DESCRIPTION

The TGC-500-2 cup

is

used

in

applications where

agitation ofmaterial in the sprayguncup is required

to

prevent the settling

of

pigments and solids inthe paint

during application.

An

air

turbine mixing blade lifts

pigments and solids

from

the bottom of the cup and

keeps it in suspension.

An airregulating valveontheturbineairline regulates

the speed

of

the turbine to control the mixing action.

An air adjusting valve is also supplied at the

gun

air

inlet

to

control spray

gun

nozzle atomization.

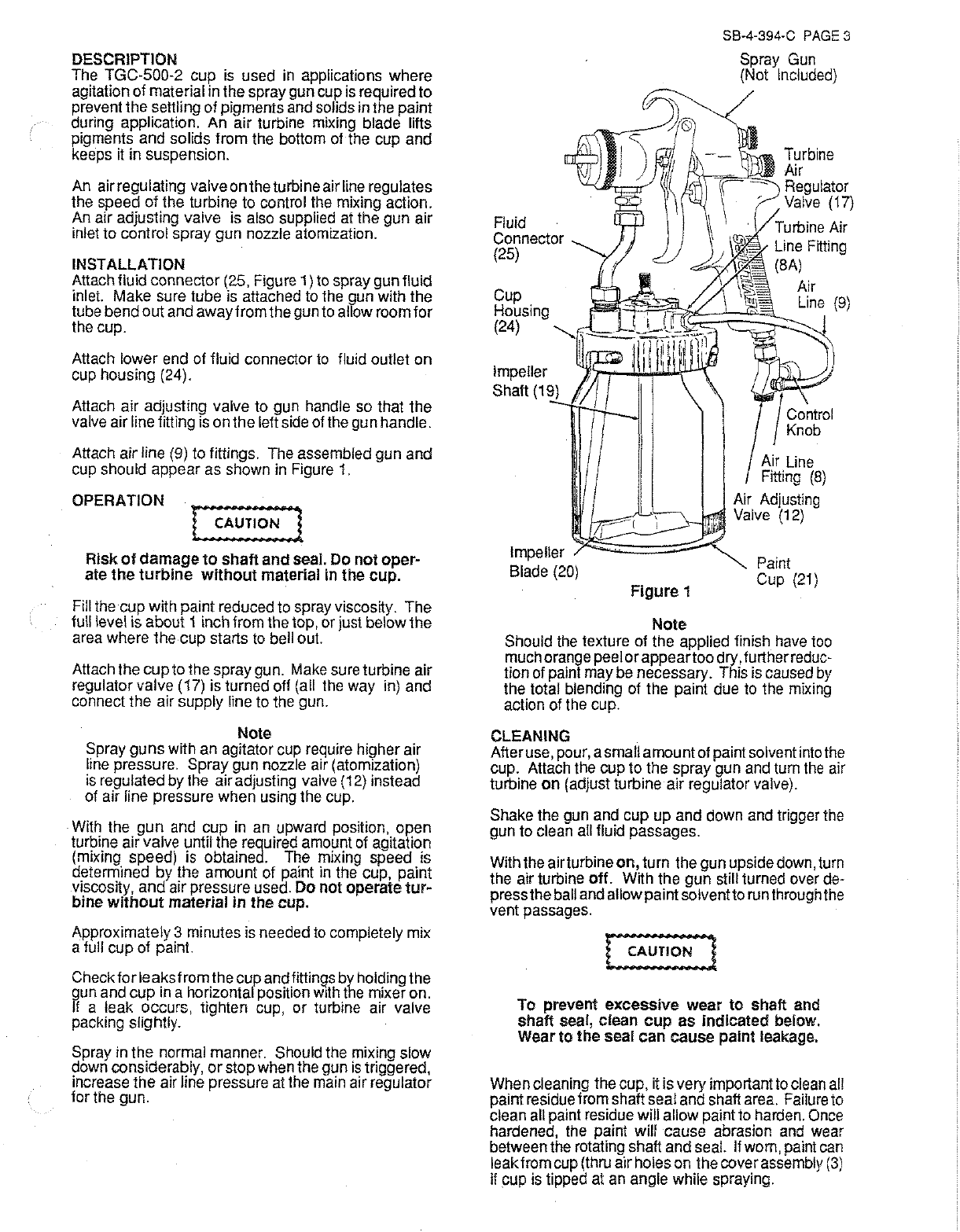

INSTALLATION

Attach fluid connector(25, Figure

1)

to spray gunfluid

inlet

Make sure tube is attached to the gun with the

tube bend

out

and awayfromthegun to allow room

for

the cup.

Attach lower end of fluid connector

to

fluid outlet

on

cup housing (24).

Attach air adjusting valve to gun handle so that

the

valve airline fitting is onthe leftside of the gun handle.

Attach air line (9) to fittings. The assembled gun and

cup should appear as shown in Figure

1.

OPERATION

Risk

of

damage

to

shaft

and

seal.

Do

not

oper-

ate

the

turbine

without

material

in

the

cup.

Fill the cup with paint reduced to spray viscosity.

The

full level is about i inch from the top, or just below

the

area where the

cup

starts to bell

out

Attach the

cup

tothe spray gun. Make sure turbine air

regulator valve (17) is turned off (all the way in) and

connect the air supply line to the gun.

Note

Spray

guns

with an agitator cup require higherair

line pressure. Spray gun nozzle air (atomization)

is regulated by the airadjusting valve (

i

2)

instead

of air line pressure when using the cup.

With the

gun

and cup

in

an upward position,

open

turbine airvalve until the required amount of agitation

(mixing speed) is obtained. The mixing speed is

determined

by

the amount of paint in the cup, paint

viscosity,

and

airpressure used.

Do

not

operate

tur-

bine

without

material

in

the

cup.

Approximately3 minutes is needed to completely mix

a full

cup

of paint.

Check

for

leaks

from

thecupandfittings by holdingthe

gun and

cup

in

a horizontal position

w1th

the mixeron.

If a leak occurs, tighten cup,

or

turbine air valve

packing slightly.

Spray in the normal manner. Should the mixing slow

down considerably,

or

stopwhen the

gun

is

triggered,

increase

the

air line pressure at the main airregulator

for the gun.

Fluid

Connector

(25)

Cup

Housing

(24)

Impeller

Shalt

(1

Impeller

~ft:;;;~:::;;;~

Blade (20)

Figure

1

Note

SB-4-394-C PAGE 3

Spray Gun

(Not Included)

Air Adjusting

Valve (i

2)

Paint

Cup (21)

Should the texture of the applied finish have too

muchorangepeel

or

appear

toodry,furtherreduc-

tion of paint maybe necessary. This is caused by

the total blending of the paint due to the mixing

action of the cup.

CLEANING

Afteruse, pour, asmallamountofpaintsolventintothe

cup. Attach the cup to the spray gun and turn the air

turbine

on

(adjust turbine air regulator valve).

Shake the gun and cup

up

and down and trigger the

gun to clean all fluid passages.

Withthe airturbine

on,

turn the gunupsidedown, turn

the air turbine

off.

With the

gun

still turned over de-

presstheball andallowpaintsolventtorunthroughthe

vent passages.

To

prevent

excessive

wear

to

shaft

and

shaft

sea!,

clean

cup

as

indicated

below.

Wear

to

the

seal

can

cause

paint

leakage.

Whencleaning the cup, it isvery importantto clean all

paintresiduefrom shaftseal and shaft area. Failure to

clean all paint residue will allow paintto harden. Once

hardened, the paint will cause abrasion and wear

betweenthe rotating shaft and seal.

If

worn, paint can

leakfrom cup (thru airholeson thecoverassembly

(3)

if

cup is tipped

at

an angle while spraying.