2

Introduction

Thank you for purchasing the iBOOKLET.

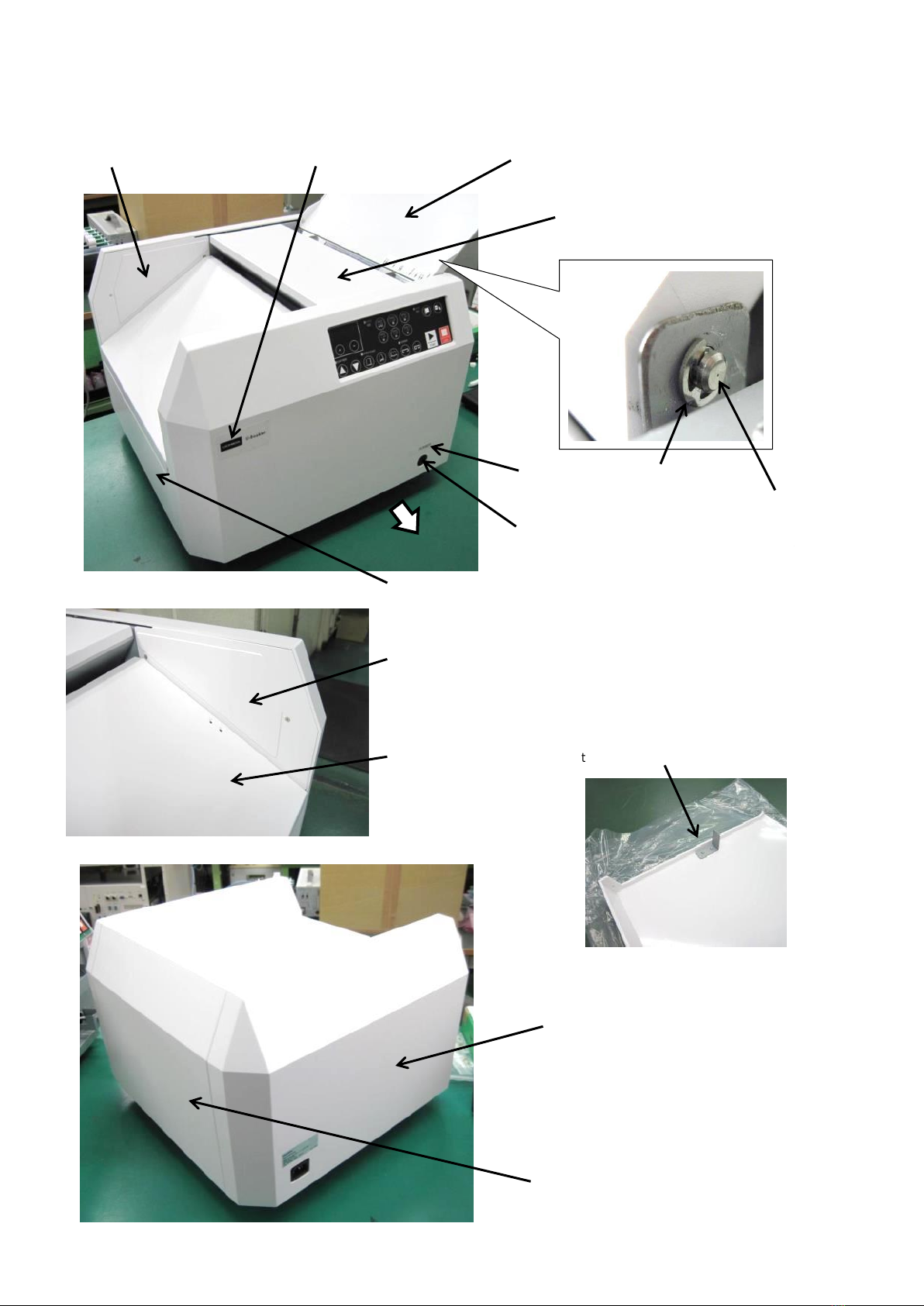

The iBOOKLET is a tabletop booklet maker.

Its major features include:

- Comfort in operation supported by touch-type switches.

- Support for two clinching methods to make a wide variety of booklets

- Automated or manual booklet making is possible only by selecting paper size.

Read this manual carefully to ensure the product is handled and used under the best

condition

Table of Contents

1. Troubleshooting...................................................................................................................5

2. Descriptions of Different Types of Screws ..........................................................................7

3. Replacing Components ........................................................................................................8

3-1 Replacing the Outer Covers .........................................................................................8

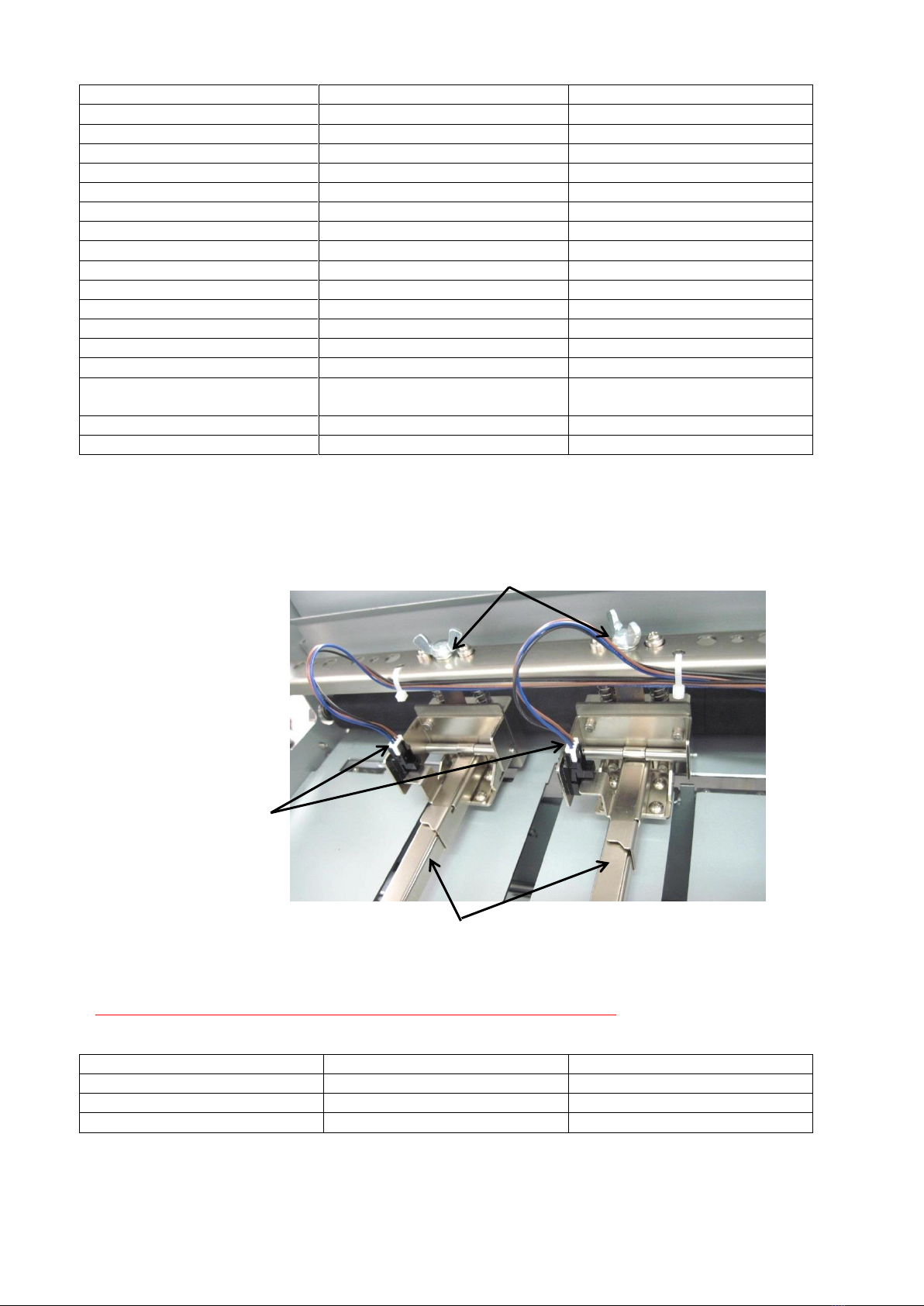

3-2 Replacing the Stapler Units..........................................................................................9

3-3 Replacing the Knock Pin ............................................................................................10

3-4 Replacing the Staple Level Sensor............................................................................10

3-5 Dissembling and Reassembling a Stapler Unit (Removing the staples that are stuck)

............................................................................................................................................11

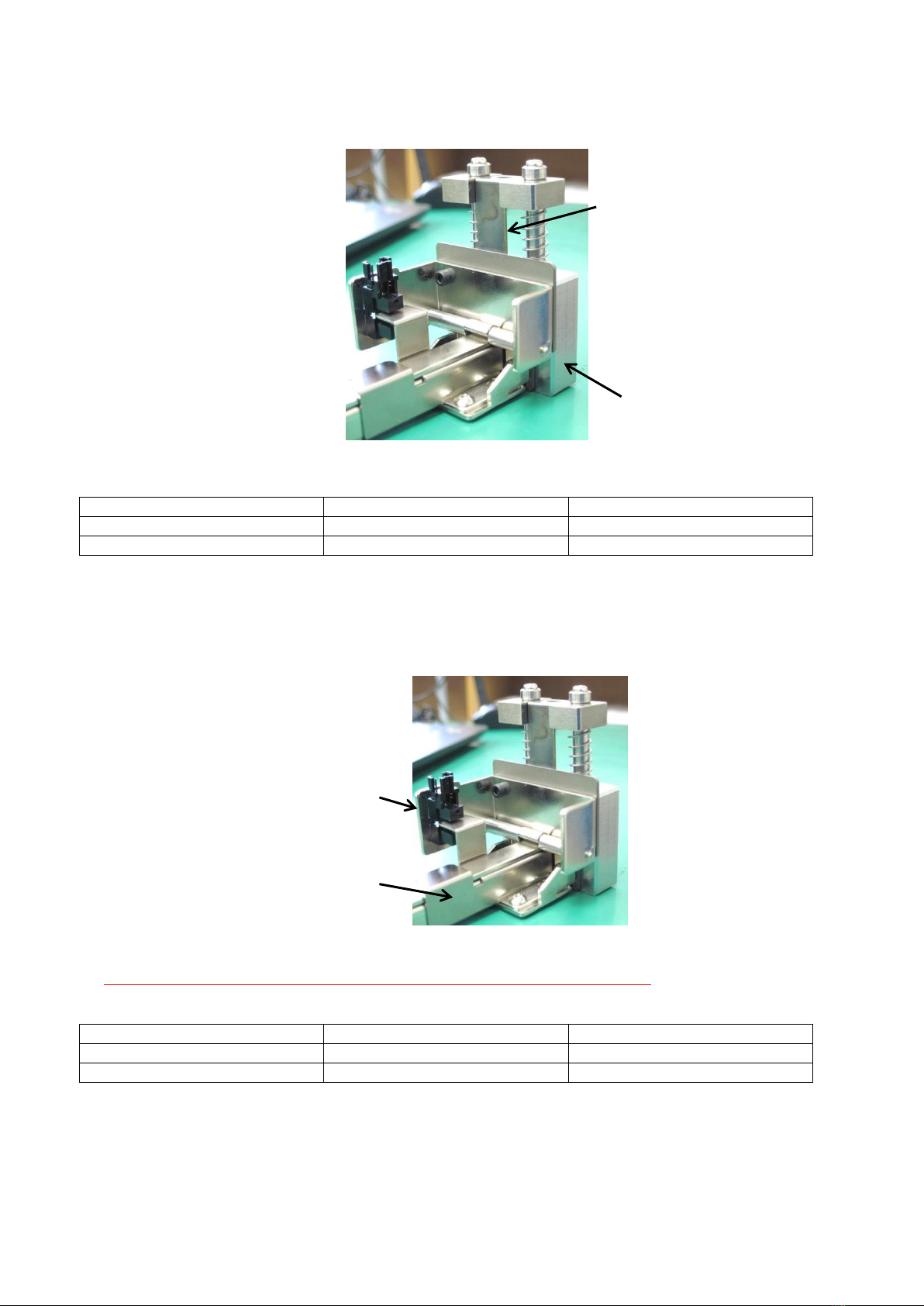

3-6 Adjusting the Stapler Unit Head.................................................................................12

3-7 Replacing and Cleaning Clincher Pieces...................................................................14

3-8 Adjusting the Clincher Position .................................................................................15

3-9 Adjusting the Cushion Piece......................................................................................16

3-10 Adjusting the Belt Tension.......................................................................................18

3-11 Replacing the Circuit Board .....................................................................................20

3-12 Replacing the Control Panel.....................................................................................21

3-13 Replacing a Joint Arm...............................................................................................22

3-14 Replacing the Power Supply Unit.............................................................................24

3-15 Replacing the Inlet ....................................................................................................25

3-16 Replacing the Switch Unit.........................................................................................26

3-17 Replacing the Cover Switch .....................................................................................27

3-18 Replacing the Paper Sensor.....................................................................................29

3-19 Replacing Sensors....................................................................................................31

3-20 Replacing the Stapler Motor.....................................................................................33

3-21 Replacing the Wind-Up Motor ..................................................................................35

3-22 Replacing the Clincher Motor...................................................................................37

3-23 Replacing the Paper Feed Motor..............................................................................38

3-24 Replacing the Timing Belt.........................................................................................40

3-25 Detaching the Cover for Removing Paper...............................................................42