1

info@delviro.com | 1.877.502.3434www.delviro.com 1

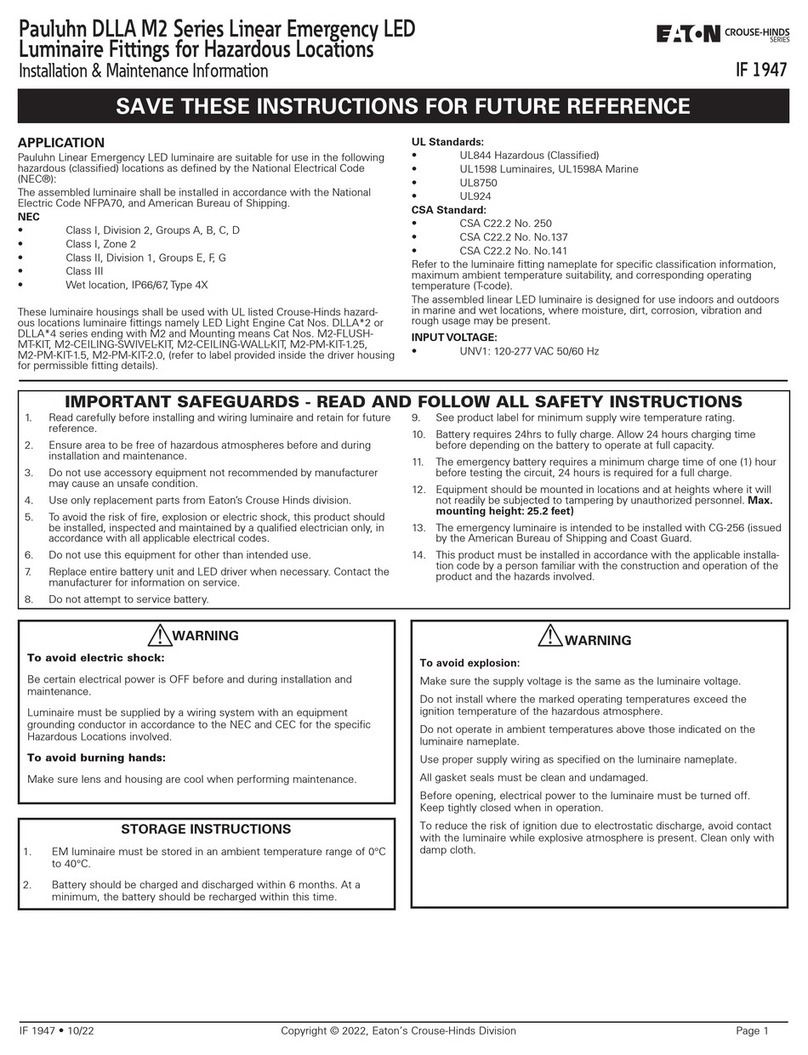

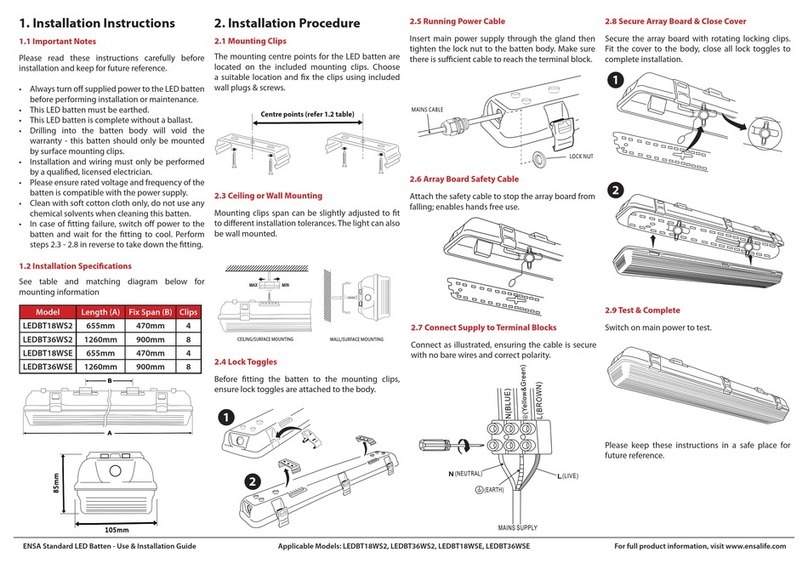

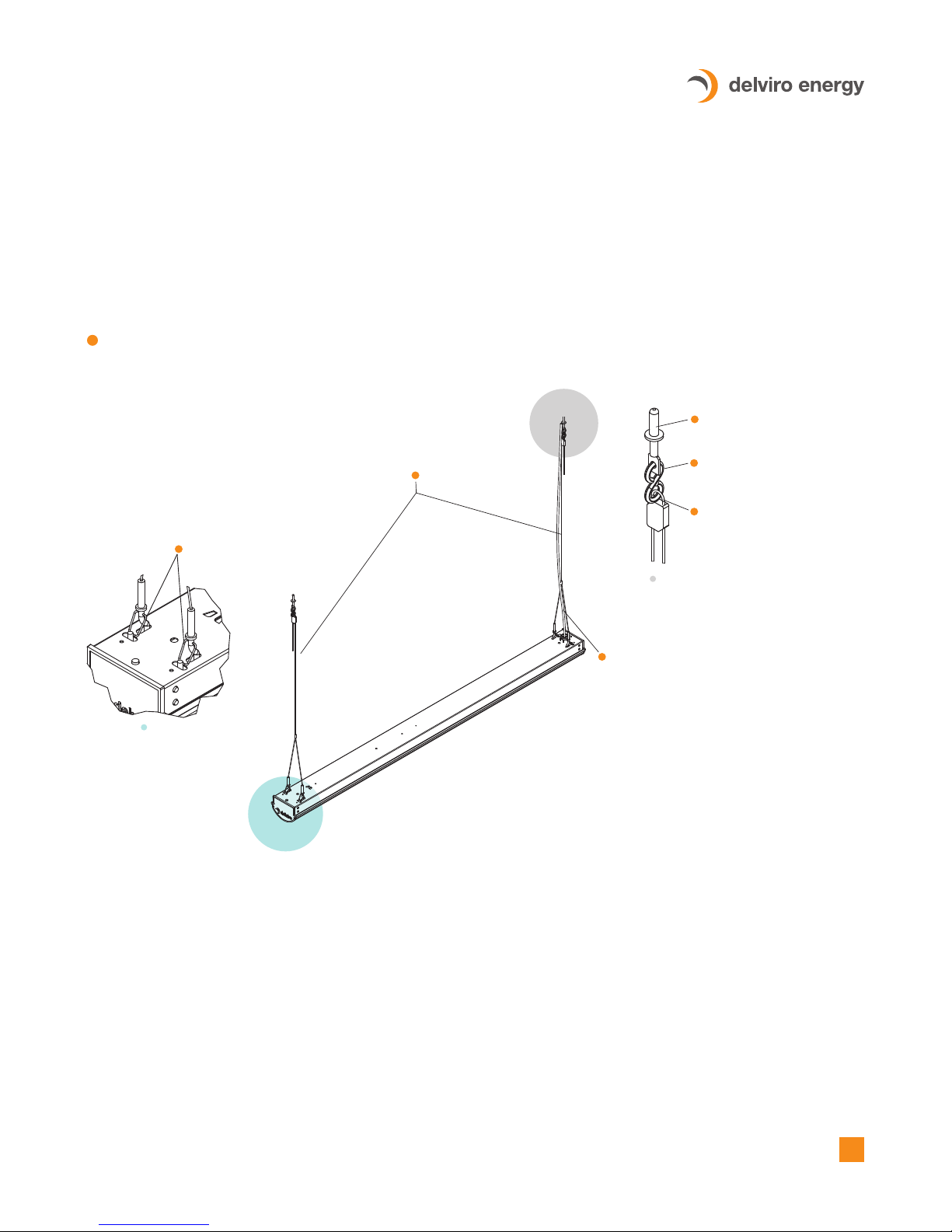

1. Disconnect the electrical power on the electrical panel prior to installing the Zip Light fixture.

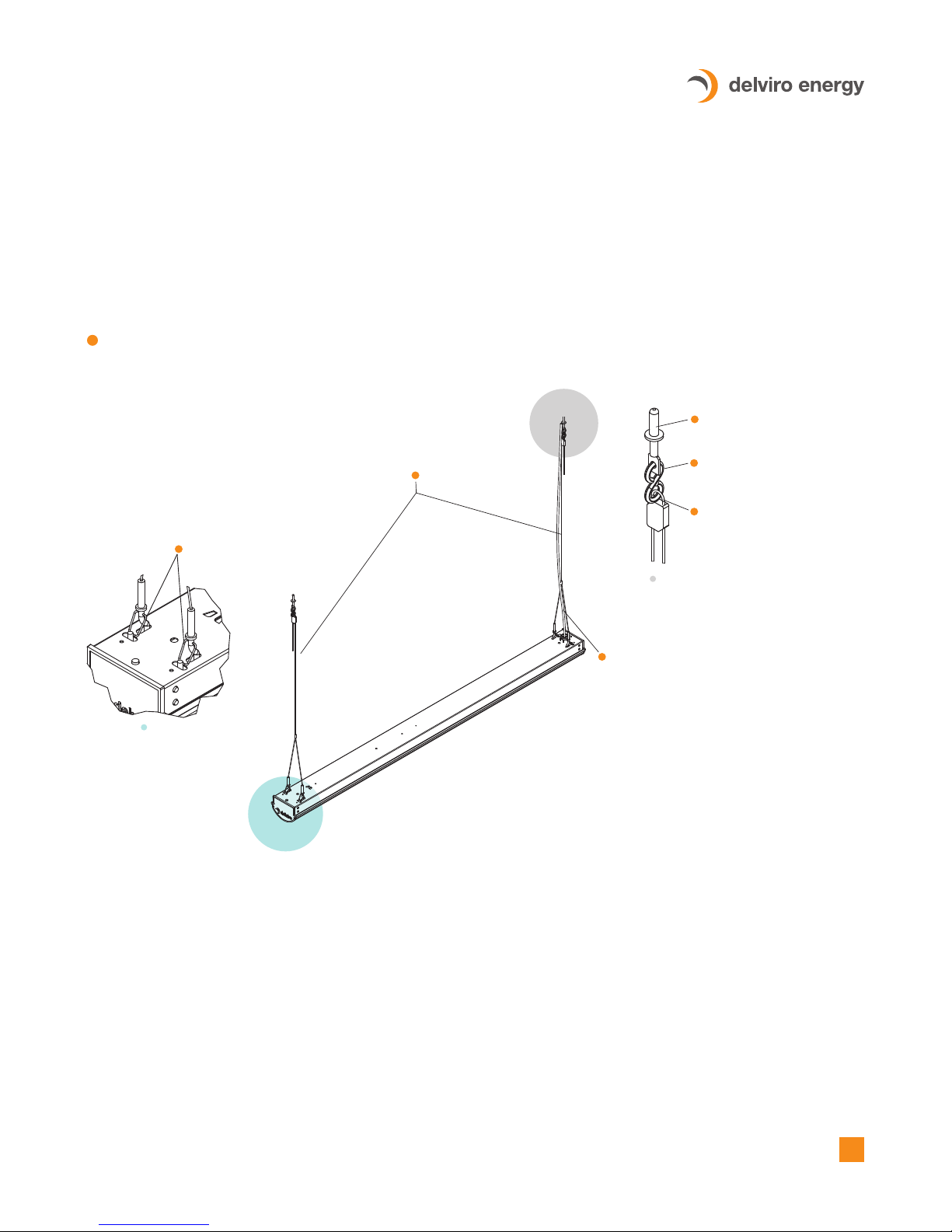

2. The Zip Light fixture has an optional aircraft cable which can be ordered. If the installer is using their own aircraft cable they

must ensure that the cable has hooks which will fit through the slots on the Zip Light fixture. The hooks should engage properly

such that the cable does not come out of the slots located at the top part of the Zip Light fixture.

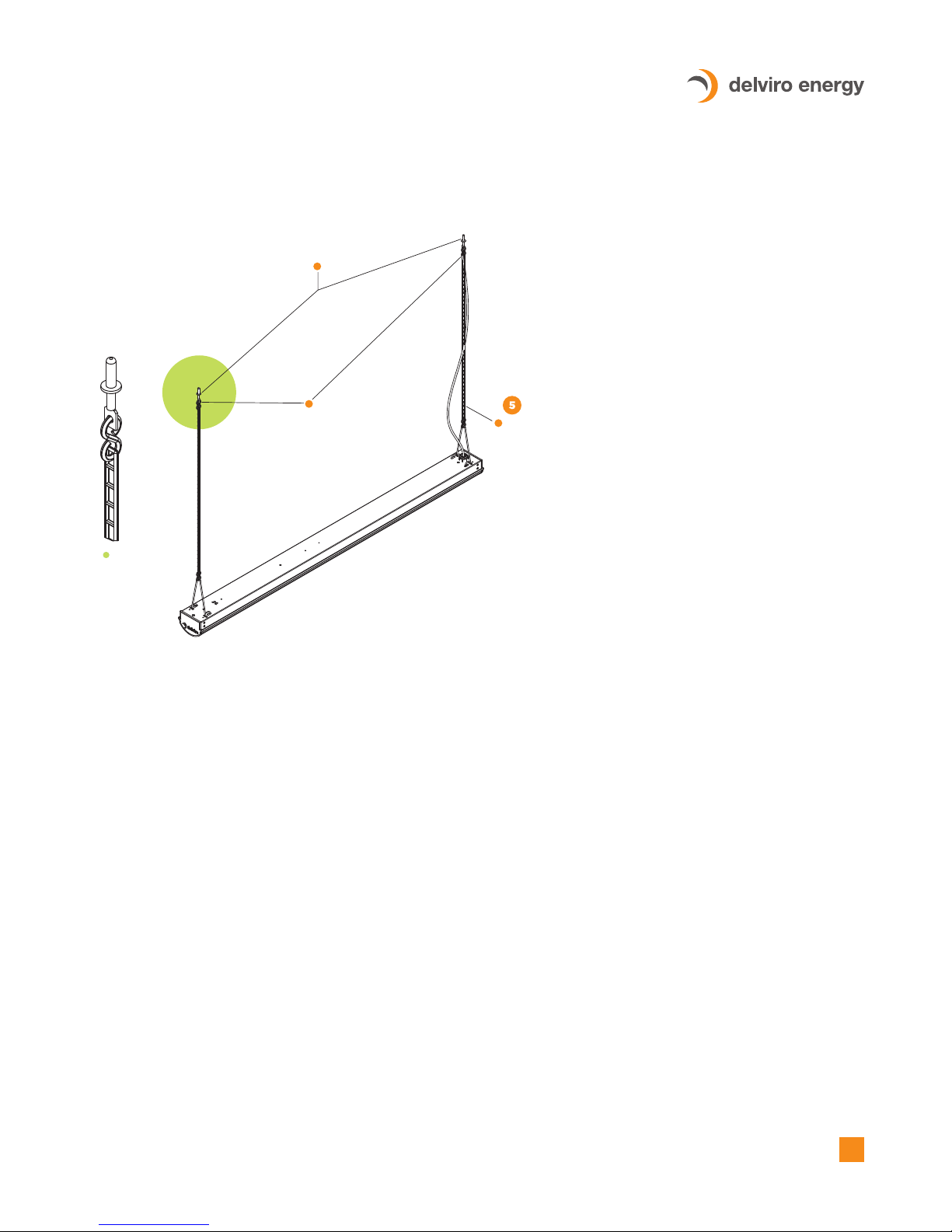

3. Run the straight wire of the aircraft cable through the adaptor which will form a loop, and adjust as per height requirement.

Once fixture is leveled, cut the excess wires. Attach an S-Hook to the loop formed and use pliers to 'close' off the ends of the

S-Hook (minimum S-Hook size 1.625" long, 0.135" thick with 0.5" ID in steel). There should be a loop at the end of this cable

at the top after inserting cable into fastener which can be attached to an S-Hook.

Follow the Electrical Codes of the Country where this fixture will be installed. For Canada follow the Canadian

Electrical Code (CE) and for the United States follow the National Electrical Code (NEC). Failure to follow these

instructions could result in electric shock or damage property. All wiring should also be performed by a qualified

electrician. Check with local electrical authority for installation compliance regulations. Due to variations in roofing

materials use these installation instructions as a guideline only.

NOTE:

Aircraft Cable

4. At the top of the S-Hook, attach an eye lag screw. The installer should choose the proper eye lag screw as there are different

types used for wood, steel and concrete. Minimum eye lag screw should be #12 size.

ZIP LIGHT

INSTALLATION INSTRUCTIONS

B

E

Optional Aircraft Cable (QTY: 2)

A

Hooks Engaged with Slot

A

B

Eye Lag Screw

Wire can be tie wrapped to Aircraft Cable but

also has to have an independent support at

the ceiling

S-Hook

Loop Optional Aircraft Cable

through fasteners and adjust

accordingly