DESOI PowerInject P1 User manual

USER MANUAL 2

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

USER MANUAL 3

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

Contents

PAGE

1.0 General ..................................................................................................................................................................... 5

1.1 Introduction .................................................................................................................................................................5

1.2 Details of the manufacturer and contact person.............................................................................................................5

2.0 Safety........................................................................................................................................................................ 6

2.1 Important Information...................................................................................................................................................6

2.2 Designation used for the instructions in the operating manual ........................................................................................6

2.3 Due diligence of the operator ........................................................................................................................................8

2.4 Qualification of personnel .............................................................................................................................................9

2.5 Bestimmungsgemäße Verwendung ...............................................................................................................................9

2.6 Prohibited operation.................................................................................................................................................. 11

2.7 Handling the product and auxiliary materials .............................................................................................................. 11

2.8 Basic hazards/hazardous locations............................................................................................................................ 12

3.0 Transport, Storage and Interim Storage............................................................................................................13

3.1 Transportsicherheit.................................................................................................................................................... 13

3.2 Delivery of the product ............................................................................................................................................... 13

4.0 Information concerning the injection device ....................................................................................................14

4.1 Type description ........................................................................................................................................................ 14

4.2 Funktion.................................................................................................................................................................... 14

4.3 Technical specification .............................................................................................................................................. 15

4.4 Scope of delivery....................................................................................................................................................... 16

4.5 Accessories............................................................................................................................................................... 16

4.6 Warranty & Legal Notice (Copyrights(.......................................................................................................................... 16

4.7 Safety devices:.......................................................................................................................................................... 17

4.8 Declaration of Conformity with EC regulations ............................................................................................................. 18

5.0 Startup procedure .................................................................................................................................................19

5.1 Safety instructions for the startup prodedure............................................................................................................... 19

5.2 Switching positions of driving unit .............................................................................................................................. 20

5.3 Procedure / Preparation for commissioning ................................................................................................................ 21

6.0 Cleaning..................................................................................................................................................................22

7.0 Maintenace and repair work ...............................................................................................................................23

7.1 Maintenance and Inspection intervals ........................................................................................................................ 24

7.2 Retightening the piston seal ...................................................................................................................................... 25

7.3 Lubrication of the mechanics ..................................................................................................................................... 26

7.4 Checking and tightening important mechanical fasteners............................................................................................ 26

7.5 Testing & replacing wear parts.................................................................................................................................... 27

8.0 Faults ......................................................................................................................................................................31

9.0 Decommissioning and disposal..........................................................................................................................32

9.1 Decommissioning...................................................................................................................................................... 32

9.2 Disposal (Recycling) .................................................................................................................................................. 32

10.0 Additional information .........................................................................................................................................33

10.1 Serviceadressen........................................................................................................................................................ 33

10.2 Part list and drawings ................................................................................................................................................ 33

10.3 Note ......................................................................................................................................................................... 36

USER MANUAL 4

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

USER MANUAL 5

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

1.0 General

1.1 Foreword

•About the document

1.2 Details of manufacturer and contact person

1.1 Introduction

We are delighted that you have chosen a Desoi® device.

This manual is intended for use by operating and maintenance personnel. It contains important information necessary for the safe

handling of the device.

The machine operator must ensure that this manual is always available to the operating and

maintenance personnel in a language that they understand.

In addition to the operating instructions, additional information is essential for the safe use of this equipment:

•Please refer to the respective guidelines for your country.

•Furthermore, always observe the manufacturer’s instructions and processing guidelines for conveying materials.

Desoi GmbH recommends supplementing this manual with all relevant guidelines and accident prevention regulations.

If problems occur with this device, or if questions arise, we will be happy to provide assistance.

About the document:

Caution!

Please read these instructions fully before installation and commissioning. It is the buyer's responsibility to retain this

manual for reference purposes. Ignoring the recommendations in these operating instructions will result in damaging

the product and to voiding of the manufacturer's warranty.

The language of the original operating manual is German. All additional languages of this manual are translations of the original

version. The installation and operating manual are part of the product. They must be kept near to the product at all times. Strict

adherence to these instructions is a precondition for the proper use and correct operation of the product. These installation and

operating instructions comply with the design of the product, the status of the underlying safety regulations, and the standards at the

time of printing.

EC declaration of conformity:

A copy of the EC declaration of conformity is part of this manual. This declaration shall become invalid in the event of technical

amendments to the construction methods named within, or disregard of the explanations given in the operating manual for the safety

of the product/personnel.

1.2 Details of the manufacturer and contact person

DESOI GmbH

Gewerbestraße 16

36148 Kalbach/Rhön

Germany

Telephone: +49 6655 9636–0

Fax: +49 6655 9636-6666

Internet: www.desoi.de

USER MANUAL 6

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

2.0 Safety

2.1 Important information

2.2 Identification of notes in the operating manual

•Warning signs

•Other signs

•Mandatory signs

•Keywords

2.3 Personnel qualifications

2.4 Operator's obligation to exercise diligence

•Safety-conscious working practice

2.5 Intended use

2.6 Improper operation

2.7 Handling the product and auxiliary materials

2.8 Basic hazards / hazardous locations

2.1 Important Information

The product has been developed, manufactured and tested in accordance with the EC Machinery Directive and state-of-the-art

technology. The maximum possible safety and a high quality standard are a matter of course. However, improper use of any device

may result in danger to life and limb of the user or third parties and impairment of the unit and other property.

This product must only be used in a perfect technical condition, in accordance with its intended use, and in awareness of safety and

risk while observing the operating manual! Faults, especially those that could adversely affect safety, must be corrected immediately!

In addition, the general safety conditions of the relevant guidelines such as accident prevention regulations etc. must be observed.

The product must only be operated in accordance with its intended use (see Chapter: Intended use). Any other use or use beyond what

is specified does not constitute an intended use. Risks and damages resulting from incorrect use are the sole responsibility of the user.

Observance of this operating manual is also considered intended use.

For this reason, all safety instructions in the operating manual must be read and followed.

2.2 Designation used for the instructions in the operating manual

Warning signs:

This symbol indicates that health risks may occur for humans and animals.

This symbol indicates that fundamental health risks to persons exist. Potentially fatal hazards are indicated separately

by the words “DANGER TO LIFE”

This symbol indicates that there is electrical danger to the health of individuals because of electrical voltages.

Potentially fatal hazards are indicated separately by the words “LIFE THREATENING”

Warning of an area where explosive atmospheres may occur, in accordance with 1999/92/EC

This symbol indicates that there may be danger of slipping, stumbling and falling in these areas.

This symbol indicates that serious injury may occur due to jamming or crushing.

This symbol indicates that injuries may occur if the hot surfaces are touched.

This symbol indicates that the machine may lead to posture problems during operation.

USER MANUAL 7

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

This symbol indicates that there may be an emission of fluid under pressure.

This symbol indicates that cutting injuries may occur.

Other signs:

Useful instructions about handling the product. It indicates potential difficulties.

This symbol indicates that professional disposal with respect to returning components, production and consumer waste

must be guaranteed within the economic cycle.

Mandatoty signs:

Wear suitable work clothing!

Wear eye protection!

Wear foot protection!

Wear ear protection!

Wear hand protection!

Disconnect power supply!

Observe the product operating manual for the required accessories as well as the

technical data sheets and safety data sheets for the pumping medium!

Keywords:

HAZARD!

Indicates an immediate high-risk health hazard to people's lives.

WARNING!

Indicates an immediate danger with a medium risk to human health,

and under certain circumstances to people's lives.

CAUTION!

Indicates an immediate hazard with low risk or a potentially dangerous situation.

NOTE!

Provides tips and valuable information about the correct handling of each product

for the user.

Health hazard!

Indicates an immediate hazard of increased health risk and possibly risk to

people's lives, other living beings and the environment

USER MANUAL 8

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

2.3 Due diligence of the operator

WARNING!

For safety reasons, no unauthorised modifications that could compromise safety may be carried out on this product.

•Modifications in the course of a necessary mixing section extension or an adaptation to the respective connection

system of the packers to be used is possible at any time!

•Required modifications or adaptation must only be carried out with components provided by Desoi GmbH and by

qualified personnel.

WARNING!

Only use original spare parts/original wear parts/original accessories - these parts are specifically designed for the

product. With respect to parts that are supplied by third companies, there is no guarantee that they have been designed

and manufactured in a way that meets the required degree of safety and performance.

NOTE!

In practice, safe operation of this product will only be achieved if all measures necessary for this purpose are taken. The

operator must ensure that these measures are planned and that their implementation is monitored.

In particular, the operator must ensure that:

•the product is used as intended.

•this product is only operated in a fault-free, operational state.

•cleaning and maintenance work is carried out within the prescribed period in accordance with the recommendations in these

operating instructions.

•where appropriate, the necessary personal protective equipment needed for installation, commissioning, repair and

maintenance personnel is available and is also used.

•the operating manual is available in the vicinity of the product's location and is always in a legible condition and only

suitably qualified, authorised and trained personnel carry out work on this product.

•the area in the vicinity of the machine is kept free of foreign particles in order to reduce the likelihood of a fire or explosion

caused by the contact of foreign particles with the hot surfaces of the product.

•The corresponding manufacturer should be consulted immediately in the event of doubt regarding the function of the

product or the parts of the required equipment.

Safety-conscious working practice:

The safety instructions contained in this operating manual and the existing national regulations on accident prevention as well as any

internal working, operating and safety provisions of the operator must be observed.

NOTE:

The machine user is obliged to report any change to the machine that could adversely affect safety to the operator, who

bears responsibility for the machine's functionality.

Consult a doctor or visit the nearest hospital immediately should injury occur. A doctor must be informed regarding the

respective medium if input material, cleansing agents or lubricants penetrate the skin.

CAUTION!

Tidiness and cleanliness are essential for safe and fault-free operation as well as for a long service life of this product.

Therefore, keep the product and its environment at the operational site clean and wash them regularly in accordance

with the recommendations in this manual.

USER MANUAL 9

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

2.4 Qualification of personnel

All work on or with this product may only be carried out by qualified and trained professionals or trained or trained personnel, who, due

to their professional training, special training courses, and experience have sufficient skills and experience in handling this product.

The personnel must have read the safety instructions and information contained in this operating manual, be familiar with them,

understand them, and be able to act accordingly.

•Specialist employee: has obtained the necessary knowledge due to professional training. This person is able to

recognise potential dangers independently and to avoid hazards.

•Instructed users: were verifiably familiarised with this product via a instruction by the operator. In doing so, tasks were

assigned to them and they were made aware of potential hazards due to improper behaviour.

•Trained employee: is qualified, due to special instruction by the manufacturer of the product, to carry out maintenance

and repair work, to recognise potential dangers independently, and to avoid hazards.

Permitted activities

Necessary qualification

Note!

Young people under the age of 16

are not allowed to "operate or

assemble this product".

Connection and operation

Instructed user

Cleaning and decommissioning

Instructed user

Service and maintenance

Specialist employee /Trained employee

Repair - mechanical

Specialist employee /Trained employee

Repair - electrical

Specialist employee or Desoi GmbH

2.5 Bestimmungsgemäße Verwendung

If faults occur, the mains plug must be pulled out immediately and the "main switch of the drive

unit" must be set to the OFF position!

NOTE:

•The relevant safety data sheet for the material being conveyed must be observed in all cases. Furthermore, the

cleaning agents recommended by the manufacturer must be used.

•Where necessary, other standards, legal provisions and sets of rules must, depending on the country of use, be

respected if this product is to be operated outside the European Community (e.g. country-specific guidelines,

electrical standards such as the UL standard, CSA standard, etc.).

•The operator of the product is solely responsible for damage resulting from incorrect use.

•The respective specialist company or the operator itself is liable for damages resulting from improper installation,

repair or maintenance.

•Make sure that this product is not exposed to direct rain.

•When working with this product, wear eye protection, hand protection, foot protection and suitable working

clothes.

HAZARD!

In accordance with 1999/92/EC, the machine must not be operated in "any" area in which explosive atmospheres

could arise.

•Products without Ex approval are "not" suitable for operation in an explosive atmosphere. "DANGER TO LIFE"

CAUTION!

Intended use also includes:

•It must be ensured that no foreign particles or other contaminants get into the product.

•Reading this operating manual, as well as consideration of all the information herein, particularly the safety and

usage instructions, as well as compliance with and implementation of all inspection and maintenance work within

the prescribed time intervals.

•The proper use, maintenance and repair of the product requires relevant professional expertise in the field of

injection technology, partly in electrical engineering, pneumatics, hydraulics or mechanics.

USER MANUAL 10

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

HAZARD!

When operating the product above the direct earth surface, there is a high risk of injury for persons who are in the

immediate vicinity below the place of installation. Hazards are caused by:

•falling of the product

•falling of separate components

•falling accessories

An increased risk of injury also exists for users, who may slip, stumble or fall.

•Always lay the supply lines in such a way that they do not represent an additional source of risk.

•Sufficient safety must always be ensured for users and products to be used.

Definition:

Destination: With the DESOI PowerInject P1, injection work is carried out in connection with approved feed materials

for the purpose of building maintenance / building renovation. The main focus is on small short-term

work assignments.

Fields of application: the product may only be used "commercially or industrially".

Starting materials: The materials that may be processed are:

•EP resins

•PUR foams

•PUR resins

•aqueous solutions

Environmental requirements: Care must be taken to ensure the following:

•Controls must be freely accessible

•Adequate ventilation must be ensured

•The machine must stand level and stable; tipping or rolling away should be prevented.

•The machine should only be installed and used where no objects can fall on it.

•This must be additionally ensured if the machine is operated above ground. It must also

be ensured that there is no risk of falling components or accessories.

•When working outdoors, the machine must be protected from severe weather.

•Wheels, supports, and foundations should not sink into the ground.

•Climatic conditions from 5° to 45°C

It is important that the specifications of the technical data sheets of the respective

processing materials are adhered to.

•Maximum 1000 m above sea level

USER MANUAL 11

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

2.6 Prohibited operation

NOTE!

The operator of the respective device is responsible for all damage to persons and property arising from any improper

use, not Desoi GmbH!

WARNING!

If the product is not used as intended, there is no guarantee that it will operate safely.

This product is not designed for any use other than that set out in section 2.5, and so any such use is considered

a prohibited mode of operation.

In particular, we would like to point out that it is not permitted to:

•use this product for distribution/transfers of unlisted feed materials.

•use this product for private purposes.

•operate this product in rooms with explosive air and gas mixtures, with high levels of humidity and severe dust pollution of

the room air.

•operate this product with unauthorised spare parts or unauthorised accessories.

•to operate this product with self-made spare parts or accessories.

•To carry out structural changes of any kind on this product which could affect the function or safety.

2.7 Handling the product and auxiliary materials

WARNING! Handling auxiliary materials or other chemical substances

•When working with materials, detergents, oils, greases, and other chemical substances that are to be processed,

the safety and dosage information of the respective manufacturer as well as the generally applicable regulations

are to be observed.

•Residues of cleansing agents, oils, greases, and other chemical substances should be recycled or disposed of in

accordance with the relevant legal provisions.

•Local, regulatory sewage protection laws apply.

•Wear eye protection, hand protection and suitable working clothes!

Installation, upkeep, maintenance, and repair work

•Upkeep and cleaning work may only be carried out by experts or by specially trained personnel.

•Maintenance and repair work may only be carried out by trained and qualified personnel.

•After these works are completed, the proper functioning of all safety devices as well as the flawless operation of the product

must be ensured.

USER MANUAL 12

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

2.8 Basic hazards/hazardous locations

This describes in which area and between which parts hazards can occur while using the machine

Fig.2.8.1

DANGER! dangerous electrical voltage (Fig.2.8.1)

Risk of fatal injury!

•Electrostatic processes

•Protect electrical components from all types of moisture

•Work on electrical components may only be carried out by

qualified personnel

•Always disconnect the power supply before working on electrical

components!

Fig.2.8.2

DANGER! of injury to skin and eyes (Fig.2.8.2)

When the machine is in operation, there is a risk of

pressurised fluids escaping

•In the area of the machine inlet and outlet

▪Insufficient sealing between fittings

▪Loose fittings

•In the entire area of the pump body

▪Worn sealing elements

▪Damage to the running surface of the piston

▪Loose screw connections

•In the area of the return device

▪Insufficient sealing between fittings

▪Return hose (bend) not correctly attached.

Warning of hand injuries

(Fig.2.8.3)

Danger from moving components

•In the entire area of the pump

body mechanics

▪In the area of the piston

▪In the area of the gears

▪In the area of the bearing

shell

Fig.2.8.3

WARNING! Hot surfaces

Risk of burns

•Higher surface temperatures on the drive unit possible when in continuous operation!

▪Allow it to cool down before working on it

▪Use hand protection

▪Keep away from direct sunlight

▪Keep air vents clean

•Pump unit may have an increased surface temperature due to friction if in continuous operation!

▪Allow to cool before starting work on the machine

▪Use hand protection

▪Keep machine away from direct sunlight

▪Observe maintenance intervals

USER MANUAL 13

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

3.0 Transport, Storage and Interim Storage

3.1 Transport safety

•Equipment damage

3.2 Delivery of the product

•Transport inspections

•Storage

3.1 Transportsicherheit

CAUTION! when transporting with pure muscle

power

Risk of injury due to "dead weight" and incorrect transport methods

•Before carrying the machine ensure that the safety clamp fits tightly.

(see detail E)

•Only carry the machine using the existing carrying device (see Fig.

3.1.1.marked in red). Ensure in advance that the drive unit is secured

via the safety clamp. (blue arrow)

•Never carry the machine with oily or greasy hands or gloves. The

machine could slip out of your hands and create additional hazards.

•Ensure that supply lines and material hoses pose no further danger

to yourself or others.

•Wear suitable work clothes and foot protection.

Fig.3.1.1

DANGER! RISK OF FATAL INJURY caused by possible damage to the product

Incorrect transport methods may cause damage to the products concerned If damage has occurred during transport, the

corresponding components must always be checked and the functions of the device ensured by qualified personnel. Failure

to observe this advice can result in serious personal injuries and damage to the environment.

•Transport via the mains plug cable of the drive unit is strictly forbidden!

3.2 Delivery of the product

NOTE!

Check the product and the corresponding accessories for transport damage, completeness and correctness of the

consignment immediately after delivery. Claims for missing parts or damages incurred during transport can be made only

via the transport insurance if the damage from the forwarding agent (also driver) has been confirmed.

All identified transport damages - including hidden - which only become visible after opening the respective packaging,

must be reported in writing immediately to the carrier who made the delivery; if necessary a damage inspector should be

commissioned to assess the damage. The carrier who made the delivery must be in receipt of the damage notification at the

latest by the 6th day after delivery of the goods. Please send a copy of this notification to Desoi GmbH in Kalbach. In cases

of non-compliance with the above information, damage will be deemed to have occurred subsequent to delivery, according

to Section 60b of the General German Freight Forwarding Terms and Conditions (ADSp.) . In this case, the burden of proof

is reversed.

The delivery of the product success in a ready to use condition, only the accessories required in each case still have to be prepared.

The product is normally shipped in a carton box, protected against dust and moisture on a suitable palle

Transport inspections: Upon receipt of the product, immediate checks for transport damage should be carried out.

If transport damage is discovered, the necessary steps must be taken with the freight carrier or

manufacturer within the relevant time periods.

Storage: Before use or when in temporary storage, the product must be kept dry, free of frost and protected from

mechanical damage.

USER MANUAL 14

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

4.0 Information concerning the injection device

4.1 Type description

4.2 Data and function

•General information

•Functional principle of the piston pump

•Description of components

4.3 Technical data

4.4 Scope of Delivery

4.5 Accessories

4.6 Warranty & Legal Notice (Copyrights)

4.7 Safety devices

4.8 EC Declaration of Conformity

4.1 Type description

These operating instructions apply to the following machines:

Machine: DESOI PowerInject P1

Item number: 15735

Year of cnstruction: from August 2014 - (Revision C)

Date of issue: January 2019

4.2 Funktion

General:

The small, compact and powerful DESOI PowerInject P1 is suitable for machine-accessible injection resins.

The main areas of use are smaller construction site projects. The structure of the mechanism turns a rotary motion into a linear piston

movement. Operating pressures up to 200 bar can be achieved via the ratio of piston diameter, piston stroke and pressure control

valve. The special feature is that the excess medium is returned to the material container through the return discharge when the set

operating pressure is reached. Clogging of the manometer is not possible because direct contact with the injection resin is prevented

by a pressure measuring unit with membrane and oil filling.

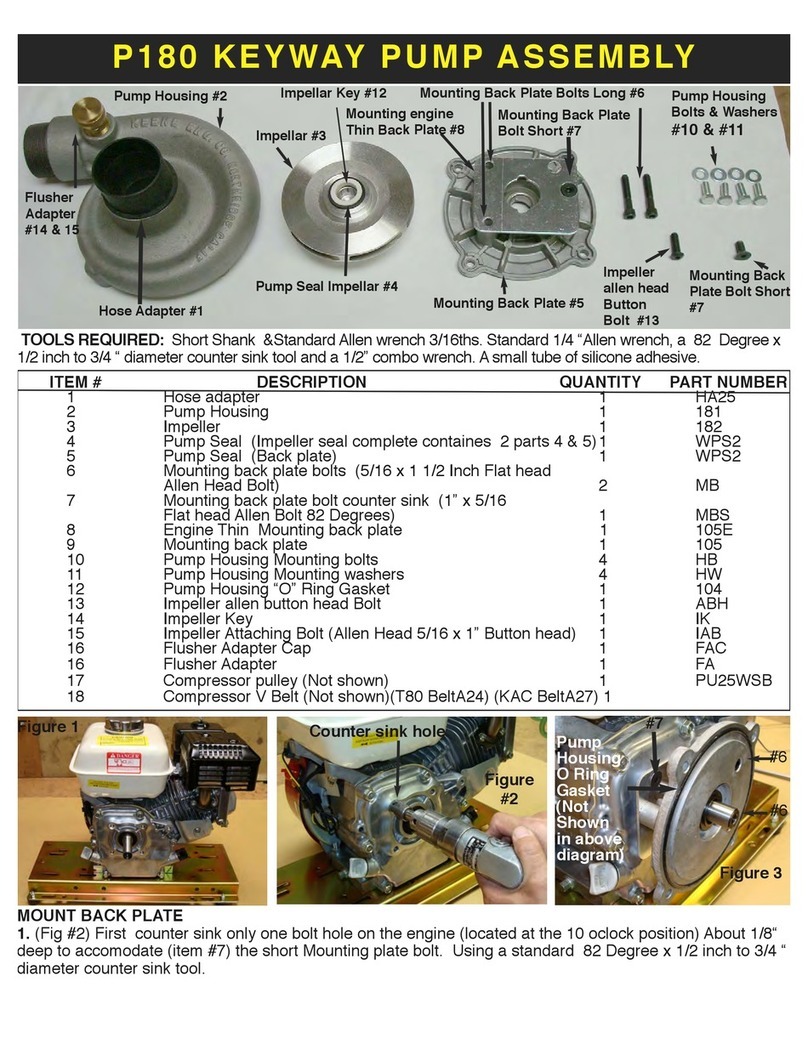

Functional principle of a piston pump: (Fig.4.2.1)

The DESOI PowerInject P1 is electrically operated. The piston operates in a suitable cylinder tube. Due to the retraction movement of

the piston, the injection material is moved from the material container into the delivery chamber. During the forward movement, the

injection material is forced out of the delivery chamber again by the outlet valve. During the forward movement, the piston closes the

inlet hole for the injection material, so that it is not immediately forced back into the material container.

Fig.4.2.1 (Function representation) (Function reprersentation : Return system)

USER MANUAL 15

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

Component description:

•Return flow system: (Fig.4.2.1)

Description - The return system is a kind of safety device. The operating principle of this system is regulated by the pressure

control valve. If the set pressure is reached and / or exceeded, the excess injection material is transported back into the

material container via a connecting line.

Advantages:

•Overload protection for the drive

•Injection material remains in motion (recirculation)

•Pressure measuring uni - this is used for pressure control. (Fig.4.2.2)

Description - The special feature of this valve is its design. This was selected so that the

respective injection material has no direct contact with the pressure gauge. In the pressure

measuring unit there are two areas separated by a diaphragm. The resulting operating pressure

(shown in red) presses the diaphragm upwards; the oil filling above the diaphragm(shown in green)

is thus compressed and the resulting pressure is transmitted directly to the pressure gauge and

displayed accurately.

Advantages:

•Pressure fluctuations and pressure deflections are strongly minimised

•Long service life of the pressure gauge

Fig.4.2.2

•Pressure regulating valve - this serves for pressure setting (Fig.4.2.3)

Fig.4.2.3 (Pressure regulating valve)

Description –On reaching the operating pressure, the pressure control

valve opens and the excess pressure is fed back into the material container

via the return flow.

ATTENTION:

The pressure control valve is a safety component. The

adjustable pressure is fixed at the factory; subsequent

adjustment by the operator is prohibited.

4.3 Technical specification

Design -230V-

The sound pressure level of this machine at a

distance of 1m is between 78 dB and 89 dB

(A) and thus under 80 dB (A).

Appropriate soundproofing agents should still be

used.

The sound pressure level was determined

according to EN ISO 11200 (using basic

standard 11203

The sound pressure level at the respective place of

operation can significantly exceed the sound pressure level

of the machine.!!!

Power requirement

230V / 50Hz

Engine power

720 W

Power output

375 W

Torque

max. 62 Nm

Speed of rotation

•1. Gear

•2. Gear

0-1200 U/min.

0-3400 U/min.

Operating pressure –infinitely

variable

10-200 bar

Delivery rate

max. 0,4 l/min.

Weight

ca. 10 kg

Height / Width / Length

(cm) 53/19/36

USER MANUAL 16

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

4.4 Scope of delivery

•Drive unit including safety clip

•Pump unit

•Return system

•Pressure gauge with manometer 0-250 bar

•Perssure control valve

•2 litre material container

•HP material hose –steel Ø 6 mm, 3 m long

•HP ball valve with mouth piece

•Tool for tensioning the piston seal

•User Manual

4.5 Accessories

NOTE

The accessory for the machine is variable depending on the application area and material. In order to achieve the optimal

injection performance, we are happy to select the accessories for you if you can tell us the material and manufacturer.

Description

Information

Item number

Spare and wear part set

15735-EVS

Set of tools

15735-WS

Hydraulic oil Mobil type HLP-68

for cleaning and preserving

1litre

5 litre

25067 / 25069

Hydraulic oil DTE 16 M

Oil filling for the pressure measuring unit

1litre

25072

HP injection gun 0 - 250 bar

whip M10x1, connection M12x1,5

16733

Soupape à bille R1/4"" H.P.

whip M10x1, connection M12x1,5

16827

Mouth piece

with M10x1 female thread

16820

DESOI Snappy

Steel version - mouth protection

16920

Sliding coupling - staight

Free passage Ø2.5 mm

Free passage Ø2.5 mm

16821 / 16831

Sliding coupling - laternal

Free passage Ø4 mm

Free passage Ø4 mm

16822 / 16837

Sliding coupling - staight

Free passage Ø1.5 mm - steel seal

16838

4.6 Warranty & Legal Notice (Copyrights)

We provide warranty for this machine for a period of 12 months from the date on the invoice

Model: DESOI PowerInject P1

Article number: 15735

Warranty for all defects based on material or manufacturing defects.

Sealing and wear parts are excluded from the warranty. Any damage caused by improper handling or overloading, the use of force

or by changes in the course of independent repair attempts are excluded from the warranty.

The warranty claim is invalidated if the operating manual is not observed, if non-listed materials are used, in the event of insufficient

cleaning and maintenance and in the event of improper handling.

The device should only be opened as specified in the operating manual instructions. Further opening or dismantling of the device

may only be carried out by trained professionals.

If you experience any operating problems, please call us or send us an email describing the fault. We will be happy to help.

The information in these operating instructions has been carefully checked. However, no liability for errors is assumed.

Legal notice:

These operating instructions may not - either in whole or in part - be electronically or mechanically reproduced, distributed,

modified, transmitted, translated into another language or used for any other purposes without the express permission of Desoi

GmbH. Desoi GmbH is not liable for damages resulting from the fact that the operating instructions were not or only partially

observed. The handover of the operating instructions does not constitute any entitlement to a license or use.

USER MANUAL 17

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

4.7 Safety devices:

Safety:

NOTE:

Always ensure that the safety devices function correctly!

The machine must not be operated with defective or missing safety devices!

In conjunction with rotating components, the wearing of conventional gloves is prohibited!

DANGER! Risk of death!

Improper installation and improper electrical connections can be life-threatening.

•Electrical connection may only be performed by licensed electricians and in accordance with the applicable

regulations!

•Observe the regulations for the prevention of accidents

DANGER!

If protection devices are not installed on the pneumatic controllers or the entire injection unit, serious injury may result.

In some circumstances this can be life threatening

•Before startup and after maintenance work, any safety devices that have been removed (e.g. terminal box covers

or coupling covers) must be reinstalled.

•Keep your distance during startup.

•Wear protective clothing, protective gloves, safety shoes, and goggles for all work

DANGER!

In accordance with 1999/92/EC, the machine must not be operated in "any" areas of explosive atmospheres.

The machine is equipped with the following safety devices. These must not be removed or manipulated under any circumstances:

•Lateral cover plates

•Safety clamp of the drive unit

•pressure measuring unit

•pressure regulating valve

USER MANUAL 18

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

4.8 Declaration of Conformity with EC regulations

In accordance with machinery directive 2006/42/EC amended by 2009/127/EC of 15 December 2011

The manufacturer / distributor Desoi GmbH

Gewerbestraße 16

36148 Kalbach

hereby declares that the following product:

Product name: DESOI InjectPower P1

Serial number: from EP600 (Revision: C)

Model / type description: electric piston pump

complies with all relevant provisions of the above directive and the other applicable directives (below) –including the amendments in

effect at the time of declaration.

The following harmonised standards were applied:

EN ISO 11203:2009 Acoustics - Noise emitted by the machinery and equipment - Determination of emission sound

pressure levels at a work station and at other specified locations from the sound power level (ISO

11203:1995)

EN ISO 12100:2010 Safety of machinery - General principles for design - Risk assessment and risk reduction (ISO

12100:2010)

EN ISO 13857: 2008 Safety of machinery - Safety distances to prevent hazard zones being reached with the upper and

lower limbs (ISO 13857: 2008)

The following national or international standards (parts / clauses thereof) and specifications were applied:

•not specified

Name and address of the person authorised to compile the technical documents: Desoi GmbH

Gewerbestraße 16

D-36148 Kalbach / Rhön

Germany

Kalbach, 21. January 2019

Siegfried Desoi Michael Engels Martin Desoi

Managing director Managing director Managing director

Copy of the Original Declaration of Conformity

Translation of the Declaration of Conformity

USER MANUAL 19

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

5.0 Startup procedure

5.1 Safety instructions for the startup procedure

5.2 Switching positions of driving unit

5.3 Procedure / Preparation for commissioning

•Checks after the commissioning

5.1 Safety instructions for the startup prodedure

NOTE!

•The product may only be used with a FI (error protection switch 30 mA) or with a PRCP (personal safety switch) on

the supply grid.

•Please note the processing times of the materials used. Material that is already hardened or that has undergone

a reaction can damage machine parts and accessories that come into contact with it.

•The machine may at no time be started under full load. If the machine is started under full load, overload

protection is activated and the machine switches off promptly.

DANGER! Danger to life!

Improper installation and improper electrical connection can be life-threatening.

•Observe accident prevention regulations!

CAUTION! unexpected, automatic start-up of the machine is possible!

Before connecting the power supply, the ball valve on the pneumatic control must be brought into the closed position. It

is only in this way that an automatic startup of the machine can be prevented.

HAZARD! due to discharging pressurised feed medium

Serious injuries may result from defective sealing elements or damage to necessary accessories.

•The respectively required injection head should never be directed at yourself or others.

•Eye protection, hand protection and suitable work clothes as well as work shoes must be worn!

•Before each start-up, the fluid hose and the respective injection head must be inspected for wear, damage and

proper fit.

•Maintenance intervals must be observed

WARNING! from getting caught or crushed between moving components

The resulting pumping movements may result in danger of jamming or crushing between moving components.

•During a pump cycle, it must be ensured that no other person can intervene in the created danger area.

•Only operate after the protective cover of the pneumatic control unit has been installed

CAUTION! Risk of injury due to improper body posture (postural problems)

A healthy posture must be maintained while carrying out any work on the machine.

•In case of prolonged exposure, posture may need to be changed. (e.g. squatting and kneeling)

Harmful to health!

Contact with processing materials, cleaning agents or auxiliary lubricants can lead to hazards.

•Protective clothing, protective gloves, safety shoes and goggles must be worn.

•In case of contact, the affected area should be cleaned immediately.

•Technical data sheets and safety data sheets of the manufacturer of the processing medium and the cleaning

agent must be observed and adhered to.

•Please note the processing times of the materials used. Material that is already hardened or that has undergone a

reaction can damage any machine parts and accessories that come into contact with the material.

•The consumption of foodstuffs is strictly prohibited in conjunction with feed materials, cleaning agents and

auxiliary lubricants.

ATTENTION!

Supply and connection lines (material hose) can become tripping hazards!

•Lay material and supply lines in such a way that no additional source of danger emanates from them.

USER MANUAL 20

DESOI GmbH | Gewerbestraße 16 | D-36148 Kalbach | Phone +49 6655 9636-0 | Fax +49 6655 9636-6666 | [email protected] | www.desoi.de

5.2 Switching positions of driving unit

Direction –of - rotation switch:

Fig.5.2.1

Direction of rotation "right".

Direction of rotation "left".

NOTE!

In all operating modes of the machine, the direction of rotation

switch must be set to "clockwise".

Gear switch:

Fig.5.2.2

Fig.5.2.3

The drive unit has a two-stage gearbox. With

the gear switch, the maximum speed range

can be limited in advance. For this purpose

switch off the drive unit, press the push

button (red circle) into the switch and move

the switch to the desired position.

Position 1

Speed range from 0 –1200 U/min

Position 2

Speed range from 0 –3400 U/min

Main switch with latching function and speed controller

Fig.5.2.4

1. Main switch

2. Speed controller

3. Snap-in push-button

If the drive unit is connected to a suitable energy

source, it can be started by pressing the main switch

(push into the handle).

The drive unit is put into the continuous operating

state by simultaneous additional actuation of the

latching pushbutton. This can only be reset by

pressing the main switch. Via the speed controller,

the speed can also be controlled separately by

turning from "A to F".

Fig.5.2.5

Function switch

Fig.5.2.6

„Punch“

„screwing“

NOTE!

It is essential to ensure that the function switch of the drive unit is set

to the "Screws" symbol and not to the "Impact" position, as this is

the only way to ensure smooth and gentle working with the machine.

Switch off the drive unit before switching over!

Table of contents