Denios HazMat DPO-2 Guide

www.denios.com 1

Issue: 09/2012

Operation manual and spare parts list

HazMat station DPO

DPO-2 Part no.: 201601W

DPO-4 Part no.: 201602W

DENIOS AG

Dehmer Straße 58-66

32549 Bad Oeynhausen

Tel.: +49 (0)5731 7 53 – 0

Fax: +49 (0)5731 7 53 – 197

Description

HazMat station DPO-2 with open hose reel, for 2 oils in 60l or 200l barrels

HazMat station DPO-4 with open hose reel, for 4 oils in 60l or 200l barrels

Store oils in an environmentally sound way on economic 1,2 qm and dispense them directly into engines, gear boxes

and axles. Our "Fresh oil-island" is always and everywhere ready to use - just connect compressed air.

An increased variety of oils individually adapted to specific vehicle models and less consumption due to longer

service intervalls require innovative working tools.

space-saving design

economic

efficient

completely equipped

environmentally sound

Technical data

Sump tray with a volume of 210l and a mountin frame according to the German Water Resources Law (WHG)

air-operated pump „PumpMaster“ DP 3:1 with suction unit

automatic hose reels with 10m delivery hose

filling pistols with swivel and electronic flow meter appropriate for calibration

all components are mounted ready to use

In order to avoid personal injury or material loss, please read the operation manuals!

Units may only be serviced or repaired if this should be necessary by authorized specialists or company

representatives.

The following operation manuals are included:

air-operated pump DP 3:1

hose reel open

electronic flow meter

WARNING

DPO-2

2

Issue 09/2012

HazMat station DPO

1. General instructions

The general instructions for storage systems, material no. 103041, in the current version, must be observed.

National standards and safety regulations must be observed.

2. special instructions

Area of the grating must remain free as shown on the type label.

3. Use and intended purpose

The sump/storage system is used to enable drums of up to 200 litres capacity and cans and other small containers

to be stored safely. 60 and 200 litre drums can be stored upright or on their side on drum mounts.

Only store substances to which the material of the sump is resistant. See the General Operating

Instructions. Where hazardous materials of classes R10, R11 and R12 are being stored, 25% of the overall

area (of the grids) must be left unoccupied. The sumps are approved for the storage of materials in hazard

classes WGK 1-3 and flammable liquids with aflash point > 55 °C.

4. Technical details

The HazMat station is manufactured from steel, with an integrated sump and is compliant with European building

regulations. The sump capacity is 205 litres.

5. Assembly

Place the storage system on level ground.

The accessories facilitate loading, storage and dispensing from the sump.

6. Specifications

See type label.

7. Operation

After opening the lid / safety bracket (optional) the drums can be placed in the hazardous material station using

suitable equipment. Close lid / safety bracket (optional).

For types 4 GST-K and 4 GST-KS before closing the lid the blocking device of the left gas spring

must be released.

When storing combustible fluids comply with the fire and explosion protection regulations!

For hazard classes R10, R11 and R12 the free areas of 25% of the total area (gratings) must be adhered to.

(Exception: GST-KS and Depot AI)

Check drums are positioned safely and secure to prevent falling over or down!

Only store drums horizontally on drum stands!

Safe filling is possible over the collecting sump.

Access to the hazardous materials station by unauthorised persons is prohibited!

8. Maintenance and servicing

The inspection and maintenance of the storage system/sump must be carried out in accordance with

the directions in the general operating instructions enclosed in the annex. When replacing parts only

the manufacturer’s original parts may be used.

INSTRUCTIONS

www.denios.com 1

Issue: 09/2012

Operation manual and spare parts list

Automatic hose reel - open

DENIOS AG

Dehmer Straße 58-66

32549 Bad Oeynhausen

Tel.: +49 (0)5731 7 53 – 0

Fax: +49 (0)5731 7 53 – 197

Automatic single arm hose reel open - serie 506

Professional automatic single arm hose reel for oil, with delivery hose 10m nom. diam 1/2”

Inlet thread 1/2” f/m

Outlet thread 1/2” f/m

Working pressure 100 bar

Description

Installation

Hose reel can be installed directly on the fixing surface or using a plate (Fig. A) or a pivoting bracket

(Fig. B).

For achieving the reel optimal operation; its hose guide arm can be mounted in these positions:

Perpendicular reeling:

Recommended for ceiling and wall or column under 2.5 m (8 feet) (see Fig. 2).

Side reeling:

Recommended for wall, column, bench, tank, etc (see Fig. 3).

Tangential reeling:

Recommended for wall or column at a height above 2.5 m (8 feet), mobile units, lube truck,

tank assemblies, etc. (see Fig. 4).

A

5

2 3 4

Installation

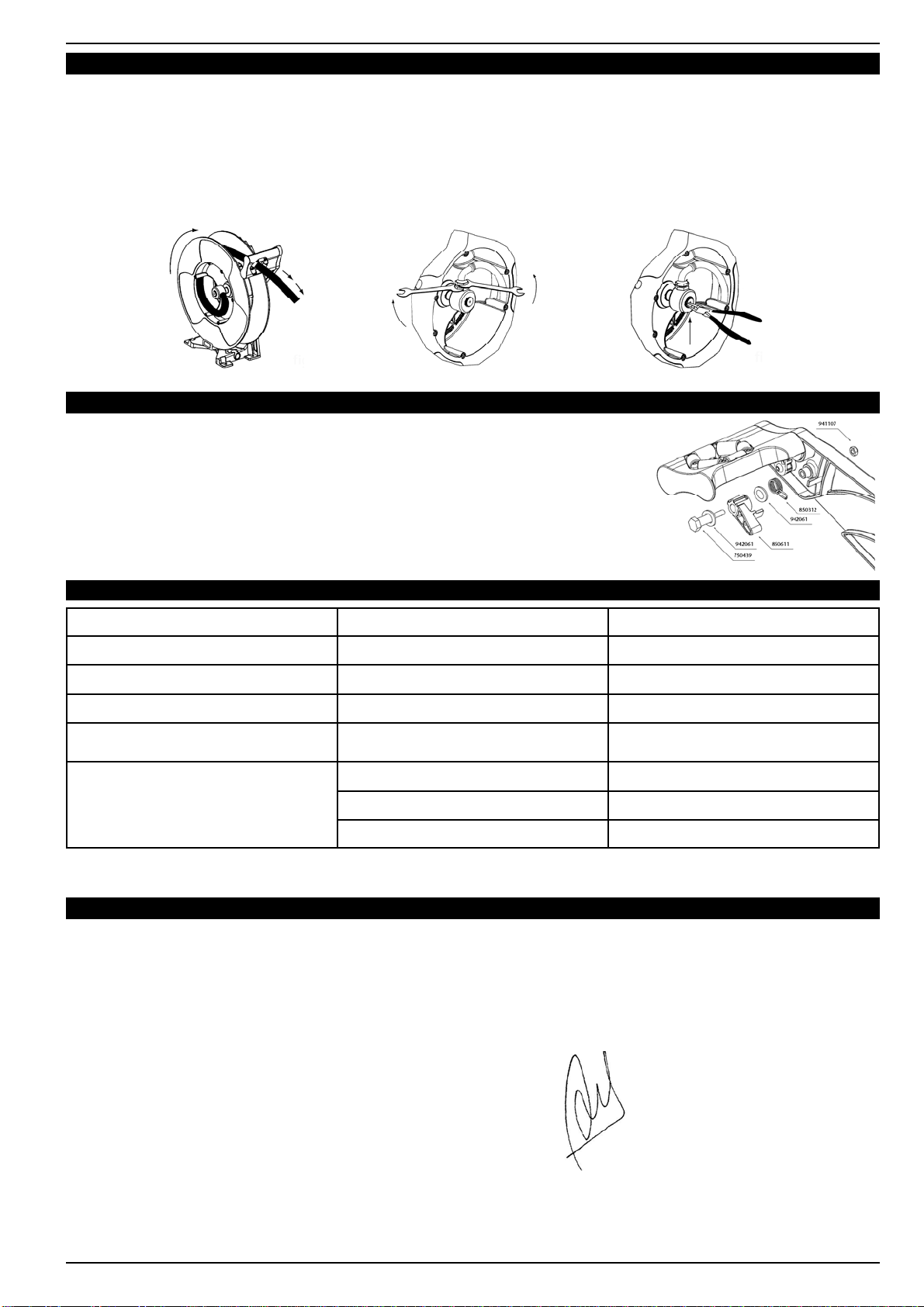

To reposition the hose guide arm, follow these steps:

Clamp the spool with c-clamp to lock the hose reel (Fig. C).

Remove the hose-stop.

Unscrew the fixing screws (Fig. 5).

Place the hose guide arm in the required position and screw the fixing screws.

Insert the hose reel through the hose outlet and assemble the hose-stop. Affix the hose-stop.

Unlock the spool.

C 5

Issue: 09/2012

Automatic hose reel open - serie 506

www.denios.com 2

Hose installation

Clamp the hose reel firmly to a work bench.

Pretension the hose reel power spring by rotating the spool:

10m spring: 16 turns.

Introduce the hose end to fix to the hose reel through the outlet guide and then through the opening in the drum

of the spool. Pull the hose through the drum towards the swivel.

Fix the hose to the swivel as indicated in Figure 8a and fix the U bolt as shown in Figure 8b.

Fix the hose stop to the free end of the outlet hose.

Pull out the hose slightly to free the spool latch and then gradually release the hose to allow the hose reel to

windup the hose.

If the hose reel does not rewind satisfactorily then adjust the tension of the power spring (see “Spring load

adjustment”).

8a 8b

8a 8b

Hose replacement

WARNING: Before removing the damaged hose, dose the nearest shut off valve to the reel and open

the fluid control gun to release the pressure inside the hose.

Unwind the hose completely and then search for the ratchet blocking position (Fig. 6).

Remove the hose stopper (Fig. 7).

Disconnect the hose as seen (Fig. 8a). Release the hose from the disk by removing the clamp (Fig. 8b).

Pass the new hose through the hose outlet and connect it again to the hose reel. Assemble the clamp and

assemble the hose stopper to the required length.

Pull the hose hard enough to release the latch, and slowly allow the hose to retract (Fig. 9).

6

7

9

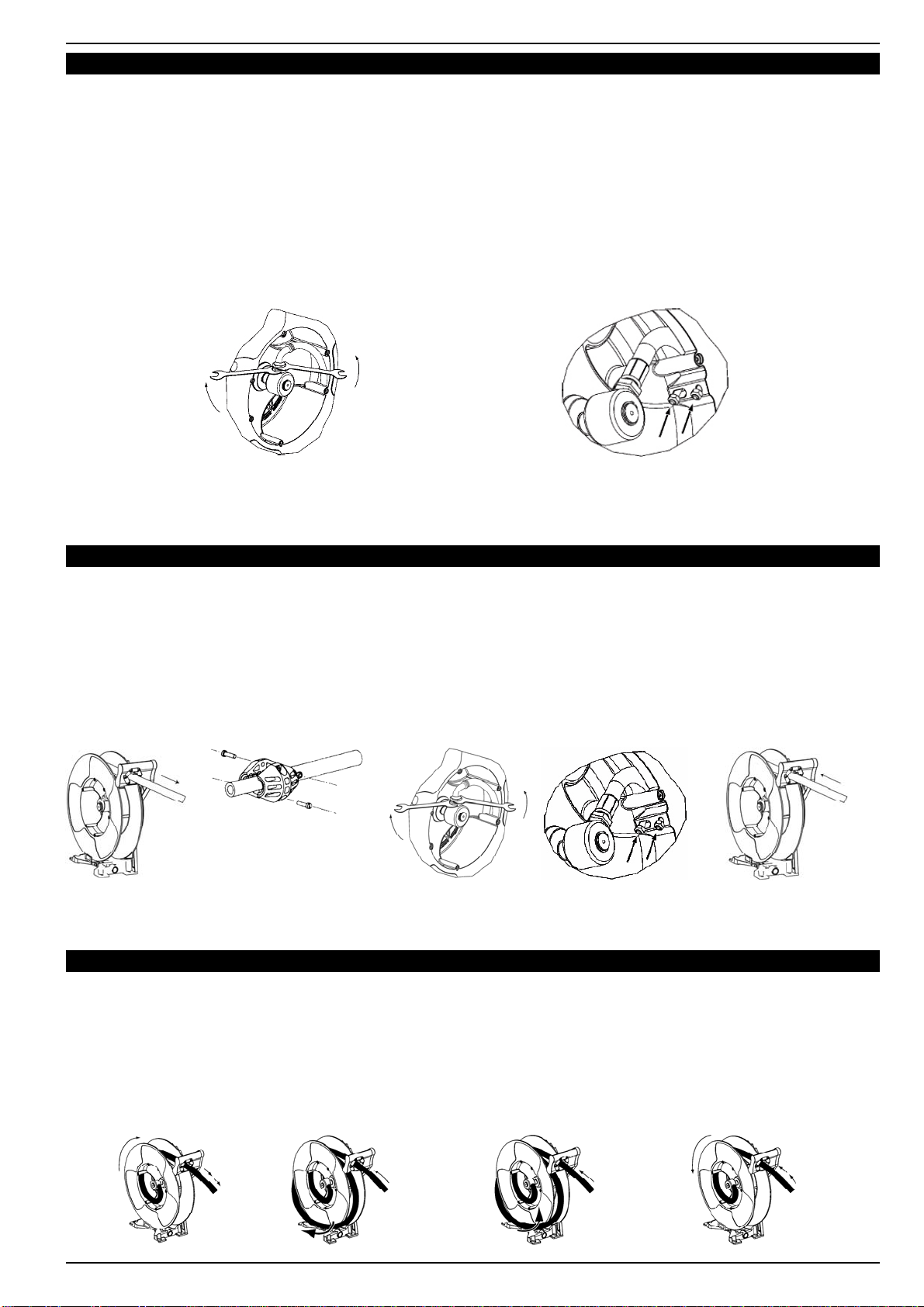

Spring load adjustment

1411 12 13

To increase spring tension

Pull the hose out 10 feet (3 meters) and let the hose

get latched (Fig. 11).

Wind the hanging hose in the reel (Fig. 13).

Gently pull the hose, it is automatically winded

(Fig. 14).

Repeat if more spring tension is required.

To decrease spring tension

Pull the hose out 10 feet (3 meters) and let the hose

get latched (Fig. 11).

Unwind one wrap and pull the hose (Fig. 12).

Gently pull the hose, the hose is automatically wind-

ed (Fig. 14).

Repeat if less spring tension is required.

Issue: 09/2012

Automatic hose reel open - serie 506

www.denios.com 3

EC Declaration of Conformity

SAMOA INDUSTRIAL, S.A., Alto de Pumarín, s/n, 33211 - Gijón - Spain, declares declares that the hose reels

506 XXX conform(s) with the EU Directive(s): (2006/42/EEC)

For SAMOA INDUSTRIAL, S.A.

Pedro E. Prallong Alvarez

Production Director

Hose does not rewind Spring is not tensioned enough Increase spring tension

Leaking hose reel Hose has a hole or ís damaged Replace the hose

Leaking swivel Damaged swivel rings Replace the swivel rings

Hose does not extend out as much

as required Spring is over tensioned Decrease spring tension

Hose reel does not latch Damaged ratchet Replace the ratchet

Ratcet not fitted Assemble the ratchet properly

Damaged spring ratchet Change the ratchet spring

Symptom Possible causes Solution

Troubleshooting

Swivel replacement

WARNING: Before removing the old swivel, dose the nearest shut off valve to the reel and open the

fluid control gun to release the pressure inside the hose.

Pull the hose out and let the hose get latched (Fig. 15).

Unscrew the nuts with two spanners (Fig. 16).

Remove the circlip and pull the swivel. Be careful not to damage the swivel O-Ring (Fig. 17).

Assemble the new swivel and re-assemble the pieces in reverse order.

Ratchet replacement

Remove the nut that fixes the latch (Fig. 18).

Replace the latch and/or the latch spring.

Re-assemble the pieces in reverse order.

15 16 17

18

Issue: 09/2012

Automatic hose reel open - serie 506

www.denios.com 4

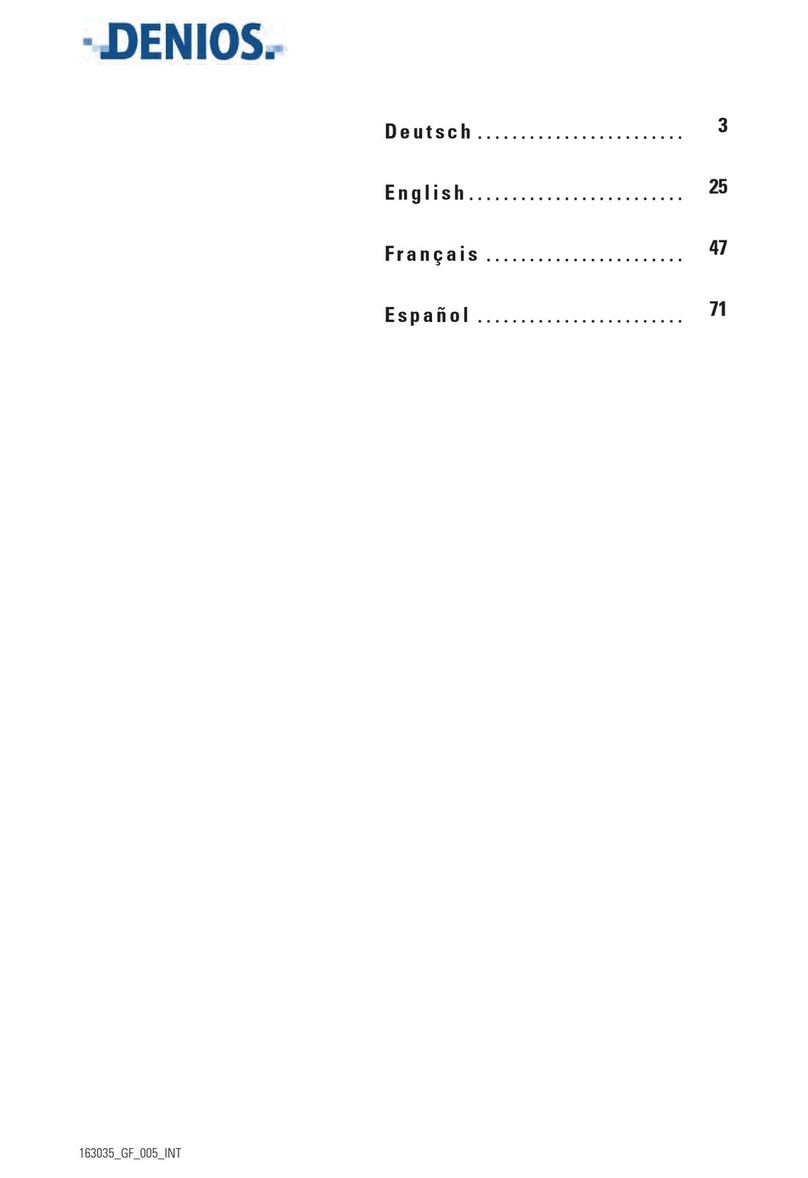

Parts list

Kit number Part. N° Description

526010 Oil swivel kit

750425 Body swivel

945593 Fitting R 1/2” - 1/2” - MM

946032 (x2) O-ring NBR

526020 Ratchet kit

850312 Ratchet spring

750439 Ratchet Axle

850611 Ratchet

941107 Nut AISI 316

942061 Washer AISI 316

526021 Hose outlet kit

850616 (x6) Hose roller

750428 (x6) Roller axle

940921 (x6) Screw AISI 316

526001 Hose-stop and U-bolt kit (oil 1/2”)

944816 U-bolt AISI 316

941126 (2) Nut AISI 316

852601 (2) Hose-stop

940610 (2) Screw

941105 (2) Nut

Plate u-bolt AISI 316

Kit number Part. N° Description

526023 Spool and fluid reel shaft kit

850615 Washer

850613 Spool

750424 Low-medium pressure shaft

950510 (x2) Ball bearing

850617 Spacer

850614 Spring cover

940522 (x6) Screw

850442 Spring washer

Part. N° Description

850310 Standard spring (10 m)

This manual suits for next models

3

Table of contents

Other Denios Storage manuals

Denios

Denios PolySafe Euro User manual

Denios

Denios base-line 1 FA User manual

Denios

Denios GF User manual

Denios

Denios HazMat station EPO-2 Guide

Denios

Denios Multistore 19.16 User manual

Denios

Denios SB User manual

Denios

Denios FW-K User manual

Denios

Denios GSN 1.15 User manual

Denios

Denios 158052W User manual

Denios

Denios drum transporter DT EX User manual

Popular Storage manuals by other brands

HP

HP NetServer Common Tray Ultra3 quick start guide

Wangtek

Wangtek 5000 E Basic Series Oem manual

Samsung

Samsung 840 PRO Series Technical specifications

Dell

Dell EMC PowerVault ME4 Series user manual

Seagate

Seagate Momentus Thin ST500LT012 product manual

Infortrend

Infortrend EonStor DS 3000 Series Quick reference guide