Detroit Radiant Products GPH Series User manual

This heater

must

be installed and serviced by a Gas Safe Registered Gas Engineer

only! Conversion of the heater for use with other gases must be carried out by a Gas

Safe Registered Gas Engineer. Read these instructions carefully before attempting to

install, operate or service the heater.

This heater is not approved for use in indoor residential applications and must

never be install indoor in the home. This heater may only be used in outdoor residential

applications or indoor/outdoor commercial (or industrial) applications. Installation in

residential indoor spaces may result in property damage, asphyxiation, serious injury

or death.

Failure to comply with these warnings and instructions, and those on the heater, could

result in personal injury or death.

WARNING

!

For Use in the UK (GB) and Ireland (IE) Only. These instructions are only valid if the country code

appears on the appliance. If the code does not appear on the appliance, refer to the technical instructions

for adapting the appliance to the conditions for use in that country.

0086

© 2011 Detroit Radiant Products Co.

LIOGPH-Rev. 23411

Print: 2M-9/10-r1_8/22/11(DRP)

Replaces: LIOGPH-1m-5/08(DRP)

WARNING

!

Keep these instructions for future reference.

For Your Safety

If you smell gas:

• Shut off gas to the appliance. • Call your gas supplier. Do not use any phone in your building.

• Extinguish any open flame. • Follow the gas supplier’s instructions.

• Do not try to light any appliance. • If you cannot reach your gas supplier, call the fire department.

• Do not touch any electrical switch.

GPH Series Manual

Gas-Fired High Intensity Patio Heater

Installation, Operation,

Maintenance and Parts

NOTICE

Contents

1.0 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Applications.......................................................... 3

Safety Signs and Labels ................................................ 4

Regulations and General Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Design.............................................................. 6

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting the Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Clearance to Combustibles..............................................10

Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.0 Operation ................................................................15

Pre-Commissioning....................................................15

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Sequence of Operation.................................................17

Heater Control Wiring ..................................................17

4.0 Maintenance..............................................................18

Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Replacement Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Converting Gas Type...................................................21

5.0 Parts ....................................................................23

Heater Component Breakdown...........................................23

Heater Component Parts List ............................................24

2

WARNING

!

WARNING

!

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, serious injury or death. Read and understand, the installation,

operating and maintenance instructions thoroughly before installing or servicing this

equipment. Only Gas Safe Registered Gas Engineers and service personnel may

install or service this equipment.

3

1.0 Safety • Applications

Applications

This heater is certified for use in both commercial and outdoor domestic installations. Ventilation

requirements vary according to the type of installation.

Commercial Installations

The heater may be installed indoors in commercial buildings subject to the ventilation requirements of the

space to be heated. Refer to page 14.

Infrared heaters are designed and certified for use in industrial and commercial buildings such as outdoor

restaurant patios, warehouses, manufacturing plants, aircraft hangars and vehicle maintenance shops.

For maximum safety, the building must be evaluated for potential hazards before installing the heater

system. A critical safety factor to consider before installation is the clearance to combustibles.

Outdoor Domestic (Residential) Installations

This heater is NOT suitable for use in any indoor residential situation. It may be installed outdoors subject

to the following conditions:

The heater must be installed in accordance with the requirements of EN 14543:2005 and other relevant

standards. The heater must be protected against direct rainfall by a roof, canopy or other means. Ensure

that clearances to combustibles (See Table 2.2, page 10) are maintained at all times and that the area is

amply ventilated. Refer to page 14.

Not For Indoor Residential Use. Installation of an infrared heater system in

residential indoor spaces may result in property damage, asphyxiation,

serious injury or death. In residential applications, this heater may only be

used outdoors.

1.0 Safety

WARNING

!

Storage of petrol or other flammable vapors or liquids in the vicinity of this or any other

appliance may result in fire or explosion.

1.0 Safety • Safety Signs and Labels

4

!

CLEARANCE TO COMBUSTIBLES

FIRE HAZARD. Always maintain published clearance to combustibles.

In locations used for the storage of combustible materials, signs must be

posted. Consult manual for additional guidelines.

MODEL NO.

DANGER

SIDE(S) BELOW TOP BEHINDEND(S) FRONT

ALL MODELS

(in millimeters)

MOUNTING

ANGLE

0°

0°

30°

30°

22”

559mm

22”

559mm

14”

356mm

N/A

N/A

46”

1168mm

46”

1168mm

13”

330mm

17”

432mm

N/A

N/A

8”

203mm

N/A

N/A

46”

1168mm

ALL MODELS

(in inches)

Contact may cause burn.

Do NOT touch hot surface.

Allow to cool before

servicing.

This heater must be installed

by qualified personnel only

and in accordance with the

latest edition of the

ANSI/NFPA Standards.

(ANSI/NFPA 88A Parking Structures), 88B

(Repair Garages), 409 (Aircraft Hangars).

Observe all country, state and local codes.

LIGHTING INSTRUCTIONS

1. Rotate heater’s valve knob to “ON” position.

2. Close electrical circuit (usually thermostat).

3. If the heater fails to light, turn “OFF” gas, open electrical circuit and wait 5 minutes

before repeating.

Avoid Serious Injury or

Death. Improper installation,

adjustment, alteration, service

or maintenance can cause

property damage, injury or

death. Read the installation, operation and

maintenance manual thoroughly before

installing or servicing this equipment.

This is not an explosion-proof heater. Where

there is the possibility of flammable vapors or

dusts, consult the local fire marshal, fire

insurance carrier or other authorities for

approval of the proposed installation. Always

maintain minimum ventilation requirements.

30°

This side down

END VIEWSIDE VIEW 0° Mounting END VIEW

30° Mounting

The minimum end clearance is 22” or 559mm.

F/N: LLDR009 - Observe Proper Gas Type (Natural Gas)

F/N: LLDR010 - Observe Proper Gas Type (LP Gas)

Safety Signs and Labels

It is important to provide warnings to alert individuals to potential hazards and safety actions. It is

important to post a sign “specifying the maximum permissible stacking height to maintain the required

clearances from the heater to the combustibles” near the heaters thermostat or in absence of such

thermostats in a conspicuous location.

Safety warning labels must be maintained on the infrared heater. Illustrations of the safety labels, and their

locations, are pictured below. In locations used for the storage of combustible materials, signs must be

posted to specify the maximum permissible stacking height to maintain the required clearances from the

heater to combustibles. Signs must either be posted adjacent to the heater thermostats or in the absence

of such thermostats in a prominent location.

Top Panel

F/N: LLPCL003

230V Patio Heater

Clearance to Combustibles Label

WARNING OBSERVE

PROPER GAS

DO NOT

ROTATE CONTROL

ASSEMBLY FOR

GAS TYPE

ONLY

USE TWO

WRENCHES

TO TIGHTEN

5

1.0 Safety • Regulations • General Specifications

Regulations

Notwithstanding their limited scope, this appliance must be installed in accordance with the relevant

provisions of the following regulations:

UNITED KINGDOM

Gas Safety (Installation and Use) Regulations 1984 and BS 6896:2005. Due account should be taken of

any obligations arising from the Health and Safety at Work etc Act 1974, the current Building Regulations,

the current I.E.E. Regulations and other relevant codes of practice.

IRELAND

I.S. 3212:1987, ICP 4, I.S. 327. Due account should be taken of any obligations arising from the current

Building Regulations, the current I.E.E. Regulations and other relevant codes of practice.

General Specifications

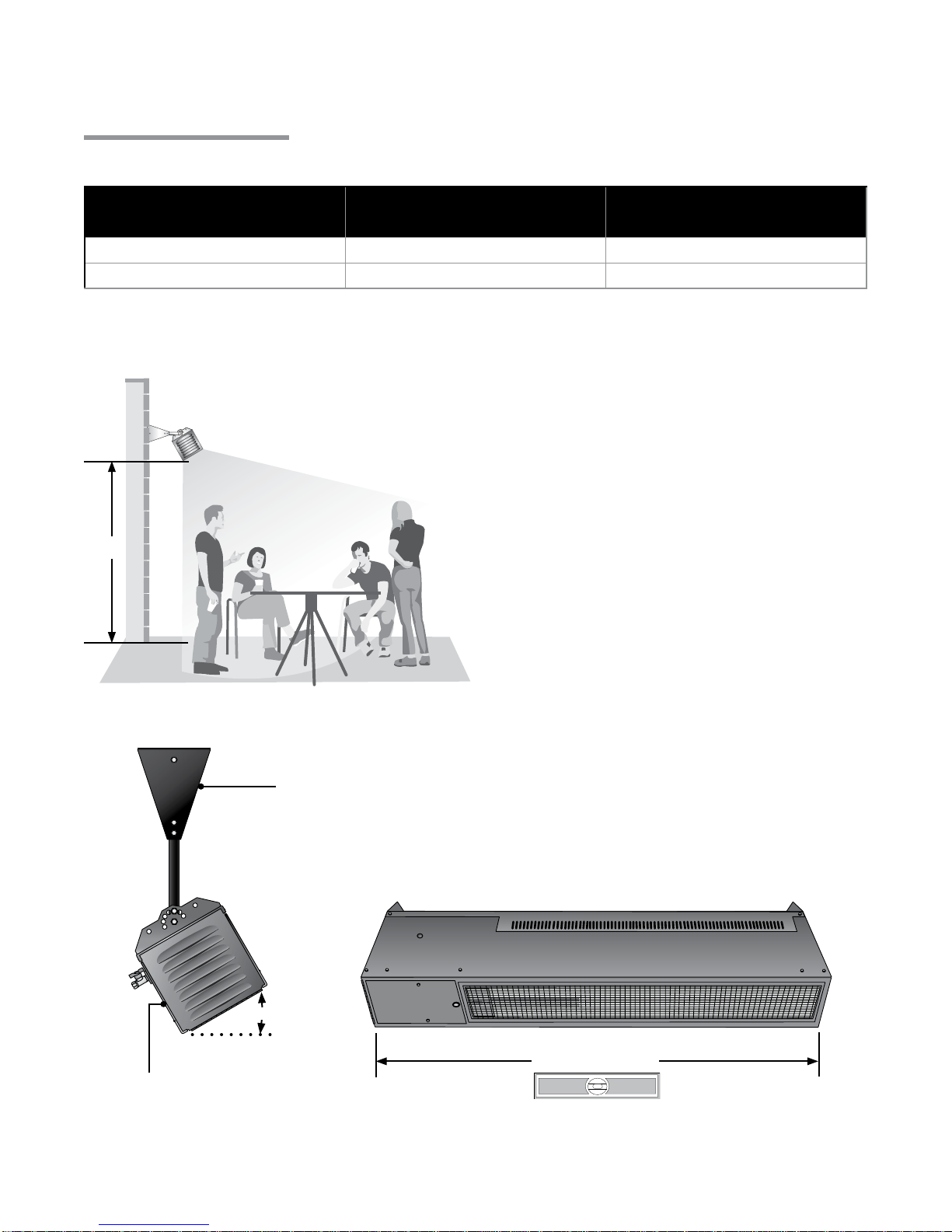

Figure 1.1 • Main Dimensions

END VIEW

216 mm

229 mm

SIDE VIEW

1074 mm

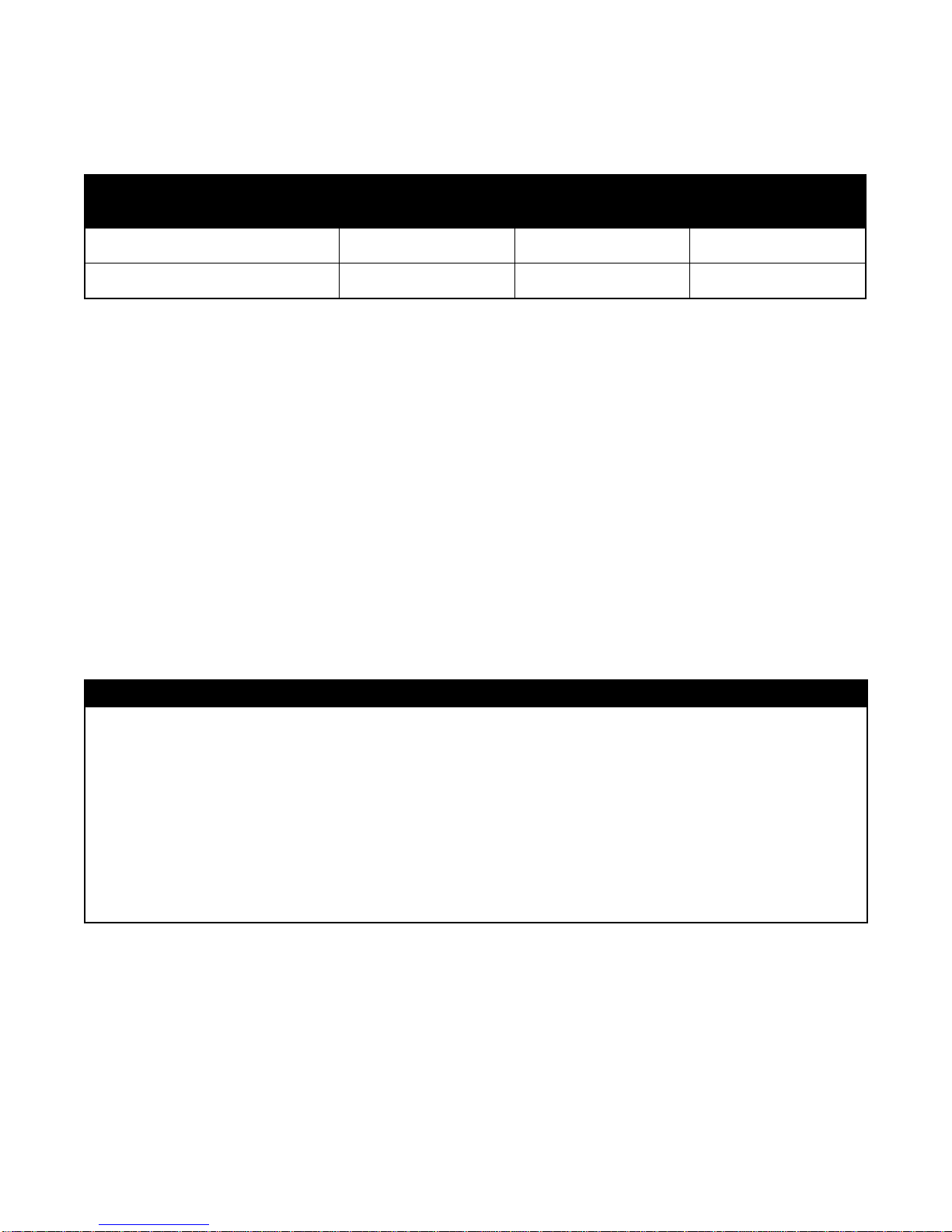

Model No. Nominal

Input Weight

(kg) Nox

Class Electrical Supply

Voltage Current Frequency Max. Power

GPH 9 9 kW 26 Class 4 230V 0.15A 50Hz. 38W

GPH 10 10 kW 26 Class 4 230V 0.15A 50Hz. 38W

Table 1.1 • Specifications

6

1.0 Safety • Design

To ensure a safe, properly designed heating system, a layout should be developed for the correct

placement of the infrared heater(s). Aside from safety factors such as clearance to combustibles

(see Table 2.2 on page 10), you should take into consideration:

• The environment (e.g., is it cold/drafty, average, protected)?

NOTE: The effective infrared surface temperature of a person or object may be diminished

with wind above 10 kph, wind barriers may be required.

• What is the area of heat coverage needed?

• Is the heater being used in a social gathering area, or work station(s)?

• The mounting height of the heater (see Table 2.1, Figure 2.1, page 8).

• The type of mounting to be used.

• Gas supply and connections.

• Combustion, ventilating air supply and exhaust path.

• Electricity and wiring to the heater.

This installation manual along with local codes and regulations address these issues. It is critical that you

read, understand and follow all guidelines and instructions. Always inspect and evaluate the mounting

conditions, space for exhaust, gas supply and wiring.

Design

IMPORTANT: Fire sprinkler heads must be located at an appropriate distance from the heater. This

distance may exceed the published clearance to combustibles. Certain applications will require the use of

high temperature sprinkler heads or relocation of the heaters.

Sprinkler systems containing propylene glycol or other flammable substances are not to be used in

conjunction with this heater without careful consideration for and avoidance of potential fire or explosion

hazards.

7

2.0 Installation • Mounting the Heater

2.0 Installation

WARNING

!

Read and understand, the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Only Gas Safe Registered Gas Engineers and service personnel may install or service

this equipment.

To ensure your safety, and comply with the terms of the warranty, all units must be installed in accordance

with these instructions.

WARNING

!

Mounting the Heater

Improper suspension of the infrared heater may result in collapse and persons being

crushed. Always suspend from a permanent part of the building structure that can

support the total force and weight of the heater.

Failure to maintain minimum clearance to combustibles may result in fire and/or explosion,

property damage, serious injury or death. Always maintain minimum clearances and post

signs where needed. Signs should state the hazards for the particular application and be

legible for the building occupants. Consult the factory or a factory representative for

additional information on signage compliance.

The heater can be suspended with chains or rigid threaded rod. Regulations, codes, or conditions such

as wind drafts or other variables can cause movement of the heater and may require rigid threaded rod.

Avoid excessive movement and/or vibration of the gas connection by rigidly mounting the heater (see

Figure 2.3). Optional mounting brackets (P/N: PH-BKT) can be used in place of rigid threaded rods.

Consult all applicable codes and regulations before installation.

The heater must be level from end to end and can be set at an angle between 0° and 30° from horizontal.

The gas connection and power cord must be located on the lower side (see Figure 2.2).

Whenever possible, fit the heater at the recommended fixing height above floor level (Table 2.1).

When considering heater position, ensure that the required minimum clearances between the various

heater surfaces and combustible material are preserved (Table 2.2).

WARNING

!

Conditions such as wind drafts or other variables can cause movement of the heater and

may require it to be rigidly mounted. Avoid excessive movement and/or vibration of the

gas connection by rigidly mounting the heater.

8

Table 2.1 • Recommended Mounting Heights

Model & Input Recommended Fixing Height

(Dim. A) Approximate

Area Covered

GPH 9 (9 kW) 2000 to 2700 mm 6.0 m2

GPH 10 (10 kW) 2000 to 3100 mm 7.5 m2

A

Figure 2.1 • Recommended Mounting Heights

NOTE: This table is provided as a guideline. Actual conditions dictate variances from this data.

Level end to end

Optional mounting

bracket (P/N: PH-BKT)

30° End

Figure 2.2 • Heater Orientation

End

Mounting the Heater

The heater must be level end to end and mounted

between a 0° to 30° angle from horizontal

2.0 Installation • Mounting the Heater

When mounting the heater on an angle

(0-30°), the gas inlet and power cord

must be located towards the lower side

of the heater (towards the floor).

9

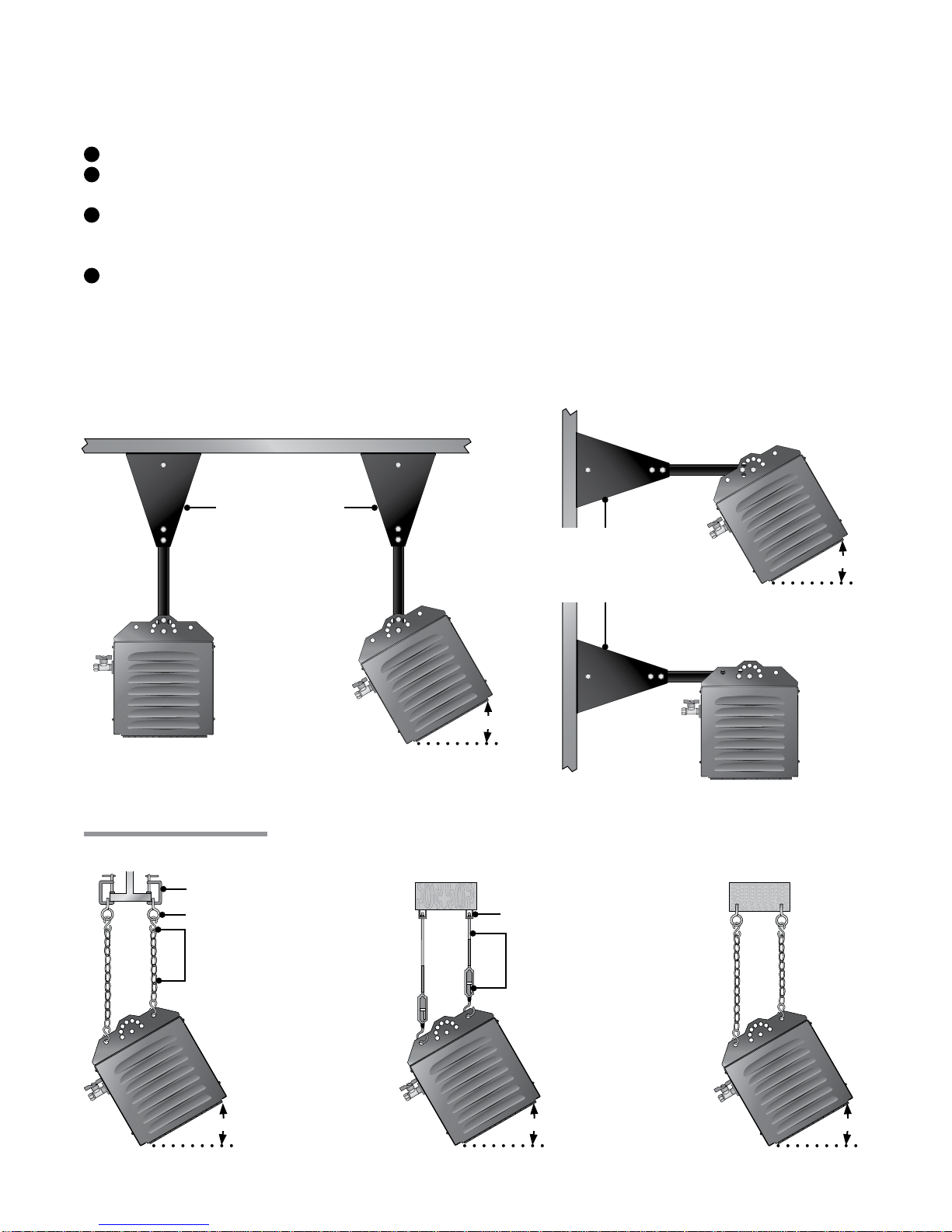

Figure 2.3 illustrates the most common methods for heater mounting. Depending on the type of mounting

you use, be sure to:

Prepare mounting surface. If necessary, weld blocks to mounting structure, drill holes, etc.

Fasten beam clamp, screw hook or other type of suspension anchor to hanging point.

Attach and close S-Hook (P/N: S-HOOK) and #1 double-loop chain (P/N: THCS includes a 1524 mm

chain and two S-hooks, four required) to anchor. Check that it is securely attached.

Attach heater to chains. Adjust chain lengths until the heater is level and equal weight distribution is

achieved. Chains must be straight up and down, do not install chains at an angle.

NOTE: Conditions that would cause the unit to move (e.g. wind drafts, blowers, crane rails, etc.) or codes

may require the heater to be rigidly mounted.

Optional mounting

bracket (PH-BKT)

attached to ceiling. Optional mounting

bracket (PH-BKT)

attached to wall.

Figure 2.3 • Common Heater Mounting

0-30°

0-30°

0° Mounting Angle

30° Mounting Angle

30° Mounting Angle0° Mounting Angle

2.0 Installation • Mounting the Heater

Steel C-clamp

Screw Hook

S-Hook and

#1 double-loop

chain (recommended)

Bar Joist Clip

Rigid threaded rod

and turnbuckle

(field supplied)

Wood Beam

I-Beam Concrete Beam

0-30° 0-30° 0-30°

Other Heater Mounting

1

2

3

4

30˚

10

2.0 Installation • Clearance to Combustibles

Figure 2.4 • Clearance to Combustibles

Below

Side Side

End

END VIEW

0° ANGLE

Top

Clearance to Combustibles

When installing the infrared heater system, the minimum clearances to combustibles must be maintained.

These distances are shown in Table 2.2 and on the minimum clearance to combustibles label

(F/N: LLPCL003) found on the heater.

WARNING

!

Failure to comply with the published clearances to combustibles could result in personal

injury, death and/or property damage.

In locations used for the storage of combustible materials, signs must be posted to

specify the maximum permissible stacking height to maintain the required clearances

from the heater to the combustibles. Signs must either be posted adjacent to the heater

thermostats or in the absence of such thermostats, in a conspicuous location.

Table 2.2 • Clearance to Combustibles in millimeters (see Figure 2.4)

Certain applications (awnings, fabrics, plastics, sprinklers, insulation) may require the heater to be

mounted at a distance in excess of the published clearances to combustibles. Contact the factory.

IMPORTANT! If the heater is mounted beneath a non-combustible surface a 200 mm minimum top

clearance must be maintained from the top of the heater to prevent overheating the controls.

Model No. Mounting

Angle* Sides Behind Top Below End(s) Front

GPH 9

(9 kW) 0° 360 N/A 330 1170 560 N/A

30° N/A 200 430 1170 560 1170

GPH 10

(10 kW) 0° 360 N/A 330 1170 560 N/A

30° N/A 200 430 1170 560 1170

* Heaters mounted on an angle between 0° to 30° must maintain clearances posted for 0° or 30°;

whichever is greater.

Front

Behind

Below

Top

END VIEW

30° ANGLE SIDE VIEW

End

10 11

2.0 Installation • Gas Supply

Gas Supply

WARNING

!

IMPORTANT! Before connecting the gas supply to the infrared heater(s):

• This appliance must be used on a governed gas supply.

• Gas and electrical lines must not be located in the path of exhaust or in direct contact with infrared rays.

• Check for conditions such as drafts or other variables which might cause excessive movement of the

unit and cause damage to the gas connection. Ensure that the unit is securely mounted and connect the

gas with an approved connection device suitable for the environment of use.

• The gas supply to the heat must terminate with an isolation cock and a flexible connector. This will

allow the heater to be disconnected for maintenance or repair. The gas outlet shall be in the same room

as the appliance and the gas connector must not be concealed within or run through any wall, floor or

partition.

• All pipe work must be supported and installed in accordance with the regulations listed on page 5 and

provide the required operating gas pressure and volume for the appliance. Pipes of a smaller size than

the heater inlet gas connection must not be used. Consult gas company for correct sizing.

• The final connection is made to the heater gas valve. This has a pipe thread EN 10226 Rp 3/8”. A

flexible metallic hose conforming to B.S. 6501:1991 (minimum specification type B Class 1) must be

used for this purpose. This must be kept clear of the flue products opening at the top of the heater and

should be of adequate length.

• Take care when making the final connection to the gas valve not to apply excessive turning force to the

gas valve. Always use two wrenches when tightening mating piping connections.

• If all or a portion of the gas supply line consists of used pipe, it must be cleaned and then inspected to

determine its equivalency to new pipe.

• Pressure test all main supply lines according to local codes. Isolate the heater gas valve and supplied

ball valve during this test.

• Test the final connection to the heater for leaks according to the relevant codes of practice.

WARNING

!

Testing for gas leaks with an open flame or other sources of ignition may lead to a fire or

explosion and cause serious injury or death. Test in accordance with relevant codes of

practice.

Failure to install, operate or service this appliance in the

approved manner may result in property damage, asphyxiation,

injury or death. This heater must be installed and serviced by

Gas Safe Registered Gas Engineers and service personnel only.

The installation of this heater must conform to the requirements of EN 14543:2005 and other relevant

standards.

12

2.0 Installation • Gas Supply

Table 2.3 • Gas Pressure

The following information is valid for heaters supplied in the UK and Ireland using either natural gas or

propane fuel. Please check heater data plate and packaging to verify fuel type. Refer to page 21 for

information on converting heater for use in other countries.

NOTE: The gas pressure governor has been factory preset.

Gas Supply from LPG Cylinders

This heater may be supplied with LP gas from cylinders. It is essential the propane gas cylinders used

are sufficiently sized to ensure an adequate supply of gas to the heater. This heater is intended to be

permanently installed and supplied with gas via a metal piping system. Flexible tubing or hose is not

recommended.

A suitable regulator must also be used to supply the correct inlet pressure and gas flow rate to the

heater. A minimum flow rate of 0.72 kg/h is required. The maximum regulator pressure is 37 mbar.

Gas cylinders should not be located in any position where it is exposed to direct heat from the heater.

All relevant standards and local codes must be complied with when choosing a location for the gas

cylinders.

Consult the gas supplier for further information on propane cylinders, regulators and cylinder location.

When using LPG Cylinders

• Change the gas cylinder in an amply ventilated area, away from any ignition source (such as

candles, cigarettes or other flame producing sources).

• Check that the regulator seal is properly fitted and able to fulfill its function.

• In the event of a gas leakage, the appliance shall not be used and the gas supply shall be shut off

and the issue investigated and rectified before using the appliance.

• Check the gas piping at least once per month and each time the cylinder is changed.

• Ensure that the tightness of the cylinder’s regulator connection is adequate to ensure the no gas

leakage can occur.

Table 2.4 • LPG Cylinder Information

Type of Gas Burner Pressure

Setting Minimum Inlet

Pressure Maximum Inlet

Pressure

Natural (G20) 12.5 mbar 15 mbar 20 mbar

Liquefied Petroleum (G31) 26.5 mbar 30 mbar 37 mbar

13

2.0 Installation • Electrical Requirements

WARNING

!

This heater must be earthed.

Incorrect or improper wiring may result in shock, injury or death. Do not touch the

ignition, flame detection electrodes or any part of the circuitry while the power is

connected to the heater. These parts carry high voltage at all times and will produce an

electric shock if touched.

A 230V-50Hz single phase supply is required.

All wiring must comply with I.E.E. and local authority recommendations. The main lead wiring used on

this appliance is colored in accordance with the following:

Earth: Green and Yellow

Neutral: Blue

Mains: Brown

NOTE: If the mains lead is damaged, it must be replaced by a special cord or assembly available from the

manufacturer or distributor.

The method of connection to the electrical supply must facilitate complete isolation and should

preferably be made via a fused double pole isolator having a contact separation of at least 3 mm in all

poles and supply the appliance only. An alternative connection may be made via a fused three pin plug

and an unswitched shuttered socket both complying with the requirements of B.S. 1363.

Ensure that live, neutral and earth are connected properly as the flame detection circuit will not operate

if polarity is reversed.

A thermostat may be installed to control the heater in indoor applications if desired. The thermostat

should be located in the heated area at a height of approximately 1.5 m above floor level and in a

position where it is not directly irradiated by the heater. The use of thermostats in outdoor locations is

not recommended.

Electrical Requirements

IMPORTANT! Radiant heat may damage the flexible power cord. Always keep the flexible power cord

away from the heater. Do not allow the power cord to be subjected to radiant heat.

14

2.0 Installation • Ventilation

Ventilation

WARNING

!

Improper or insufficient ventilation may result in explosion, fire, health problems, carbon

monoxide poisoning or death. Vent enclosed spaces and buildings according to relevant

applicable codes.

This heater may only be used in outdoor residential applications or indoor/outdoor

commercial (or industrial) applications. This heater is not approved for use in indoor

domestic applications and must never be installed indoors in the home.

Figure 2.5 • Hot Flue Discharge

Discharge released from

side air channels. Keep

area clear of gas piping

and electrical wiring.

Ventilation requirements vary according to the type of installation. The installation should be carried out

by a qualified installer.

The space to be heated must be ventilated to remove the products of combustion and to provide an

adequate supply of fresh air. Ventilation may be provided by natural or mechanical means. Exhaust

opening for the removal of flue products must be above the level of the heater(s).

Ventilation requirements in accordance with BS EN 13410:2001 must be adhered to. The the volume of

fresh air entering the building should be at least 37.5 m3/h per kW of total rated heat input. The minimum

air volume requirement must comply with BS 6896:2005.

Example:

One GPH 10 is rated at 10.0 kW

Ventilation requirement = 10.0 x 37.5 m3/h

Ventilation requirement = 375 m3/h

This heater must be installed outdoors or in an amply ventilated area. An amply ventilated are must have

a minimum of 25% of the surface area open. The surface area is the sum of the wall surface.

See Figure 2.6.

Figure 2.6 • Surface Area for Ventilation

15

3.0 Operation

3.0 Operation • Pre-Commissioning Check

Important! Before operating the heater, conduct the following safety procedures:

• Check for any possible gas leaks.

• Alert all persons about the hazards of high surface temperature and to keep a safe distance away

in order to avoid burns and possible clothing ignition.

• Provide supervision when young children are in the area of the heater.

• Check to make sure clothing isn’t hung from the heater and that flammable materials are not

placed on or near the heater.

• Check that all guards or protective devices are in place and secure.

• Check the hose assembly for excessive abrasion, wear or damage. If necessary replace.

• Check control compartment, burners and circulating air passages for debris. If necessary, clean

the debris.

WARNING

!

Improper operation of the heater may result in explosion, fire, shock and

carbon monoxide poisoning. Follow all guidelines and warnings in this manual

and relevant applicable codes. Always conduct safety checks before

operating the heater. Do not operate the heater in unsafe conditions.

Pre-Commissioning Check

Inspect ceramic plaques to ensure that none have been damaged. If any cracks are detected, the heater

must not be commissioned until the affected burner unit has been replaced (see section 4.0 Maintenance).

If compressed air is used to detect leaks in the gas supply line, disconnect and cap the ball valve to avoid

damage to the regulator and gas valve.

16

Ensure that the service cock to the heater is turned off.

Purge air from gas supply and test for gas soundness in accordance with the relevant standards. See

page 5.

Check that all electrical connections are made to the heater and that the unit has a sound earth

connection.

Release burner setting pressure test point screw on the gas valve by rotating one turn counter-

clockwise. Connect the pressure gauge via the outlet pressure test point.

Open the gas service cock and close the control compartment door.

Switch on the power to the heater via remote electrical switch. After a purge period lasting a few

seconds, the solenoid valves will open and the heater will come into operation having been lit by the

electrical spark.

Check burner setting pressure. This should be set according to Table 2.3 on page 12.

The pressure governor on the gas valve has been factory preset to the correct operating pressure. If

the correct operating pressure is not measured then it may be necessary to re-adjust. Please see

page 21 for details of how this is performed.

When the correct pressure is measured, switch off the heater. Remove the pressure gauge. Tighten

the test point screw.

Test the supply between the service cock and the heater for gas soundness.

Fit the low level lighting instruction plate.

The heater is now ready for use.

Commissioning

Switching on the Heater

Ensure that the gas supply to the heater is turned on.

Ensure that the thermostat and/or time clock is calling for heat.

Switch on the electrical supply to commence the ignition sequence.

There is a delay of approximately ten seconds. The burner is then ignited by the electrical spark.

If ignition fails, the heater will make two attempts before locking out.

If lockout occurs, shut off the power supply and restore after 30 seconds. If lockout re-occurs

more than three times, switch off the heater and call a service technician.

Switching off the Heater

Switch off the electrical supply to the heater. The burner will be extinguished.

NOTE: If the heater is to be switched off for more than one month, it is recommended that both

the electrical and gas supplies are turned off.

3.0 Operation • Commissioning

1

2

3

4

5

6

7

8

9

1

2

3

4

5

17

16

GPH Series 230V-50Hz Amp draw:

.15 starting

.15 running

This heater features a fully automatic ignition and control system. When power is supplied to the heater,

the gas valve opens allowing gas to enter the burner. A spark is generated at the ignition electrode which

ignites the gas.

After ignition, the sparking ceases and the flame rod on the electrode monitors the flame as the heater

commences normal operation.

If the flame is not established, the spark is interrupted after a few seconds and the gas valve closes. The

heater will make two attempts to ignite before entering lockout. The power supply to the heater must be

switched off and then switched back on before another ignition attempt is made.

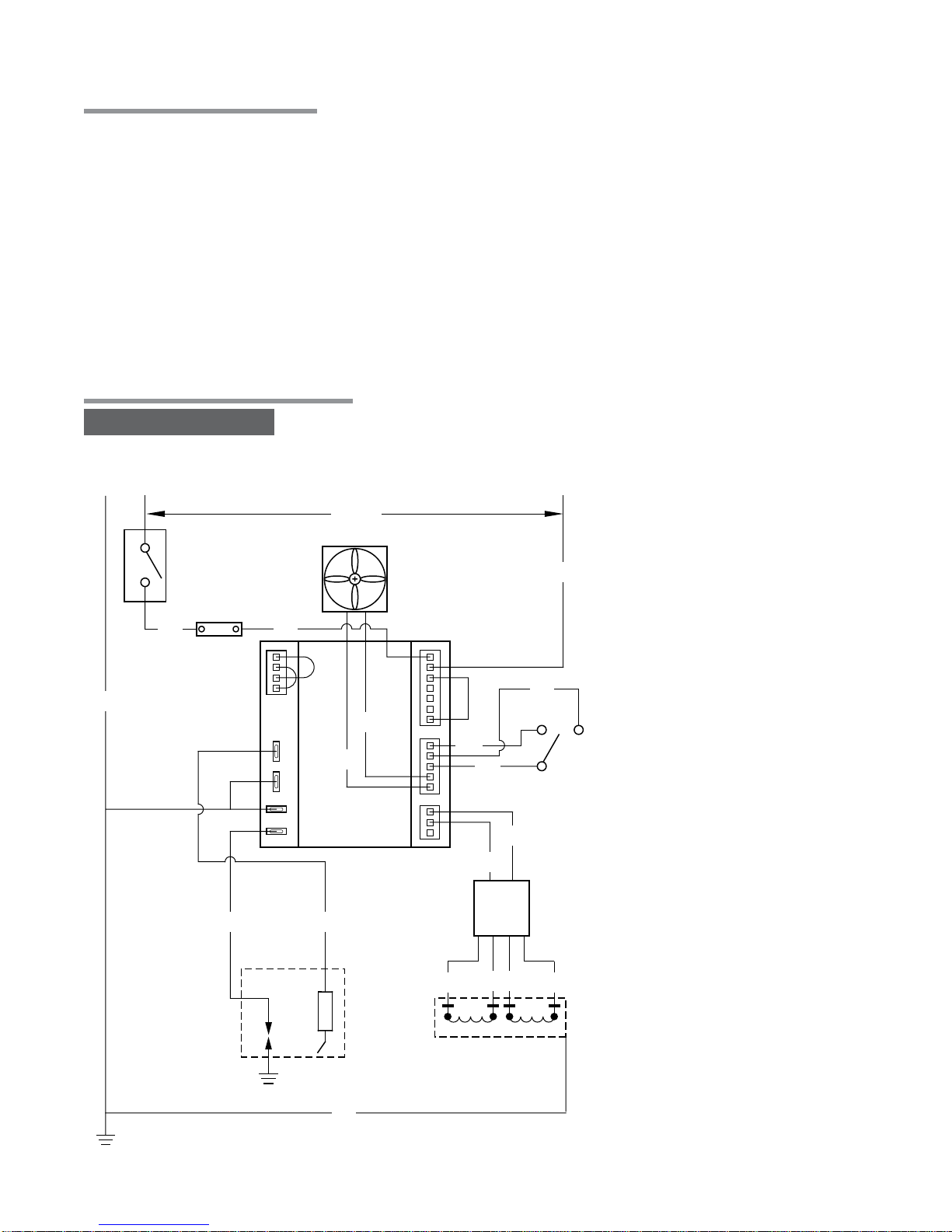

Sequence of Operation

3.0 Operation • Sequence of Operation • Heater Control Wiring

Figure 3.1 • Heater Control Wiring

230V

Fan

Gas Valve

Electrode

Assembly

BL

BR

BR

BL

BL

BR

W

BR BL

OO

Pressure

Switch

Circuit

Board

W

BK

GR NO

NC

Thermal

Switch

O230-115V

Rectifier

G

G

Door

Switch

NO

BR

NL1

18

WARNING

!

4.0 Maintenance

Electrical shock or explosion may occur when conducting maintenance while the heater

is connected to the power source and gas supply. Disconnect power and gas supply to

heater before servicing.

Do not touch the ignition or flame detection electrodes or any part of the ignition/flame

detection circuitry while power is supplied to the heater. These parts carry high voltages

at all times and will produce an electric shock if touched.

This heater requires annual service in order to ensure continued safe and efficient operation.

Periodic maintenance:

• Clean the heater with cleaning agents suitable for the unit’s construction material.

NOTE: Stainless steel cleaner is recommended on stainless steel surfaces.

• Inspect the gas supply piping system for signs of corrosion or failure. Replace if necessary.

Annual maintenance is normally sufficient unless abnormal site conditions necessitate that such work be

carried out at more frequent intervals (e.g. dusty environments, etc.).

The following service procedure should be followed:

Turn OFF the electrical isolating switch and gas cock.

Remove dirt and other deposits form all heater surfaces. Low pressure compressed air may be used

to clean ceramic plaques and venturies. Air hose pressure must not exceed 200kPa or 30psi as it

could cause damage to the heater elements and cause equipment failure. Gently pass the air hose

over the entire exposed area of the ceramic. A distance of 600-1200 mm from the unit is

recommended.

Remove and clean the injector.

Check that:

• All ceramic plaques are free from cracks or damage.

• The heater fixing arrangements are satisfactory.

• The flue products outlet is free of obstructions.

• The minimum clearances between the various heater surfaces and combustible materials are

preserved.

Re-commission the heater as outlined in section 3.0 Operation.

Switch OFF the heater. Close the gas service cock if the heaters are not to be used for an extended

period. During long periods of non-usage, remove or cover heater with a polyethylene bag and shut

off gas supply. If further service to the heater is desired, contact your distributor.

4.0 Maintenance • Periodic Maintenance

1

2

3

4

5

6

19

4.0 Maintenance • Troubleshooting • Replacement Procedures

Troubleshooting

Symptom:

Power is connected to the heater, but nothing happens.

Remedy:

Check the electrical supply and all electrical connections. If this reveals nothing, it is likely that the fan,

gas controller or pressure switch has failed. Check the fan, pressure switch and controller sequence.

Replace as necessary.

Symptom:

The electrode sparks, but the heater fails to ignite.

Remedy:

Check the heater inlet gas pressure (test point located on gas valve). This should be at least 18 mbar

for natural gas or 30 mbar for propane.

Check electrode spacing (3 mm gap recommended).

Check gas valve operation. Replace if necessary.

Replace controller if the valve is not defective.

Symptom:

The heater ignites satisfactory, but it switches off after a short period.

Remedy:

Check electrode spacing (3 mm gap recommended. A 3 mm clearance should also be maintained to

the surface of the ceramic plaques).

If this does not resolve the problem, replace the controller.

Symptom:

A burner does not reach its normal operating temperature (orange color) and a loud,

roaring noise is audible.

Remedy:

This indicates that the burner has flashed back. The condition is caused by damage to the ceramic

plaques. Replace the burner unit.

Replacement Procedures

Replacement of gas controller:

Switch OFF electrical and gas supplies.

Unscrew the screw which retains the hinged

cover of the control enclosure.

Disconnect all electrical connection from the

control box terminals.

Unscrew the two screws which retain the gas

controller in place. Lift controller clear.

Replace controller and re-assemble.

Re-commission the heater. Gas controller retaining screw

Figure 4.1 • Control Enclosure

1

2

3

4

5

6

20

Replacement Procedures

Replacement of gas valve (see Figure 4.2):

Switch OFF electrical and gas supplies.

Disconnect the electrical connections from gas valve.

Disconnect the inlet gas connector from the heater.

Unscrew the inlet gas pipe from gas valve inlet.

Unscrew the brass fitting from gas valve outlet.

Remove gas valve.

Replace valve and re-commission heater.

Replacement of electrode set (see Figure 4.3):

If electrodes are damaged, they must be replaced

complete with holder.

Switch OFF electrical supply and gas service cock.

Disconnect the leads from electrode.

Remove the electrode set from mounting bracket by

unfastening the retaining screws.

Replace with the new electrode set.

Re-assemble and re-commission the heater.

Replacement of Burner (see Figure 4.4):

If the ceramic plaques are damaged, it is necessary

to replace the entire burner assembly.

Remove the four nuts and bolts which retain the

burner unit to the heater frame.

Remove burner and replace.

Re-commission heater.

Replacement of Pressure Switch (see Figure 4.5):

If the pressure switch fails, it is necessary to replace it.

Disconnect the wiring.

Remove the retaining screws; retain.

Disconnect the pipes.

Replace the switch, refasten screws, connect pipes

and reconnect the wiring.

Re-commission the heater.

4.0 Maintenance • Replacement Procedures

Burner setting pressure test point

Inlet pressure

test point

Burner setting pressure

adjustment screw

Electrode retaining

screws

Burner retaining screws

Figure 4.2 • Gas Valve

Figure 4.3 • Electrode

Figure 4.4 • Burner Assembly

Figure 4.5 • Pressure Switch

1

2

3

4

5

7

6

1

2

3

4

5

1

2

3

1

2

3

4

5

Table of contents

Popular Patio Heater manuals by other brands

Blumfeldt

Blumfeldt 10035250 manual

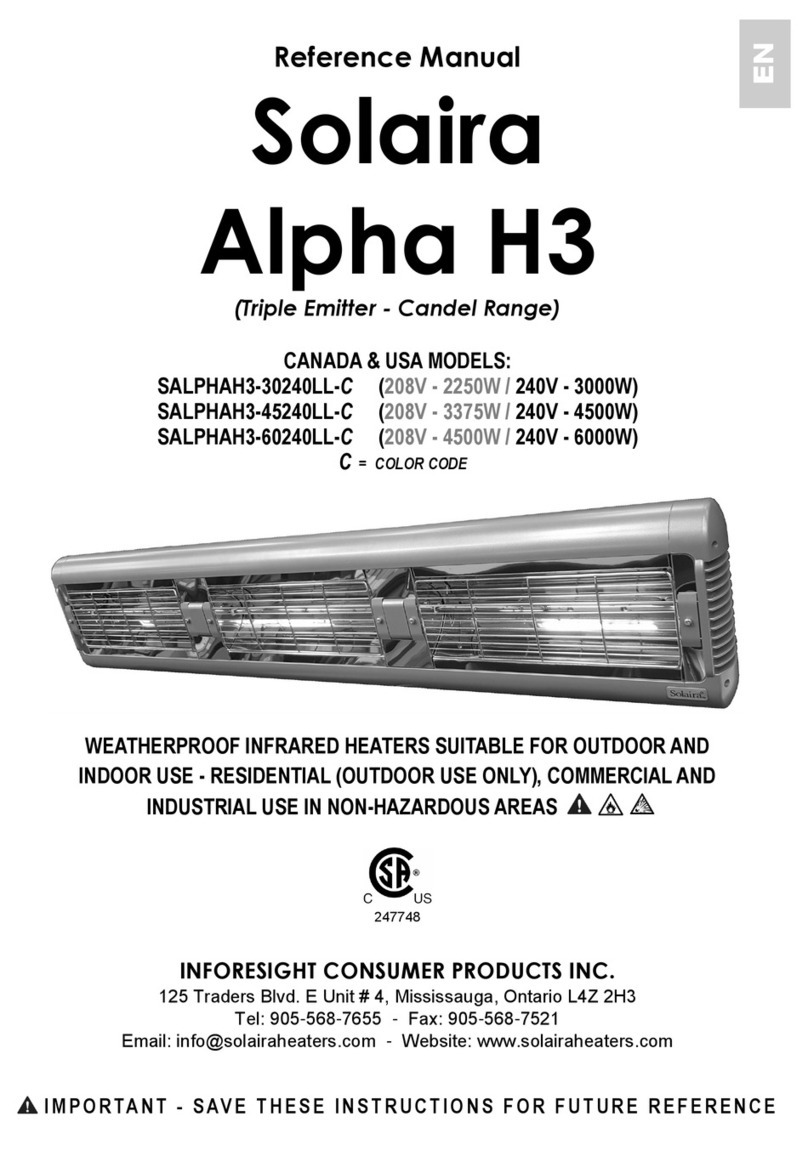

Solaira

Solaira Alpha H3 SALPHAH3-30240LL-C Reference manual

Blumfeldt

Blumfeldt Heatbell Tower manual

Sunred

Sunred RD-SILVER-2000W Translation of the original instructions

SunGlo

SunGlo PSA 265 Installation, operation & maintenance manual

Parasol

Parasol OZGLOW HE40 Installation, operation and maintenance instructions

Brander

Brander TR6029 NG User installation and operation guide

IR Energy

IR Energy HABANERO HAB Series Manual for installation, operation & maintenance

Lehner Versand

Lehner Versand ZHQ2566-RM-S instruction manual

Hiland

Hiland BURN-2400-BRZ manual

Hiland

Hiland GS-2400-BLK manual

Hortus

Hortus 211-377 instructions