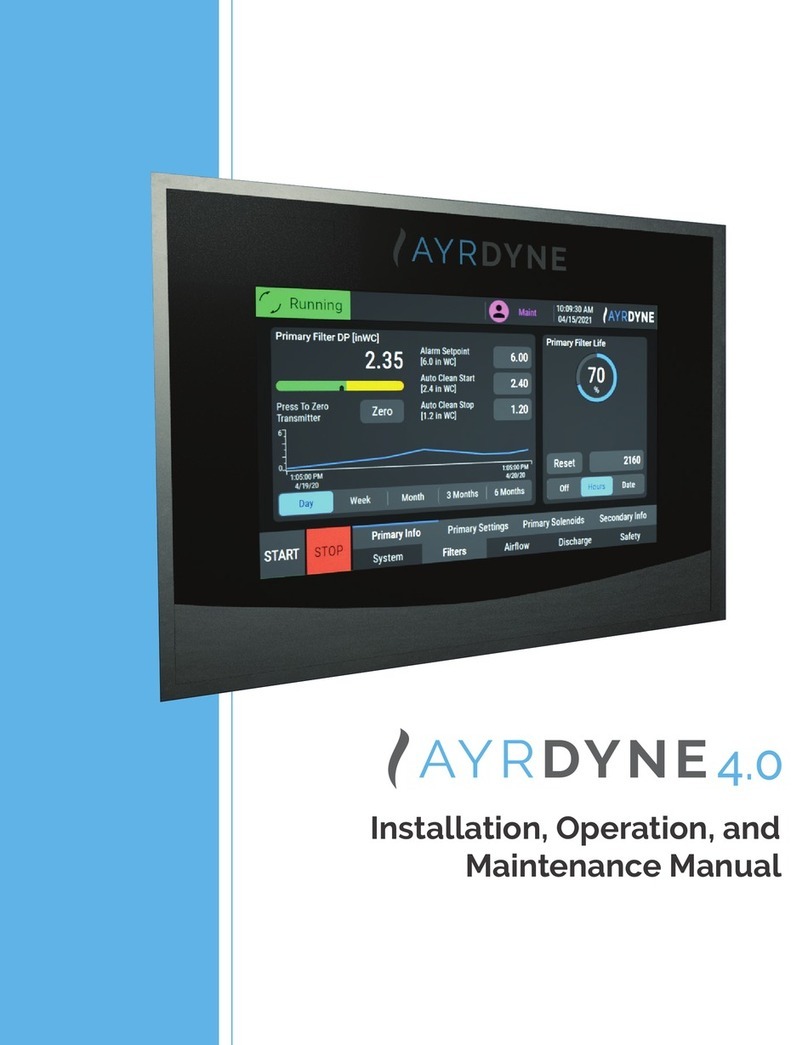

Dentech AYRDYNE User manual

www.ayrdyne.com

Installation, Operation, and

Maintenance Manual

www.ayrdyne.com

2

www.ayrdyne.com

3.1.2 Navigation Bar

3.1.3 Home

3.2 Filters

3.2.1 Primary Filter

3.2.2 Hand Clean

3.2.3 Secondary Filter

3.3Airow

3.3.1 Airow Settings

3.3.2 VFD Settings

3.4 Discharge

3.4.1 Rotary Valves

3.4.2 Double Dump

3.5 Safety

3.5.1 Safety Relay

3.5.2 Isolation Valve

3.6 System

3.6.1 Alarms

3.6.2 Settings

3.6.3 I/O

3.6.4 Metrics

3.6.5 Service Reminders

4 - Troubleshooting

4.1 Alarms

Glossary

. . . . . . . . . . . . . .17

. . . . . . . . . . . . . . . . . . . . . . . 18

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . 20

. . . . . . . . . . . . . . . . 22

. . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . 24

. . . . . . . . . . . . . . .26

. . . . . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . .32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

. . . . . . . . . . . . . . . . . . . . . .33

. . . . . . . . . . . . . . . . . . . . .34

. . . . . . . . . . . . . . . . . . . . . . . . . .35

. . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . .38

. . . . . . . . . . . . . . . . . . . . . . . . . . . .40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Introduction

1-Overview

1.1 Safety

2 - Installation and Removal

2.1 Removal of HMI

2.2 Installation of HMI

2.3 Removal of PLC

2.3.1 Installing and Removing

the CPU from DIN rail

2.3.2 Installing and Removing

an SB, CB, or BB

2.3.3 Installing or Replacing

the battery in the BB 1297

battery board

2.3.4 Installing and Removing

an SM

2.3.5 Installing and Removing

a CM or CP

2.3.6 Removing and Reinstalling

the S7-1200 terminal

block connector

3 - Operation

3.1ScreenOverview

3.1.1 Status Bar

TABLE OF CONTENTS

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . .7

. . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . .10

. . . . . .10

. . . . . . . . . . . .11

. . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . .15

3 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . .17

www.ayrdyne.com

INTRODUCTION

OVERVIEW

4

The purpose of this document is to outline proper

installation, maintenance, operation, and care

of the AyrDyne® Monitoring System Human

Machine Interface (HMI). This document is in

no way intended to be used to determine the

reliability of this product outside of its originally

intended application. It is the duty of the end user

or integrator to perform the appropriate risk

analysis in order to determine the relevance of its

use within any specic application.

All pertinent state, regional, and local safety

regulations must be observed when installing and

using this product. For reasons of safety and to

help ensure compliance with documented system

data, only the manufacturer should perform

repairs to components.

Failure to follow the guidelines outlined in this

manual may result in injury, harm, or improper

operating results. Failure to observe this

information may also result in equipment damage,

premature wear, or failure.

www.ayrdyne.com

SAFETY

SAFETY

OVERVIEW

5

The installation, maintenance, operation, and care of the

AyrDyne® Monitoring System Human Machine Interface

(HMI) should only be performed by individuals who are

qualied and trained to do so. A “qualied” person in this

context is a person who has skills and knowledge related

to the construction and operation of electrical equipment

and its installation through both work experience and

training. Additionally, a qualied person is one who

has received and undergone safety training specic to

electrical maintenance. Anyone who has not undergone

safety training specic to this system should not operate or

perform maintenance on the system.

In terms of maintenance of this system, “lock out tag

out” safety protocol applies. This means that any time

maintenance on this system is performed, the machine

must be shut down, unplugged and tagged or labeled,

explaining that maintenance is taking place.

DenTech is not liable for any consequences

arising from misuse of this system. If you are

unsure of whether you are qualied to use or maintain this

system, please contact an electrician or other qualied

professional for assistance. Failure to follow safety

protocol for this and any other system could result in

serious bodily harm or other injury. No responsibility is

assumed by DenTech for any consequences arising out of

the use of this material.

This symbol indicates that an electrical

hazardexistswhichcouldresultinpersonal

injuryiftheinstructionsarenotfollowed.

This safety alert symbol is used to alert you

to potential personal injury hazards. Obey all

safetymessagesthatfollowthissymbolto

avoid possible injury or death.

1.1

www.ayrdyne.com

REMOVAL OF HMI

INSTALLATION & REMOVAL

6

Figure 2.3.1a

Figure 2.3.1b

Front view of HMI.

Rear view of HMI.

2.1

MECHANICALLY UNSTABLE TERMINAL

AlwayskeepHMIstableinpanelcut-outwhileyouare

installing or removing installation fasteners.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN INJURY, OR EQUIPMENT DAMAGE.

CAUTION!

ELECTRICAL SHOCK HAZARD EXISTS

-Ensurethatthecontrolenclosurewithinwhichyou

areworkingispowereddownandlockedout.

-Verifythatallpowersourcesareinazeroenergy

state.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN INJURY, DEATH, OR EQUIPMENT DAMAGE.

WARNING!

www.ayrdyne.com

REMOVAL OF HMI

INSTALLATION & REMOVAL

7

Figure 2.3.1c

Figure 2.3.2

Power connection removed from HMI.

Ground wire with T-20 Torx screw.

2.1 REMOVAL OF HMI

Pull green connector downward to remove

power connection from HMI.

Use a T-20 Torx screwdriver to remove the

ground wire.

2.1

1

2

www.ayrdyne.com

REMOVAL

INSTALLATION & REMOVAL

8

Figure 2.3.3

Figure 2.3.4

Loosening HMI fasteners.

Installation fasteners removed.

With the HMI free from all electrical wiring,

begin to loosen the 10 installation fasteners that

secure the HMI to the control enclosure door

using a small at head screwdriver. Make sure to

support the HMI with the other hand.

Continue to loosen fasteners until they can be

removed from the HMI.

2.1

3

4

www.ayrdyne.com

REMOVAL & INSTALLATION

INSTALLATION & REMOVAL

9

Figure 2.3.5a

Figure 2.3.5b

Removal of the HMI from the front of the

enclosure.

HMI completely removed.

Once the installation fasteners have been

removed, gently remove the AyrDyne HMI from

the front of the enclosure door, taking care not

to damage or displace the installation gasket.

2.1

5

2.2 INSTALLATION OF HMI

To install the HMI, follow the steps on pages

six through nine in reverse order.

1

www.ayrdyne.com

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

10

For the removal of the PLC portion of the AyrDyne

Monitoring System, please visit the AyrDyne website

for a link to the Siemens installation manual.

Siemens S7-1200 Manual System Manual, 04/2012,

A5E02486680-06

Pages 50-55

2.3

2.3.1 INSTALLING & REMOVING THE CPU ON A DIN RAIL

TASK PROCEDURE

1. Ensure that the CPU and all S7-1200 equipment are

disconnected from electrical power.

2. Disconnect the I/O connectors, wiring, and cables from the

CPU (Page 55).

3. Remove the CPU and any attached communication modules as

a unit. All signal modules should remain installed.

4. If an SM is connected to the CPU, retract the bus connector:

– Place a screwdriver beside the tab on the top of the signal

module.

– Press down to disengage the connector from the CPU.

– Slide the tab fully to the right.

5. Remove the CPU:

– Pull out the DIN rail clip to release the CPU from the rail.

– Rotate the CPU up and off the rail, and remove the CPU

from the system.

TASK PROCEDURE

1. Install the DIN rail. Secure the rail to the mounting panel every 75 mm.

2. Ensure that the CPU and all S7-1200 equipment are disconnected from electrical

power.

3. Hook the CPU over the top of the DIN rail.

4. Pull out the DIN rail clip on the bottom of the CPU to allow the CPU to t over

the rail.

5. Rotate the CPU down into position on the rail.

6. Push in the clips to latch the CPU to the rail.

// b) REMOVING THE CPU FROM A DIN RAIL

// a) INSTALLING THE CPU ON A DIN RAIL

www.ayrdyne.com

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

11

// a) REMOVING AN SB, CB, or BB

2.3

2.3.2 INSTALLING & REMOVING AN SB, CB or BB

TASK PROCEDURE

1. Ensure that the CPU and all S7-1200 equipment are

disconnected from electrical power.

2. Remove the top and bottom terminal block covers

from the CPU.

3. Place a screwdriver into the slot on top of the CPU at

the rear of the cover.

4. Gently pry the cover up and remove it from the CPU.

5. Place the module straight down into its mounting

position in the top of the CPU.

6. Firmly press the module into position until it snaps

into place.

7. Replace the terminal block covers.

TASK PROCEDURE

1. Ensure that the CPU and all S7-1200 equipment are

disconnected from electrical power.

2. Remove the top and bottom terminal block covers

from the CPU.

3. Place a screwdriver into the slot on top of the module.

4. Gently pry the module up to disengage it from the

CPU.

5. Remove the module straight up from its mounting

position in the top of the CPU.

6. Replace the cover onto the CPU.

7. Replace the terminal block covers.

// a) INSTALLING AN SB, CB, or BB

www.ayrdyne.com

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

12

// a) INSTALLING AN SM

The BB 1297 requires battery type CR1025. The

battery is not included with the BB 1297 and must be

purchased by the user.

TO INSTALL A NEW BATTERY,

FOLLOW THESE STEPS:

TO REPLACE THE BATTERY IN THE BB 1297:

2.3.3 INSTALLING OR REPLACING THE BATTERY IN THE BB 1297 BATTERY BOARD

2.3.4 INSTALLING & REMOVING AN SM

In the BB 1297, install a new battery with the

positive side of the battery on top, and the

negative side next to the printed wiring board.

The BB 1297 is ready to be installed in the CPU.

Follow the installation directions on page 11 to

install the BB 1297.

1

2

Remove the BB 1297 from the CPU following

the removal directions on page 11.

Carefully remove the old battery using a small

screwdriver. Push the battery out from under

the clip.

Install a new CR1025 replacement battery with

the positive side of the battery on top and the

negative side next to the printed wiring board.

Re-install the BB 1297 battery board following

the installation directions on page 11.

1

2

3

4

2.3

TASK PROCEDURE

Install your SM after installing the CPU.

1. Ensure that the CPU and all S7-1200 equipment are disconnected

from electrical power.

2. Remove the cover for the connector from the right side of the CPU.

3. Insert a screwdriver into the slot above the cover.

4. Gently pry the cover out at its top and remove the cover. Retain the

cover for reuse.

Connect the SM to the CPU:

1. Position the SM beside the CPU.

2. Hook the SM over the top of the DIN rail.

3. Pull out the bottom DIN rail clip to allow the SM to t over the rail.

4. Rotate the SM down into position beside the CPU and push the

bottom clip in to latch the SM onto the rail.

Extending the bus connector makes both mechanical and electrical connections for the SM.

1. Place a screwdriver beside the tab on the top of the SM.

2. Slide the tab fully to the left to extend the bus connector into the CPU. Follow the same

procedure to install a signal module to a signal module.

www.ayrdyne.com

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

13

2.3

TASK PROCEDURE

You can remove any SM without removing the CPU or other SMs in place.

1. Ensure that the CPU and all S7-1200 equipment are disconnected from electrical

power.

2. Remove the I/O connectors and wiring from the SM (Page 55).

3. Retract the bus connector.

– Place a screwdriver beside the tab on the top of the SM.

– Press down to disengage the connector from the CPU.

– Slide the tab fully to the right.

If there is another SM to the right, repeat this procedure for that SM.

Remove the SM:

1. Pull out the bottom DIN rail clip to release the SM from the rail.

2. Rotate the SM up and off the rail. Remove the SM from the system.

3. If required, cover the bus connector on the CPU to avoid contamination. Follow

the same procedure to remove a signal module from a signal module.

// b) REMOVING AN SM

www.ayrdyne.com

// b) REMOVING A CM OR CP

// a) INSTALLING A CM OR CP

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

14

Attach any communication modules to the CPU and install the assembly as a unit, as shown in Installing and

Removing the CPU (page 49).

CAUTION!

Do not use a tool to separate the modules because this will

damage the units.

2.3

2.3.5 INSTALLING & REMOVING A CM OR CP

TASK PROCEDURE

1. Ensure that the CPU and all S7-1200 equipment are disconnected

from electrical power.

2. Attach the CM to the CPU before installing the assembly as a unit

to the DIN rail or panel.

3. Remove the bus cover from the left side of the CPU:

– Insert a screwdriver into the slot above the bus cover.

– Gently pry out the cover at its top.

4. Remove the bus cover. Retain the cover for reuse.

5. Connect the CM or CP to the CPU:

– Align the bus connector and the posts of the CM with the

holes of the CPU

– Firmly press the units together until the posts snap into place.

6. Install the CPU and CP on a DIN rail or panel.

TASK PROCEDURE

Remove the CPU and CM as a unit from the DIN rail or panel.

1. Ensure that the CPU and all S7-1200 equipment are disconnected from electrical

power.

2. Remove the I/O connectors and all wiring and cables from the CPU and CMs.

3. For DIN rail mounting, move the lower DIN rail clips on the CPU and CMs to the

extended position.

4. Remove the CPU and CMs from the DIN rail or panel.

5. Grasp the CPU and CMs rmly and pull apart.

www.ayrdyne.com

// a) REMOVING THE CONNECTOR

INSTALLING & REMOVING PLC

INSTALLATION & REMOVAL

15

The CPU, SB, and SM modules provide removable connectors to make connecting the wiring easy.

2.3

2.3.6 REMOVING & REINSTALLING THE S7-1200 TERMINAL BLOCK CONNECTOR

TASK PROCEDURE

Prepare the system for terminal block connector removal by removing the power

from the CPU and opening the cover above the connector.

1. Ensure that the CPU and all S7-1200 equipment are disconnected from electrical

power.

2. Inspect the top of the connector and locate the slot for the tip of the screwdriver.

3. Insert a screwdriver into the slot.

4. Gently pry the top of the connector away from the CPU. The connector will

release with a snap.

5. Grasp the connector and remove it from the CPU.

// b) INSTALLING THE CONNECTOR

TASK PROCEDURE

Prepare the components for terminal block installation by removing power from the

CPU and opening the cover for connector.

1. Ensure that the CPU and all S7-1200 equipment are disconnected from electrical

power.

2. Align the connector with the pins on the unit.

3. Align the wiring edge of the connector inside the rim of the connector base.

4. Press rmly down and rotate the connector until it snaps into place.

Check carefully to ensure that the connector is properly aligned and fully engaged.

www.ayrdyne.com

SCREEN OVERVIEW

OPERATION

16

This section covers the navigation and operation of the standard AyrDyne monitoring system. The operation and

functionality of each screen is covered in detail in later sections. The table below shows the layout of the screens.

Available screens depend on system requirements and conguration.

Home

Discharge

System

Filters

Airow

Safety

Secondary Filter

Primary Filter

Airow Settings

Settings

Metrics

Alarms

Hand Clean

VFD Settings

I/O

Service Reminders

An overview of the system and the rst screen to display when power is applied

Secondary lter differential pressure monitoring

Contains all monitoring, settings, and controls related to the discharge system

Contains system wide monitoring, settings, and controls

Primary lter differential pressure monitoring and

cleaning

Airow monitoring and control settings

System settings

System Metrics

Contains all monitoring, settings, and controls related to the lters

Contains all monitoring, settings, and controls related to airow

Contains all monitoring, settings, and controls related to safety

Monitors and controls alarms

Primary lter cleaning system monitoring and manual

control

VFD monitoring and control settings

Input/Output monitoring and control settings

Service reminder settings

3.1

www.ayrdyne.com

SCREEN OVERVIEW

OPERATION

17

3.1.1 STATUS BAR

3.1.2 NAVIGATION BAR

The status bar, which displays system information, is visible on all screens. This bar displays system information,

active alarm description, and corrective action.

The navigation bar is located at the bottom of each screen and can be used to navigate through the various

systems. The underline indicates the section currently displayed. The circle with the exclamation symbol denotes

when a section is in alarm.

3.1

SYSTEM FAULTS

This text display shows details of any active

faults as well as corrective actions.

LOGO

This graphic display shows the logo of the

company that you may contact for information

on the system, spare, or replacement parts

ordering and help with the system. Pressing the

logo will display the contact information. Once

on the contact information screen, you may

press anywhere on the screen to return to the

home screen.

3

2

AYRDYNE

This button displays the home screen

FILTERS

This button displays the lters screen

AIRFLOW

This button displays the airow screen

1

2

3

DISCHARGE

This button displays the discharge screen

SAFETY

This button displays the safety screen

SYSTEM

This button displays the system screen

4

5

6

SYSTEM STATE INDICATOR

This graphic display shows the current

system state.

1

System is Stopped (Black)

System is Running (Green)

System is Downtime Cleaning

System is Faulted

www.ayrdyne.com

SCREEN OVERVIEW

OPERATION

18

3.1.3 HOME

The home screen serves as the overview for the system. This screen will be the rst screen displayed once the

system is powered up.

1

5 6

8

7

9 10 11

2

3

4

3.1

www.ayrdyne.com

SCREEN OVERVIEW

OPERATION

19

START

This button starts the system.

STOP

This button stops the system on the rst press

and stops the downtime cleaning, if running, on

the second press.

LOG OUT

This button allows the user to log-out.

MUTE ALARMS

This button mutes the alarm horn, if equipped.

New alarms will reactivate the alarm horn.

PRIMARY FILTER CLEANING STATE

This text display shows the current state of the

lter cleaning system.

PRIMARY FILTER DP (inWC)

This numeric display shows the current

differential pressure measured between clean

and dirty sides of the lter(s).

PRIMARY FILTER LIFE

This text and bar graph display shows lter

status and remaining life.

PRIMARY FILTER DP TREND

This trend display shows the historic trend of

the lter DP. This data is lost when the HMI is

powered off.

ELAPSED RUN TIME (Hrs)

This numeric display shows the run time of the

system.

ESTIMATED POWER USAGE (MWh)

This numeric display shows estimated power

usage if equipped with a VFD.

ESTIMATED POWER COST (USD)

This numeric display shows estimated power

usage cost if equipped with a VFD.

1

2

7

3

8

4

9

5

6

10

11

3.1

www.ayrdyne.com

FILTERS

OPERATION

20

3.2.1 PRIMARY FILTER

The Filters section contains screens related to ltering. Screens may vary based on system conguration.

PRIMARY FILTER DP

This numeric display and bar graph show the

lter differential pressure measured between

the dirty and clean sides of the lters.

LIFE

This bar graph shows the remaining life of

the lter.

PRIMARY FILTER STATUS

The lter status shows lter life. When the

lter is nearing end of life, it will remind you

to order or schedule the lter change. Once

the lter has reached end of life, it will prompt

you to change the lter.

CLEAN MODE SELECTION

This multi-selector sets the type of lter

cleaning performed by the system. There

are three types of cleaning: On Demand, On

1

2

ZERO METER

The Zero push button will zero the differential

pressure reading, should it wander from zero

over the lifespan of the differential pressure

sensor. This can only be done when the system

is not running. Additionally, the pneumatic

tubing should be disconnected from the

control panel.

SAVE, LOAD AND RESET

These buttons affect items on the displayed

screen only. The reset button must be held

until all indicators in the button turn blue,

approximately 3 seconds.

Save

Saves the settings for later use.

Load

Loads previously saved settings.

Hold To Reset

Resets settings to factory defaults.

a

b

c

5

6

3

4

3.2

34 6

7

8

9

10

11

12

5

1

2

Other manuals for AYRDYNE

1

Table of contents

Other Dentech Measuring Instrument manuals