-Related Problems ................................................................. 112

5-6-1 The Sheets Are Trimmed Incorrectly.............................................................. 112

5-6-2 Incorrect Trim Position.................................................................................... 112

5-7 Scratched Sheets ..................................................................................................... 113

5-8 Specific Symptom-Related Problems .................................................................... 114

5-8-1 The Buzzer Beeps at an Interval of Two Seconds.......................................... 114

5-8-2 Fine Adjustment from the Touch Panel Does Not Work................................. 114

5-8-3 The Delivery Conveyor Does Not Move......................................................... 114

5-8-4 The Trim Is Not Collected (The pump does not operate) ................................ 114

5-8-5 The Touch Panel Does Not Light Up.............................................................. 115

5-8-6 A Stitcher Head is Jammed............................................................................ 115