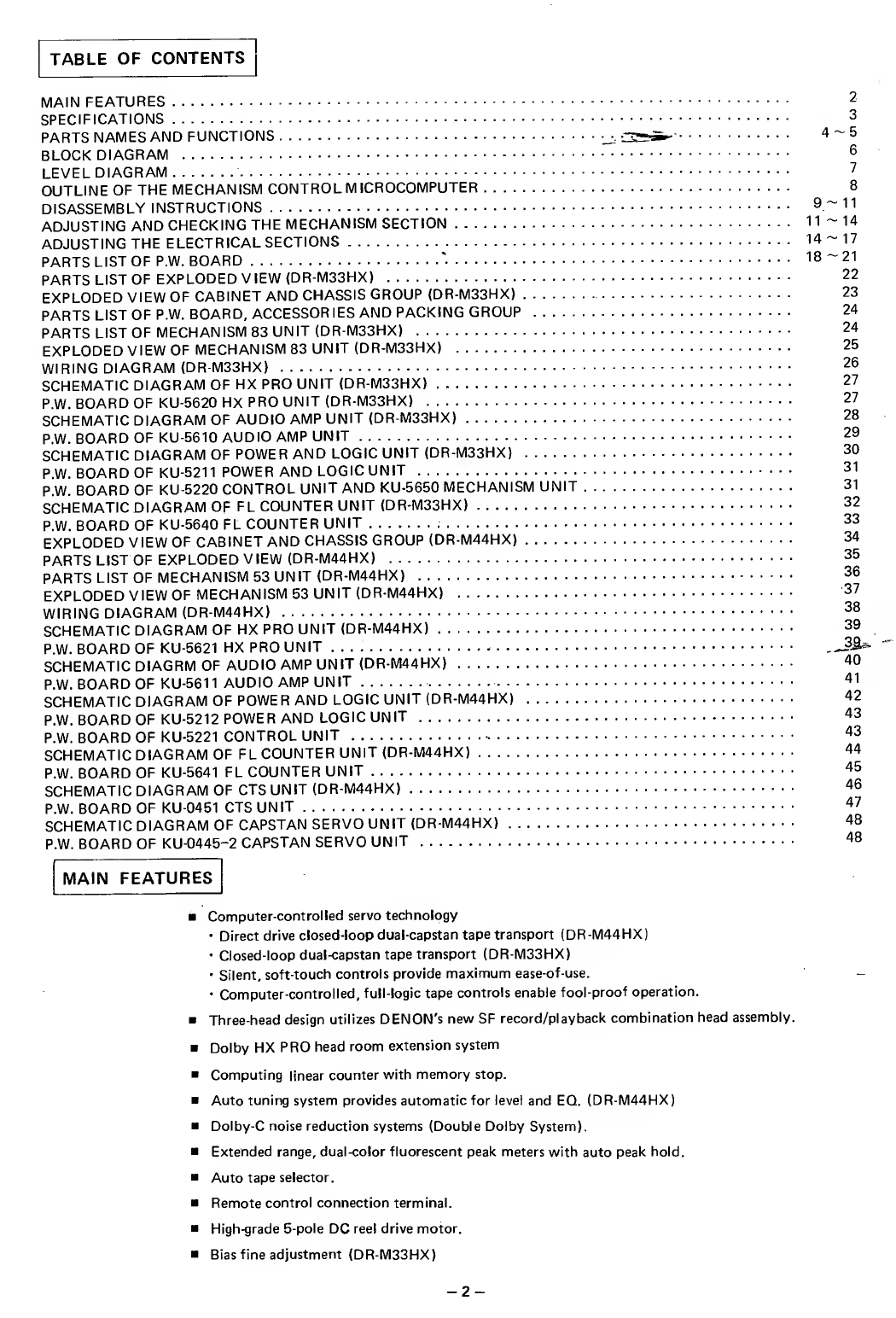

Denon DR-M33HX User manual

Other Denon Stereo Receiver manuals

Denon

Denon AVR-791 User manual

Denon

Denon DRA-F109 User manual

Denon

Denon AVR-X3700H User manual

Denon

Denon DRA-CX3 User manual

Denon

Denon AVR-X5200W User manual

Denon

Denon AVR-3805 User manual

Denon

Denon AVR-X2600H DAB User manual

Denon

Denon AVR-S750H User manual

Denon

Denon AVR-X1600H User manual

Denon

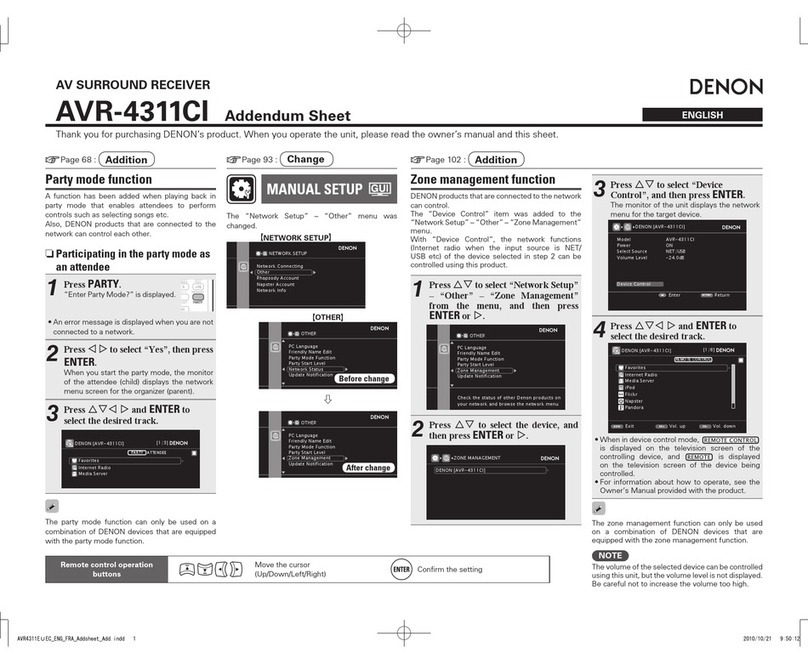

Denon AirPlay AVR-4311CI User manual

Denon

Denon AVR-2307CI User manual

Denon

Denon AVR-X8500HA User manual

Denon

Denon DRA-685 User manual

Denon

Denon AV Surround Receiver AVR-5803 User manual

Denon

Denon AVR-X6700H User manual

Denon

Denon AVR-1708 User manual

Denon

Denon AVR-589 User manual

Denon

Denon ADV-700 User manual

Denon

Denon AVR-E400P User manual

Denon

Denon AirPlay AVR-4311CI Installation and operating instructions

Popular Stereo Receiver manuals by other brands

Sony

Sony XAV-1500 operating instructions

Radio Shack

Radio Shack DX-399 owner's manual

Sony

Sony STR-DE535 - Fm Stereo/fm-am Receiver operating instructions

Pioneer

Pioneer SX-1000TA operating instructions

Yamaha

Yamaha MusicCast TSR-5B3D owner's manual

Sony

Sony STR-DE335 - Fm Stereo/fm-am Receiver operating instructions