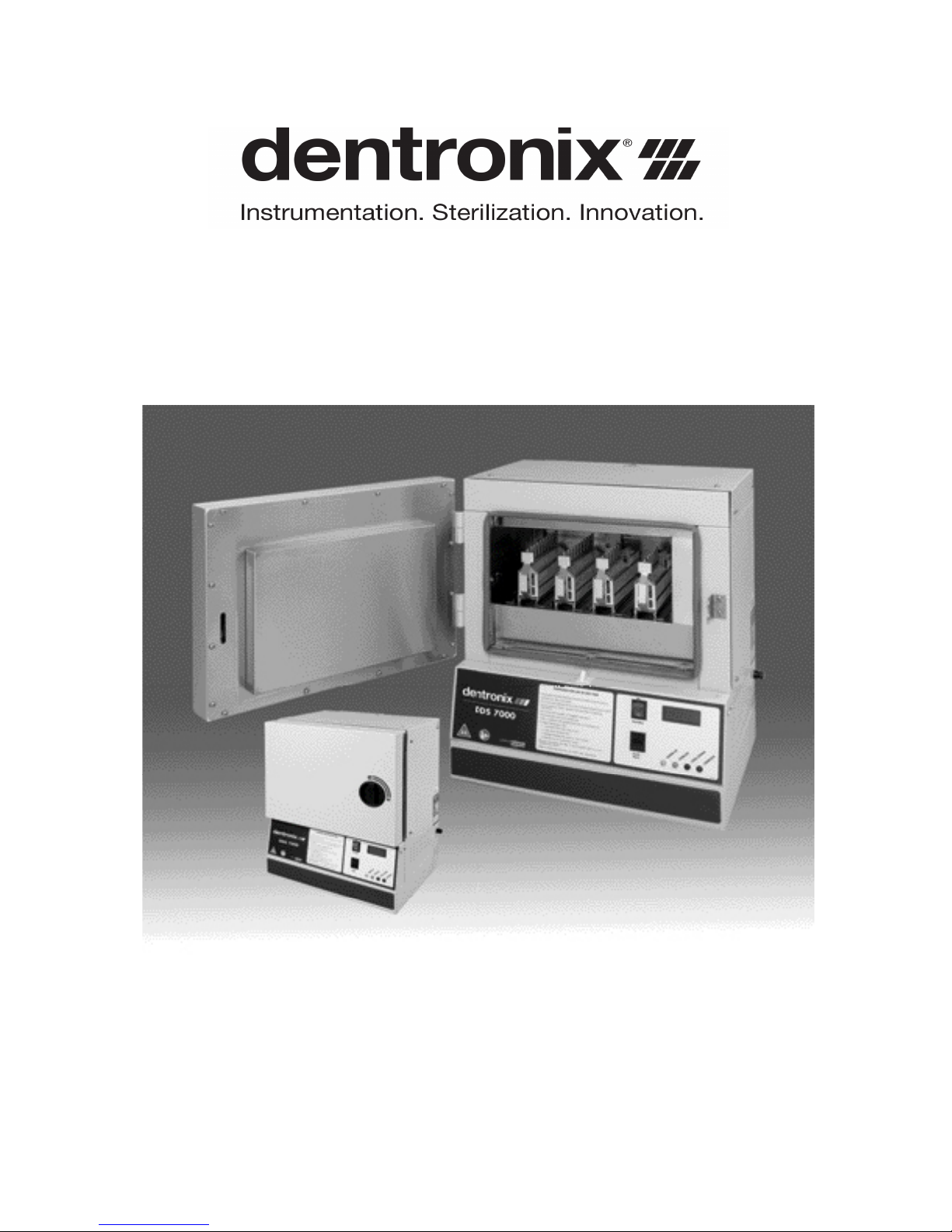

dentronix DDS 7000 User manual

DDS 7000

Dry Heat Sterilization System (115V/230V)

Operating Instructions

2

3

TABLE OF CONTENTS

INTRODUCTION 4

GENERAL AND TECHNICAL SPECIFICATIONS 5

DDS 7000 UNIT OVERVIEW 6

UNPACKING YOUR DDS 7000 7

SERIAL NUMBER LABELS 7

SELECTING YOUR STERILIZATION AREA 8

VENTING 9

CONNECTING TO A POWER SOURCE 10

STERILIZER CONTROLS 10

INDICATOR LED LIGHTS 11

DIGITAL TEMPERATURE DISPLAY 11

DOOR LATCH 11

SAFETY DOOR INTERLOCK 12

FIRST TIME USE CYCLE TEST 12

STERILIZING YOUR INSTRUMENTS 12

INSTRUMENT HANDLING 13

PLIER RACKS 14

LOADING YOUR DDS 7000 PLIER RACKS 14

LOADING THE STERILIZATION CHAMBER 16

OPERATION 17

SPECIAL NOTE ON MOUTH MIRRORS 19

ABORTING A CYCLE 20

RESETTING THE TEMPERATURE OVERLOAD SENSOR 20

BIOLOGICAL TESTING IN YOUR STERILIZER 21

MAINTENANCE AND CLEANING 22

SELECTING USER OPTIONS 24

USING THE COM PORT 26

WARRANTY / RETURN POLICY 28

STERILIZER RETURN PROCEDURE 28

APPENDIX I (SYMBOL EXPLANATION). 29

APPENDIX II (ERROR CODES) 30

4

INTRODUCTION

Thank you for your purchase of the DDS 7000 Dry Heat Sterilization System. We appreciate your

commitment to safe sterilization and eective patient care. The DDS 7000 Dry Heat Sterilizer is a

convection type unit, designed for the sterilization of un-bagged orthodontic instruments that can

withstand temperatures of up to 420ºF(215ºC). The DDS 7000 System is programmed to rap-

idly increase load temperature to 374ºF (190ºC), maintain this temperature for an eective and

complete kill in three (3) minutes and then quickly cool the load for immediate handling. Optimum

results are achieved with the Dry Heat method by uniform load distribution. Your DDS 7000 is

equipped with a unique rack system for sterilizing hinged instruments. This design guarantees equal

spacing of instruments and racks in the sterilization chamber and greatly simplies loading, han-

dling, and dispensing of all instrumentation. Since no moisture, pressure, or chemicals are used in the

DDS 7000 sterilization cycle, your valuable instruments are protected from rust, corrosion, and dulling

of cutting edges. The design includes a safety interlock switch on the door to prevent access to the

chamber until the load has been properly cooled. Dentronix is condent that you will nd this sys-

tem easy to integrate into your oce procedures, as well as simple to use by all sta members. The

following operating instructions have been written to familiarize you with the principles of Dry Heat

Sterilization and the specic operating procedures for the DDS 7000. It is imperative that you read

these operating procedures carefully before operating your unit.

NOTE: The DDS 7000 Sterilizer has been manufactured for specic and safe operating procedures

as contained in this manual.

CAUTION!

Never use the DDS 7000 for other uses. i.e. sterilization of bagged instruments or

use of cassettes, as a warming chamber or heating device, for the preparation of

food or other items. If you are unsure of your unit’s correct usage, please contact

your sales representative or the Dentronix Customer Service Hotline.

Questions? Please call the Dentronix Sterilizer Repair Hotline – 800-523-5944 (ext.

8925) in U.S. and Canada or 330-916-8925 or e-mail tech@dentronix.com or fax 330-

645-8758 so that we can help you maximize the full capabilities of the DDS 7000 System.

Please record your Serial Number here for more ecient customer service:

5

Outside Dimension

(w x d x h)

18¾” x 20”x 22 ¾”

(47.6 cm x 50.8 cm x 57.8 cm)

Same

Inside Chamber

(w x d x h)

12 ½” x 9”x 6 ½”

(31.8 cm x 22.9 cm x 16.5 cm)

Same

Net Weight 96 lbs (43.64 Kg) Same

Total Cycle Time

(Load sensitive)

Less than 40 minutes Same

Power Connection 115 Volt 15 Amps

grounded outlet

230 Volt 10 Amps

grounded outlet

Typical Power Consumption 1400 watts / 12.1 Amps 1700 watts / 7.3 Amps

Fuse 1 required @ 15 Amps 2 required @ 10 Amps

Load Capacity 4 full plier or combo racks, or 8 full

mini racks, or two full racks and

the half tray or a full tray. Refer to

section “Loading Your DDS 7000

Plier Racks”on pages 14 & 15

Same

Sterilization Temperature 374°F +/- 9°F

(190°C +/- 5°C)

Same

Controls & Displays Standby/On switch Same

Cycle Start switch Same

Lighted indicators for Warm-up,

Sterilize, Cool Down, and Cycle

Complete

Same

LED Digital Indicator displays

temperature, user options, and

error codes

Same

Audible tone on Cycle Complete Same

Rack Size Large 1 ½” x 8”x 4”

(3.8 cm x 20.3 cm x 10.2 cm)

Same

Mini Rack Size 1 ½” x 4 5/8”x 4”

(3.8 cm x 11.7 cm x 10.2 cm)

Same

Horizontal Tray Size

(optional)

12 ½” x 7 ¼”

(31.8 cm x 18.4 cm)

Same

Half Tray Size 6 ¼” x 7 ¼”

(15.9 cm x 18.4 cm)

Same

Combo Rack Size 1 ½” x 8”x 4¼”

(3.8 cm x 20.3 cm x 10.7 cm)

Same

Printer/PC Port Com port IOIOI Same

Door Safety Lock Door will not open until

sterilizer temperature is at a

safe level.

Same

GENERAL AND TECHNICAL SPECIFICATIONS

Description 115V 230V

6

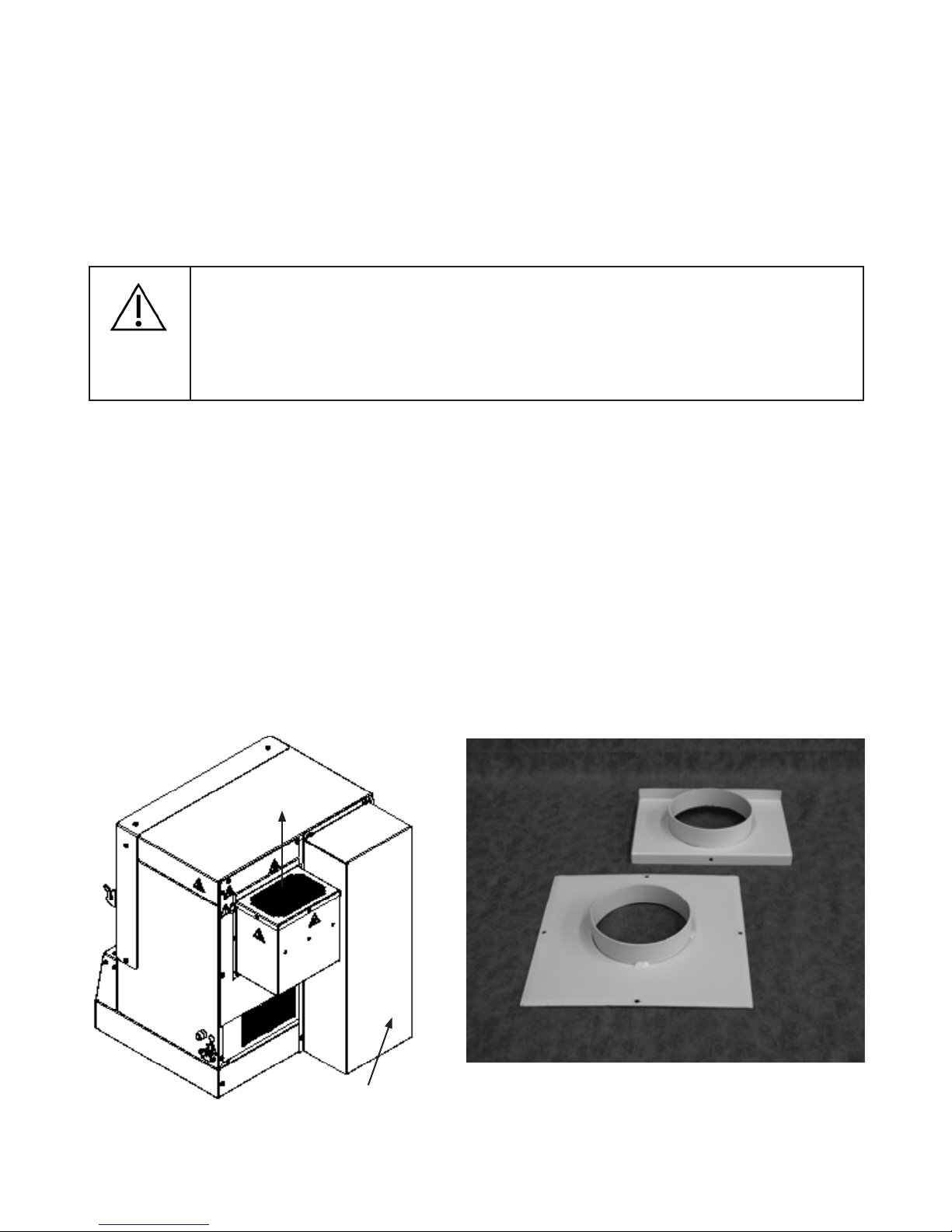

DDS 7000 UNIT OVERVIEW

Figure 1: Outside view of the DDS 7000

Louvers

Door Switch

COM

Port

Rack

Channels

Standby/On

Door Lock

Digital

Display

Cycle

Start Switch

Cycle

Indicator

Lights

Magnetic HEPA Filter Cover

1. 2. 3. 4.

7

DDS 7000 UNIT OVERVIEW

UNPACKING YOUR DDS 7000

Your DDS 7000 Dry Heat Sterilization System is delivered in two or more packages:

1. One large carton containing the DDS 7000 Dry Heat Sterilizer, Operating Instructions

and Accessory Kit.

2. One or more small cartons containing other accessories that may have been purchased.

WARNING!

This is a heavy piece of equipment. Please follow safe handling methods.

Examine each carton for any external damage. Be sure to check the corners of the box.

Immediately upon receipt open the large box, remove the protective packaging inserts and the sterilizer

from the carton. Carefully inspect the DDS 7000 for any damage.

Damage should be reported immediately to the transport carrier that delivered your unit as well as to the

Dentronix Sterilizer Repair Department 800-523-5944 (ext. 8925) or 330-916-8925 or e-mail tech@dentronix.

com or fax 330-645-8758.

CAUTION!

Read the Operating Instructions completely before operating the sterilizer

.

Set-up your DDS 7000 Sterilizer in a dry location according to the directions in the Operating

Instructions. Run your unit through a complete cycle with an empty chamber.

WARNING!

This is a heavy piece of equipment (96 pounds/43.64 Kg). Please make sure the counter

top will safely support the weight.

NOTE: RETAIN PACKAGING MATERIALS FOR FUTURE SHIPPING. The DDS 7000 should be

serviced by a professional on an annual basis, or when two consecutive spore strip test results

come back positive.

SERIAL NUMBER LABELS

Before proceeding further, check the specication label on the sides of the DDS 7000 to obtain

important information regarding model number, serial number and power requirements. Make

sure that this unit matches the power capabilities in your oce regarding voltage, amperage

and cycles. Record the serial number for future reference. (See Introduction Section, Page 4)

8

SELECTING YOUR STERILIZATION AREA

This is a heavy piece of equipment. Please make sure the counter top will safely support the weight. Locate

your sterilizer in an area that is clean and dry with easy access to patient treatment areas. Utilizing extra

counter space, in close proximity to your cleaning area, will make instrument processing smooth and orga-

nized. When placing your unit on the counter, do not push the exhaust stack against the wall. Leave a minimum

of 1”(2.54 cm) back clearance between the exhaust stack and wall to prevent heat damage to building materi-

als. Leave at least 4”(10.2 cm) side clearance between cabinets and walls to allow unrestricted passage

of cool down intake air. Failure to allow a four-inch side clearance could result in a considerably longer cool

down cycle and may result in an error message. For direct venting, the minimum clearance is 12” (30.5cm)

from top of unit to allow hot exhaust air to exit. The optimum clearance is 36” (91 cm) When building the DDS

7000 into a cabinet system, maintain a minimum of 4” (10.2 cm) clearance around the entire unit and use vent

adaptors DAD-UL or DAD-BL.

Exhaust stack of DDS 7000 - It is important to leave 4-inches around the sides of the unit and

12-inches above the top of the unit to maintain proper airow during the cool down cycle.

Exhaust Stack

Figure 2

8

9

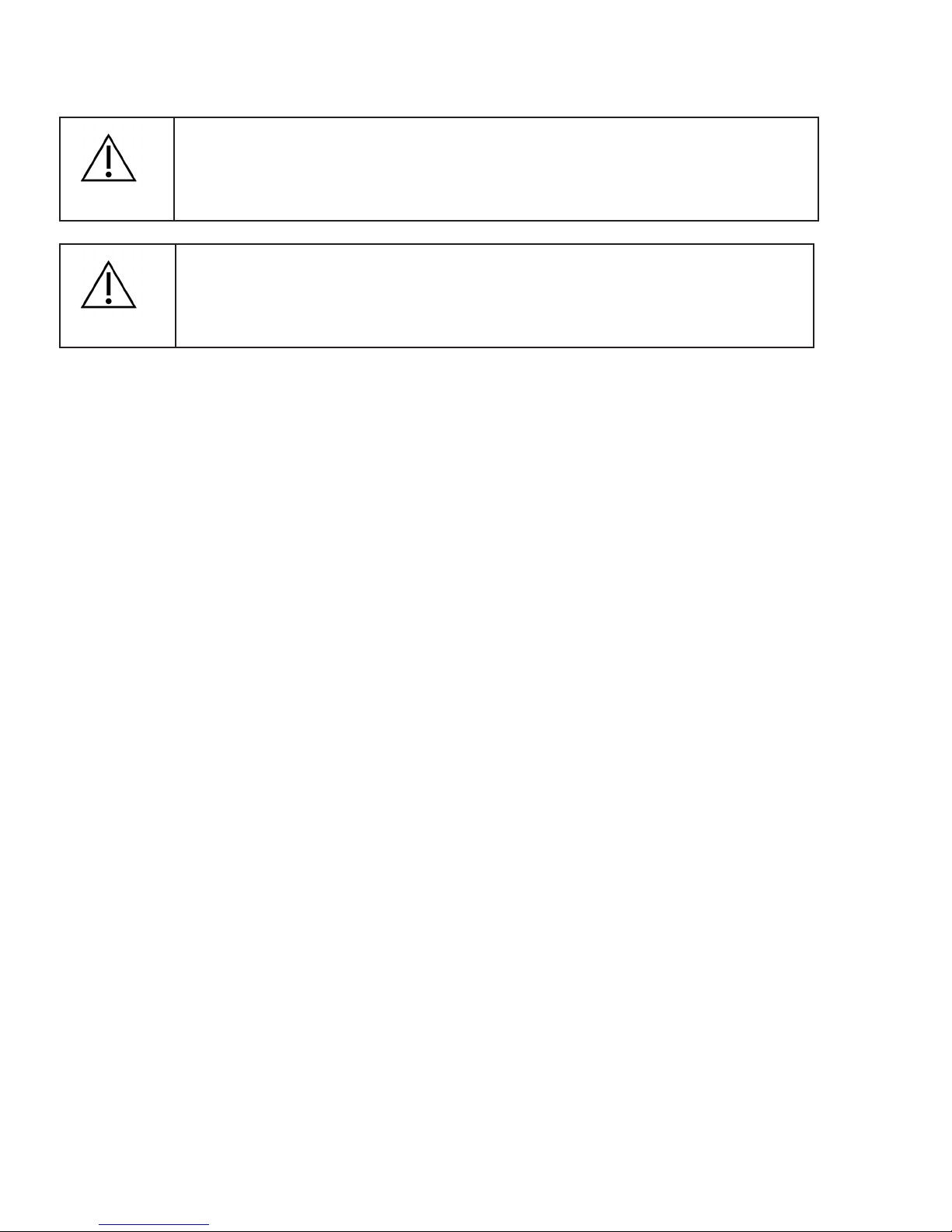

VENTING

Standard mounting of the exhaust stack positions the opening of the stack pointing up (see Figure

3), or to the left when facing the back of the unit. CAUTION: Never point the stack opening down

towards the fan (unless a DAD-UL vent adapter is used with a exible metal duct). To mount the

exhaust stack remove the three screws corresponding to the exhaust stack mounting holes in the back

of the sterilizer surrounding the exhaust opening (the opening with the exposed louvers). Place the

stack in position and secure with screws.

CAUTION

CAUTION: Do not remove cooling duct for any reason (See Figure 3)

Venting is recommended under the following conditions:

a) Installation of the DDS 7000 in a small room less than 12’ x 12’

(3.66m x 3.66m).

b) Installation of the DDS 7000 under cabinets or built into cabinets.

Two styles of vent adapters are available: (See Figure 4 Below)

Type DAD-UL – attaches to the exhaust stack allowing additional venting options – converts 5” x 7”

(12.7cm x 17.8cm) rectangular exhaust port to a 4” (10.2cm) diameter round ange.

Type DAD-BL – replaces the exhaust stack allowing vent connection directly to back of unit.

Both adapters utilize a 4” (10.2cm) diameter round duct. Metal or foil ducting material must be used. Vent

adapters can be used on vent runs of up to 6-8 ft (1.8m-2.4m). If your vent pipe is longer, sucient

back pressure will be created in the airow path reducing your unit’s cooling eciency, resulting in extended

cycle times and possible E-19 error codes.

Figure 4

Figure 3

Exhaust Air

Cooling Duct

DAD-BL

DAD-UL

10

CONNECTING TO A POWER SOURCE

Connect the DDS 7000 to a grounded power source in compliance with the specication label on the

side of the unit.

115V: Sterilizers used in the U.S. and Canada require a 15-amp, 115-volt grounded receptacle and operate at

50/60 Hz. A dedicated circuit is recommended. Other high-powered equipment (such as lathes, trimmers, X-ray

equipment) should not be placed on the same circuit.

CAUTION!

Do not install more than one DDS 7000 Sterilizer in a single circuit.

230V: Sterilizers require a 10-amp minimum 230V receptacle and operate at 50/60 Hz.

STERILIZER CONTROLS

The DDS 7000 is an automatic sterilizing system. Sterilization time and temperature have been pre-set

at the factory providing for optimum performance.

1) Standby/On switch – push the top of the switch to the “ON” position to activate all electrical

control circuits. Push the bottom of the switch to deactivate all electrical control circuits. If the switch

is switched to the Standby position during warm-up, sterilization or cool down cycles, an error code

will be displayed. This switch does not actually break incoming power. That can only be accomplished

by unplugging the device.

2) Cycle Start switch – depress the top of this switch in order to initiate the sterilization cycle.

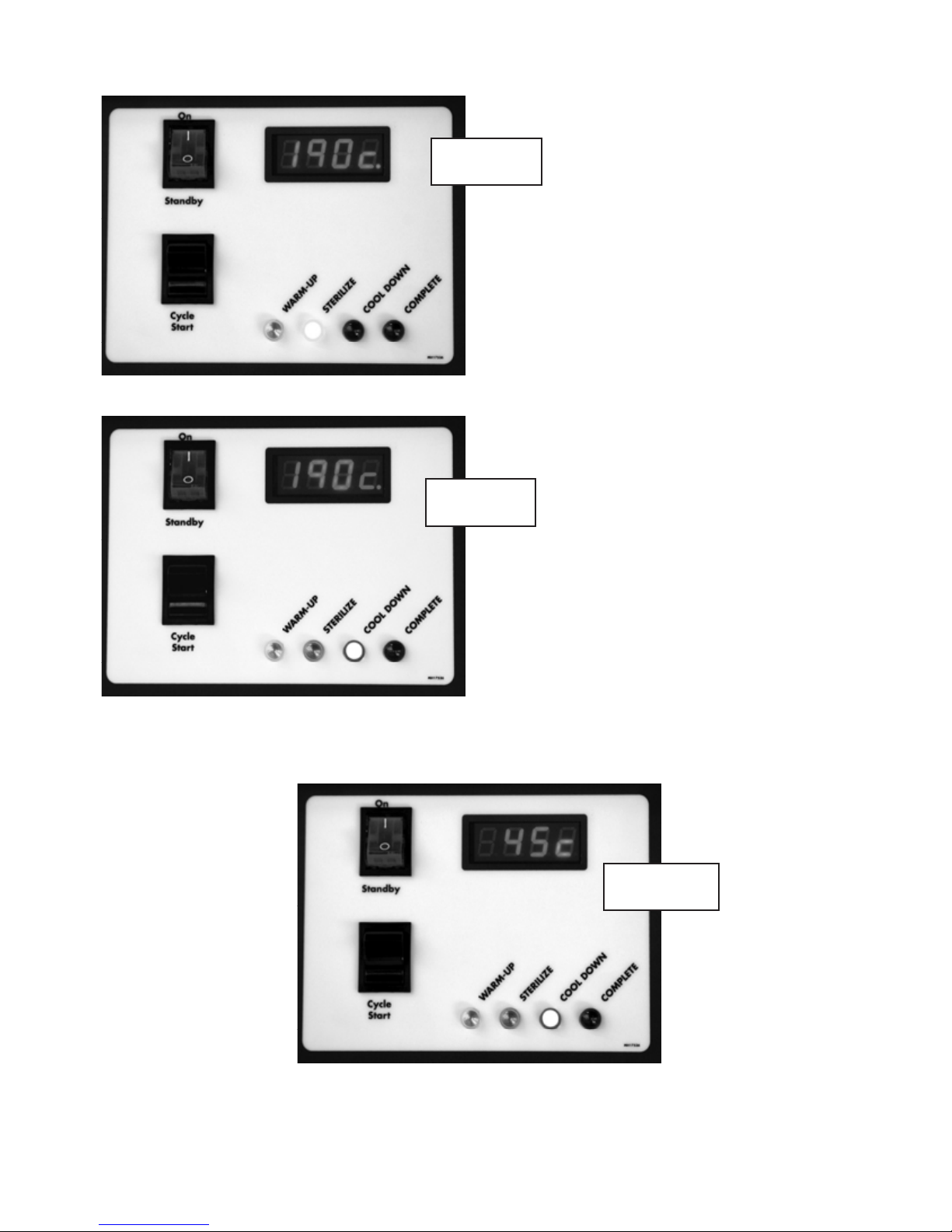

Figure 5: Control Panel for DDS 7000.

11

INDICATOR LED LIGHTS

The control panel of your DDS 7000 is equipped with four (4) indicator lamps to monitor progress of

the sterilization cycle.

1) Warm-up – this Yellow LED will illuminate after pressing the“Cycle

Start”switch. It indicates heating element activation to raise instrument

load to sterilizing temperature of 374°F (190°C). The warm up time is load

sensitive and will vary based on the load density.

2) Sterilize – this Amber/Orange LED indicates that the temperature controller

has sensed a load temperature of 374°F (190°C) and has started the 3-minute

sterilizing phase. During this phase, the heating element will cycle on and

o to maintain an even temperature in the chamber. This LED

will turn o at the beginning of the Cool Down phase.

3) Cool Down – this Blue LED will illuminate during the Cool Down phase.

In this phase, cool air is drawn into the unit through a HEPA

lter. The LED will stay lit until instruments reach a safe handling temperature.

4) Cycle Complete – this Green LED will illuminate at the completion

of the cool down phase and indicates that instruments are sterilized

and ready to unload. It is also your indication that the DDS 7000

has completed the sterilization process. An audible tone will

signal the completion of the cycle. The door must be opened, to turn

this LED o and to allow unit to begin a new cycle.

WARNING!

DO NOT UNLOAD INSTRUMENTS UNLESS THE “CYCLE COMPLETE” LIGHT IS ON.

NOTE: The indicator LIGHTS will ash when a problem is detected during a cycle.

Refer to APPENDIX II for error code explanations.

DIGITAL TEMPERATURE DISPLAY

An LED display on the right-hand side of the control panel monitors sterilizing chamber/load

temperature in degrees Fahrenheit or Celsius. This display is activated when the “Standby/

On” switch is in the “On” position. User options and error codes will also display in this area.

DOOR LATCH

Turning the handle clockwise unlocks the door and allows it to swing open. To close, push the

door gently against the rubber door gasket and turn the knob counter – clockwise to engage

the cam lock, which pulls the door against the gasket, sealing the chamber.

12

SAFETY DOOR INTERLOCK

Your DDS 7000 is equipped with a cut-o switch beneath the door. (see Page 6) This switch

prevents the sterilization cycle from starting whenever the door is not properly closed. This switch also

interrupts the cycle if the door is opened during any cycle.

WARNING!

DISABLING THE DOOR LOCK AND OPENING THE DOOR AT ANY TIME DURING THE CYCLE PRI-

OR TO “CYCLE COMPLETE” MAY EXPOSE OPERATOR TO DANGEROUSLY HOT INSTRUMENTS.

DO NOT ATTEMPT TO REMOVE THESE INSTRUMENTS WITHOUT SUFFICIENT PROTECTION.

The DDS 7000 has an additional safety door lock mechanism, which prevents the door from open-

ing until the chamber temperature is at a “safe handling temperature”. In the event of an emergency,

requiring access to the chamber during any cycle, press and hold down the “cycle start” switch for 5

seconds. The door safety lock mechanism will unlock temporarily for a few seconds allowing access.

NOTE WARNING ABOVE: An Error Code will display notifying the operator of an interruption. Toggling

the “Standby/On” switch from “On” to “Standby” then back to “On” will clear the error message. To

restart the cycle, press “Cycle Start”. The DDS 7000 will rst cool down and then restart the complete

cycle from the beginning.

FIRST TIME USE CYCLE TEST

After the sterilizer is connected to a properly rated and grounded outlet (see page 10) follow the opera-

tion procedures found on pages 17-19 with an EMPTY CHAMBER.

Make sure that air is blowing out of the exhaust stack during the cool down phase.

WARNING!

The dry air may be hot 265˚F (129˚C).

STERILIZING YOUR INSTRUMENTS

What CAN be sterilized in the DDS 7000?

All metal instruments can be safely processed – stainless steel, aluminum, chrome and nickel-plated,

silver-brazed components and some high temperature plastics.

What CANNOT be sterilized in the DDS 7000?

Bagged instruments, cassettes, vinyl, rubber and plastic items, paper products, soldered components

(such as some impression trays, boley gauges, some band pushers), petroleum-based lubricants, and

any materials not capable of withstanding 420°F (215°C).

12

13

CAUTION!

ITEMS THAT ARE LABELED “AUTOCLAVABLE” ARE NOT NECESSARILY DRY HEAT STERILIZ-

ABLE. IF IN DOUBT ABOUT SPECIFIC PRODUCTS, CONTACT THE MANUFACTURER.

CAUTION!

REMOVE ALL VINYL GRIPS FROM PLIERS BEFORE STERILIZING.

14

INSTRUMENT HANDLING

The most important guideline in any sterilization procedure is:

STERILIZE ONLY CLEAN INSTRUMENTS!

Pre-cleaning is essential with any sterilization process because the elevated temperatures of the sterilization cycle will

bake on any residual materials or debris. The most eective and thorough method of cleaning is to use an Ultrason-

ic Cleaning Unit (such as the Dentronix DDUS60 Ultrasonic Cleaner). Non-Ionic multi-purpose cleaning concentrates,

which include a rust inhibitor and require no rinsing (such as Dentronix MP-US Plus), are highly eective for the process-

ing of orthodontic pliers. Ultrasonic cleaning will remove dirt, debris and old lubricants, which could cause discoloration

and stiening of joints. Weekly lubrication of the plier joint with a pure silicone product (such as Dentronix DSL-16 or

DSY-20) will maintain smooth joint travel.

WARNING!

If instruments are dropped, sprayed, or mishandled after sterilization, the instruments must

be pre-cleaned as recommended above. Never return the items to the sterilizer without rst

cleaning them.

WARNING!

DO NOT USE ANY OF THE FOLLOWING:

• DO NOT USE IODOPHORS TO CLEAN PLIERS PRIOR TO STERILIZATION

• DO NOT USE ALCOHOL TO CLEAN PLIERS OR TO DISPLACE MOISTURE PRIOR TO STERIL-

IZATION

• DO NOT USE ANY CLEANER WHICH LEAVES A RESIDUE. THIS MAY RESULT IN SMOKING

OR UNDESIRED FUMES DURING THE STERILIZATION CYCLE.

• DO NOT USE PLAIN SOAP AND WATER TO CLEAN PLIERS PRIOR TO STERILIZATION.

• DO NOT DIP PLIERS IN ANY FLAMMABLE LIQUID PRIOR TO LOADING IN STERILIZER.

• DO NOT LUBRICATE PLIERS OR INSTRUMENTS WITH PETROLEUM-BASED LUBRICANTS.

• DO NOT USE WITH CASSETTES OR INSTRUMENT BAGS

• DO NOT LOAD INSTRUMENTS ON THE BOTTOM OF THE CHAMBER OR BETWEEN THE

PLIER RACKS. FOR INSTRUMENTS THAT DO NOT FIT THE RACKS AS SHOWN, USE HORI-

ZONTAL TRAY CAT. NO. D5000S-T OR HALF TRAY CAT. NO. D5000S-HT.

• DO NOT PLACE ANY ITEMS BELOW THE TRAY OR SHELF UNITS TO BE STERILIZED.

• DO NOT PLACE ANY INSTRUMENTS INSIDE THE PLIER RACKS.

15

PLIER RACKS

The four anodized plier racks that are supplied with your DDS 7000 are manufactured from aluminum for optimum heat

transfer and to reduce weight. Also available are:

A) Mini Rack holds 4 pliers

B) Combo Rack holds 5 pliers plus 5 Mathieu Hemostats or other hand instruments.

C) Long Handle Combination Rack holds 2 Long Handle Pliers,

3 Regular Pliers, 5 Mathieu Hemostats or other hand instruments.

D) The plier racks supplied oer convenient transport to chairside.

WARNING!

The DDS 7000 has been tested and approved for use with Dentronix racks. Do not

use cassettes or other delivery systems as they may cause overheating or failure to

sterilize.

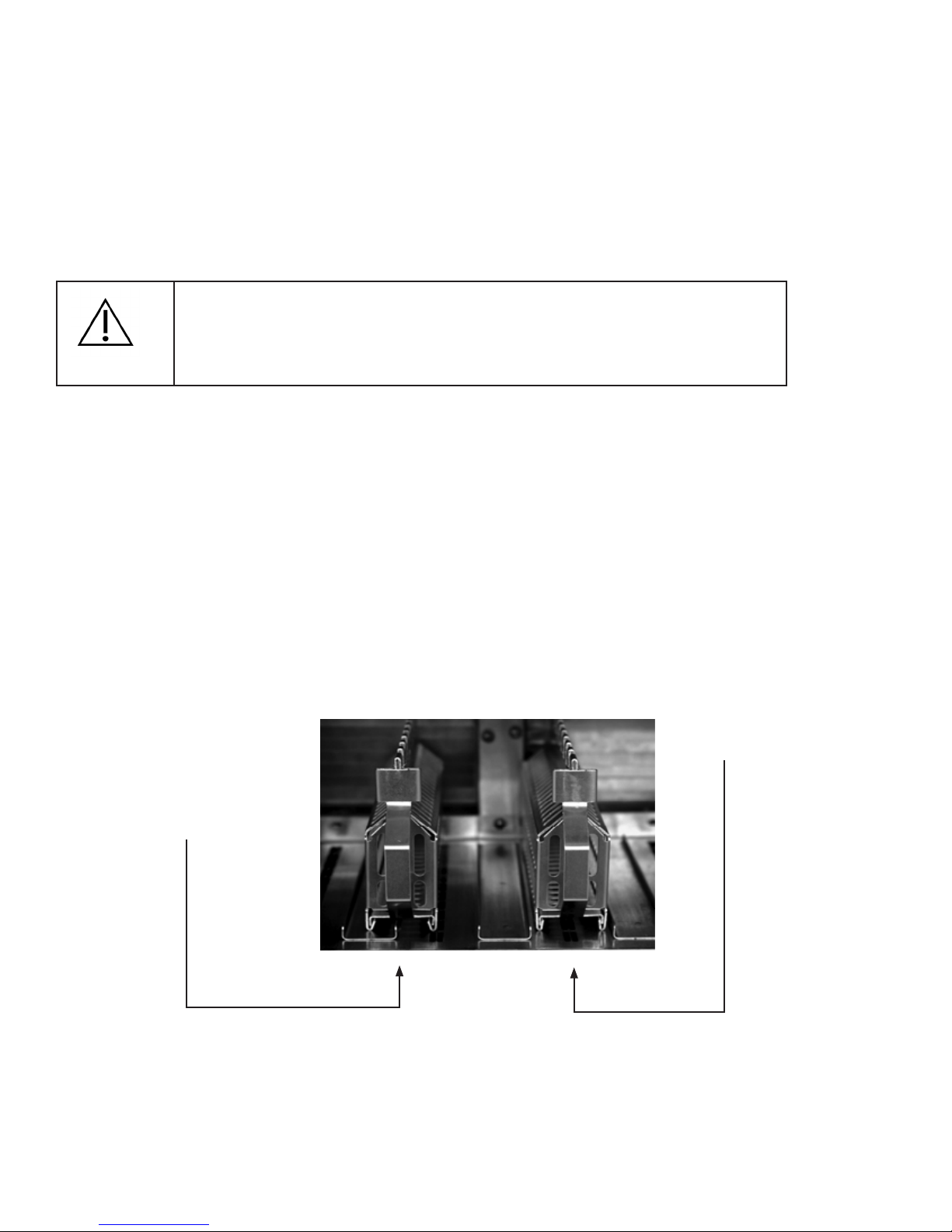

LOADING YOUR DDS 7000 PLIER RACKS

The eectiveness of Dry Heat is dependent on exposure of the instrument load to the convective properties of the

heated airow in the sterilization chamber. The DDS 7000 rack system was designed to provide a predictable location

and spacing for the instrument load so that optimum exposure can be achieved. Pliers should only be loaded in the

notches of the rack (see Figure 6). Never place instruments inside of plier racks. Doing so may impede air ow resulting in an

error code or failure to sterilize.

In addition to the plier racks, Dentronix also oers a Horizontal Tray (Part No. D5000S-T) and a Half Horizontal Tray (Part

No. D5000S-HT). These trays can be used for instruments that do not t onto the racks. These trays were specially de-

signed for use in a Dry Heat Sterilizer. The half tray allows the user to sterilize single-handled instruments along with two

full racks of pliers. Use of trays other than the D5000S-T and D5000S-HT will impede the airow around the instruments

and will result in failure to sterilize the instruments.

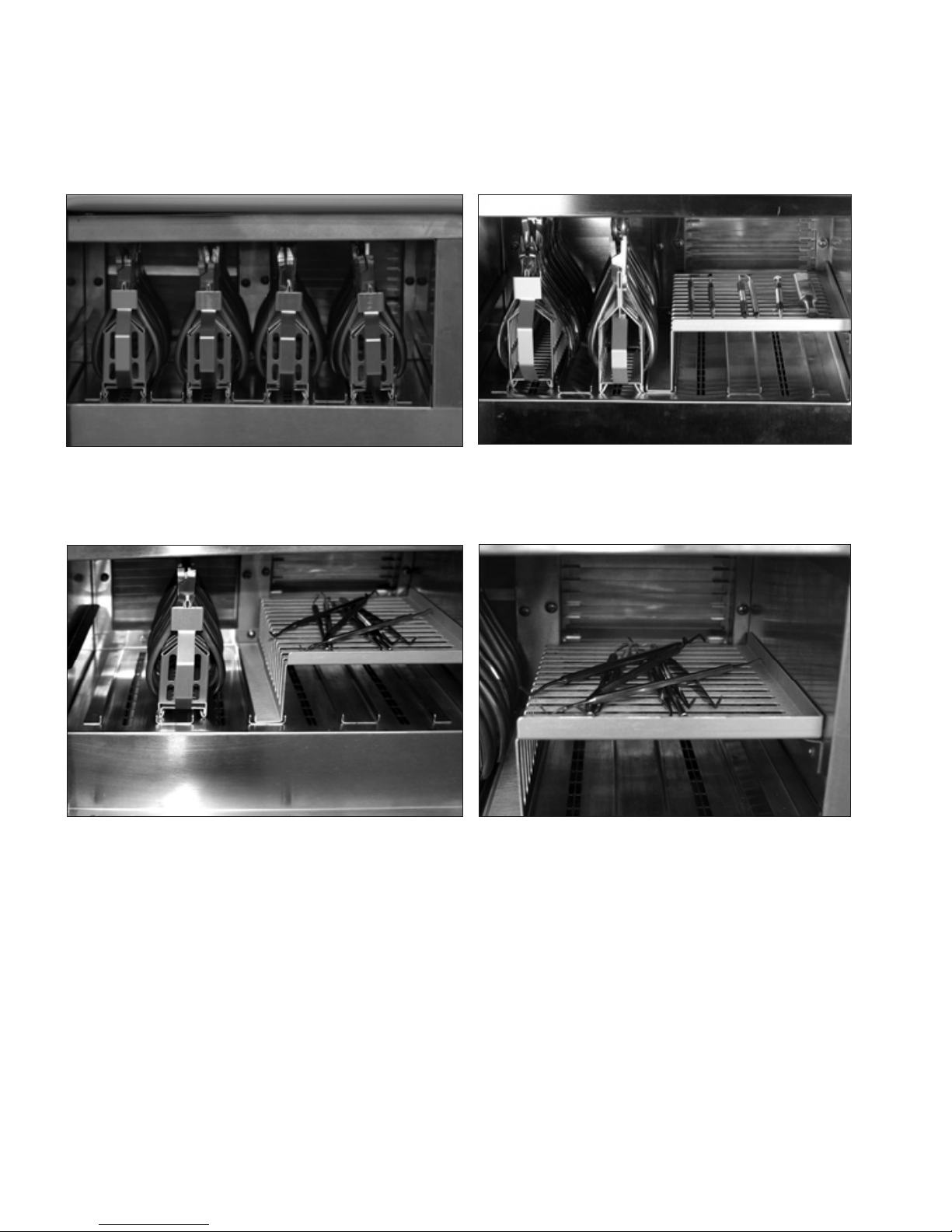

Figure 6

Correct and Incorrect placement of racks in DDS 7000. Note: The incorrectly placed rack is not over the air vents of the

rack channel, whereas the correctly placed rack is.

WRONG

Incorrect

Rack

Placement

Correct Rack

Placement

16

Table 1 describes the maximum loading for each possible combination of racks and/or trays. It is important for

good sterilization practices not to add more instruments than outlined above. Doing so may impede the ow of

air around some of the pliers and may cause overheating or a failure to sterilize all the instruments. Sterility is not

guaranteed when the chamber is improperly loaded. When loading a rack to less than full capacity, distribute the

load evenly over the full length of the rack (below).

Figure 7: Rack Loading

CAUTION!

Never load instruments on the bottom of the chamber or between the plier racks. For instruments

that do not t the racks as shown, use Horizontal Tray Cat. No. D5000S-T or HalfTray Cat. No. D5000S-

HT. Never place any items below the Tray units to be sterilized. Never Use Cassettes in the DDS 7000.

Loading Scenario Maximum Loadings

Racks Only Four (4) Plier Racks capable of holding nine (9) orthodontic pliers

each for a total of thirty-six (36) pliers or two (2) plier racks holding

nine (9) orthodontic pliers each for a total of eighteen (18) and two (2)

combo racks each holding ve (5) Mathieu Hemostats or other hand

instruments.

Full Tray Only One (1) Horizontal Tray capable of holding up to six (6) orthodontic

pliers or up to (12) single-handle hand instruments. Other combinations

can include: (5) orthodontic pliers with up to (2) single-handle hand

instruments; (4) orthodontic pliers with up to (4) single-handle hand

instruments; (3) orthodontic pliers with up to (6) single-handle hand

instruments. (2) orthodontic pliers with up to (8) single-handle hand

instruments. (1) orthodontic plier with up to (10) single-handle hand

instruments.

Half Tray and Racks Two (2) Plier Racks capable of holding nine (9) pliers each for a total

of eighteen (18) pliers or two (2) combo racks each holding ve (5)

orthodontic pliers and three (3) Mathieu Hemostats and three (3)

single ended hand instruments along with one of the following tray

congurations: one (1) Half Tray capable of holding three (3) orthodontic

pliers or six (6) single-handle hand instruments; or one (1) Half Tray

capable of holding two (2) orthodontic pliers with up to two (2) single-

handle hand instruments; or one (1) Half Tray capable of holding one (1)

orthodontic plier with up to four (4) single-handle hand instruments.

Table 1: Maximum loading for the DDS 7000

Right Way to Load Wrong Way to Load

17

LOADING THE STERILIZATION CHAMBER

Example of proper and improper loadings

Figure 7A: Properly Loaded DDS 7000 with Figure 7B: Properly Loaded DDS 7000

four Plier Racks. with Half-Tray and two Plier Racks.

Figure 7C: Improperly loaded Half Tray with Figure7D: Close up of improperly loaded

Plier Rack. The Plier Rack is not in the proper half tray. Instruments should be placed so

rack channel and covers the air vents. This that they do not touch one another or extend

will impede airow around the instruments. over the tray periphery.

ALSO AVAILABLE: FULL TRAY FOR HAND INSTRUMENTS.

18

OPERATION

Once the DDS 7000 is loaded, it is time to begin the sterilization process. Close the door by gently

pushing the door against the rubber door gasket and turning the knob counter-clockwise. This will

engage the cam lock, which pulls the door against the gasket, sealing the chamber.

Figure 8A Figure 8B

Depress the“Standby/On”switch to“On”. The Standby/On switch activates the control panel. The display

shows ambient temperature. No LEDs are lit at this time. Press the Cycle Start switch to initiate a cycle. The

cycle is preprogrammed and cannot be altered by the user.

Figure 8C Figure 8D

Once the “Cycle Start” switch is pressed, the “warm up” LED lights up indicating that the DDS 7000 is

in the warm-up phase of the cycle.

The Safety Door Interlock engages as chamber exceeds 122ºF (50ºC). The lock activation is

indicated by a dot that appears in the lower right corner of the display. The device will

continue warm-up until the set point is reached. The time required for warm-up is

dependent on the size of the load.

73°F

73°F 124°F

19

The DDS 7000 is programmed to sterilize for three (3) minutes. At the completion of three (3) minutes,

the DDS 7000 automatically begins the cool down phase of the cycle. The blue “Cool Down” LED is lit.

Cool down is achieved by forcing ambient ltered air across the load and expelling the heated air.

The door interlock disengages at 113ºF (45ºC) and the indicator dot disappears from the lower right

of the display.

Once the operating temperature of

374ºF (190ºC) is reached, the DDS 7000

begins the sterilize (exposure) phase.

The amber “Sterilize” LED lights up.

During this phase, the internal temperature

is closely monitored and controlled. The

temperature on the display is the

temperature of the air as measured

after it has left the chamber. The

displayed temperatures during this

phase are typically between 368 - 376ºF

(187 – 191ºC). If the display tempera-

ture ever drops below 365ºF (185ºC), the

cycle will fail.

374°F

374°F

113°F

Figure 9

Figure 10

Figure 11

20

Once cool down is complete @ 104˚F (40˚C), the green “complete”LED lights up indicating that it is now safe to

remove the sterilized tools from the chamber (ABOVE).

WARNING!

DO NOT UNLOAD INSTRUMENTS UNLESS THE “CYCLE COMPLETE” LIGHT IS ON.

NOTE: The indicator lights will ash if there was a problem during any phase of the cycle. Refer to APPENDIX

II for error code explanations.

During cool down, the fan is drawing air through the HEPA Filter and into the chamber to cool the in-

struments. An audible tone will signal the completion of the cycle. The door must be opened to turn

this LED o and to begin a new cycle. If instruments are not immediately removed from the oven cham-

ber, they may reheat slightly from warm areas inside the chamber.

SPECIAL NOTE ON MOUTH MIRRORS

The DDS 7000 has been tested to safely sterilize good quality metal mouth mirrors. However,

depending on the age of your mirrors and their exposure to chemical disinfectants and cleaning

solutions, there may be moisture leakage behind the glass. This moisture will vaporize during the ster-

ilization cycle and cause shattering of the mirror. When sterilizing mirrors, wrap them in aluminum foil

to contain any glass fragments that may occur.

For best results, wipe mirror faces with a clean cloth after ultrasonic cleaning and before sterilization

to prevent fogging.

104°F

Figure 12

Table of contents

Popular Laboratory Equipment manuals by other brands

Hydro systems

Hydro systems HydroChem 912 quick start guide

THORLABS

THORLABS OCTG Series user manual

Holland Green Science

Holland Green Science 10301001 user manual

Bungard

Bungard Compacta L30 Instructions for use

Fisher Scientific

Fisher Scientific Fisherbrand Isotemp RT AVCD HPS Advanced Operation manual

SCHOTT

SCHOTT EasyLED Spotlight Plus user manual