DentalEZ Core User manual

CORETM Delivery Unit

Console Mount

User Manual

i

www.DentalEZ.com 866-DTE-INFO

i

DentalEZ®Equipment

PN: 2717-269C

Table of Contents

Section I Introduction

Product Overview ............................................... 1

Console Mounted Unit Features........................2

Dimensions ........................................................ 3

Specications .................................................... 4

Classications ................................................... 5

Explanation of Symbols & Signs ...................... 5

Safety Precautions............................................ 6

Section II Preinstallation

Packaging .......................................................... 9

Unit Placement ................................................. 10

Utility Service Center (USC).............................10

Section III Installation

Console Adaptor Mount................................... 13

Console ............................................................. 15

Assistant’s Arm (Optional)............................... 16

Assistant’s Instrumentation............................ 17

Cuspidor (Optional) ..........................................18

Delivery Head Arm Assembly.......................... 19

Light Post (Optional) ........................................ 19

Fiber Optic Electrical (Optional) ..................... 20

Handpiece Tubing ........................................... 20

Finalizing USC Installation ............................... 21

Power Module (Optional)................................. 23

Section IV Testing

Delivery System............................................... 25

Syringe ............................................................. 26

Foot Control and Handpieces......................... 26

Cuspidor........................................................... 28

Other Optional Features.................................. 30

Section V Operation

Delivery Head.................................................... 31

Syringe ............................................................. 32

Foot Control ..................................................... 32

Assistant’s Vacuum Accessories................... 33

Clean Water System........................................ 33

Cuspidor........................................................... 34

Section VI Care

Cleaning ........................................................... 35

Disinfecting...................................................... 36

Section VII User Service Information

Troubleshooting .............................................. 37

Service Instruction .......................................... 40

Disposal of Equipment.................................... 40

Section VIII Parts Lists/Diagrams

Utility Service Center ....................................... 41

Assistant’s Arm (Optional)............................... 41

CORE Delivery Head ........................................ 42

Touch Pads....................................................... 43

Console ............................................................ 44

Simplicity Cuspidor (Optional)........................ 45

Galaxy Cuspidor (Optional) ............................. 46

Foot Control ..................................................... 47

Air/Water Syringe ............................................ 47

HVE Nozzle....................................................... 48

Saliva Ejector Nozzle....................................... 48

EMC Information.............................................. 49

Limited Warranty.............................................. 51

www.DentalEZ.com 866-DTE-INFO

ii

CORETM Console Mounted Unit

PN: 2717-269C

1

www.DentalEZ.com 866-DTE-INFO

1

DentalEZ®Equipment

PN: 2717-269C

This manual contains installation, operation and

care instructions, and user service information

for the DentalEZ® CORE™ Console Mounted Unit

(CMU).

The CORE CMU is intended to be used by trained

professional dental care personnel only, as an

interface device to connect the dental operatory

hand instruments to the appropriate supply utility

such as air, water, vacuum, drain and electrical.

It functions as a system management device

that provides a method of operating the hand

instruments from a single control input device.

The CORE CMU is manufactured to be used

with a dental chair that supports a patient in

a reclined seated position. Operators will be

positioned around the patient’s head as required

for optimum access for the specic procedure

being performed. The delivery unit positions the

handpieces for the optimum presentation to the

operator.

The CORE CMU is designed to provide trouble-

free service when installed, operated and cared

for according to the procedures set forth in this

manual.

To ensure proper installation, carefully

read all of the instructions contained in

this manual, paying close attention to all

warnings, cautions and notes.

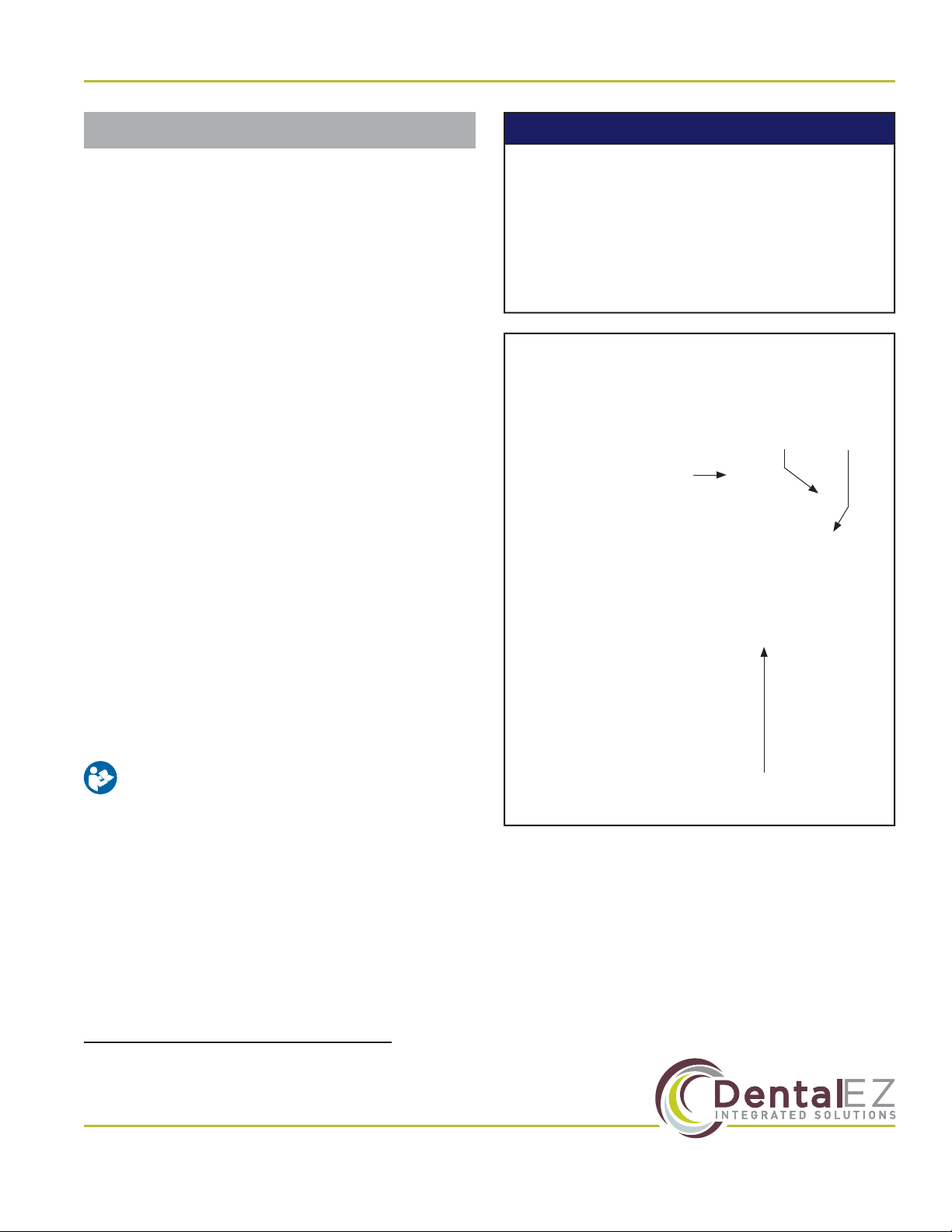

Before starting installation procedures, review

the illustration to become familiar with the

components of the CORE CMU (Figure 1).

After the CORE CMU is installed, review the

features, operation procedures, and care

guidelines with the doctor’s sta.

Leave this manual in the doctor’s oice.

Section I Introduction

Product Overview

• Installation by an authorized

DentalEZ dealer service technician is

recommended.

• For any questions about an order, please

contact a DentalEZ Equipment customer

service representative at 866-DTE-INFO.

NOTICE

Figure 1. Main components of the CORE CMU

Adjustable

Arm

Light Post

(Optional)

Delivery

Head

Clean

Water

System

www.DentalEZ.com 866-DTE-INFO

2

CORETM Console Mounted Unit

PN: 2717-269C

Console Mounted Unit Features

Designed with simplicity in mind, the CORE product line provides a straightforward, easy-to-use delivery

unit with common components, simple integrated holders and an easy-to-read pressure gauge. The

console mounted unit positions StarDental® handpieces and ancillaries within easy, comfortable reach.

Standard Features

• Secure tray placement.

• Air gauge for easy pressure monitoring.

• Break release handle.

• Easy access control block and internals

for easy maintenance.

• Aluminum ex arm for stability and ease

of positioning.

• Built standard with BioFreeTM tubing.

Optional Features

• Optional integrated dual access touchpad

controls.

• Rear assistant’s arm/instrumentation

with centrally located solids collector and

tubing.

NOTE: Image shown contains optional

handpieces and upgraded features: Galaxy

Cuspidor, Simplicity Telescoping Assistant

Instrumentation, Unit Touchpad and Wired Foot Control.

Section I Introduction

3

www.DentalEZ.com 866-DTE-INFO

3

DentalEZ®Equipment

PN: 2717-269C

Section I Introduction

Dimensions

Figure 2. Top and side view dimensions for the CORE console mounted delivery unit

23½"

7¾"

27½"

19"

15¾" 16¼"

10½" to 23⅞"

6¼"

17½"

17½"

21¾"

57"

20¾"

15¼"

16"

16"

2"

4"

18"

22"

www.DentalEZ.com 866-DTE-INFO

4

CORETM Console Mounted Unit

PN: 2717-269C

Power Supply

• 115V AC, 50/60 Hz, as applicable

Air Pressure

• 551.6 kPa (80 PSI) (at regulator in USC)

Water Pressure

• 275.8 kPa (40 PSI) (at regulator in USC or clean

water manifold)

Clean Water System

• Reservoir capacity: 1.0 L

Shipping (Package) Weight

• CORE Traditional Delivery Head and Arms:

24.5 lb. (11.1 kg)

• Magellan Delivery Unit Post: 13 lb. (5.8 kg)

• Magellan Delivery Unit Support: 20 lb. (9 kg)

• Utility Service Center (USC): 15 lb. (6.8 kg)

• Assistant’s Arm: 16 lb. (7.2 kg)

• Light Post (Optional): 15 lb. (6.8 kg)

Specications

Recommended Environmental Conditions

Transportation and Storage

• Temperature range: -20°F to 165°F

(-29°C to 74°C)

• Relative humidity range: 0% to 95%

Operation

• Conditioned air

• Temperature range: 59°F to 80°F (15°C to 27°C)

• Atmospheric pressure range: 50 to 105 kPa

Section I Introduction

5

www.DentalEZ.com 866-DTE-INFO

5

DentalEZ®Equipment

PN: 2717-269C

Section I Introduction

Explanation of Symbols & Signs

Classications

For the purposes of this user manual, the UL

approval is for the unit (head/arm assembly) and

power supply. All other regulatory markings are

provided in their respective manuals.

• Type of Protection Against Electric Shock:

Class 1 Equipment.

• Degree of Protection Against Electric Shock:

Type B Applied Parts. The handpiece is

considered an applied part.

• Degree of Protection Against Ingress of Water:

Ordinary

• Flammable Gases: Equipment not suitable for

use in the presence of a ammable anesthetic

mixture with air, oxygen or nitrous oxide.

• Not intended for use in an oxygen rich

environment.

• Mode of Operation: Continuous

Medical-General Medical Equipment

Certied as to electrical shock, re

and mechanical hazards only in

accordance with:

ANSI/AAMI ES60601-1:2005

CAN/CSA C22.2 NO. 60601-1-08

IEC 80601-2-60:2012

53HN

E355890

The authorized European representative is:

Dental Hygienics & Decontamination (DHD)

41 Blackwell Drive, Braintree Business Park

Braintree Essex, CM7 2PU, UK

Phone: +44 01787 877877 (ext. 200)

= Caution

= Warning

= Biohazard

= Warning - Dangerous Voltage

= General Mandatory Action

= Refer to Manual (Follow Instructions)

= Alternating Current

= Direct Current

= Protective Earth (Ground)

= Type B Applied Part

= European Certication

= Serial Number

= Manufacture Date

= Manufacturer

= Electromagnetic Radiation

= Do Not Trash

= Box Must Remain Upright

= Do Not Place Box on Unlevel Surface

= Do Not Stack Box

= Box Contents Safe Temperature Range

= Box Contents Safe Humidity Range

www.DentalEZ.com 866-DTE-INFO

6

CORETM Console Mounted Unit

PN: 2717-269C

Section I Introduction

Safety Precautions

To satisfy FCC RF exposure requirements

for mobile and base station transmission

devices, a separation distance of 20 cm or

more should be maintained between the

antenna of this device and persons during the

operation. To ensure compliance, operation at

closer that this distance is not recommended.

The antenna(s) used for this transmitter must

not be co-located or operating in conjunction

with any other antenna or transmitter.

CAUTION

• Some illustrations and instructions in

this user manual include installation of

optional city water. If optional city water

is wanted, purchase kit PN 3658-455 for

units with a cuspidor or PN 3658-456 for

units without a cuspidor.

• Isolating the unit from the supply mains is

accomplished by unplugging the unit from

the power receptacle.

NOTICE

Before proceeding with electrical

installation, all wiring must be in

accordance with NEC and local electrical

codes.

To avoid the risk of electrical shock, this

equipment must only be connected to a

supply mains with protective earth.

• Do not modify this equipment without

permission from DentalEZ. Unauthorized

modication will void the warranty and

could result in serious injury. If this

equipment is modied, appropriate

inspection and testing must be conducted

to ensure continued safe use of

equipment.

• Property damage and/or personal injury

may result if directions are not followed or

OEM parts are not used.

• The use of ACCESSORY equipment not

complying with the equivalent safety

requirements of this equipment may lead

to a reduced level of safety of the resulting

system. Consideration relating to the

choice shall include:

• Use of the accessory in the PATIENT

VICINITY

• Evidence that the safety certication

of the ACCESSORY has been

performed in accordance to the

appropriate IEC 60601-1 harmonized

standard.

• Always turn ounit and remove power

from unit when servicing. (Turn opower

at disconnect or service breaker.

• Never leave children unattended when

unit is in use.

WARNING

7

www.DentalEZ.com 866-DTE-INFO

7

DentalEZ®Equipment

PN: 2717-269C

Section I Introduction

Safety Precautions (Continued)

• Medical electrical equipment needs

special precautions regarding

electromagnetic (EMC) compatibility

and needs to be installed according to

EMC information. (See EMC Information

provided in this manual.)

• In accordance with Part 15 of FCC rules,

this equipment was tested and complies

with Class A digital device limits. These

limits are designed to give equipment

reasonable protection against

detrimental interference when operated

in a commercial environment.

• Mobile radio frequency (RF)

communications equipment can aect

medical electrical equipment.

• Accessory equipment not complying with

the Medical Device Safety standard IEC

60601-1 may contribute to a reduced level

of safety of the CORE Delivery Unit. It is

necessary for all accessory equipment

and attachments to comply with IEC

80601-2-60 Medical Electrical Equipment.

NOTICE

This equipment has been tested and found

to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful

interference in a residential installation.

This equipment generates, uses and

can radiate radio frequency energy, and

if not installed and used in accordance

with the instructions, may cause harmful

interference to radio communications;

however, there is no guarantee that

interference will not occur in a particular

installation. If this equipment does cause

harmful interference to radio or television

reception (which can be determined by

turning the equipment oand on) the

user is encouraged to try to correct the

interference by one or more of the following

measures:

• Reorient or relocate the receiving

antenna.

• Increase the separation between the

equipment and receiver.

• Connect the equipment to an outlet on

a circuit dierent from that to which the

receiver is connected.

• Consult the dealer or an experienced

radio/TV technician for help.

NOTICE

www.DentalEZ.com 866-DTE-INFO

8

CORETM Console Mounted Unit

PN: 2717-269C

9

www.DentalEZ.com 866-DTE-INFO

9

DentalEZ®Equipment

PN: 2717-269C

Section II Preinstallation

Packaging

Unpacking Unit Cartons

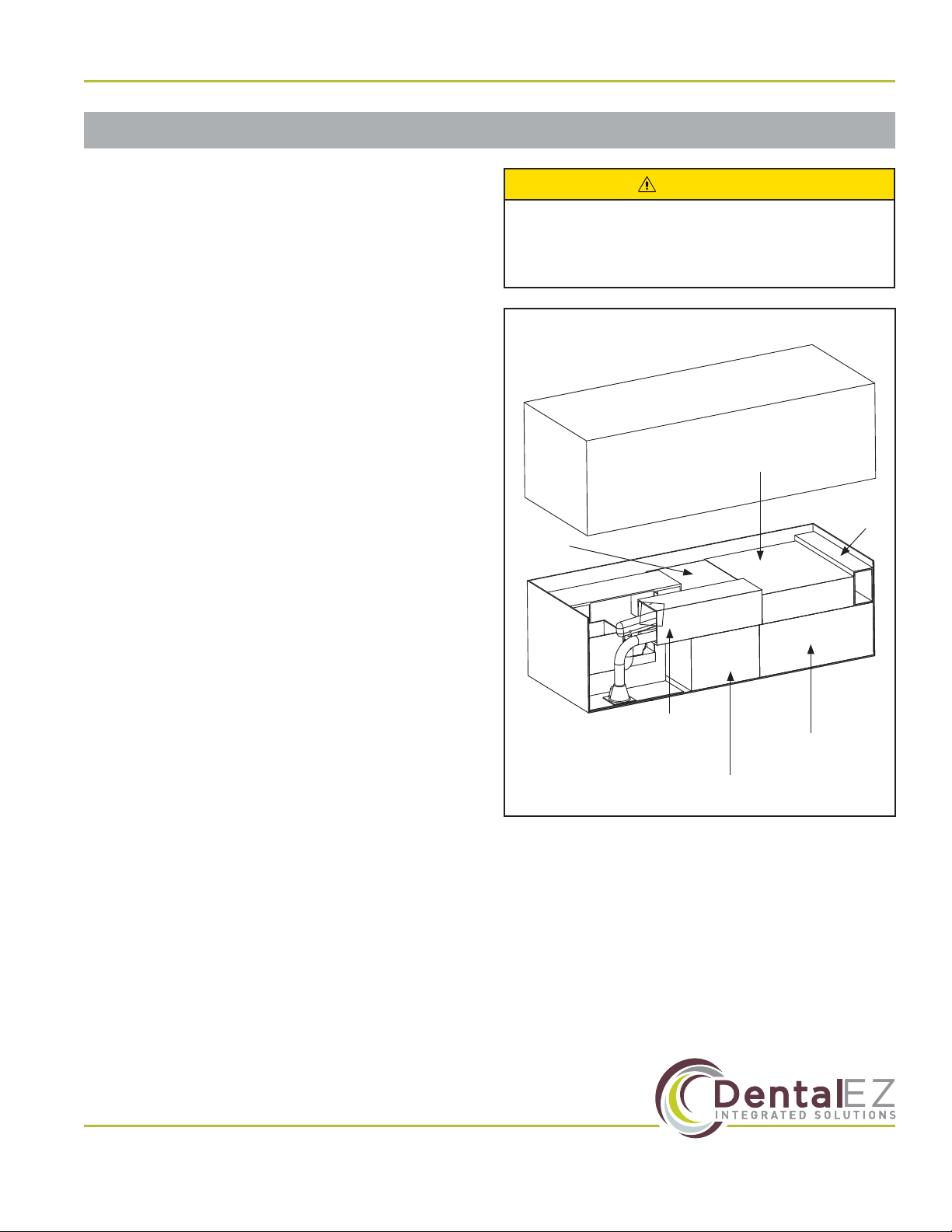

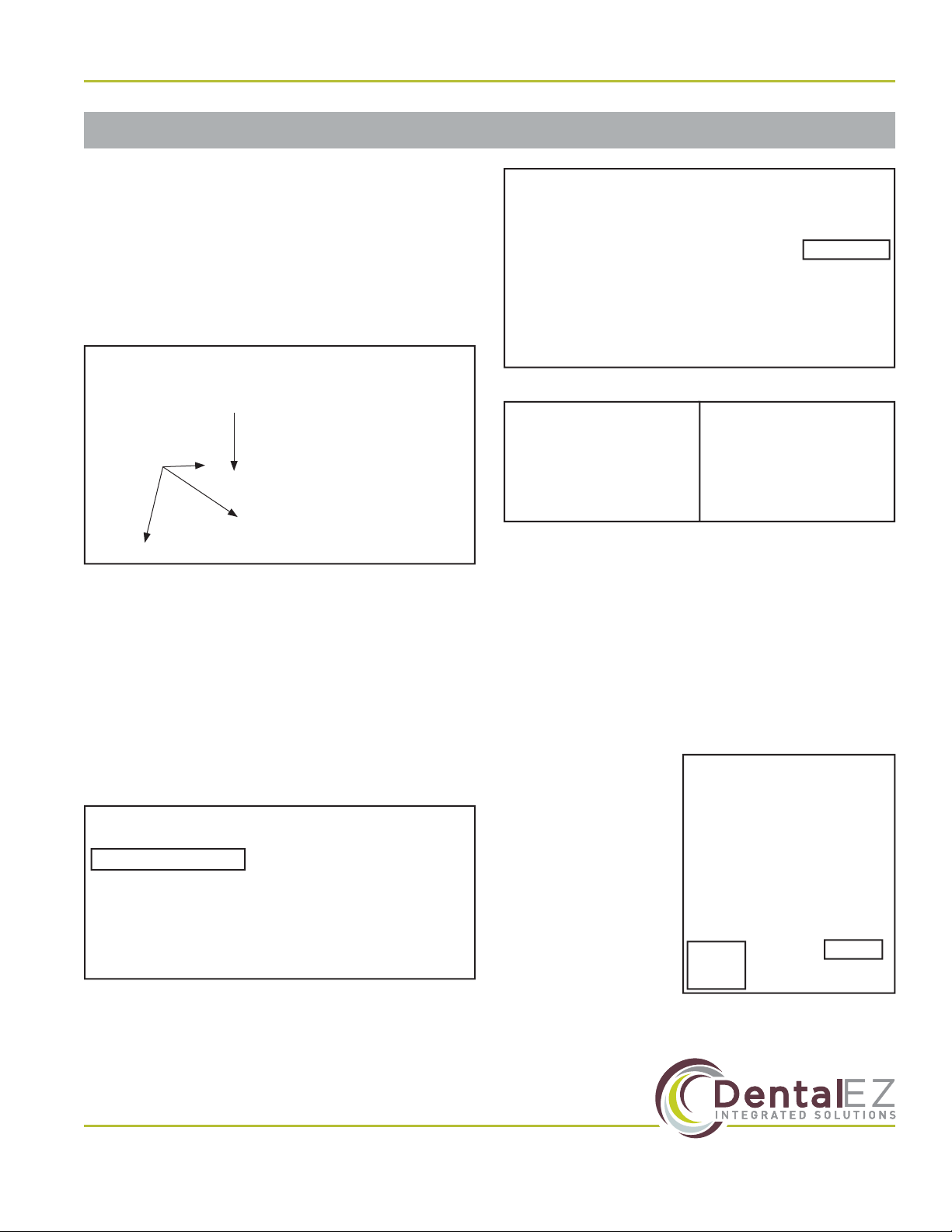

The CORE CMU components are packaged and

shipped according to the carton diagram shown

(Figure 3).

Verify the components packaging contents against

the packing list. All parts supplied are necessary for

proper installation; DO NOT discard any hardware

or components until installation is complete.

NOTE: Cartons may contain empty packing inserts

(even if optional components were ordered).

NOTE: If a pre-tubed chair was ordered, items

marked with an asterisk (*) will be on the chair.

NOTE: If light post was ordered, entire contents

will be inside light post box.

Console Mounted Unit Carton Contents

• Accessory/Options

– Syringe Tubings

– Tray/Tray Pad

• Utility Service Center

• Delivery Head Assembly

• Post-mounted Service Console (with/without

cuspidor)

– Umbilical Assembly

– Foot Control

– Plastic Trim Components

• Optional Components

– Light Post

– High Volume Evacuator (HVE)

– Assistant’s (Instrumentation) Arm

To avoid damage to the carton contents, do

not use a knife or sharp object to open the

packaging.

CAUTION

Delivery

Head Arm

Assembly

Cuspidor

Assembly

Utility

Service

Center

(USC)

Figure 3. CORE CMU carton contents

Console

Assembly

Assistant’s

Instrumentation

Arm (Optional)

Chair

Adaptor

Arm

www.DentalEZ.com 866-DTE-INFO

10

CORETM Console Mounted Unit

PN: 2717-269C

Section II Preinstallation

Unit Placement

• DO NOT position equipment any place

where it would interfere with unplugging

the power cord from the receptacle.

• The plug cannot be located in a position

that requires tools to access.

WARNING

Utility Service Center (USC)

Parts Included

• Utility Service Center (USC)

• USC Cover

• USC Template

• Bag of Supplies

• Set the USC cover aside until all

installation and testing of the delivery

system is complete.

• DO NOT DISCARD the USC template after

use. Neatly refold it and place in it the

back of this user manual.

NOTICE

Tools Required

• Drill

USC Site Preparation

1. Remove and unfold the full-size USC template

found in the USC carton.

2. Position the USC template according to the

exact layout indicated, making certain correct

distance from base to chair is maintained.

3. Using the USC template, drill four corner

mounting holes for the USC base. DO NOT

secure the base to the oor at this time.

NOTE: For wood or metal oors, drill 5/32" holes.

For concrete oors, drill 1/4" holes and install

plastic anchors.

11

www.DentalEZ.com 866-DTE-INFO

11

DentalEZ®Equipment

PN: 2717-269C

Utility Service Center (USC) (Continued)

Plumbing Contractor’s Procedure

Tools Required

• 5/8" Open-end Wrench

USC Installation

NOTE: Items marked with an asterisk (*) are

optional components.

NOTE: If installing the optional cuspidor, optional

city water system components must be installed.

1. Open the USC bag of supplies.

2. Orient the utilities as described in the USC

template and stub through the oor. Vacuum

and drain ttings not supplied; refer to the USC

template for requirements

(Figure 4).

NOTE: Pay close attention to the orientation of the

template to the chair.

3. Sweat the valve adapters to the air and *water

stubs.

4. Apply the appropriate thread sealant to the

valve adapter(s) and install the stop valve(s)

(Figure 5).

• If use of the optional city water system

is planned for in the future, it is highly

recommended to install necessary

components now.

• For reference, a color-coded tubing

diagram is included with this user manual.

NOTICE

Section II Preinstallation

5. Sweat the vacuum elbow to the stub.

6. Sweat the hose connector to the elbow as

applicable and orient as shown in the template.

7. Flush the air and *water lines to remove trash

and debris.

8. Connect the air tting assembly to the air stop

valve as shown in the template. Using a 5/8"

open-end wrench, tighten the nut securely.

9. Connect the *water actuator valve assembly to

the water stop valve as shown in the template.

Using a 5/8" open-end wrench, tighten the nut

securely.

• Before proceeding with plumbing

installation, comply with and maintain all

applicable utility codes and regulations.

WARNING

Figure 4. Utility service center with optional city water

Figure 5. Utility service center with optional city water

Drain

Fitting (Not

Supplied)

Air Stop Valve

Vacuum

Fitting (Not

Supplied)

*Water Actuator

Valve Assembly

Chair Side

(Optional City Water Installation Shown)

Water Stop Valve

(Picture for reference only!)

(Picture for reference only!)

Air Fitting

Assembly

www.DentalEZ.com 866-DTE-INFO

12

CORETM Console Mounted Unit

PN: 2717-269C

Electrical Contractor’s Procedure

The electrical contractor is to provide a covered

115V AC receptacle that meets all applicable utility

codes and regulations (Figure 6).

For the recommended location of the 115V AC

receptacle, refer to the USC template.

NOTE: Electrical contractor’s parts are NOT

supplied.

Rating of main circuit breakers should be

20 Amps maximum.

CAUTION

(Picture for reference only!)

115 V AC

Receptacle

Figure 6. 115V AC receptacle

Section II Preinstallation

13

www.DentalEZ.com 866-DTE-INFO

13

DentalEZ®Equipment

PN: 2717-269C

Console Adaptor Mount

Section III Installation

CORE Chair

Parts Included

• Console Adaptor (Pinch Bolt/Washer Installed)

• Three Leveling Set Screws

• M16 Bolt

Installation

1. Raise the chair base and back to full UP

position.

2. Disconnect the chair from the power supply.

3. Take othe chair seat upholstery by removing

the ve Phillips-head screws from underneath

the chair (Figure 8).

4. Position the support so that the lip of the

chair rests underneath the lip of the washer.

The mount will hold itself in place (Figure 9 -

Figure 10).

Pinch Bolt &

Washer

Figure 7. Console adaptor mount

Leveling Set

Screw Holes (3)

5. Install the M16 bolt loosely into the back of the

mount and into the chair.

6. Rotate console adaptor to the side of the chair

and tighten bolt.

7. Place a level on the support, parallel with and

perpendicular to the chair center line, then

check the level of the support.

NOTE: If leveling is

necessary, adjust the

3/16" set screws until

the unit support is

level

(Figure 11)

.

8. Tighten M16 bolt

(55 foot-pounds).

Figure 8. Remove ve (5) Phillips-head screws

Phillips-head Screws (5)

Figure 9. Position the unit support under the chair

Unit Support

Figure 10. Slide lip of washer onto lip of chair

Figure 11. Adjust set screws

Leveling

Set

Screws

M16 Bolt

www.DentalEZ.com 866-DTE-INFO

14

CORETM Console Mounted Unit

PN: 2717-269C

Section III Installation

Console Adaptor Mount (Continued)

NuSimplicity Chair

Parts Included

• Console Adaptor

• Spacer

• Two 1/4-20 × 1¼" Hex Head Screws

• Four 1/4-20 × 4" Hex Head Cap Screws

• Ten Zinc Plated, Split Lockwashers

• Four 1/4 × 20 Hex Nuts

• Three 1/2-13 × 1½" Hex Head Screws

• Three 1/2" Split Lockwashers

• Two 3/8-16 × 1/2" Socket Set Screws

• Four 1/2" Flat Washers

Installation

1. Raise the base and back to full UP position.

2. Disconnect the chair from the power supply.

3. Determine if the two outside 1/2" threaded

hole mounting pads and the adaptor bar are

level. If the mounting pads or adaptor bar

are not level, select the necessary amount

of 1/2" at washers needed to provide a level

condition across the two pads.

4. Position the adaptor bar so that the three 1/2"

through holes align with the corresponding

threaded holes of the chair mount casting.

5. Install the two outside 1/2" bolts and lock

washers and the number of 1/2" at washers

determined in step 3 through the adaptor bar

and thread into the chair mount casting.

6. Tighten both outside 1/2" bolts to allow a 3/16"

clearance at the middle 1/2" bolt location.

7. Install the middle 3/8" set screws in the

bottom of the adaptor bar.

8. Install the middle 1/2" lock washer and 1/2"

bolt, but

do not

fully tighten.

9. Place a level on the adaptor bar, parallel with

and perpendicular to the chair center line,

then check the level of the adaptor bar.

NOTE: If leveling is necessary, adjust the 3/8" set

screws until the adaptor bar is level

(Figure 13)

.

10. Tighten all hardware (55 foot-pounds for 1/2"

bolt).

11. Attach the spacer using the 1/4-20 ×1¼" hex

head screws.

Figure 13. Adjust 3/8" set screws if leveling is necessary

1/2" Bolts

Leveling Set Screws

Figure 12. Console adapter parts

1/4-20 ×1¼"

Hex Head Cap Screw

1/4-20

Hex Head Nut

Adaptor Bar

Spacer

Flat

Lockwasher

1/4-20 ×4"

Hex Head Cap Screw

1/2-13 ×1½"

Hex Head Screw

Zinc Plated

Lockwasher

3/8-16 ×1/2"

Socket Set

Screw

1/2" Split

Lockwasher

15

www.DentalEZ.com 866-DTE-INFO

15

DentalEZ®Equipment

PN: 2717-269C

Console

Section III Installation

Tools Required

• Torpedo Level

Installation

1. Place the console on top of the adaptor.

2. Orient the console parallel to the chair with

the water quick-disconnect facing toward the

back of the chair.

3. Locate the four 1/4-20 bolts, washers and nuts

and assemble as shown (Figure 14).

4. Using a torpedo level, check the perpendicular

and parallel levels of the console.

NOTE: If leveling adjustments are necessary,

adjust the set screws on the ange of the console

until the console is level

(Figure 15)

.

Service Console Covers

1. To remove the side covers, simply lift the

covers until the magnets turn loose and take

the side covers oof the console.

NOTE: It is highly recommended to keep the

console side covers ountil all installation and

testing is completed.

2. To replace the side covers, simply align the

magnets and let the covers snap into place.

3. To remove the top cover (the side covers must

be o), remove the two screws holding the

top cover in place (Figure 16).

Figure 14. Locate/assemble 1/4-20 bolts, washers & nuts

1/4-20

Bolts,

Washers &

Nuts (4)

Figure 15. Adjust set screws to level console

Leveling Set Screws

Figure 16. Top cover screws

Screws (2)

www.DentalEZ.com 866-DTE-INFO

16

CORETM Console Mounted Unit

PN: 2717-269C

Assistant’s Arm (Optional)

Basic Fixed Asstistant’s Arm (Cuspidor

Mounted) Carton Contents

• High-volume Evacuator (HVE) Valve Handle

• Saliva Ejector (SE) Valve Handle

• Solids Collector Trap

• Two Inline Connectors (For Syringe Connection)

• 5' Length HVE Tubing

• 5' Length SE Tubing

NOTE: For right-hand operation, mount the

assitant’s arm on the left side (from the

perspective of sitting in the chair).

1. Holders are found attached to the cuspidor.

2. Install the saliva ejector valve, high-volume

evacuator valve and syringe following the

steps outlined in the next section.

Telescoping Assistant’s Arm

1. Place the bushing end of the telescoping arm

onto the pivot pin of the console (Figure 17).

2. If leveling is needed, adjust the set screw on

the underside of the arm section closest to

the end cap (Figure 18).

3. Insert the pivot pin of the tool holder into the

bushing of the telescoping arm. Use the set

screw on the end of the telescoping arm to

adjust the amount of rotational drag desired

(Figure 19).

Figure 17. Place telescoping arm onto pivot pin

Telescoping Arm

Pivot Pin

Figure 18. Adjust set screw if needed

End Cap

Leveling Screw

Figure 19. Use set screw to adjust rotational drag

Set Screw

Tool Holder

Section III Installation

17

www.DentalEZ.com 866-DTE-INFO

17

DentalEZ®Equipment

PN: 2717-269C

Section III Installation

Assistant’s Instrumentation

Saliva Ejector (SE)

1. Connect the SE valve to the 5/16" OD SE

tubing (Figure 20).

2. Hang the SE valve in the instrument holder.

3. Route the SE tubing from the holder through

the access holes on the bottom of the console

chassis (holes found at the edge of the

chassis closest to the head of the chair).

4. Connect the SE tubing to the open 1/4" port

under the solids collector in the service

console.

High-Volume Evacuator (HVE)

1. Connect the HVE valve to the 5/8" OD tubing

(Figure 21).

2. Hang the HVE valve in the instrument holder.

3. Route the HVE tubing from the holder through

the access holes on the bottom of the console

chassis (holes found at the edge of the

chassis closest to the head of the chair).

4. Connect the tubing to an open 1/2" port under

the solids collector in the service console.

Air/Water Syringe

NOTE: The syringe for the delivery head is factory

installed.

1. Pass the syringe tubing from the assistant’s

arm through the bottom opening of the

console and route the tubing up to make

connection in the console. (See the tubing

diagram provided with this manual.)

2. Inside the console, cut othe tubing plug

from the 1/8" red tubing that is marked A

coming from poppet valve (indicated as Point

#1 on the tubing diagram); and cut othe

tubing plug from the 1/8" green tubing that is

marked Wcoming from the 1/4" green water

supply tube (indicated as Point #2 on the

tubing diagram).

IMPORTANT NOTE: Leave the slide clamp on the

A

and

W

tubings at this stage.

3. Connect the Aand Wtubing to the syringe

tubing marked Aand Wfrom the assistant’s

arm by aligning then threading the male and

female quick connects.

4. Connect the syringe to the valve body and

install the nozzle tube assembly.

5. Hang the syringe in the instrument holder.

6. Slide the clamp othe air and water tubes in

the CMU to permit ow.

SE Valve

5/16" OD Tubing

Figure 20. Connect SE valve to OD tubing

HVE Valve

5/8" OD Tubing

Figure 21. Connect HVE valve to OD tubing

Other manuals for Core

2

Table of contents

Other DentalEZ Medical Equipment manuals

Popular Medical Equipment manuals by other brands

PN MEDICAL

PN MEDICAL THE BREATHER CLEANING YOUR DEVICE

Cardiac Science

Cardiac Science Powerheart AED G3 Plus 9390E Operator's and service manual

ProMed

ProMed Lec Control Plus quick guide

RTI

RTI Barracuda Reference manual

burmeier

burmeier DALI II 24 Volt instruction manual

Dräger

Dräger Infinity C700 Quick reference guide