1. Important instructions 05...........................................................................................

2. Orientations 06................................................................................................................

3. Introduction 06...............................................................................................................

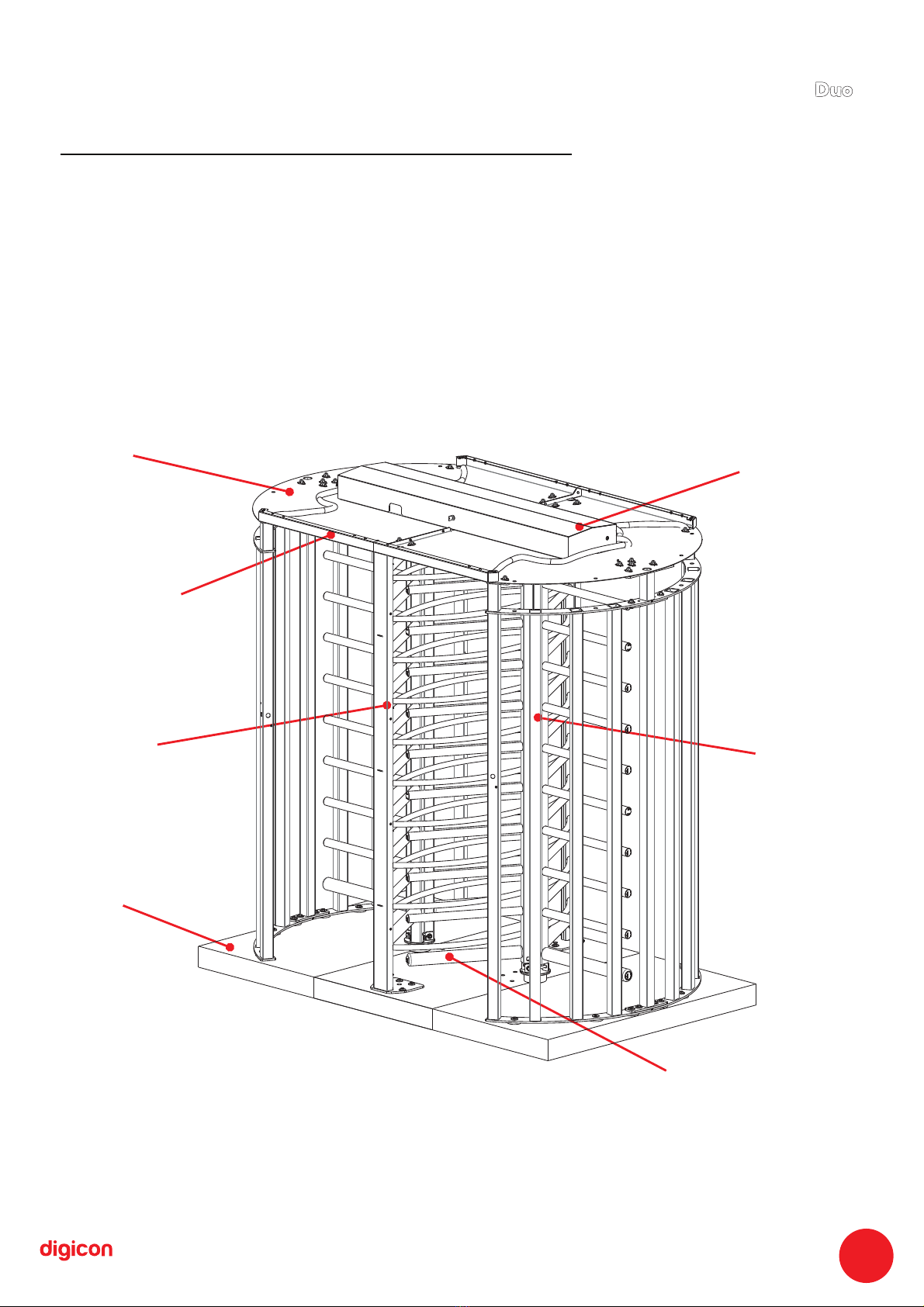

4. Features of Turnstile Duo 07.....................................................................................

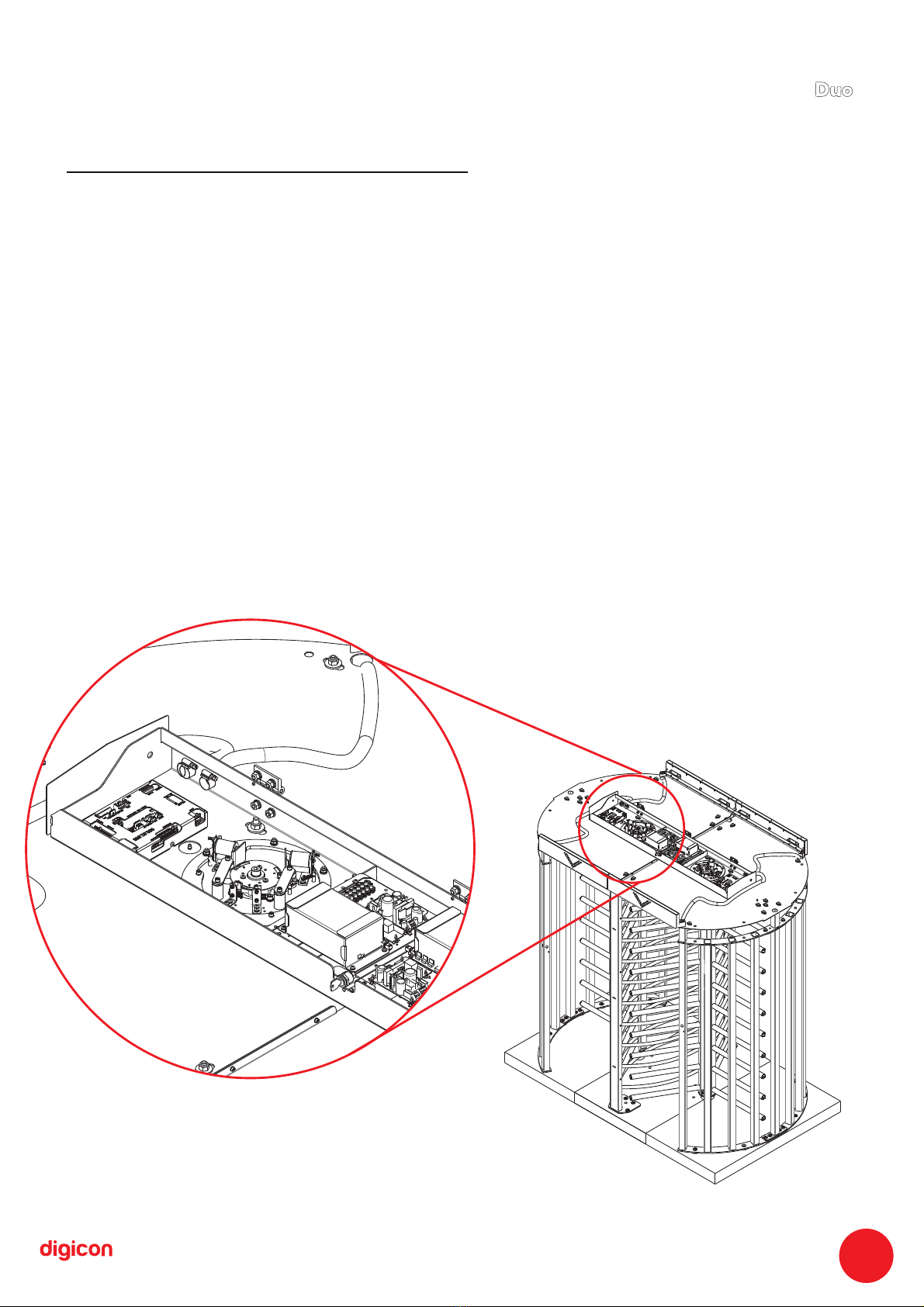

5. Turnstile Duo operation 08.........................................................................................

6. Installing Duo 09............................................................................................................

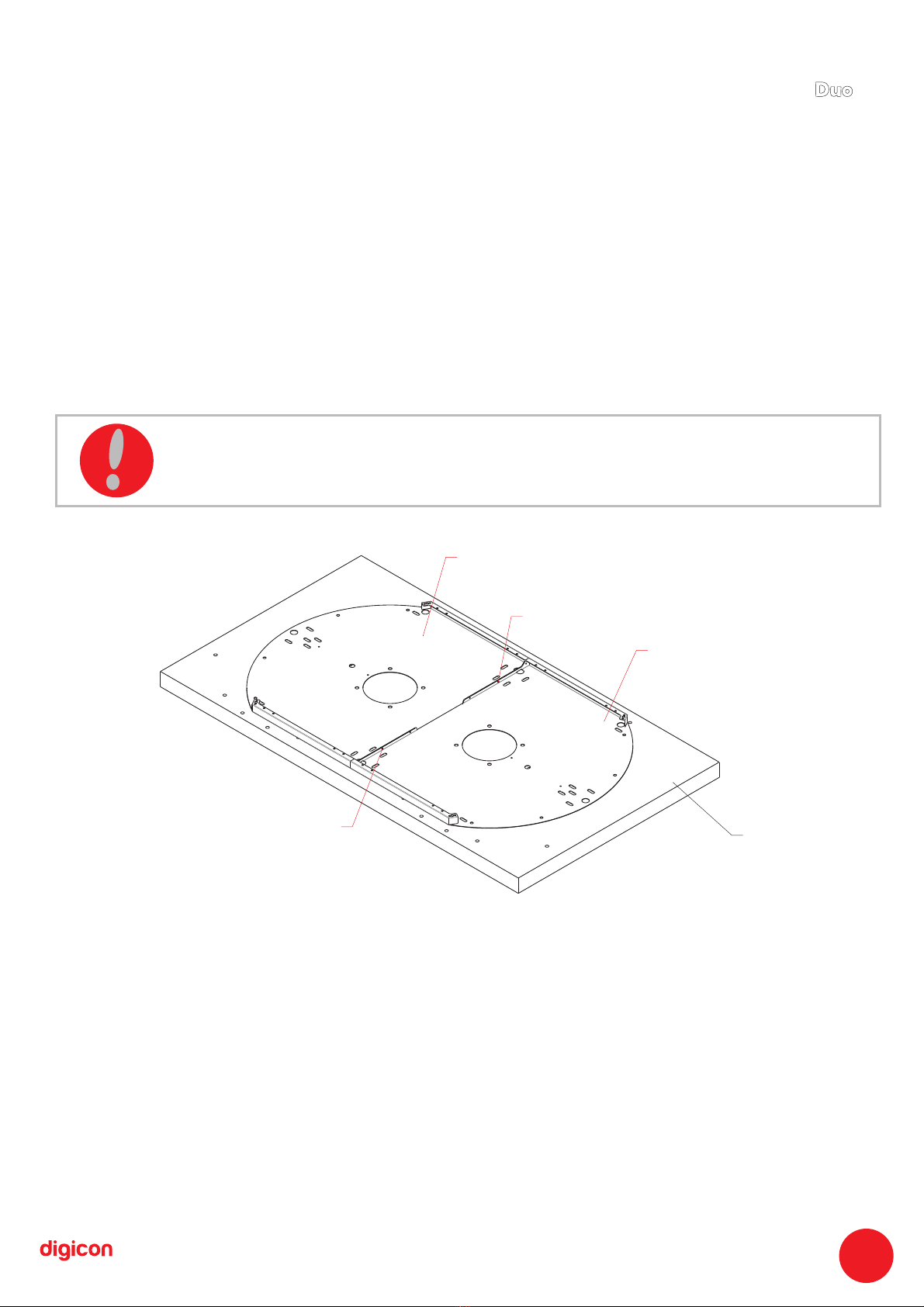

6.1 Preparing assembly of Duo 09...............................................................................

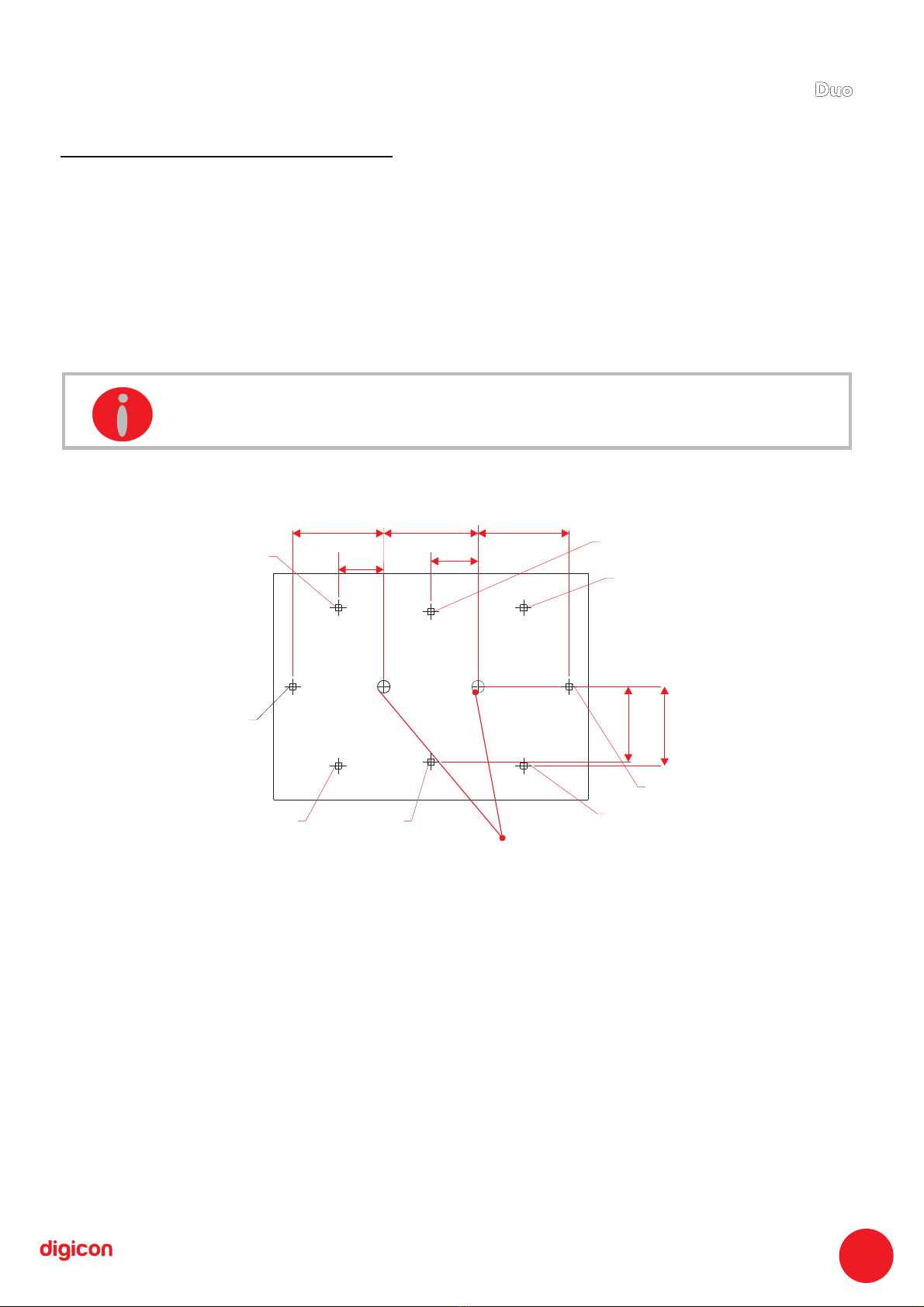

6.2 Drilling device 10.........................................................................................................

6.3 Lateral assembly with rods or glasses 11..........................................................

6.4 Assembling the arms 12...........................................................................................

6.5 Fixing bearing rods 14..............................................................................................

6.6 Fixing the sides 15......................................................................................................

6.7 Assembling stationery arms 16..............................................................................

6.8 Fixing stationery arm 17..........................................................................................

6.9 Fixing the roof 18........................................................................................................

6.10 Fixing the coverage 19...........................................................................................

6.11 Fitting the pivoting arm 20...................................................................................

6.12 Fitting the lock system 21.....................................................................................

6.13 Cable passage 22.....................................................................................................

6.14 Mounting the card reader bracket 22................................................................

6.15 Turnstile assembled 23...........................................................................................

7. Optional items 23..........................................................................................................

7.1 Power supply 23...........................................................................................................

7.2 ontrol board 24C ..........................................................................................................

7.2.1 Inputs 26....................................................................................................................

7.2.2 Outputs 27.................................................................................................................

7.3 Configuration of control board – switch Ds1 29..............................................

7.4 Examples of configuration 29.................................................................................

7.5 serial communication 30...........................................................................................

7.6 Orientation pictogram kit 31..................................................................................

8. Module 31MCA ...............................................................................................................

8.1 Powering up Duo 32....................................................................................................

8.1.1 Initializing Duo 32.....................................................................................................

8.1.2 Configuring Digicon Firmware 32.....................................................................

9. Maintenance 35..............................................................................................................

9.1 Preventive and corrective maintenance routine 35........................................

9.2 defects, causes, and solutions 37.........................................................................

9.3 Dimensions 38..............................................................................................................

9.4 Other information 40.................................................................................................

10. Warranty and technical assistance 41.................................................................

Contents:

Turnstile

Duo