1

EN

Contents

1. General information .............................................................................................................................. 3

2. Safety information ................................................................................................................................ 4

2.1 Symbols and information .......................................................................................................................... 4

2.2 Intended use............................................................................................................................................. 4

2.3 Warranty and liability................................................................................................................................ 4

2.4 Employer‘s obligations .............................................................................................................................. 5

2.5 Personnel‘s obligations ............................................................................................................................. 5

2.6 Laser safety officers .................................................................................................................................. 5

2.7 Protection of the eyes against laser radiation ............................................................................................ 6

2.8 Protection of the skin against laser radiation ............................................................................................. 7

2.9 Further important safety issues, welding fume extraction .......................................................................... 8

2.10 Service and maintenance .......................................................................................................................... 8

2.11 Laser warning signs .................................................................................................................................. 9

2.12 Location of laser warning signs ............................................................................................................... 10

3. Basics of the laser and the welding process...................................................................................... 11

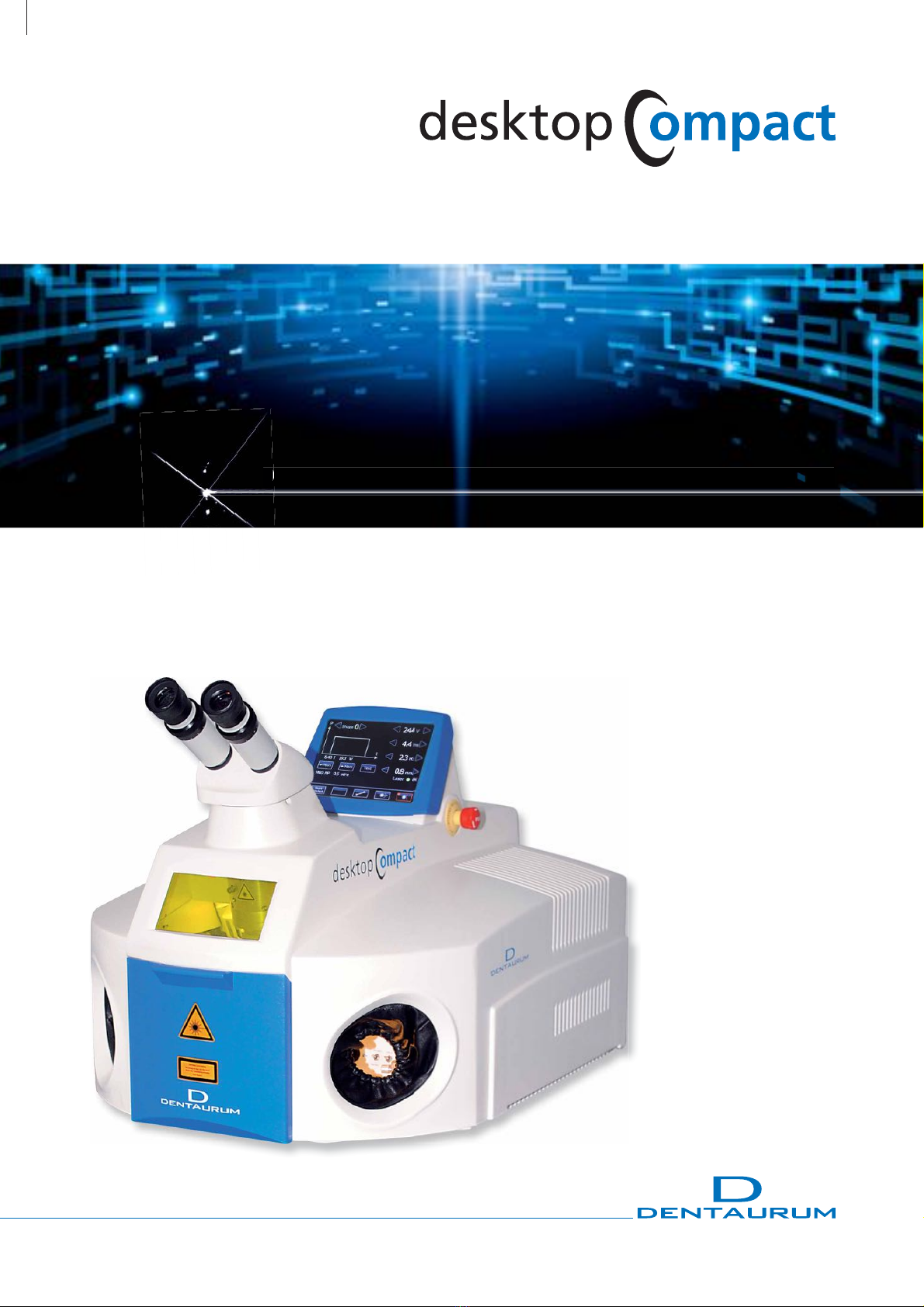

4. Machine description ............................................................................................................................ 12

4.1 Overview ................................................................................................................................................ 12

4.2 The working chamber............................................................................................................................. 14

4.3 Design of the desktop Compact.............................................................................................................. 15

4.4 External connections............................................................................................................................... 16

4.5 Installation and commissioning ............................................................................................................... 17

4.6 Operating the desktop Compact............................................................................................................. 18

5. The stereo microscope......................................................................................................................... 20

6. Setting the pulse parameters ............................................................................................................. 22

7. Operating the touchscreen / working chamber ................................................................................ 25

7.1 Setting pulse parameters on the touchscreen.......................................................................................... 25

7.2 Opening/closing safety shutter on touchscreen ....................................................................................... 26

7.3 Saving/loading parameter sets on touchscreen or in working chamber.................................................... 26

7.4 Resetting error message on touchscreen ................................................................................................. 28

7.5 Displaying and modifying basic settings on touchscreen.......................................................................... 29