SB-4-205-M PAGE 3

Safety Valve, Regulator, Pressure Gauge

The safety valve limits the maximum

air pressure. If the safety valve does

not work properly, over pressuriza-

tion may occur and cause the cup

to rupture or explode. Occasionally

pull the ring on the safety valve and

make sure it operates freely. If the

valve is stuck or does not operate

smoothly, it must be replaced with a

valve having the same rating. Never

attempt to adjust or disassemble the

safety valve.

The safety valve (14) is factory set at approxi-

mately 55 lbs. Never disassemble. If damaged,

replace. Never submerge in solvents.

Regulator Disassembly

1. Pull the knob on the bonnet outward to

unlock regulator knob.

2. Turn the knob counterclockwise to stop.

3. Remove bonnet (24) by turning it coun-

terclockwise. Use pliers if necessary.

4. Remove adjusting screw and nut, regu-

lating spring, slip ring and diaphragm.

5. Use a wide blade screw driver and turn

valve seat (18) counterclockwise to re-

move along with o-ring.

6. Carefully remove valve (17) and valve

spring (16).

Regulator Reassembly

1. Place valve spring (16) into center hole of

cast housing. Place valve (17) on the

spring (16).

2. Use a wide blade screw driver and

tighten valve seat and o-ring assembly

(18) to 4-6 in. lbs. torque.

3. Place diaphragm (19) on the valve seat.

Diaphragm tube must slide freely through

valve seat after valve seat is torqued

into the body.

4. Place slip ring (20) on inside shoulder of

bonnet (24).

5. Place adjusting screw (23), nut (22) and

regulating spring (21) into bonnet (24).

6. Tighten bonnet assembly (24) to 65-75 in.

lbs. torque.

PREVENTIVE MAINTENANCE

Always relieve pressure in cup be-

fore removing lid by turning bleed

valve out.

NOTE

Do not unthread the pressure bleed

valve (6) all the way, as it may fall

out and be lost.

Cleaning

Do not wash the lid assembly in a

gun washer. The safety valve, gauge

and regulator contain parts that will

be damaged. The cup only can be

washed in a gun washer.

Use of the KK-5051 disposable cup liner

will significantly reduce cleaning time and

sol-vent. Another accessory item, KK-5052

Adapter and Hose Kit, can also be used in

conjunction with the Solvent Saver™ to

save further time and solvent cleaning the

fluid passages of the tube, hose, and spray

gun. See Accessories page 4.

Grasp lid handle and push down with one

hand and turn the retaining ring (1) counter-

clockwise with the other hand. Pour out any

remaining material and add a suitable solvent.

Close cup lid as explained in "OPERATION"

section. Spray until clean solvent appears.

Cup and gun material passages should now

be clean. Empty any remaining solvent from

cup. Wipe cup with a solvent soaked cloth.

Check Valve

If contaminated, carefuly remove check valve

(12) from lid. Soak in suitable solvent. If dam-

aged, replace. Do not torque to more than

10 in. lbs.

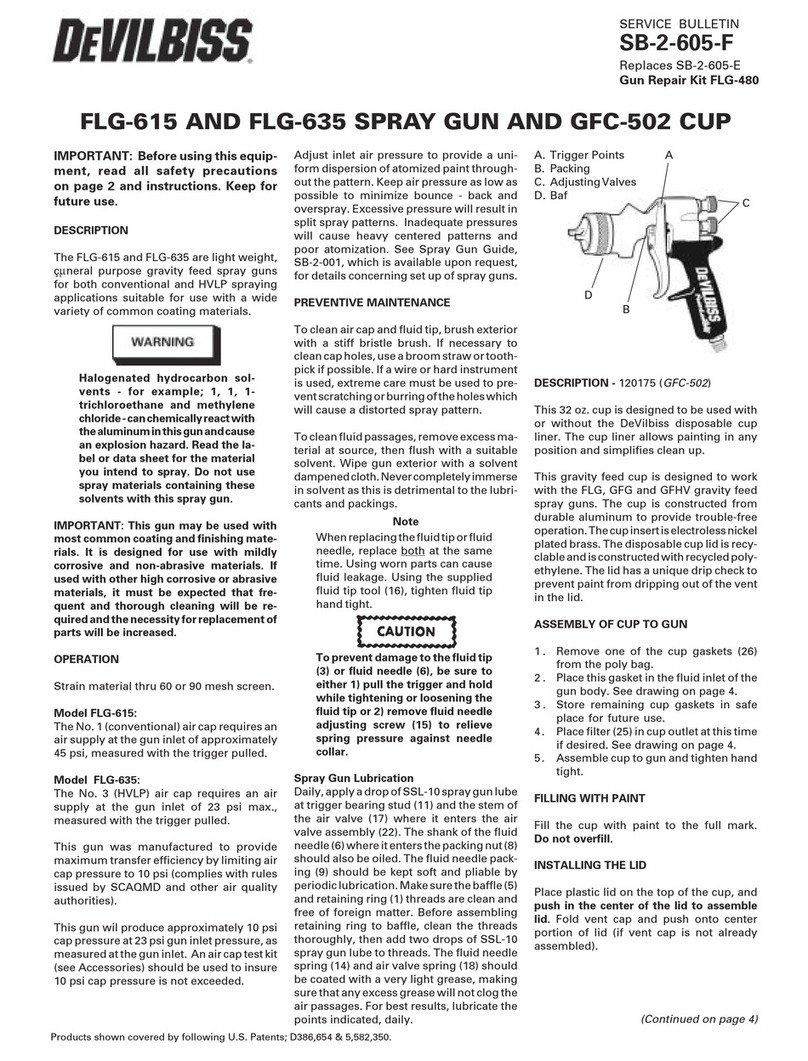

Description of Controls (Ref. Fig. 2, page 5)

Regulator Assembly (15) - Controls pressure

on material in cup.

Pressure Bleed Down Valve (6) - Allows air

to be bled from cup

To reduce pressure in cup, turn knob of regu-

lator assembly counterclockwise. Bleed off

excess air by momentarily turning pressure

relief valve (6) counterclockwise. Readjust

pressure by turning knob of regulator (24)

assembly clockwise. Turning regulator all the

way out shuts off air supply to the cup.

NOTE

Turn pressure bleed valve (6) coun-

terclockwise to vent air from the

cup; it is important to do this before

removing lid.

1. Place lid on cup. Grasp lid handle and

push down with one hand and tighten

retaining ring (1) with other hand.

2.

Turn regulator knob (24) out (counterclock-

wise) until no spring pressure is felt.

3. Close pressure bleed valve (6) by turning

it in all the way clockwise.

4. Set air supply pressure at approximately

50-60 pounds at transformer.

5. Set material pressure at 10 pounds by

turning in regulator knob and reading the

gauge. Make sure fluid adjusting screw

on spray gun is open (turned out coun-

terclockwise until first thread shows).

6. Test for amount of paint in relation to the

speed at which you want to spray. If too

much paint is coming out or atomized

particle size of paint is too large, follow

one of the procedures below.

A. Turn regulator knob counterclock-

wise until gauge shows lower pressure.

Bleed off excessive air in cup by turning

pressure bleed valve (6) counterclock-

wise.

B. Raise air pressure at transformer

until well defined atomized pattern of

paint is evident. This increases air pres-

sure to spray gun while maintaining

same pressure in the cup.

TROUBLESHOOTING CHART

PROBLEM CAUSE CORRECTION

Excess pressure in cup. Gauge (8) registering incorrectly Replace.

Safety valve (14) setting too high. Replace.

Valve spring (16) broken or distorted. Replace.

Diaphragm (19) damaged. Replace.

Leak at regulator valve (17 and 18). Replace.

Insufficient pressure in cup. Safety valve (14) leaking. Replace.

Check valve (12) stuck shut. Clean or replace.

Gauge (8) registering incorrectly. Replace.

Leak at cup lid (11) threads. Tighten cup or replace gasket (9) or slip ring (2).