dentalfarm H8 Operating instructions

WATER SOFTENER mod. H8

USER AND MAINTENANCE MANUAL

INDEX

1. INTRODUCTION AND GENERAL INFORMATION

1.1 OBJECTIVE OF THE MANUAL

1.2 KEEPING THE MANUAL

1.3 EQUIPMENT IDENTIFICATION

1.4 DECLARATION OF COMPLIANCE

1.5 HYGIENIC SAFETY NORMS AND TiFQ TESTING

1.6 RECOMMENDATIONS AND WARNINGS

2. ABOUT THE EQUIPMENT

2.1 HOW DOES IT WORK?

2.2 EQUIPMENT DESCRIPTION

2.3 THE PACKAGING CONTAINS

2.4 TECHNICAL FEATURES

2.5 FEATURES OF FEED WATER

2.6 EQUIPMENT PERFORMANCE BASED ON WATER HARDNESS

3. INSTALLATION

3.1 PACKAGING

3.2 CHOOSING THE PLACE OF INSTALLATION

3.3 CONNECTION TO THE WATER NETWORK

3.3.1 QUICK JOINTS

3.4 CONNECTION TO THE DRAIN SYSTEM

4. ACTIVATION AND INSTRUCTIONS FOR THE REGENERATION

4.1 RINSING RESINS

4.2 PERIODIC REGENERATION

4.3 MIXER CONTROL

5. MAINTENANCE FOR THE INSTALLER

5.1 CHANGING THE RESINS

5.2 RESIN PRESERVATION AND ACTIVATION AFTER A LONG PERIOD OF INACTIVITY

6. IMPROPER USE OF THE EQUIPMENT

7. EQUIPMENT DISPOSAL

8- EXPLODED DRAWING AND SPARE-PART LIST

WARNINGS FOR THE USER

- This equipment must not be used by children or by people with physical, mental or sensory impairments, or by

people lacking experience, unless they are supervised by someone responsible for their safety or they have

received instructions regarding the correct and safe way to use the equipment and were warned against the risks.

- Never try to repair the equipment by yourself: you may cause damage. Ask your seller for assistance.

- Never touch or use the water softener with wet or damp hands or feet, or barefoot.

1. INTRODUCTION AND GENERAL INFORMATION

1.1 OBJECTIVE OF THE MANUAL

This instruction manual is addressed to qualified personnel who must have knowledge of the health and safety

rules of the place of installation. The objective of this manual is to give useful information and warnings, both to

the installer and the user, regarding: HOW TO STORAGE AND KEEP THE EQUIPMENT BEFORE USE:

• Place and room conditions

• Expiry date

FOR THE INSTALLER

• Precautions for hygienic safety

• Equipment description and features

• Place and mode of installation

• Activation

• Procedures to follow after a period of inactivity of the equipment

• Equipment disposal

• Solutions to some problems

FOR THE USER

• Instructions for the periodic rinsing of the resins

• Instructions for the care and cleaning of the equipment

• Health and hygiene warnings concerning the water produced by the equipment.

The manual also gives you the guidelines to avoid ayn improper use of the equipment and it specifies the installer

and the user’s responsibilities, therefore we suggest to read through this manual before installing or using the

water softener. If the instructions are not followed, the manufacturer will decline responsibility for any damage

caused to people, things or animals and will consider the guarantee null and void.

1.2 KEEPING THE MANUAL

This manual is an integral part of the product. It must be kept with care by the user and it must accompany the

equipment, even in case of a property transfer.

1.3 EQUIPMENT IDENTIFICATION

The equipment is identified by the numbers written in bold on the bottom left side of the label (pic. 2, I) on the

softener’s tank, on the package and on the back of this manual.

1.4 DECLARATION OF COMPLIANCE

This product complies with the Community Regulations and national laws applicable at the moment of its

entrance on the market. The declaration of compliance signed by the manufacturer is available on request and

online.

1.5 HYGIENIC SAFETY NORMS AND TIFQ TESTING

This equipment has been tested to verify its compliance with the hygienic safety regulations specified by the

Italian rules on the subject, the Legislative decree n. 31/2001, according to Ministerial decree 25/2012. It is

necessary to use original replacement parts for repairs and maintenance to guarantee hygienic safety. To

preserve hygienic safety, we recommend to remove the equipment from the package only at the moment of

installation. The equipment has been tested by the TiFQ Institute for the Hygienic Quality of Food Technology in

their licensed laboratory (see table, end of manual).

1.6 RECOMMENDATIONS AND WARNINGS FOR THE STORAGE:

• Store the water softener in a dry place

• The temperature in the storage place must be between 0 and 35 °C

• We recommend to use the equipment within 24 months

FOR THE INSTALLER

We suggest to install the equipment after carefully reading the instruction manual. Should complications arise, we

suggest asking your seller for assistance. The seller’s information is written on the last page of this manual.

FOR THE USER

• Never try to repair the equipment by yourself: you may cause damage. Ask your seller for assistance.

• For manual regeneration and regular salt refillings, read the “ACTIVATION AND INSTRUCTIONS FOR

REGENERATION”.

• Cleaning the water softener is part of the user’s duties. The manufacturers are not responsible for any damage

or harm that may derive by not following these precautions.

2. ABOUT THE EQUIPMENT

2.1 HOW DOES IT WORK?

The cationic resins in the softener’s tank transform calcium carbonate in sodium carbonate which is water-soluble

at the working temperatures of both coffee and ice machines. The transfer of sodium ions between the resins and

water is imperative to soften drinking water, but this process tends to decline in proportion to the flow rate and

to the consumption of water. For this reason, it is necessary to regenerate the exhausted resins by making water

and salt flow through them, therefore returning them to their active state. The resins gradually lose their cationic

function, and consequently their efficiency, with each regeneration. We recommend replacing them after seven

years of use.

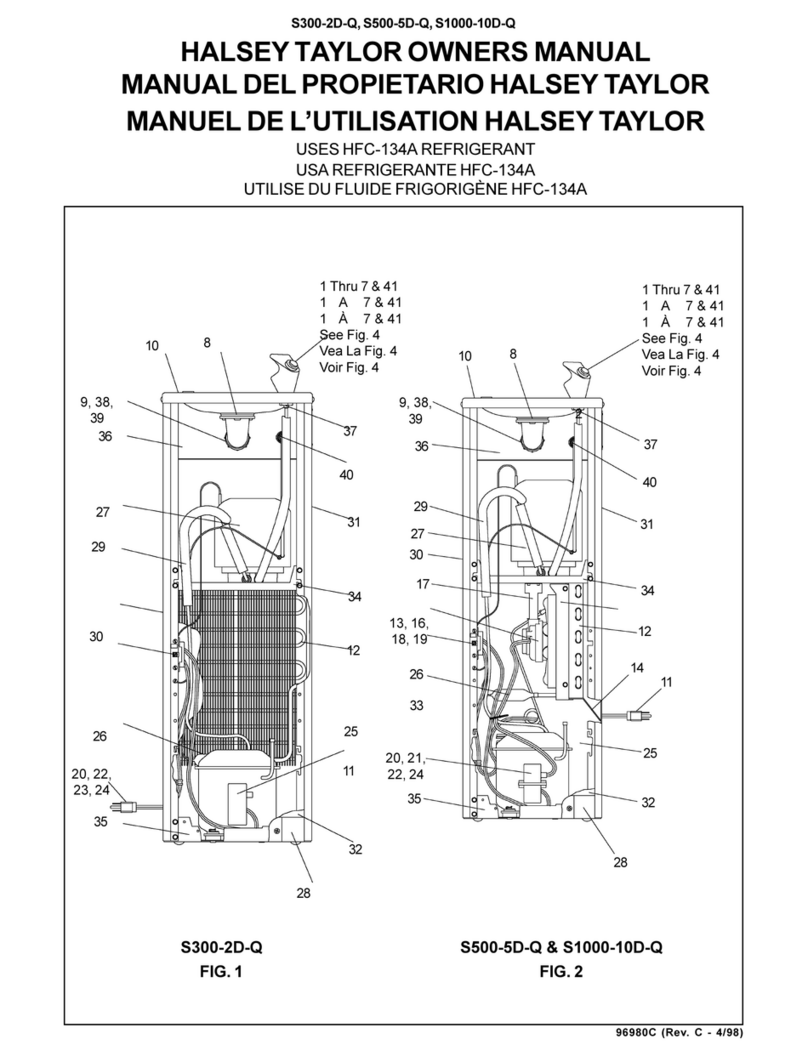

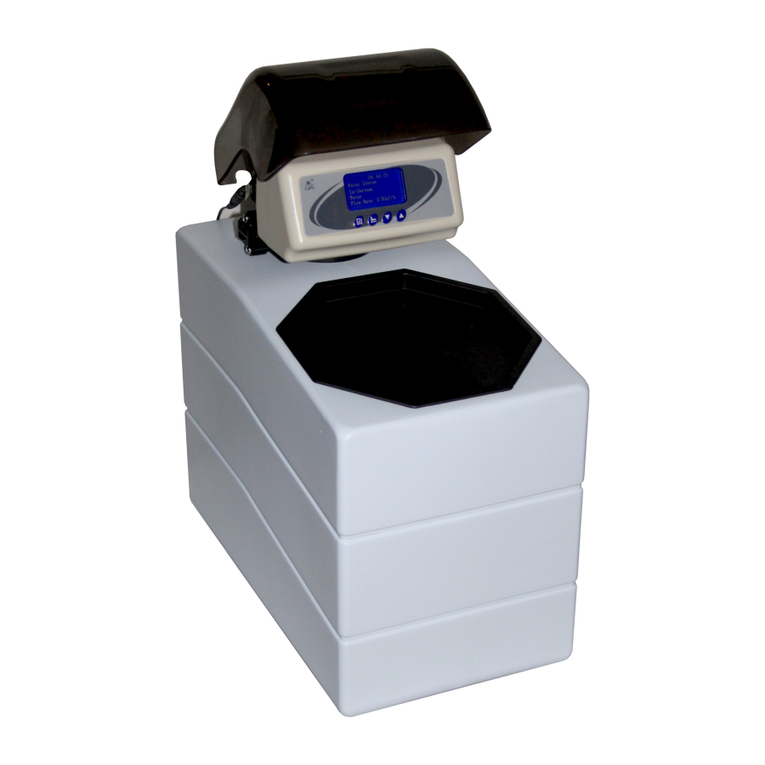

2.2 EQUIPMENT DESCRIPTION

Main components of the water softener are:

• 1 IV valve allowing use of water even during resins regeneration

• 1 tank containing the resins for water softening

• 1 tank lid

LEGENDA

A INLET

B OUTLET

C TAP ON WATER SUPPLY

D HANDLE

E WATER HARDNESS ADJUSTMENT SCREW

F DRAIN PIPE

G TANK LID

H UNIDIRECTIONAL VALVE

2.3 THE PACKAGING CONTAINS

• 1 complete water softener IV

• 1 instruction manual

• 1 drain pipe

• 2 joints for connection to the water sullpy network

2.4 TECHNICAL FEATURES

Pressure of feed water:

0,1 ÷ 0,8 MPa (1 ÷ 8 bar)

Nominal flow rate at 4 bar:

800 l/h

R

oom temperature:

4°C

-

35°C

Joints for the connection to the water

network:

-

inlet 3/4 "G (for normal washing machine or model trimmer hose

- outlet for D. = 8x6 hose)

2.5 FEATURES OF FEED WATER

Feed water must be:

• Drinkable and clean

• Temperature must be between 6° and 25°C

• Hardness must be below 900 ppm CaCO3 (90°f)

2.6 EQUIPMENT PERFORMANCE BASED ON WATER HARDNESS

3. INSTALLATION

3.1 PACKAGING

• Before the installation, check that the equipment was not damaged by the transport and does not show any

anomaly. In case of doubt, ask your seller.

• Don’t throw the package away for some time, being careful to keep any dangerous or small parts of the package

away from children.

3.2 CHOOSING THE PLACE OF INSTALLATION

• Ensure that any other water treatment machine is not present upline of the place of installation.

• Ensure that feed water comes from a drinking water pipe. We recommend to check the chemical and physical

parameters of the drinking water as well as its hardness before installation.

• Install the equipment near a floor sink to dispose of the waste water produced by the regeneration.

• Install the equipment in a dry place easily accessible to maintain, regenerate and clean the equipment.

Do not install the equipment in dirty and unhygienic places or in any place difficult to clean.

• Ensure that room temperature in the place of installation is between 4°C and 35°C.

• Keep away from corrosive or acid products.

• Do not install in places where electric or personal safety regulations are openly disregarded.

• Hydric pressure must not be under 0.1 Mpa (1 bar) or over 0.8 Mpa (8 bar). (We recommend at least 3 or 4 bar)

• If water pressure is over 8 bar, it will be necessary to install a pressure regulator.

• Salt packages or boxes must not be kept in humid places or in direct contact with the floor: keep it, for example,

on a wooden pallet.

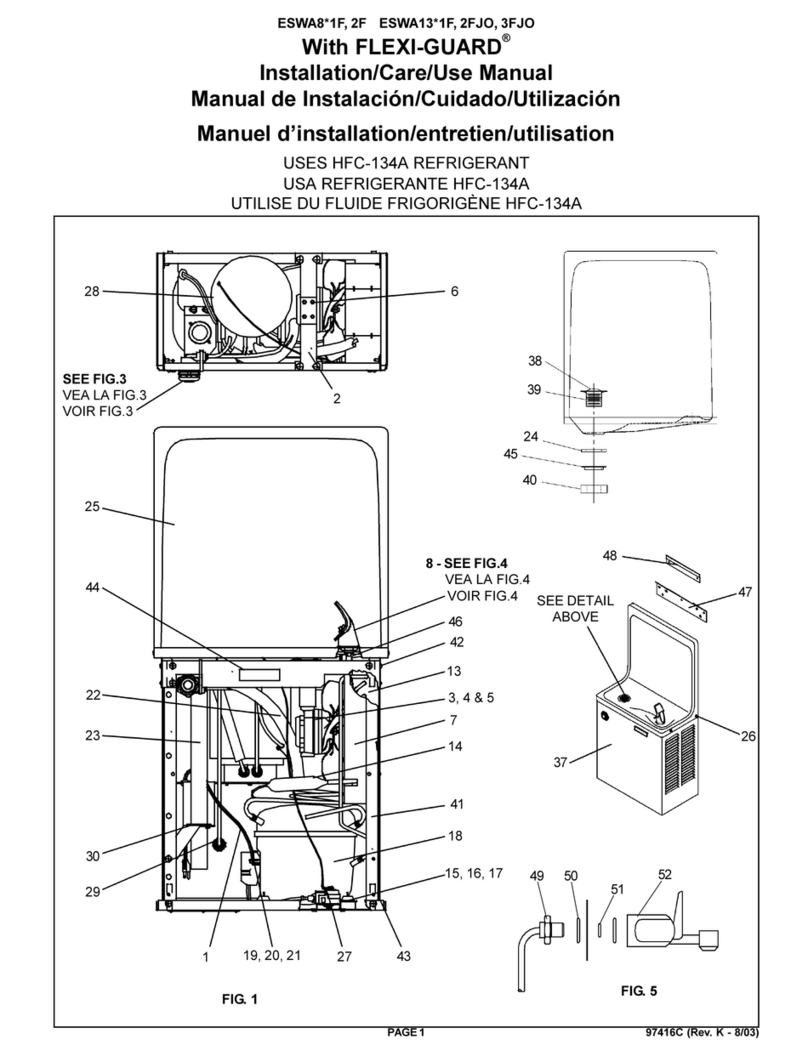

3.3 CONNECTION TO THE WATER NETWORK (pic. 2)

The connection of the equipment to the water system must be done according to all applicable rules, following

the instructions of the manufacturer and qualified personnel. During the installation use pipes, hoses, valves and

components which comply with the applicable Italian rule on hygienic safety, the Ministerial Decree 174/2004.

They must be kept in their sealed package until the moment of installation to preserve their hygienic safety. It is

forbidden to use components that are not suitable for drinking water contact or components whose hygienic

safety was compromised, as they could corrupt the quality of treated water and the equipment itself. Check if

there are hygienic safety taps on the input and output of the equipment. Remove them only during this phase

and not before.

3.3.1 QUICK JOINTS

The pipes are connected to the valve by quick joints.

Connect the water inlet (A) and outlet (B) pipes to

the joints in the package, tightening them safely.

To connect the joint to the valve it is necessary to

insert it all the way in. The metal inserts of the quick

joint will prevent the pipe from disconnecting.

To remove the pipe it is necessary to depressurize

the tank, then press on the black ring that surrounds

the pipe next to the insertion and extract the pipe.

Ensure that:

• The water inlet and outlet pipes comply with the

regulations on drinking water pipes.

• A water inlet tap (C) must be installed by the user

between the water system and the water softener to ensure that water flow can be interrupted in case of

necessity.

• It is advisable to install a one-way valve (H) on the outlet to avoid unwanted refluxes.

• Install a tap to take a sample of the outlet water in order to test its hardness. All pipes must be free, not crushed

or constricted.

3.4 CONNECTION TO THE DRAIN SYSTEM

Waste water resulting from the regeneration is funnelled into the floor sink by the flexible pipe (pic. 1, E) included

in the package.

Warning: keep the drain pipe suspended over and not immersed in the water of the sink (pic. 1, L). At the end of

the installation, before opening the water inlet tap (pic. 1, C), rinse the resins as explained in the chapter

“ACTIVATION AND INSTRUCTIONS FOR THE REGENERATION”.

4. ACTIVATION AND INSTRUCTIONS FOR THE REGENERATION

4.1 RINSING THE RESINS

Turn the valve handle on number 4, backwash mode. Open the water inlet tap and let the water flow through the

flexible pipe (E) until it is clean. Turn the handle back on number 1.

4.2 PERIODIC REGENERATION

Position 2 (DEPRESSURIZATION MODE

)

- Turn the valve handle on number 2. Loosen the cover handle and wait

until depressurization.

- Remove the lid and add the required quantity of salt according to the

model (1.0 kg)

Cleaning

Clean the lid and the seal from any salt residue.

Clean the upper part of the water softener from any salt residue and

clean both the tank and under the cover of the weld joint of any leaked

salt water.

The manufacturer does not take responsibility for the corrosion of the

tank caused by the failure to follow these instructions.

- Put the lid back on (pic. 1, G) and tighten the cover handle (pic. 1, F)

safely.

Po

sition 3 (RINSING MODE)

- Turn the valve handle on number 3.

- Let the salt water come out from the drain pipe until the water is fresh

(around 40 minutes)

Position 4 (BACKWASH CLEANING MODE)

- Turn the valve handle on number 4 and wait for 30 seconds

(during the backwash mode, the water softener does not supply water)

Position 1 (SERVICE MODE)

- Put the valve handle back on number 1, service mode.

WARNING: during regeneration, the machine connected to the water

softener is supplied with non-softened water.

4.3 MIXER CONTROL

The regulator (REG.) has a special screw. By gradually loosening the

screw, the equipment leaves a residue of hard- ness in the exiting

water. The more you loosen the screw, the more hardness it leaves.

This operation must be performed with care. At the end of the

operation, it is necessary to check the hardness levels.

Attention: the hardness levels in water must be periodically checked by

the installer.

5. MAINTENANCE FOR THE INSTALLER:

5.1 CHANGING THE RESINS

The resins’ softening capacity ends after 5-7 years. This period can vary based on the characteristic of the feed

water and the quantity of softened water. After this period of time, the user needs to decide if it is enough to

change the resins or if it is better to replace the water softener itself.

To change the resins it is necessary to turn the valve handle on number 2 (pic. 3). Wait a few seconds until tank

depressurization. When water stops coming out of the drain, move the plastic blocks outwards (pic. 3, A). It will

then be possible to separate the valve from the tank (pic. 3, B) Bring the tank to an appropriate place to change

the resins and clean the interior of the tank. Open the lid and change the resins.

Do not throw the resins in the sewers. The resins are not biodegradable and must be considered a non-hazardous

waste (EU code CER 190905).

After changing the resins, clean the lid seal and the upper part of the softener from any resin residue. Close the lid

and connect the valve to the tank. Close the blocks and turn the handle on number 4. Let the water flow from the

drain pipe until it is clean.

Turn the handle back on number 1.

5.2 RESIN PRESERVATION AND ACTIVATION AFTER A LONG PERIOD OF INACTIVITY

If the water softener is not to be used for more than 30 days, it is necessary to do a double regeneration first and

then leave the water softener with the lid closed. We suggest avoiding a period of inactivity longer than 12

months. It is forbidden to reactivate the system after this period of inactivity. If the period of inactivity is shorter

than 12 months, it is necessary to rinse the resins and do a manual regeneration (paragraph 4.1 and 4.2) before

reactivating the equipment.

6. IMPROPER USE OF THE EQUIPMENT

This equipment has been designed to soften drinking water for domestic and technological use. The equipment

must not be used for any different purpose and it must not be modified or tampered with in any way. Any other

use than the one specified in this manual is improper and therefore dangerous. The manufacturer cannot be

considered responsible for any damage caused by improper, mistaken or illogical use of the equipment.

• It is forbidden to feed the equipment with any liquid other than drinking water.

• It is forbidden to introduce in the tank any products other than salt (NaCl).

7. EQUIPMENT DISPOSAL

Any waste must be disposed of according to the applicable regulations. The water softener was

built with non-hazardous materials like polymers and stainless steel, and they must be disposed of

according to the applicable rules. Do not throw the resins in the sewer. The resins are not

biodegradable. They are classified as non-hazardous waste and must be disposed of accordingly (EU

code CER 190905)

8- EXPLODED DRAWING AND SPARE-PART LIST

Pos.

Codice

-

Item

Descrizione

Description

1

B12

PROFILO COPRI SALDATURA

WELDING COVER

2

C16

TAPPO PER MANOPOLA

KNOB CAP

3

C15

MANOPOLA TAPPO IN NYLON

NYLON CAP KNOB

4

C14

GUARNIZIONE TAPPO 72x7 TN

CAP

JOINT

5

C18

CORPO TAPPO IN PLASTICA + TIRANTE

PLASTIC CAP BODY + STAY BOLT

6

C17

STAFFA TAPPO IN PLASTICA

PLASTIC CAP CLAMP

7

B50

BOMBOLA 8 litri

8 liters CYLINDER

8

D19

FILTRO ENTRATA IV

INPUT IV WIRE

9

D24

FILTRO USCITA IV8

OUTLET IV8 WIRE

10

VB1

FLANGIA IV

IV FLANGE

11

V3

DADO FILTRO IV

IV FILTER NUT

12

VB0

VALVOLA IV SENZA ATTACCHI

IV VALVE WITH NO CONNECTION

13

TUBO

TUBO SCARICO IN GOMMA 8 x 12

8x12 RUBBER EXHAUST PIPE

14

B3

BASAMENTO

BASE

15

VB3

RACCORDO 3/8"G

-

T10

3/8"G

-

T10

PIPE

-

FITTING

17

VB4L

RACCORDO 3/4"G

-

T10

3/

4

"G

-

T10

PIPE

-

FITTING

18

NPR119

RACCORDO 8x6

-

1/4"

8x6

-

1/4"

PIPE

-

FITTING

20

VB5

TAPPO MANOPOLA IV

IV KNOB CAP

21

VB6

O

-

RING 114

OR JOINT 114

22

VB7

MANOPOLA IV

IV KNOB

23

VB8

COPERCHIO VALVOLA IV

IV

VALVE CAP

24

VB36

MISCELATORE IV

IV MIXER

25

VB12

MOLLA VALVOLA IV DIA.21x26

IV VALVE SPRING Ø21x26

26

VB13

O

-

RING 108

OR JOINT 108

27

VB14

SELETTORE IV

IV SELECTOR SWITCH

28

VB15

O

-

RING 3175

OR JOINT 3175

29

VB16

GUARNIZIONI PIATTE IV

IV FLAT

JOINT

30

VB18

BUSSOLE DERLING

DERLING BUSH

31

J16

O

-

RING JG10

OR JOINT JG10

32

J07

PINZETTA JG10

PLIERS JG10

33

VB2

BLOCCO VALVOLA IV CON FORO

IV VALVE BLOCK WITH HOLE

34

VB20

BLOCCO VALVOLA IV SENZA FORO

IV VALVE BLOCK NO HOLE

35

F3

O

-

RING 3075

OR

JOINT 3075

36

Z25

SACCO DI RESINA DA 25 Lt.

25 Liters RESIN SACK

DENTALFARM s.r.l.

Via Susa, 9/a - 10138 TORINO – ITALY

COMMERCIAL SERVICE - (+39) 011/4346588

TECHNICAL SUPPORT - 011/4346632

FAX 011/ 4346366

E-mail: info@dentalfarm.it

Web: www.dentalfarm.it

Table of contents

Popular Water Dispenser manuals by other brands

Calspas

Calspas CalSalt Filtration owner's manual

Atlantis

Atlantis AT210 owner's guide

Clean Water Systems

Clean Water Systems Fleck 7000 Greensand Installation & start?up guide

IBC Water

IBC Water AS1375MP-960 Installation & operating instructions

GE

GE FXMLH use and care manual

Mijar

Mijar MINIBOY VE user manual

Ispring

Ispring DS4S Installation instructions & user manual

Follett

Follett Chewblet 7 Series installation guide

Columbia

Columbia aqua FC-525-ROP manual

Murdock

Murdock A171 Series Installation and maintenance instructions

Franklin

Franklin PWS1 Series Installation instructions and owner's manual

Modena

Modena DD Series manual