Desco Europe Combo Tester X3 Service manual

TB-3080.E Page 1 of 8 © 2019 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Combo Tester X3

Installation, Operation and Maintenance

Description

The Desco Combo Tester X3 verifies the functionality

of personnel grounding devices (wrist straps1, foot

grounders, ESD shoes, smocks2). Three independent

tests are performed simultaneously on the wrist strap

and each foot. Green lights indicate a pass condition.

Red and yellow lights plus an audible alarm indicate

when the wrist strap and/or footwear (left or right) have

failed. DIP switches may be accessed for test limit

preferences. Access control to an ESD Protected Area

can be further enforced by using the relay terminal on

the Combo Tester X3 and connecting it to an electronic

door lock or turnstile to grant access only to those who

have passed their personnel grounding device tests.

The Combo Tester X3 is calibrated to NIST standards

and includes a certificate.

Desco Combo Tester X3 Technology

• The solid-state touch test switch maintains test

accuracy and extends the lifetime of the tester

• The 30 volt test signal increases test reliability

• Pairs with the EMIT 50755 ESD Glove Test Fixture

to test operators that wear ESD gloves or finger cots

per Compliance Verification required by ESD TR53

The factory test limits are set to:

Wrist Straps: 750 kilohms and 10 megohms

Footwear: 750 kilohms and 35 megohms

(See page 3 for alternate test limit settings)

June 2019

The Combo Tester X3 and its accessories are available

as the following item numbers:

Item Description

19270 Combo Tester X3

19271 Combo Tester X3 with Stand

19287 Combo Tester X3 with 10 mm Adapter

19288 Combo Tester X3 with 10 mm Adapter & Stand

50755 ESD Glove Test Fixture

50424 Limit Comparator

19262 Power Adapter, 100-240 VAC Input, 12 VDC

0.5 A Output, All Plugs

19273 Replacement Dual Foot Plate

19274 Replacement Ground Cord

62103 Replacement Foot Plate Cord

This product can be used as one of the tools to fulfil

EN 61340-5-1 Compliance verification requirements

“Process monitoring (measurements) shall be conducted

in accordance with a compliance verification plan that

identifies the technical requirements to be verified, the

measurement limits and the frequency at which those

verifications must occur. … Compliance verification

records shall be established and maintained to provide

evidence of conformity to the technical requirements.

The test equipment selected shall be capable of making

the measurements defined in the compliance verification

plan.”

“Wrist straps should be tested periodically. The

frequency of testing, however, is driven by the amount

of usage, wear and ESD risk exposure that can occur

between tests. For example, what is the quantity of

product handled between test periods?

Because wrist straps have a finite life, it is important to

develop a test frequency that will guarantee integrity

of the system. Typical test programs recommend that

wrist straps that are used daily should be tested daily.

However, if the products that are being produced are of

such value that a guarantee of a continuous, reliable

ground is needed then continuous monitoring should be

considered or even required.”

(IEC TR 61340-5-2 Wrist strap use and selection clause

4.7.2.4.4 Test frequency)

Made in the

United States of America

TECHNICAL BULLETIN TB-3080.E

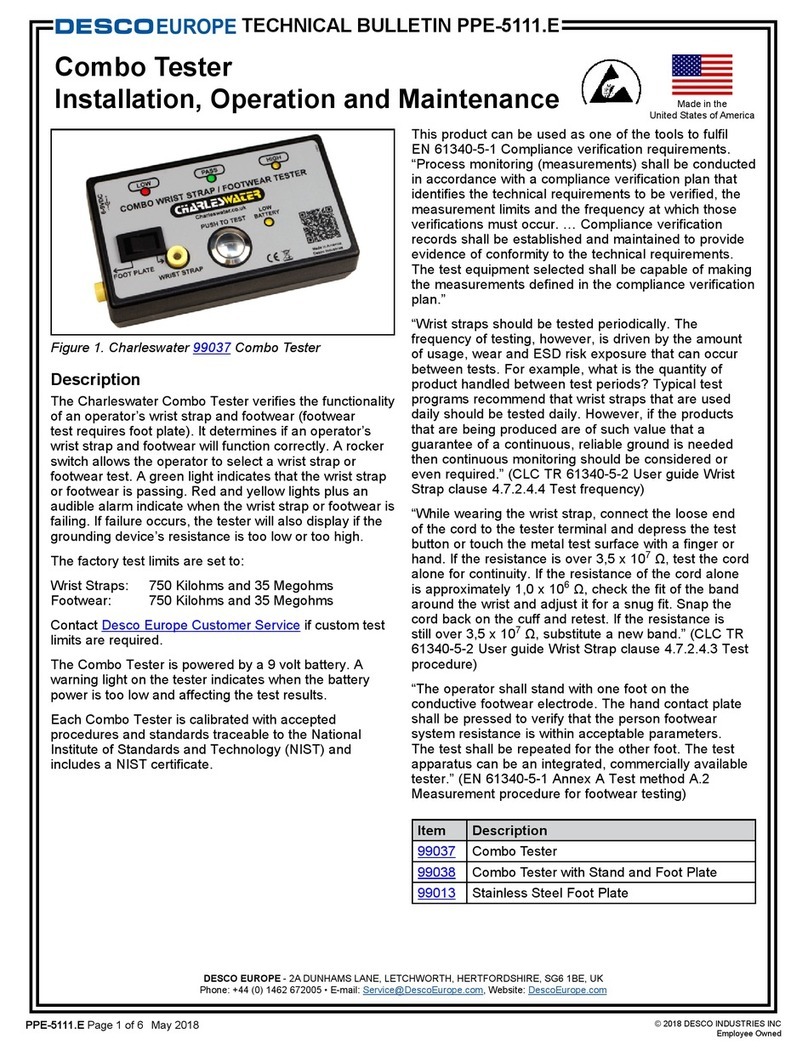

Figure 1. Desco Combo Tester X3 and Dual Foot Plate

1. The Combo Tester X3 can verify single-wire and dual-wire wrist

straps.

2. The Combo Tester X3 will also test a Groundable Static Control

Garment System. The Groundable Static Control Garment System

must have an RTG of < 3.5 x 10⁷ohms to meet the required limit

of IEC 61340-5-1 tested per IEC 61340-4-9.

TB-3080.E Page 2 of 8 © 2019 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Packaging

19270 COMBO TESTER X3

1 Combo Tester X3

1 Dual Foot Plate

1 Power Adapter, 12 VDC, with interchangeable plugs

(North America, UK/Asia, Europe)

1 Foot Plate Cord, 1.8 m

1 Ground Cord

1 Certificate of Calibration

19271 COMBO TESTER X3, WITH STAND

1 Combo Tester X3

1 Dual Foot Plate

1 Power Adapter, 12 VDC, with interchangeable plugs

(North America, UK/Asia, Europe)

1 Foot Plate Cord, 1.8 m

1 Ground Cord

1 Pedestal (two pieces)

1 Base Plate

5 Socket Head Screws, 1/4-20 x 1/2"

2 Phillips Head Screws, 10-32 x 5/8"

2 Nuts, 10-32

2 Spacers

1 Certificate of Calibration

19272 STAND, FOR COMBO TESTER X3

1 Pedestal (two pieces)

1 Base Plate

5 Socket Head Screws, 1/4-20 x 1/2"

2 Phillips Head Screws, 10-32 x 5/8"

2 Nuts, 10-32

2 Spacers

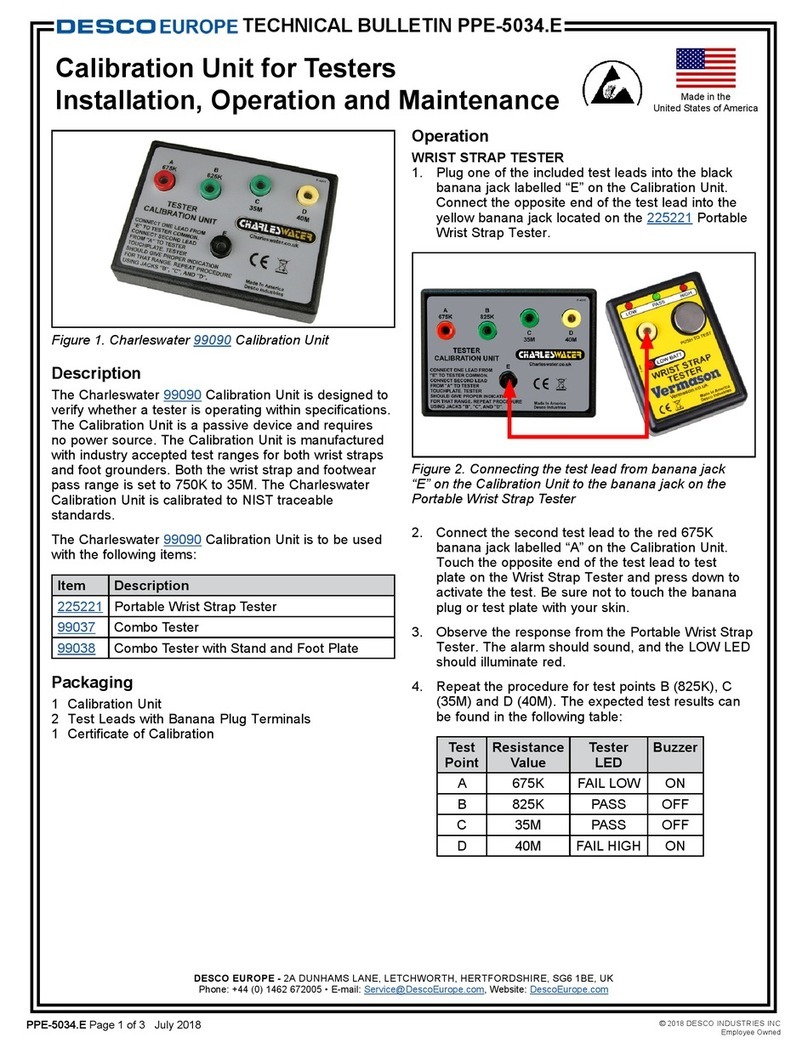

Features and Components

A. Test Limit DIP Switch: Use this DIP switch to

configure the resistance limits of the tester. See the

section titled “Tester Configuration” for more information.

B. Footwear Status LEDs: Displays the footwear test

results.

C. 12 VDC Power Jack: Connect the included power

adapter here to power the Combo Tester X3.

D. Steady-State Test Switch: Place and hold your

finger here to begin the test.

E. Single-Wire Wrist Strap Jack: Insert your

single-wire wrist cord here to test your wrist strap.

F. Dual-Wire Wrist Strap Jack: Insert your dual-wire

wrist cord here to test your wrist strap.

G. Wrist Strap Status LEDs: Displays the wrist strap

test results.

H. ESD Glove Test Fixture Port: Used for connecting

the EMIT 50755 ESD Glove Test Fixture. See TB-6586

for more information.

I. Relay Terminal: Can be integrated with electronic

door locks, lights, buzzers, etc. It is capable of switching

up to 1 A @ 30 VDC or 0.5 A @ 125 VAC.

Terminals 1 & 2 = Normally Closed

Terminals 2 & 3 = Normally Open

NOTE: All tests must pass in order for the relay to

activate. The relay timer lasts approximately

2.5 seconds and cannot be modified. The timer starts

once the finger is removed from the test switch.

J. Ground Jack: Insert the banana plug end of the

included ground cord to this jack. Connect the ring

terminal end of the cord to equipment ground. This

connection will remove any static charge from the user

before the test.

NOTE: Failure to correctly ground the Combo Tester X3

may result in damage not covered under warranty.

K. Foot Plate Jack: Connect one end of the foot plate

cable cord and the other end to the dual foot plate.

L. Buzzer Volume Adjustment: Turn the trimpot

clockwise to increase the buzzer volume and

counter-clockwise to decrease the volume.

Figure 2. Combo Tester X3 features and components

B

D

H I

1 2 3

A

C GFE

J K L

TB-3080.E Page 3 of 8 © 2019 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

Installation

TESTER CONFIGURATION

The resistance limits for footwear and wrist strap tests

are controlled by the DIP switches located on the left

side of the Combo Tester X3. Use the following tables

for the DIP switch settings and their corresponding test

values.

Footwear Resistance

DIP switches 1 and 2 control the HIGH test limit.

Switch 1 Switch 2 HIGH Limit Resistance

ON ON 10 Megohms (1 x 107)

OFF OFF 35 Megohms (3.5 x 107)

ON OFF 100 Megohms (1 x 108)

OFF ON 1 Gigohm (1 x 109)

DIP switches 3 and 4 control the LOW test limit.

Switch 3 Switch 4 LOW Limit Resistance

OFF OFF footwear test disabled

ON OFF 100 Kilohms (1 x 105)

OFF ON 750 Kilohms (7.5 x 105)

default setting

NOTE: At 1 Gigohm high limit resistance, a dirty foot

plate could result in a false pass. Be sure to keep the

foot plate clean particularly when using this setting. This

setting is not suitable for relative humidity greater than

50 %.

Wrist Strap Resistance

DIP switches 5 and 6 control the HIGH test limit.

Switch 5 Switch 6 HIGH Limit Resistance

OFF OFF wrist strap test disabled

ON ON 10 Megohms (1 x 107)

ON OFF 35 Megohms (3.5 x 107)

default setting

DIP switch 5 must be ON (default setting) for the wrist

strap test to be active. The wrist strap test will be

disabled if DIP switch 5 is set to OFF.

The LOW limit for the wrist strap test is set to

750 kilohms and cannot be modified by the user. 5. Insert the ground cord’s banana plug into the

ground jack located at the bottom of the tester.

Connect ground cord’s ring terminal to equipment

ground. This connection will remove any static

charge from the user before the test.

NOTE: Failure to correctly ground the Combo

Tester X3 may result in damage not covered under

warranty.

6. Power the Combo Tester X3 with the power

adapter.

INSTALLING THE COMBO TESTER X3

1. Mount the tester at the desired location using the

four mounting holes located in the corners of the

yellow mounting plate.

2. Set the dual foot plate below the tester.

3. Insert one end of the foot plate cord into the stereo

jack located at the bottom of the tester. Insert the

opposite end of the cord into the stereo jack located

on the underside of the dual foot plate.

4. Use the guides located on the underside of the dual

foot plate to route the cord either out the top or the

side. This will prevent the foot plate cord from being

accidentally tripped and unplugged.

Figure 3. Routing the foot plate cord through the top

Figure 4. Routing the foot plate cord through the side

TB-3080.E Page 4 of 8 © 2019 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

INSTALLING THE COMBO TESTER X3 AND STAND

1. Assemble the pedestal and base plate using the 5

socket head screws.

2. Route the ground cord, foot plate cord and power

adapter through the pedestal. Feed the cords from

the bottom and have them exit through the top.

3. Align the backplate’s two holes located above and

below the tester to the two holes on the pedestal’s

mounting bracket. Secure the backplate using the

two phillips head screws, spacers, and nuts.

4. Plug the ground cord into the ground jack located

on the bottom of the tester and connect the ring

terminal to equipment ground. This connection will

remove any static charge from the user before the

test. NOTE: Failure to correctly ground the Combo

Tester X3 may result in damage not covered under

warranty.

5. Plug the foot plate cord into the tester and the dual

foot plate.

Figure 5. Assembling the pedestal and base plate using

the 5 socket head screws

Figure 6. Securing the Combo Tester X3 to the pedestal

6. Lay the dual foot plate onto the base plate.

Figure 7. Connecting the cords to the Combo Tester X3

TB-3080.E Page 5 of 8 © 2019 DESCO INDUSTRIES INC

Employee Owned

DESCO EUROPE - 2A DUNHAMS LANE, LETCHWORTH, HERTFORDSHIRE, SG6 1BE, UK

7. Power the Combo Tester X3 with the power

adapter.

WIRING THE COMBO TESTER X3 TO AN ACCESS

CONTROL SYSTEM

The Combo Tester X3 may be connected to an Access

Control System to grant access when both a valid

proximity badge is read and PASS test results are

achieved at the tester. Figure 8 shows an example

when using a turnstile.

*NOTE: The Access Control System must have a time

delay feature in order to achieve the configuration

described above. Set the Access Control System’s

relay to remain active for a few seconds when a valid

proximity badge is accepted. The relay will need to

remain active long enough for an operator to perform a

test on the Combo Tester X3. The access control device

will only unlock when it receives an active signal from

both the Access Control System and Combo Tester X3.

Operation

1. A circling light around the test switch indicates when

the Combo Tester X3 is on standby and ready to

perform a test.

Access Control System*

NORMALLY

OPEN RELAY

DATA

INPUT

Proximity

Reader

Combo

Tester X3

ACC

INPUT

Turnstile

DATA

LINES

Figure 9. Wiring the Combo Tester X3 to an Access

Control System

(normally open relay

contacts shown above)

2. While wearing a wrist strap and/or ESD footwear,

plug the wrist cord into its corresponding jack

located on the face of the Combo Tester X3. Place

one foot on each foot plate.

3. To begin the test, use your finger to bridge the test

switch’s inner and outer contacts. The blue standby

LED will become solid to indicate that the test has

been initiated. Hold your finger down until the test

results are displayed.

If your finger is removed too early, the tester’s LEDs

will blink three times to indicate that the test was not

completed. DO NOT touch any other metal while

performing your test as this will affect your results.

Figure 10. Steady-State Test Switch features and

components

OUTER

CONTACT

INNER

CONTACT

STANDBY

LED

Figure 8. Installing the dual foot plate onto the baseplate

Table of contents

Other Desco Europe Test Equipment manuals

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started