DEMA CPM 311 User manual

- 2 -

1. About DEMA p.6

1.1. General Information p.7

1.2. Product Range p.9

1.3. Contact Us p.10

2. Introduction p.11

2.1. General Specifications & Advantages p.12

2.2. Physical Introduction p.14

2.3. Protection and Reset Curves p.22

2.3.1. IEC Protection Curves p.23

2.3.2. IEC Thermal Overload Protection Curve p.25

2.3.3. ANSI / IEEE Protection Curves p.26

2.3.4. Custom Protection Curves p.28

2.3.5. DMT: Definite Minimum Time Characteristic p.30

2.3.6. RIDMT: Reset Inverse Definite Minimum Time Characteristics p.31

3. Packing & Labeling Information p.32

4. Operating Manual p.34

4.1. General Principles p.35

4.2. Mounting p.36

4.2.1. Panel Cut-out p.36

4.2.2. Mounting the Case p.37

4.2.3. Mounting the Inner Unit and the Cover p.37

4.3. Cabling p.38

4.3.1. Cabling Diagram p.38

4.3.2. Cabling Material p.42

4.4. Setting p.43

4.4.1. Example Setting and Calculation p.44

4.4.2. Dip-switch Settings p.47

4.4.3. Example Dip-switch Settings p.49

4.4.4. Warnings p.49

4.5. Commissioning p.50

4.6. Operating p.51

4.6.1. Normal Operation p.51

4.6.2. Fault Diagnosis and Maintenance p.51

4.6.3. Recommissioning p.51

4.7. Testing & Maintenance & Reparation p.52

5. Relay Menus Manual p.53

5.1. Introduction p.54

5.2. The Menu Tree p.55

5.3. Reset Menu p.62

5.4. Circuit Breaker Monitoring and Control Menu p.64

5.5. Settings Group Selection Menu p.65

5.6. Protection and Control Settings Menu p.66

5.6.1. I> Phase Overcurrent 1st Threshold Protection Menu p.67

5.6.2. I>> Phase Overcurrent 2nd Threshold Protection Menu p.68

5.6.3. I>>> Phase Overcurrent 3rd Threshold Protection Menu p.69

5.6.4. Ie> Earth Overcurrent 1st Threshold Protection Menu p.70

5.6.5. Ie>> Earth Overcurrent 2nd Threshold Protection Menu p.71

5.6.6. Ie>>> Earth Overcurrent 3rd Threshold Protection Menu p.72

5.6.7. I2> Negative Sequence Overcurrent 1st Threshold Protection Menu p.73

- 3 -

5.6.8. I2>> Negative Sequence Overcurrent 2nd Threshold Protection Menu p.74

5.6.9. %(I2/I1)> Broken Conductor Protection Menu p.75

5.6.10. I< Phase Undercurrent Protection Menu p.76

5.6.11. IΘ> Thermal Overload Protection Menu p.77

5.6.12. Auto-recloser Settings Menu p.80

5.7. Main Menu p.83

5.7.1. Measurement Menu p.85

5.7.1.1. RMS Current and Frequency Measurements Menu p.86

5.7.1.2. Max RMS Current Measurements Menu p.87

5.7.1.3. Fundamental Harmonics Measurements Menu p.88

5.7.1.4. Positive and Negative Sequence Current Measurements Menu p.89

5.7.1.5. Thermal Θ Measurements Menu p.90

5.7.1.6. Input & Output Status Monitoring Menu p.91

5.7.1.7. Circuit Breaker Measurements p.92

5.7.1.8. Auto-recloser (ARCL) Measurements Menu p.93

5.7.2. Communication Settings Menu p.94

5.7.3. Event Records Menu p.95

5.7.4. System Settings Menu p.96

5.7.5. Current Transformer Settings Menu p.99

5.7.6. Automatic Control Settings Menu p.101

5.7.6.1. Cold Load Pickup Settings Menu p.102

5.7.6.2. Output Relay Settings Menu p.104

5.7.6.3. Trip Settings Menu p.105

5.7.6.4. Input Settings Menu p.106

5.7.6.5. Blocking Logic Selectivity Settings Menu p.107

5.7.6.6. Circuit Breaker Failure Recognition Settings Menu p.110

5.7.6.7. Auxiliary Timer Settings Menu p.112

5.7.6.8. Delaying Logic Selectivity Settings Menu p.113

5.7.6.9. Auto-recloser (ARCL) Settings Menu p.114

5.7.6.10. CB Supervision Settings Menu p.117

5.7.6.11. Programmable LEDs Settings Menu p.120

5.7.6.12. Latching Settings Menu p.122

5.7.6.13. Alarm Settings Menu p.124

5.7.7. Function Test Menu p.125

5.7.8. Fault Records Menu p.126

6. DigiConnect PC Program Manual p.127

6.1. Operating System & Hardware Requirements p.128

6.2. Program Setup p.129

6.3. Program Start-up p.132

6.4. Software Introduction and Guide p.135

6.4.1. Welcome Screen p.136

6.4.2. Measurements p.137

6.4.2.1. Analog Values p.137

6.4.2.1.1. RMS Current p.137

6.4.2.1.2. Fundamental Harmonics p.138

6.4.2.1.3. P/N Sequences p.139

6.4.2.1.4. Max. RMS Current p.140

6.4.2.2. Circuit Breaker Measurements p.141

6.4.2.3. ARCL Measurements p.142

6.4.2.4. Remote Control p.143

6.4.3. Alarms / Event Records Menu p.144

6.4.3.1. Alarms p.144

6.4.3.2. Event Records p.145

6.4.3.3. Trip Records p.146

6.4.4. Settings Menu p.147

6.4.4.1. Protection Settings p.148

- 4 -

6.4.4.1.1. Phase Protection Settings p.150

6.4.4.1.2. Earth Protection Settings p.151

6.4.4.1.3. Broken Conductor Protection Settings p.152

6.4.4.1.4. Negative Sequence Protection Settings p.153

6.4.4.1.5. Thermal (Overload) Protection Settings p.154

6.4.4.2. CT Settings p.155

6.4.4.3. System Settings p.156

6.4.4.4. Automatic Control Settings p.157

6.4.4.4.1. Input Settings p.158

6.4.4.4.2. (Auxiliary) Timer Settings p.159

6.4.4.4.3. Output Relay Settings p.160

6.4.4.4.4. Trip Settings p.161

6.4.4.4.5. Blocking (Logic) Selectivity Settings p.162

6.4.4.4.6. CB Failure Settings p.163

6.4.4.4.7. Delaying (Logic) Selectivity Settings p.164

6.4.4.4.8. Auto Recloser Settings p.165

6.4.4.4.9. Cold Load Pickup Settings p.167

6.4.4.4.10. CB Supervision Settings p.168

6.4.4.4.11. (Programmable) LED Settings p.169

6.4.4.4.12. Latch Settings p.170

6.4.4.4.13. Alarm Settings p.171

6.4.4.5. Communication Settings p.172

6.4.5. Buffer Menu p.173

6.4.6. Disturbance (Waveform) Records Menu p.179

7. Application Diagrams p.188

7.1. On the Use of Application Diagrams p.189

7.2. Sample Application p.189

7.3. Fundamental Cabling Diagram p.192

7.4. Application Diagram No.1 p.193

7.5. Application Diagram No.2 p.194

7.6. Application Diagram No.3 p.195

7.7. Application Diagram No.4 p.196

7.8. Application Diagram No.5 p.197

7.9. Application Diagram No.6 p.198

7.10. Application Diagram No.7 p.199

7.11. Application Diagram No.8 p.200

7.12. Application Diagram No.9 p.201

7.13. Application Diagram No.10 p.202

8. Technical Diagram p.203

8.1. USB Connection Cable p.204

8.2. Technical Drawings p.205

8.3. Technical Specifications p.206

8.4. Default Settings p.213

8.5. Type Tests p.217

8.6. Ordering Codes p.218

9. Glossary p.219

- 5 -

DEMA Role San. ve Tic. A. S. is a secondary protection relays

and accessories manufacturer carrying out its activities in a

plant with 2000 m² closed area in Maltepe, Istanbul, Turkey.

The plant itself inspires creativity and innovation by its high-

tech infrastructure, laboratory-clean environment and the art

collection it hosts.

DEMA Role San. ve Tic. A. S. has manufactured over 100,000

pieces of protection units since its foundation in 1977, and has

great reputation among its clients.

The innovations history of DEMA is as follows:

•1977 - R3AS20E: The first DMT electromechanical overcurrent protection relay in the country,

•1985 - R1TA112: The first draw out type electromechanical overcurrent protection relay in the country

with IDMT delay,

•1990 - R1SA01: The first draw out type electromechanical earth fault protection relay in the country with

DMT delay,

•1990 - R1ST04: The first draw out type electromechanical thermal overload protection relay in the country

with thermal image display,

•1997 - MCR Series: The first draw out type electronic overcurrent protection relay series in the country

with DMT and IDMT delay,

•1997 - MVR Series: The first draw out type electronic over/undervoltage protection relay series in the

country with DMT and IDMT delay,

•2000 - IR1021: Double-flashing annunciator relay with

LEDs,

•2006 - CPM Series: The first draw out type DSP-based

digital overcurrent protection relay with digital communication

and LCD display features.

•2011 - CPM 311: The first digital relay with separate

control and main units.

DEMA Role San. ve Tic. A. S. invests more than 10% of its total

revenue into R&D projects, which clearly demonstrates DEMA’s

commitment into innovation.

The R&D philosophy of DEMA focuses particularly on user-

friendliness, assurance of high-quality, reliability and

international standards compliance of its products.

A good example on the outcomes of DEMA’s R&D philosophy is

the innovative features of CPM 310 series digital overcurrent

protection relays –a product which introduced the most user-

friendly interface yet by employing the mobile phone

navigation technology into protection relays era.

Some other innovations are as follows:

•The most secure secondary shorting mechanism on

the world yet, which enables under-load replaceability of

overcurrent protection units more safely than ever,

•Withdrawable unit locking mechanism,

Employment of high-frequency band measurement

transformers in protection relays.

- 6 -

The molding workshop of DEMA is one of the most advanced

facilities in its sector. The workshop

•Works only for prototyping,

•Or production molding construction for DEMA

products.

The molding workshop hosts

•Wire erosion machines,

•Through erosion machines,

•Erosion drills,

•Taşlama,

•And CNC systems worthing over 3,000,000 USD of

investment into production precision.

All of the metal, plastic, electro-mechanical and graphical

components used in DEMA’s products are designed, prototyped

and manufactured in the same facility by DEMA engineers and

technicians.

50% of DEMA’s total revenue comes from international sales

with an increasing proportion. DEMA imported to over 10

countries all over the world in 2009.

The innovative and leading policy of DEMA has been recognized

and awarded by many national titles in the past years. DEMA

promises its clients better solution partnership and wider range

of high quality products in the future, just as provided in the

past.

- 7 -

1. DSP-based Digital Protection Relays

CPM 310 G Three phase + earth overcurrent protection relay with draw-out system.

CPM 311 Three phase + earth overcurrent protection relay with seperated units.

2. Microprocessor-based Protection Relays

MCR 010 1-module earth overcurrent protection relay in draw-out case.

MCR 100 1-module phase overcurrent protection relay in draw-out case.

MCR 210 3-modules 2 phase + earth overcurrent protection relay in draw-out case.

MCR 300 3-modules 3 phase overcurrent protection relay in draw-out case.

MCR 310 4-modules 3 phase + earth overcurrent protection relay in draw-out case.

MVR 100 1-module over/undervoltage protection relay in draw-out case.

MVR 200 2-modules over/undervoltage protection relay in draw-out case.

MVR 300 3-modules over/undervoltage protection relay in draw-out case.

MVR 400 4-modules over/undervoltage protection relay in draw-out case.

3. Annunciating System Components

IT1-6 6-windows optical annunciator.

K 101 - A2 Multitone acoustic horn / annunciator.

KR30 Horn Relay.

IR61K-A2 6-windows optical annunciator with relay and horn outputs in draw-out case.

IR101K-A2 10-windows optical annunciator with relay and horn outputs in draw-out case.

IR1021 10-windows double-flashing optical annunciator with relay and horn outputs in

draw-out case.

4. Auxiliary Devices

KAC Capacitor-based auxiliary supply unit.

GKR15 DC auxiliary supply supervision relay.

RY600 Auxiliary relay

ZR20 On-delay auxiliary time relay.

ZR25 Off-delay auxiliary time relay.

BR25 Flash relay

WR25 Impulse relay.

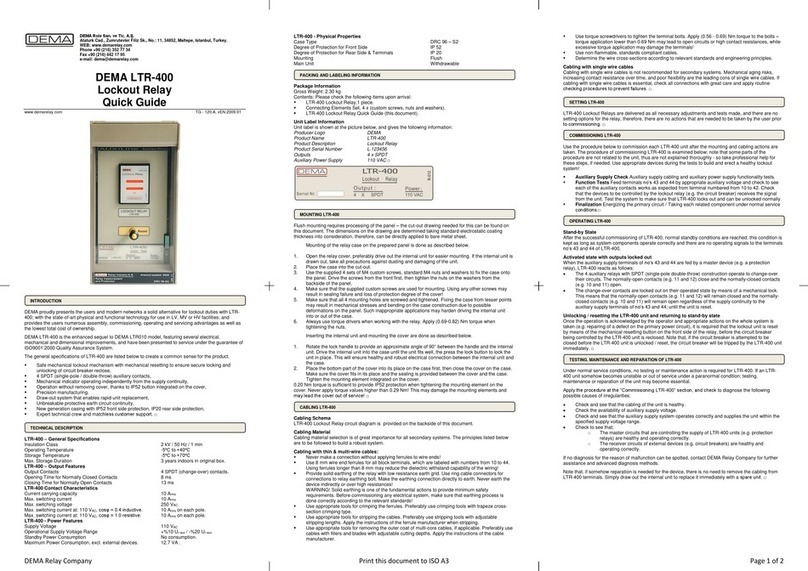

LTR-400 Lock-out relay.

For detailed information on products; please see our WEB site at www.demarelay.com, or contact us using the

information in the Contact Us section on the next page. □

- 8 -

Address DEMA Role San. ve Tic. A. S.

Zumrutevler Mh. Ataturk Cd. Inanc Sk.

No.: 4, 34852,

Maltepe, Istanbul, Turkey.

Phone +90 (216) 352 77 34

+90 (216) 352 77 35

Fax +90 (216) 442 17 95

E-mail [email protected]

WEB www.demarelay.com

□

DEMA Role San. ve Tic. A. S. Plant at Istanbul, Turkey.

- 9 -

INTRODUCTION

- 10 -

DEMA proudly presents the users and modern networks a solid alternative for overcurrent protection

with CPM 311; with the state-of-art electronic, physical and functional technology for use with (X/5) A

or (X/1) A conventional type current transformers. As a DSP based digital multi-function protection &

control relay with 3 phase & earth overcurrent protection, DEMA CPM 311 is tested to fulfill

international standards requirements; and provides the users numerous assembly, commissioning and

service advantages, thanks to its separated construction (as control unit and main unit) that

eliminates the need to extend the secondary, auxiliary and control cabling to the panel door.

DEMA CPM 311 Digital Overcurrent Protection Relays are designed to protect electrical facilities

against phase and earth faults. These relays provide phase & earth overcurrent and thermal overload

protection for overhead lines, underground cables, power transformers, generators and high-power

motors; while providing selectivity with various methods. These features of DEMA CPM 311 provide

highest degree of protection while ensuring maximum availability.

DEMA CPM 311 Digital Overcurrent Protection Relays are type tested in internationally accredited

laboratories to comply with IEC 60255, IEC 60529, IEC 60695 and IEC 60068 standards, and have

been introduced into service under the guarantee of ISO9001:2008.

The general specifications of CPM 311 are listed below to create a common sense for the product. □

Function

ANSI Code

CPM 311

Phase Overcurrent Protection –Instantaneous

50

3 thresholds

Phase Overcurrent Protection –Delayed

51

3 thresholds

Earth Overcurrent Protection –Instantaneous

50N

3 thresholds

Earth Overcurrent Protection –Delayed

51N

3 thresholds

Thermal Overload Protection

49

2 thresholds

Phase Undercurrent Protection

37

1 thresholds

Negative Sequence Overcurrent Protection

46

2 thresholds

Output Latching

86

✓

Circuit Breaker Failure Detection

50BF

✓

Auto –Reclosing

79

4 shots

Thermometer –Buchholz Protection

26 / 63

✓

Broken Conductor Protection

✓

Cold Load Pickup

✓

Protection and Settings Groups

2 groups

Circuit Breaker Trip Circuit Supervision

TCM

✓

Circuit Breaker Monitoring and Control

✓

Blocking Logic Selectivity

68

✓

Delaying Logic Selectivity

✓

Circuit Breaker Remote Control

94

✓

5 inputs and 4 outputs

✓

Disturbance Waveform Recording

3 x 5 s

Event & Fault Recording

SER

150 records

USB & RS485 Communication Ports

✓

X/1 A & X/5 A CT Compatibility

✓

Frequency, Current and Thermal Imaging Measurements

✓

Positive & Negative Sequence Current Measurements

✓

Phase Rotation Monitoring

✓

Auto-reclosing Measurements

✓

Self-check

✓

Protection Functions Testing

✓

- 11 -

▪Wide IEC, ANSI and custom delay curve support, enabling selectivity setup with all types of

protection relays including electromechanical relays,

▪DMT and IDMT delay curve support for all overcurrent protection functions,

▪Remote control and monitoring of the circuit breaker via dedicated menu with mimic diagram,

▪Annunciating functions and 5 optically coupled programmable inputs that eliminate the need to

use external annunciators (e.g. to evaluate Buchholz, temperature and pressure signals),

▪Buchholz & thermometer alarm & trip functions and pressure trip functions that can be appointed

to programmable inputs & outputs & LEDs,

▪4 outputs: Trip (SPDT) and watchdog (SPDT) plus 2 programmable outputs (2 SPST),

▪Full screen R –S –T and N ampermeter display, measurement functions that eliminate the need

to use double core CTs, external ampermeter and frequency-meters,

▪(X/1) A and (X/5) A current transformer compatibility in a single unit,

▪Wide setting ranges; (0.1-40) Incurrent setting range, (0.01-150) s DMT delay setting range,

(0.025-3.2) IDMT (TMS & RTMS) delay setting range,

▪2 independent settings groups,

▪3 independent thresholds for phase overcurrent protection,

▪3 independent thresholds for earth overcurrent protection,

▪2 independent thresholds for negative sequence overcurrent protection,

▪1 independent threshold for undercurrent protection,

▪Thermal overload protection with thermal image according to IEC 60255-8 ed.2.0,

▪Auto-recloser with 4-shots, auto-reclosing programmability for each protection function,

▪Cold-load pickup function with high reliability CB-triggering,

▪Blocking logic selectivity feature,

▪Delaying logic selectivity feature,

▪Circuit breaker failure supervision and alarming,

▪Circuit breaker supervision functions: opening and closing time supervision; charging spring

supervision; numerator, ΣA and ΣA² supervision for each pole; trip circuit supervision,

▪Main menu that displays the activated protection functions so as to provide quick overview by the

user,

▪2 level password system to provide access security to settings menus and remote CB control

menu,

▪Quick alarm menu access and enhanced alarm explanations with manual and automatic alarm

resetting option,

▪8 programmable alarm LEDs,

▪Event and fault records up to 150 instances,

▪5 waveform records with 3 seconds duration each,

▪Electro-magnetic compatibility tested to satisfy related IEC directives,

▪Separated construction (as control unit and main unit) that eliminates the need to extend the

secondary, auxiliary and control cabling to the panel door,

▪Protection function testing feature for checking the fundamental cabling and settings without need

to use external testing devices,

▪Largest LCD graphics screen in its class (128 px x 64 px); easy-to-navigate user friendly menus

similar to mobile phones’,

▪Auxiliary supply voltage compatibility with all voltages in the field;

Uaux = (21 –250) VDC / (100 –250) VAC,

▪IP52 front side and IP20 backside environmental protection,

▪SCADA ready,

▪USB and RS485 communication ports; MODBUS RTU, IEC 60870-5-103 and DEMCOM

communication protocols support,

▪Free-of-charge PC software and accessories,

▪Matchless customer support, a variety of application schemas and technical documents. □

- 12 -

CPM 311: General Overview

•CPM 311 Control Unit

CPM 311 Control Unit is a man –machine interface unit. The unit does not have any protection

circuitry; the primary role of the unit is rather providing the accessibility to the settings,

measurements etc., which are run and stored on the main unit. The USB port needed for PC

communication is also located on the rear side of the control unit

CPM 311 Control Unit is intended to be flush –mounted on the panel door. The innovative design

of the product reduced the quantity of cables that have to be carried to the cover to only two

cables. One of them is the RJ45 terminated communication cable which enables the data

exchange between the main and control units, and the other one is the protective earth conductor

of the control unit. No other cabling is required on the panel door.

CPM 311 Control Unit can be replaced during operation, if needed. During the replacement, the

main unit functions normally, without having to interrupt the facility protection. Once the

replacement is completed, restarting the relay will provide the main unit to identify the new

control unit and start to function normally.

•CPM 311 Main Unit

CPM 311 Main Unit has the main circuitry that runs the measurement, protection, control and

recording processes. The secondary circuit terminals as well as the auxiliary supply, output, input

and RS 485 terminals are located on the bottom side of the main unit. All of the terminals

excluding the secondary circuit terminals are of plug –receptacle type, which provides easy

cabling and unit replacement.

- 13 -

CPM 311 Control Unit: Front View

•Status LEDs

4 status LEDs are located on the front side of the CPM 311 Control Unit.

oTrip: This LED reports the trip relay activity. The LED runs continuously if the trip relay is

closed at that time, and flashes if the trip occurred but the trip relay is then released.

oAlarm: This LED reports the alarming events. The LED flashes if there are new alarms on

the alarm menu that has not been viewed by any user, and starts to run continuously if

the alarms are viewed but not reset.

oPower: This LED reports the auxiliary supply status. If the auxiliary power supply is

healthy, the LED runs continuous green.

oWarning: This LED reports the internal circuitry errors by running continuous red if any

internal errors are detected.

•Phase Protection LEDs

4 phase protection LEDs are located on the front side of the CPM 311 Control Unit.

oTrip Θ: If the thermal overload protection (IΘ›) is activated, this LED will run continuously

red in case of thermal overload tripping.

oI›: If the phase overcurrent protection (I›) is activated, this LED will run continuously red

in case of phase overcurrent tripping.

oI››: If the phase short-circuit protection (I››) is activated, this LED will run continuously

red in case of phase short-circuit tripping.

•Earth Protection LEDs

4 earth protection LEDs are located on the front side of the CPM 311 Control Unit.

oIe›: If the earth overcurrent protection (Ie›) is activated, this LED will run continuously red

in case of earth overcurrent tripping.

oIe››: If the earth short-circuit protection (Ie››) is activated, this LED will run continuously

red in case of earth short-circuit tripping.

•(124 x 64) px Graphics Screen

128 px x 64 px backlit graphics display provides a large viewing area that ensures easy operation

and readability.

•Multi-functional Buttons

Similar to cell phone technology, multifunctional buttons provide easy command and navigation

between the menus. The reset button in this group provides access to the programmable LEDs

and alarms menu, lets the user to reset alarm if any available and unlatch any outputs, if

applicable.

•Unit Label

The inerasable label indicates the ordering code, serial number and other information to comply

with IEC standards.

- 14 -

CPM 311 Control Unit: Rear View

•Mounting Flanges

By plugging the mounting pieces (which comes with the unit) on the mounting flanges, the

control unit is fixed on the panel door.

•RJ45 Terminal

One end of the RJ45 terminated communication cable provided along with the product is plugged

into that terminal. The cable enables the data exchange between the main and control units.

•Ground Terminal

The protective earthing connection of the control unit is achieved via this terminal. Appropriate

cable lugs are provided within the product box.

•USB Port

USB communication port is the connection point for PC communications via DigiConnect software.

Connection cable is supplied within the product box.

- 15 -

CPM 311 Main Unit: General Overview

•Main Unit Cover Screw

The main unit cover is fixed on the base plate via this screw. In case of need (e.g. for setting the

dip-switches or replacing the fuse), the internal circuits can be reached by removing the cover

screw.

•Secondary Cabling Terminals

The CT secondary cables and the returning neutral cable are to be connected to these terminals.

The terminals feature exceptional thermal and dynamic withstand capabilities and robust contact

performance to ensure maximum operating reliability.

•Auxiliary Supply Terminals

The auxiliary supply conductors and the operating ground conductor are to be connected on these

terminals. The terminals are of plug –receptacle type.

•Output Terminals

The trip, watchdog and 2 programmable output conductors are to be connected on these

terminals. The terminals are of plug –receptacle type.

•Input Terminals

The common supply and signal conductors for the 5 programmable inputs are to be connected on

these terminals. The terminals are of plug –receptacle type.

•RS485 Port

The data cables, termination load bridge and the reference cabling are to be done on these

terminals. The terminals are of plug –receptacle type.

- 16 -

CPM 311 Main Unit: Right Side View

•Ground Terminal

The protective earthing connection of the control unit is achieved via this terminal. Appropriate

cable lugs are provided within the product box.

The case of the CPM 311 main unit is made of inoxidant metal material. This construction

functions as a Faraday cage around the main circuits, filtering any electromagnetic and electrical

disturbances that may otherwise impact the healthy operation of the relay. Just like any other

electrical appliance, solid grounding of the main unit is essential to provide maximum protection

for the operators and the relay.

•RJ45 Terminal

One end of the RJ45 terminated communication cable provided along with the product is plugged

into that terminal. The cable enables the data exchange between the main and control units.

- 17 -

CPM 311 Main Unit: Internal Overview

•Dip-switch Group

CPM 313 Digital Overcurrent Protection Relays can operate with X/1 A or X/5 A current

transformers. The dip-switches shown on the image above enables the setting of the relay to

work with X/1 A or X/5 A current transformers. The dip-switches are used also for earth fault

protection setting range.

•Current Transformers

These high-technology CTs transform secondary current into useful signals to provide the

measurement and protection circuits with the information they need. Current transformers are

integrated into the internal unit –this guarantees fast maintenance and replacement operations

without having to carry out calibration procedures.

•Fuse Holder

The T1A fuse protecting the main unit circuits is mounted on this fuse holder. The fuse ensures

the protection of the circuits in case of any auxiliary supply faults and provides maximum service

continuity. The placement of the fuse holder enables quick access and fast replacement of the

fuse.

•Real-time Clock Battery

Real-time clock is run by the auxiliary supply power while the relay is in service; in case of

auxiliary supply shortage or internal unit drive out, real-time clock battery takes the duty over.

Life expectancy of the lithium-ion battery is 10 years under normal conditions. □

- 18 -

X/1 A & X/5 A CT Compatibility

CPM series relays are suitable for

use with conventional X/1 A and

X/5 A current transformers. By

making appropriate settings on

the dip-switch group on the

internal unit, the secondary

nominal current can be changed

as In= 1 A or In= 5 A within

seconds.

Phase & Earth Fault

Instantaneous Protection

(ANSI 50 / 50N)

There are 3 thresholds for

instantaneous phase & earth

fault protection. The setting

zones are given below.

For phase protection:

I›= (0.1 - 25) In

I›› = (0.5 - 40) In

I››› = (0.5 - 40) In

There are two setting zones for

earth fault protection. These are

available via appropriate dip-

switch settings on the internal

unit, and have the following

setting zones:

For T1 earth fault protection:

Ie›= (0.1 - 25) Ien

Ie›› = (0.5 - 40) Ien

Ie››› = (0.5 - 40) Ien

For T2 earth fault protection:

Ie›= (0.02 - 5) Ien

Ie›› = (0.02 - 5) Ien

Ie››› = (0.02 - 5) Ien

Phase & Earth Fault Delayed

Protection (ANSI 51 / 51N)

DEMA CPM 311 provides a large

variety of protection curves for

delayed phase & earth fault

protection. These curves consist

of standard IEC/ANSI curves,

definite time delay (DMT) as well

as custom curves that are

compatible with

electromechanical relays. To

help the users apply flexible and

precise settings, these curves

feature a large setting zone with

relatively small steps. The

resetting delay setting zones are

likewise flexible and precise.

Thermal Overload Protection

(ANSI 49)

Best protection for power

transformers, overhead lines and

underground cables at loads

around (100 –150) % is

provided by thermal overload

protection schemes. Unlike the

overcurrent curves, the thermal

overload protection curve

delivers relatively longer delays

to provide maximum power

availability, while preventing

excessive thermal stresses on

the protected equipment by

utilizing thermal imaging

technology. By applying

appropriate combination of

thermal overload and phase

overcurrent functions, it is

possible to achieve the optimal

protection, selectivity and power

availability solutions. In addition

to the automatic protection

function, the thermal stress on

the equipment is monitored in

real time for checking on

demand. It should be noted that

the thermal overload protection

function fulfills the requirements

of the IEC 60255-8 standard.

Phase Undercurrent Protection

(ANSI 37)

This function is used in

applications where undercurrent

monitoring is required (e.g.

tripping of a contactor

controlling a water pump when

the water source is exhausted).

The function requires a 52a

(normally open contact) signal

for reliable operation. Setting

zone is I‹ = (0.02 - 1.0) In.

Negative Sequence Overcurrent

Protection (ANSI 46):

Unbalanced phase current

conditions without earth faults

on the primary circuit of a

distribution line or unbalanced

current conditions with or

without earth faults on the

secondary circuit of a power

transformer can be detected and

intervened by this function. The

delaying options are the same

with phase overcurrent

protection function.

Output Latching (ANSI 86)

CPM 311 allows users to latch

the trip output relay and the 2

programmable output relays on

demand. The latching settings

menu on the relay allows

independent latching control for

the mentioned 2 outputs.

Unlatching of the outputs is

available via the reset button or

an external signal to an

appropriately programmed input.

Circuit Breaker Failure Detection

(ANSI 50BF)

This function checks to see if

any poles of a circuit breaker

fails to interrupt the primary

circuit current when tripped. If

such case is detected, the alarm

menu notices the user about the

fault and the logic signal to an

upstream relay is removed, if

applicable. The process starts

with the opening of the CB; if

the current measurements from

one or more poles of the CB do

not fall below the defined level

of detection, then the fault is

diagnosed. After a defined delay,

the alarm is given and an output

reacts, if programmed so. In

applications where blocking or

delaying logic selectivity

schemes are utilized, the logic

signal to the upstream relay is

removed by means of this

programmed output.

Auto-reclosing (ANSI 79)

The auto-reclosing function that

CPM series relays feature allows

the users to auto-reclose the CB

up to 4 shots. The auto-reclosing

behavior of CPM 311 can be

customized for all phase and

earth protection functions and

auxiliary timers, independently of

each other. The inhibit time, the

dead time and the delays

between the auto-reclosing shots

can be independently set. The

advanced auto-reclosing

algorithm of CPM 311 ensures

the safety of the system by

blocking the auto-reclosing

function in certain cases, such as

the manual operation of the CB,

detection of a fault current

within the inhibit time, and

detection a CB failure.

- 19 -

Broken Conductor Detection

The current faults in a

distribution system are easily

detected and cleared by

protection relays. However,

faults without overcurrent such

as:

•breaking of an overhead

line jumper,

•single phase fuse blow,

•closing failure of one of the

poles of a CB,

•conducting problems of a

primary power equipment,

•or open circuit on one of

the current transformer

secondary circuits introduce

dangerous and intolerable

conditions where different

methods of protection should be

utilized. The broken conductor

detection function on CPM 311

calculates the ratio between the

negative sequence current and

positive sequence current to

sense and intervene these kinds

of problems reliably, even at

relatively low current signal

levels from the healthy phases.

The function behavior can be

modified by setting the critical

ratio threshold and the delay.

Cold Load Pickup

The cold load pickup function

provides the chance to shift the

threshold values of the phase &

earth & negative sequence

overcurrent protection functions

temporarily when the circuit

breaker closes to drive cold loads

such as high power motors,

capacitor banks and power

transformers. The shifting ratio

can be set within the zone (20-

500) % by 1 % steps, while the

duration of this temporary state

can be determined between 0.1

s and 3,600 s by 0.1 s steps. The

function resolves the pickup

problems by shifting any

independent thresholds desired

and leaving others unchanged,

while blocking none. The cold

load pickup function is triggered

by means of activation of a

programmed input over one of

the auxiliary contacts of the CB /

contactor, or by a signal from an

external device; thus, the risks

of triggering by primary events

which some other algorithms

suffer are removed.

Settings Groups

In open ring distribution

systems, the setting values of a

protection relay are closely

related to the power flow

direction at the point the relay is

operated. Meanwhile, the time to

change these settings when the

power flow direction is to be

altered under a force major is

scarce. Taking these into

account, the CPM 311 relay

features 2 settings groups that

can handle 2 completely

independent sets of values of

protection and automatic control

functions that would save

valuable time for the user while

switching to the suitable settings

in a new condition. Altering

between the settings groups can

be done manually on the control

panel, via remote control over

communication systems or by

means of triggering of a

programmed input.

Circuit Breaker Trip Circuit

Supervision (ANSI TCM)

The trip circuit of a circuit

breaker comprises the trip coil,

the trip output of a relay and the

cabling between them. An open

circuit on one of these

components would prevent the

correct operation of the CB when

needed. CPM series relays are

capable of supervising the

condition of the trip circuit

continuously by one of the

programmable inputs. In the

case an open circuit is detected,

the user is noticed about the

situation by the alarm signal on

the control panel, and if desired,

remotely by means of a

programmed output.

Circuit Breaker Supervision and

Control

CPM series relays have built-in

CB supervision and control

functions that manage the

essential values and statistics to

keep track of the CB condition.

•The last opening and closing

times of the CB,

•The total opening number of

the CB,

•And the ΣA and ΣA² values

(pole condition)

are continuously supervised by

the function to notice the user in

abnormal or critical conditions by

means of local and / or remote

alarming.

Blocking Logic Selectivity

(ANSI 68)

CPM 311 supports the blocking

logic selectivity scheme. This

scheme is to be applied on

networks where power flow is

unidirectional.

When this scheme is applied,

each of the relays on a series

primary line blocks the next

upstream relay by means of

sending a blocking signal to their

programmed input, blocking and

preventing the latter to react.

This circuit design leads to the

blocking of all relays but the one

closest to the fault point,

enabling total selectivity without

applying time stepping settings.

Time delayed phase & earth &

negative sequence overcurrent

protection functions and the

broken conductor detection

function can be blocked this

way.

Delaying Logic Selectivity

CPM 311 supports the delaying

logic selectivity scheme. This

scheme is to be applied on

networks where power flow is

unidirectional.

When this scheme is applied,

each of the relays on a series

primary line shifts the trip delays

of the next upstream relay by

means of sending a delaying

signal to their programmed

input, delaying the latter to

react. This circuit design leads to

the delaying of all relays but the

one closest to the fault point,

enabling total selectivity without

applying time stepping settings.

The tripping delays of the 2nd

and 3rd thresholds of the phase

& earth overcurrent protection

functions can be prolonged this

way.

Circuit Breaker Remote Control

(ANSI 94)

CPM series relays can remotely

control circuit breakers by means

of their trip relays and

programmable outputs. The CB

control can be done from the

control panel of the relay and

over the DigiConnect PC

software.

- 20 -

Inputs and Outputs

(Including ANSI 26 & 63)

CPM 311 is equipped with 5

optically isolated &

programmable inputs and 4

output relays to fulfill demanding

requirements of modern

applications. The inputs accept

any signals within the range (24

- 250 VDC) and (100 - 250 VAC).

The outputs feature 2 SPDT and

2 SPST relays, each operating

below 10 ms delays and rated 8

A / 250 VAC. Two of the outputs

are predefined as trip and

watchdog relays, and the rest

are programmable.

Disturbance Waveform

Recording

CPM series relays can digitally

save the disturbance waveforms

they measure, and the saved

files can be downloaded and

viewed over the DigiConnect

software. CPM 311 can hold up

to 5 instances of disturbance

recordings, each totaling 3

seconds of sampling with 0.4 s

predisturbance recording.

Being able to observe the

disturbance waveforms allows

users to analyze faults, confirm

the convenience of the

parameter settings, and

understand the network behavior

better.

Event and Fault Recording

(ANSI SER)

CPM series relays store up to

150 events and fault records.

The event and fault records are

time-stamped with the

information from a real-time

clock which is supplied by a

built-in extra long-life lithium-ion

battery. The records comprise

the precise timing, type and

details of the events / faults. The

records can be viewed on the

device screen as well as on a PC

utilizing the DigiConnect

software.

Communications Features

CPM series relays make use of

two serial communication ports.

•One of the ports is the hi-

speed USB port located on the

front panel of the device. The

USB port is suitable for

establishing a direct

communication link between the

device and a PC over a standard

USB cable, which is already

supplied within the product box.

Note that communication over

USB port does not require the

utilization of an adaptor, thus is

the recommended and easier

method of using DigiConnect.

•The other port is a RS485

serial communications port,

which is accessible from the

terminals at the rear side of the

device.

CPM series relays are compatible

with MODBUS RTU and IEC

60870-5-103 communication

protocols at rates between 1,200

bauds and 38,400 bauds.

Measurement Functions

CPM series relays feature the

following measurement

functions:

•Frequency measurements:

The primary circuit power

frequency once the secondary

current exceeds 0.1 In.

•Current measurements: The

momentary & maximum RMS

current values and fundamental

harmonic value of the phases

and the earth circuits.

•Positive / negative

sequence measurements:

The absolute values of positive

and negative sequence current,

and the ratio of these in

percentage.

•Thermal Θ measurements:

Thermal stress in percentage.

•Input & Output

measurements: The states of

programmable inputs and

outputs as well as the trip and

the watchdog relays.

•CB measurements: The last

opening and closing times, total

opening number, and ΣA & ΣA²

(pole condition) for each of the

circuit breaker poles.

•Auto-reclosing

measurements: All statistics and

measurements of the auto-

reclosing activity, including

number of successful auto-

reclosing cycles, and auto-

reclosing blockings.

•LED states: The momentary

states of all 8 programmable

LEDs.

Self-check & Watchdog

CPM series relays utilize a circuit

to watch over the condition of

the internal circuits and the

power supply continuity to the

device. At an instance of internal

failure or power supply shortage,

the watchdog relay reacts to

close the normally closed

contact, which is fixed at the

open state in healthy operation

conditions.

The positive operation

characteristic of the watchdog

relay therefor allows the users to

monitor the healthiness of the

protection system remotely,

using appropriate circuitry

evaluating the information from

the N/O and N/C contacts of the

watchdog relay.

Function Test

CPM series relays feature a built-

in functional test. The test is

launched manually from the

control panel. Once the test is

initiated, the digital signal

processor within the relay

produces virtual overcurrent

signals to run the protection

functions activated by the user,

leading to tripping of the circuit

breaker and termination of the

test. This test allows the users to

check the basic condition and

behavior of the protection

system elements (such as the

trip circuit cabling, the circuit

breaker and the auxiliary supply

system) without having to use

an external testing device. □

Table of contents

Languages:

Other DEMA Relay manuals

Popular Relay manuals by other brands

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-501-2 instruction manual

Velleman

Velleman K6714 manual

Schweitzer Engineering Laboratories

Schweitzer Engineering Laboratories SEL-487V manual

Yokis

Yokis MD3300MRP quick start guide

Pilz

Pilz PNOZ s6.1 operating instructions

Pilz

Pilz PNOZ XV3.3P operating instructions