Denwa Communications DW-GTW-AC-E1060 User manual

1Introduction

This document provides a hardware description of the DW-GTW-AC-E1060 (hereafter

referred to as device) and step-by-step procedures for mounting and cabling the

device.

The device supports the following interfaces:

●2 E1/T1 port interfaces.

●4 FXS port interfaces

●4 Gigabit Ethernet ports

2Package content

Follow the procedure below for unpacking the carton in which the device is shipped.

●DW-GTW-AC-E1060

●Four anti-slide bumpers for desktop installation

●One FXS Lifeline cable adapter

●Two mounting brackets for 19-inch rack mounting

●One AC power cable

3Physical Description

This section provides a physical description of the device.

3.1 Physical Dimensions and Operating Environment

The device's physical dimensions and operating environment are listed in the table

below:

Table 3-1: Physical Dimensions and Operating Environment

Physical Specification

Description

Dimensions (H x W x D)

1U x 32 x 34.5 cm (12.6 x 13.6 inches)

Weight

2.5 kg (5.5 lbs.)

Environmental

Operational: 5 to 40°C (41 to 104°F)

Storage: -25 to 85°C (-13 to 185°F)

Humidity: 10 to 90% non-condensing

MTBF

238,834

3.2 Front Panel Description

The front panel provides the telephony port interfaces, various networking ports,

reset pinhole button, and LEDs.

Table 3-2: Front Panel Description

Item

#

Label

Description

1

USB/WWAN

USB port, used for various functionalities such as saving

debug captures to a USB storage device.

2

Console

Port RJ-45 to RS-232 port for serial communication.

3

POWER /

STATUS

LEDs indicating the status of the power and

reboot/initialization.

4

PRI / Digital

Telephony port interfaces that can include two E1/T1 port

interfaces (RJ-48)

5

-

Reset pinhole button for resetting the device and optionally,

for restoring the device factory defaults. To restore the

device to factory defaults, do the following:

With a paper clip or any other similar pointed object, press and hold down

the Reset pinhole button for at least 12 seconds, but no more than 25

seconds.

6

LAN

Four 10/100/1000Base-T (Gigabit Ethernet) LAN ports for

connecting IP phones, computers, or switches. These ports

support the following features:

Half- and full-duplex modes

Auto-negotiation

Straight or crossover cable detection

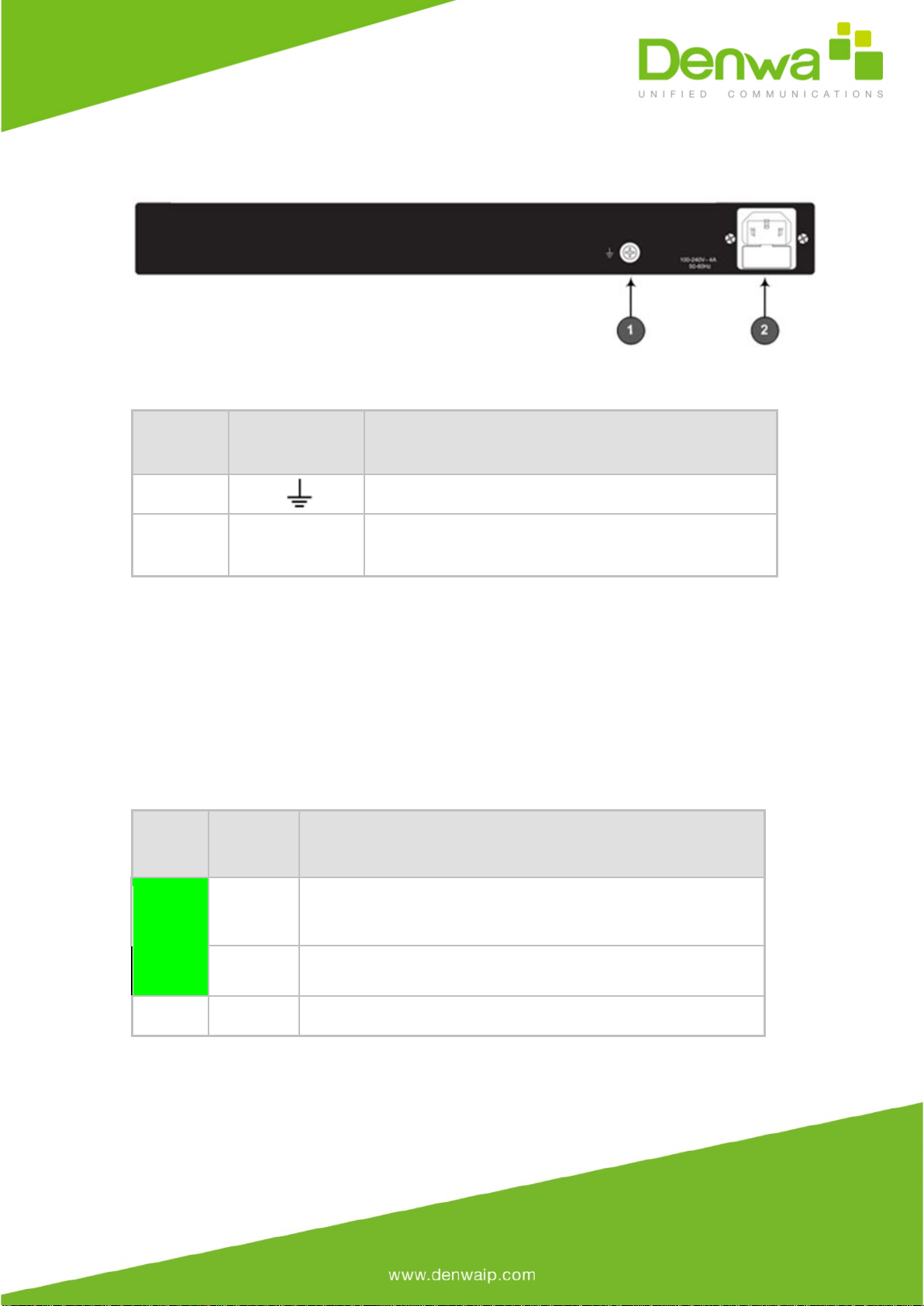

Table 3-3: Rear Panel Description

ITEM

Label

Description

1

Protective earthing screw.

2

100-240V~4A

50-60Hz

3-Prong AC power supply entry.

3.2.1 LEDs Description

The front panel provides LEDs on the device's hardware (e.g., the available telephony

interfaces). These LEDs are described in the subsequent subsections.

3.2.1.1 LAN Interface LEDs

Each LAN port provides a LED (located on its left) for indicating LAN operating status,

as described in the table below.

Table 3-4: LAN LEDs Description

LED

Color

LED

Staus

Description

Green

On

Ethernet link established.

Flashing

Data is being received or transmitted.

-

Off

No Ethernet link.

3.2.1.2 E1/T1 LEDs

Each trunk port provides a LED for indicating operating status, as described in the

table below:

Table 3-5: E1/T1 LEDs Description

Color State Description

Green On Trunk is synchronized (normal

operation).

Red On

Loss due to any of the following signals:

●LOS - Loss of Signal

●LOF - Loss of Frame

●AIS - Alarm Indication Signal

(the Blue Alarm)

●RAI - Remote Alarm

Indication (the Yellow Alarm)

-

Off

Failure / disruption in the AC power supply

or the power is currently not being

supplied to the device through the AC

power supply entry.

3.2.1.2 Operational Status LEDs

The STATUS LED indicates the operating status, as described in the table below.

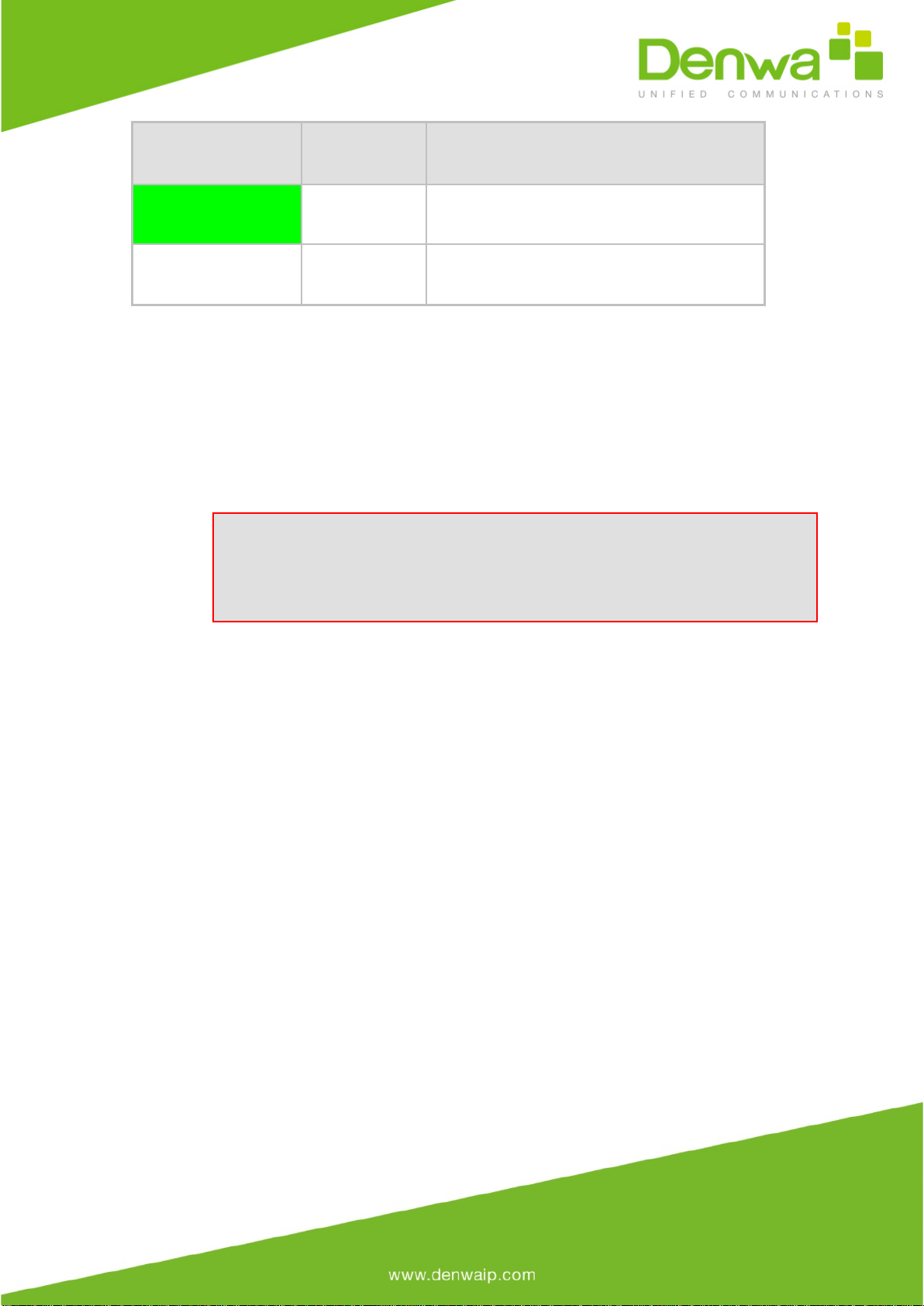

Table 3-6: STATUS LEDs Description

LED Color LED State Description

Green

On

The device is operational and in Standalone mode

(not in High-Availability mode).

Flashing

Initial rebooting stage.

Red

On

Boot failure.

Off

Advanced rebooting stage.

1.1.1.2 Power LEDs

The POWER LED indicates the operating status, as described in the table below.

Table 3-7: POWER LEDs Description

LED Color LED State Description

Green

On

Power is received by the device.

-

Off

No power received by the device.

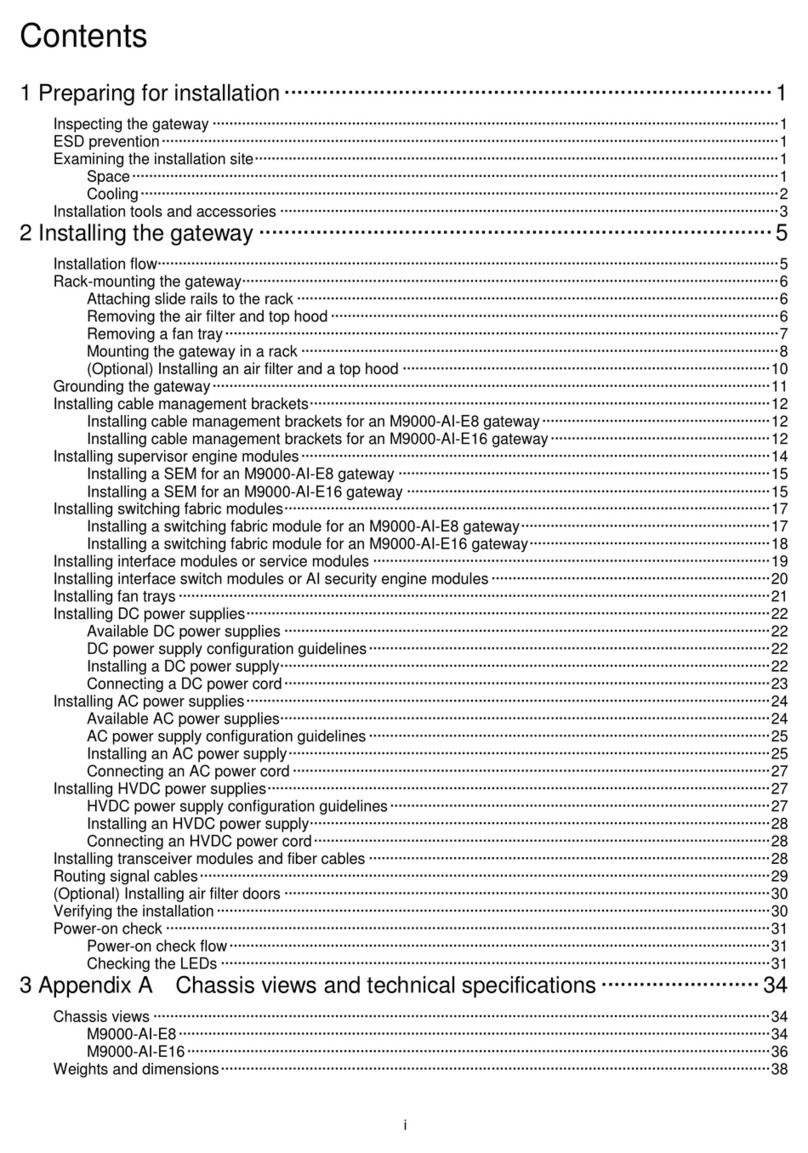

4Mounting the Device

The device can be mounted in one of the following ways:

●Placed on a desktop

●Installed in a standard 19-inch rack

Warning: Do not place any equipment directly on top of the device or

adjacent to its sides (at least 13-cm separation). In addition, if you are

mounting the device in a 19-inch rack, ensure that at least a 3U separation

is maintained between the device and other mounted devices or equipment.

4.1 Desktop Mounting

The device can be placed on a desktop when its four anti-slide bumpers (supplied)

are attached to the underside of the device.

To attach the anti-slide rubber bumpers to the device:

1. Flip the device over so that its underside faces up.

2. Locate the four anti-slide grooves on the underside - one in each

corner.

3. Peel off the adhesive, anti-slide rubber feet and stick one in each anti-

slide groove.

Figure 4-1: Rubber Foot Attached to Underside of Device

4. Flip the device over again so that it rests on the rubber feet and place

it in the required position on a desktop.

4.2 19-Inch Rack Mounting

The device can be installed in a standard 19-inch rack by implementing one of the

following mounting methods:

●Placing it on a pre-installed shelf in a 19-inch rack

●Attaching it directly to the rack’s frame using the device's mounting brackets

(supplied) that need to be attached to the chassis

Rack Mount Safety Instructions

When installing the chassis in a rack, implement the following safety

instructions:

·Elevated Operating Ambient Temperature: If installed in a

closed or multi-unit rack assembly, the operating ambient temperature

of the rack environment may be greater than room ambient temperature.

Therefore, consideration should be given to installing the equipment in

an environment with maximum ambient temperature (Tma) of 40°C

(104°F).

·Reduced Air Flow: Installation of the equipment in a rack should

be such that the amount of air flow required for safe operation on the

equipment is not compromised.

·Mechanical Loading: Mounting of the equipment in the rack

should be such that a hazardous condition is not achieved due to uneven

mechanical loading.

·Circuit Overloading: Consideration should be given to the

connection of the equipment to the supply circuit and the effect that

overloading of the circuits might have on over-current protection and

supply wiring. Appropriate consideration of equipment nameplate ratings

should be used when addressing this concern.

·Reliable Earthing: Reliable earthing of rack-mounted equipment

should be maintained. Particular attention should be given to supply

connections other than direct connections to the branch circuit (e.g., use

of power strips).

4.2.1 Using a Pre-installed Rack Shelf

The procedure below describes how to place the device on a pre-installed shelf in a

19-inch rack.

To mount the device on a pre-installed shelf in the rack:

1. Before installing it in the rack, ensure that you have a pre-installed rack

shelf on which the device can be placed.

2. Place the device on the pre-installed shelf in the rack.

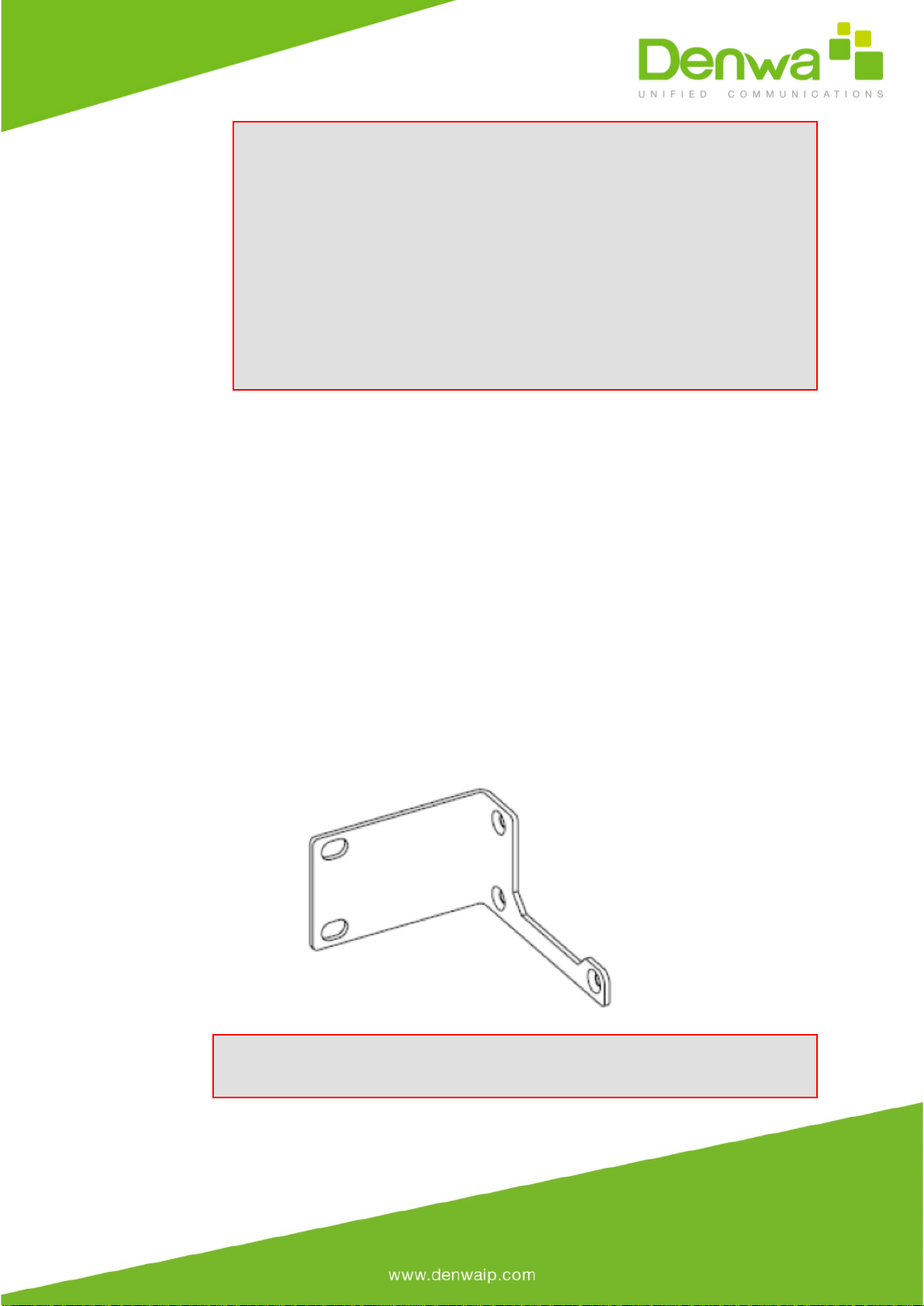

4.2.2 Using Mounting Brackets

The procedure below describes how to mount the device in a 19-inch rack. Rack

mounting involves placing the device on a pre-installed rack shelf and then attaching

the device's mounting brackets (to the device and rack frame). The purpose of the

mounting brackets is to secure the device to the rack.

Figure 4-2: Mounting Bracket (Right)

Note: 19-inch rack mounting using mounting brackets is a customer ordered

feature.

To mount the device in a 19-inch rack using mounting brackets:

1. Attach the two mounting brackets (supplied) to each side of the device's

chassis, using the supplied screws, as shown in the figure below:

Figure 4-3: Attaching the Mounting Brackets

2. Place the device on a pre-installed shelf in the rack.

3. Attach the ends of the mounting brackets (that you installed in Step 1)

to the vertical track of the rack's frame, using standard 19-inch rack bolts (not

supplied).

5Cabling the Device

This chapter describes the cabling of the device.

5.1 Grounding and Surge Protection

The device must be connected to earth (grounded) using an equipment-earthing

conductor.

Protective Earthing

The equipment is classified as Class I EN60950 and UL60950 and must be

earthed at all times.

For Finland: "Laite on liltettava suojamaadoituskoskettimilla varustettuun

pistorasiaan."

For Norway: "Apparatet rna tilkoples jordet stikkontakt."

For Sweden: "Apparaten skall anslutas till jordat uttag."

Grounding and Power Surge Protection

·

The device must be installed only in telecommunication sites /

centers in compliance with ETS 300-253 requirements "Earthing and Bonding

of Telecommunication Equipment in Telecommunication Centers".

·Prior to installation, earth loop impedance test must be performed

by a certified electrician to ensure grounding suitability at the power outlet

intended to feed the unit. It is essential that the impedance will be kept

below 0.5 ohms!

·Proper grounding is crucial to ensure the effectiveness of the

lightning protection, connect the device permanently to ground (as

described in the procedure below). The device's grounding screw must be

connected to the equipotential grounding bus bar located in the

Telecommunication rack or installation site, using a wire of 6 mm2 surface

wire. If the device is installed in a rack with other equipment, the rack

must be connected to the equipotential grounding bus bar of the

Telecommunication room, using a stranded cable with surface area of 25

mm2. The length of this cable must be as short as possible (no longer than 3

meters).

·Failing to install primary surge protectors and failing to comply with

the grounding instructions or any other installation instructions, may cause

permanent damage to the device.

·As most of the installation is the responsibility of the customer,

Denwa Corp can assume responsibility for damage only if the customer can

establish that the device does not comply with the standards specified

above (and the device is within the hardware warranty period).

·The device complies with protection levels as required by EN

55024/EN 300386. Higher levels of surges may cause damage to the device.

To ground the device:

1. Connect an electrically earthed strap of 16 AWG wire (minimum) to the

chassis' grounding screw (located on the rear panel), using the supplied washer and

fasten the wire securely using a 6-32 UNC screw.

Figure 5-1: Grounding the Device

2. Connect the other end of the strap to a protective earthing. This should be in

accordance with the regulations enforced in the country of installation.

5.2 ISDN E1/T1 Interfaces

This section describes how to cable the PRI interfaces.

5.2.1 Connecting to ISDN PRI (E1/T1) Trunks

The procedure below describes the cabling of the device's E1/T1 (PRI) trunk

interfaces.

Warning:

·To protect against electrical shock and fire, use a 26 AWG min wire

to connect T1 or E1 ports to the PSTN.

·To comply with EMC rules and regulations, use shielded twisted pair

(STP) cables for E1 interfaces on DW-GTW-AC-E1060.

Note: PRI interfaces are a customer-ordered item.

Cable specifications:

●Cable: STP cable of 26 AWG min.

●Connector Type: RJ-48c

●Connector Pinouts:

Figure 5-14: RJ-48c Connector Pinouts for E1/T1

To connect the E1/T1 trunk interface:

1. Connect the E1/T1 trunk cable to the device’s E1/T1 port.

2. Connect the other end of the trunk cable to your PBX/PSTN switch.

Figure 5-15: Cabling E1/T1 Ports

Notes:

·It does not matter which PRI port connects to which Tel entity (i.e.,

PBX or PSTN).

·To enable PSTN Fallback upon IP network connectivity issues, use

the TrunkLifeLineType parameter (PSTN Fallback upon power outage is done

by default).

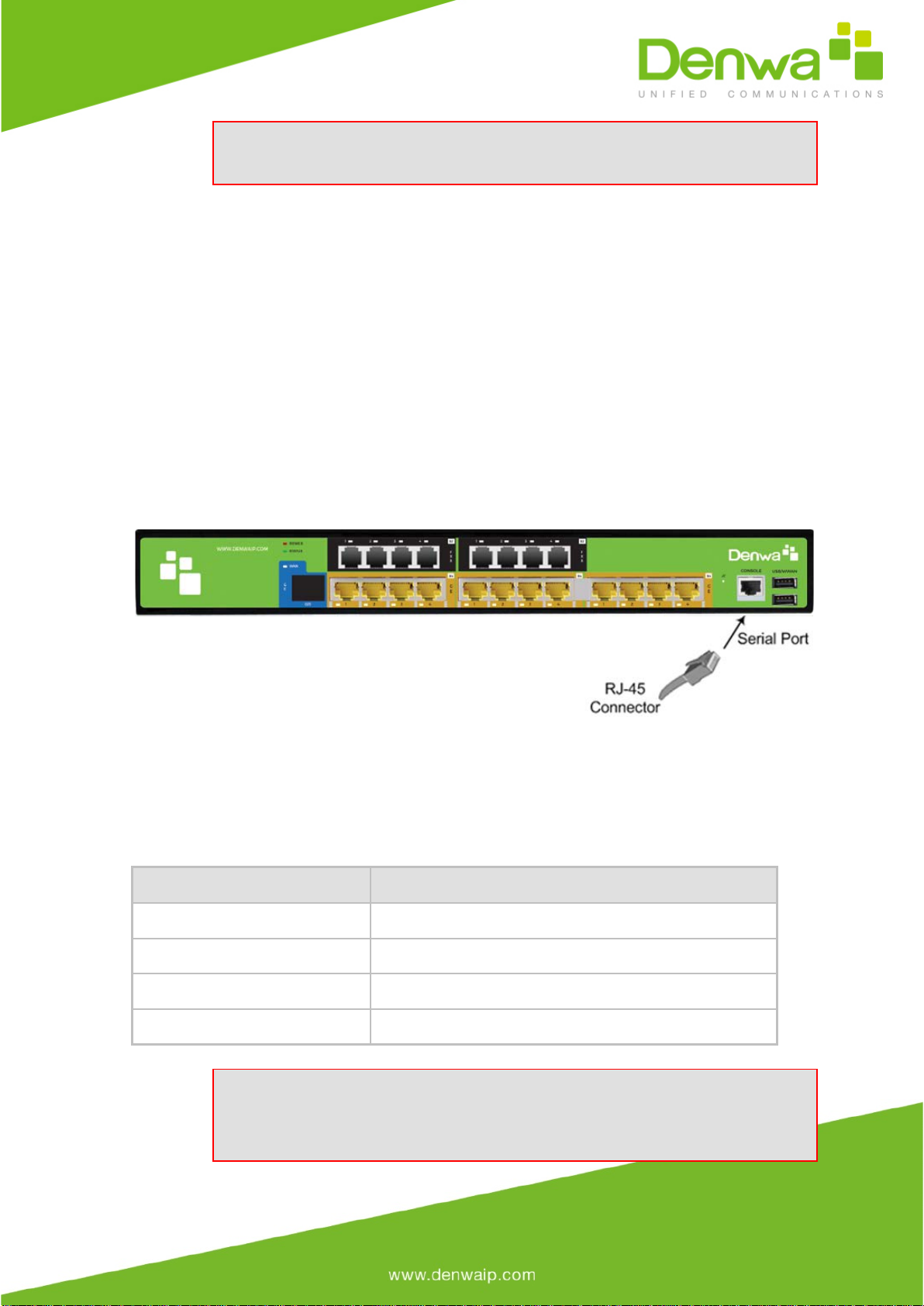

5.3 Connecting to a Computer for Serial

Communication

The device provides an RS-232 serial interface port on its front panel for serial communication with a

PC.

·Port Type: RJ-45

·Cable: RJ-45 to DB-9

To connect the device's serial interface to a computer:

a. Connect the RJ-45 cable connector to the device's serial port, labeled CONSOLE.

b. Connect the other end of the cable to the COM1 or COM2 RS-232 communication port on your

PC.

Figure 5-19: Cabling Serial Interface (RJ-45)

5.4 Powering up the Device

The device receives power from a standard alternating current (AC) electrical outlet. The connection is

made using the supplied AC power cord.

Table 5-3: Power Specifications

Physical Specification

Value

Input Voltage

Single universal AC power supply 100 to 240V

AC Input Frequency

50 to 60 Hz

AC Input Current

1.5 A

Max. Power Consumption

Gateway (without OSN): 60W*

Warnings:

·The device must be connected to a socket-outlet providing a protective earthing

connection.

·Use only the AC power cord that is supplied with the device.

To connect the device to the power supply:

1. Connect the line socket of the AC power cord (supplied) to the device's AC power

socket (labeled 100-240V ~ 4A 50-60Hz), located on the rear panel.

Figure 5-21: Connecting to the Power Supply

2. Connect the plug at the other end of the AC power cord to a standard electrical

outlet.

Once you have cabled and powered-up the device, the POWER LED on the front panel lights up green.

6Maintenance – Replacing the Power

Fuse

The device contains a fuse that protects the device from excessive current. The fuse is located on the

rear panel, below the power socket. To replace the fuse, use only one of the following fuses described

in the table below:

Table 6-1: Allowed Fuses for the Device

Manufacturer

Manufacturer Part Number

BEL

5ET2.5-R

CONQUER

UDL 2.50

LITTEFUSE

021302.5MXP

Caution

For continuous protection, replace only with the same fuse type and rating fuse.

To replace the fuse:

1. Unplug the power cord from the electrical outlet.

2. Using a small flathead screwdriver, gently pries open the fuse cavity as illustrated in

the figure below:

Figure 6-1: Opening the Fuse Cavity

3. Carefully remove the fuse from the fuse cavity.

Figure 6-2: Removed Power Fuse

4. Insert the new fuse securely into the fuse cavity until you hear a click sound.

5. Reconnect the power cord and verify that the Power LED is lit green.

Table of contents

Other Denwa Communications Gateway manuals