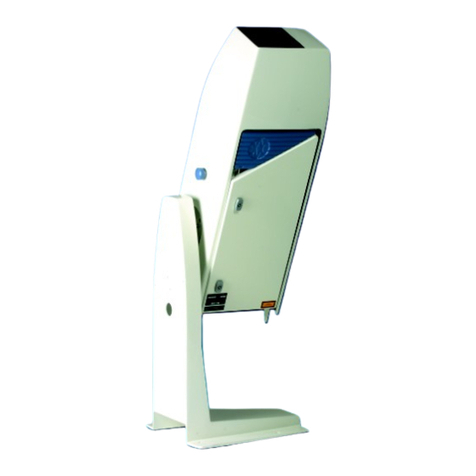

Installation and Maintenance

SPH10 Static Pressure Head

– Eliminates effectively wind

disturbances from pressure

measurements

– Adaptable to many barometers,

directly to Vaisala PTB210

– Durable and easy to clean

INTRODUCTION

Vaisala model SPH10 Pressure Head provides an effective

elimination of pressure variations in the barometer due to the

wind. The SPH10 is easy to clean and maintain. It can be

integrated directly with the Vaisala PTB210 barometer. To other

barometers the SPH10 can be connected with pressure tubing.

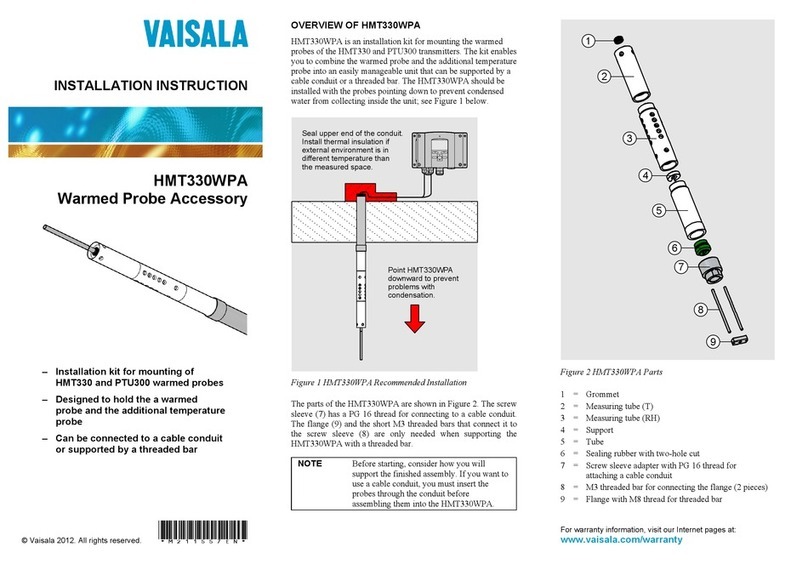

ASSEMBLING

1. Screw the lower bar to the threaded sleeve of the lower

plates (with 6 holes)

2. Screw the upper bar (with mounting plate) to the threaded

sleeve of the upper plates

MOUNTING

Select an open location, prefereably a place higher than the

surroundings, with no buildings or trees nearby. Attach the

SPH10 to a horizontal pole using a mounting plate. A suitable

pole is Vaisala sensor mast, type DKP12. However, any other

horizontal pole with two screws (M6) in a distance of 41 mm can

be used.

NOTE! The recommended distance of the SPH10 from the

vertical pole should be at least 1.5 m.

1. Loosen the two fixing screws of the pole and fix the SPH10

into the pole as indicated in Figure 1.

2. Attach the SPH10 by tightening the screws. (The pressure

Head is removed by loosening the two screws).

CONNECTION TO THE VAISALA PTB210

(see figure 2)

1. Detach the threaded nipple and the gasket (see figure 1).

2. Place the O-ring into the barometer groove.

3. Attach the PTB210 to the SPH10 with two fixing screws.

CONNECTION TO THE OTHER BAROMETERS

Connect the barometer to the threaded nipple (figure 1) by using

a plastic tube with an inner diameter of 4 mm.

Figure 1. SPH10 Static Pressure Head.

Figure 2. PTB210 barometer connection.

Pole

Upper bar

Fixing screws

Upper plate

Lower plate

Threaded sleeve

Lower bar

Upper bar

Threaded nipple and the gasket (R1/4

parallel thread)

PTB210

Barometer

Fixing screw with a

washer (included in

the PTB210)

O-ring (included in

the PTB210)

Mounting plate