3

PREVENTIVE MAINTENANCE

1. Daily lubrication and cleaning is necessary to maintain the best condition of the gun.

2. To clean the gun body, wipe exterior with solvent dampened cloth. Do not submerge the gun body in solvent as any

solids may get into the air passage causing troubles.

3. Do not leave the gun with solvent remained in the fluid cup. Clean the spray gun after use with clean solvent and by

emptying the cup. To clean the fluid cup after use, remove remaining paint through appropriate solvent and flush down

the residual paint.

4. The Air Cap can be immersed in solvent and brushed down for cleaning. If orifices are clogged, use a toothpick to

remove obstruction. Never use a steel wire or hard instrument. This will damage Air Cap and result in a distorted spray

pattern.

5. Do not immerse any plastic parts in solvent for long time.

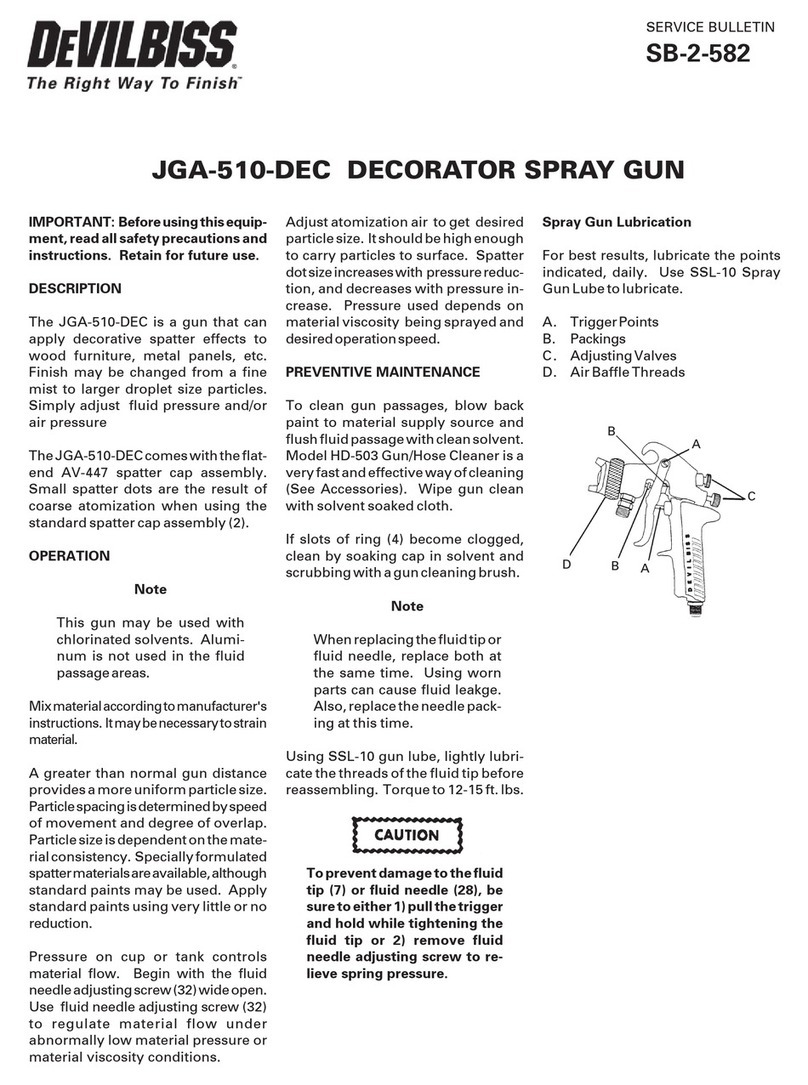

6. Certain portions of gun should be lubricated. Do not lubricate to any portion where not instructed. For lubrication,

SSL-10 Gun Lube* is recommended (*Sold separately. Vegetable oil that does not repel paint materials).

7. The following portions should be lubricated regularly; Trigger Bearing Stud (18), Pattern Valve (7), threads of Cheater

Valve (20) and Adjusting Screw (14), Air Valve Stem (9), and portion of Packing Gland (16) where Needle (12) comes in

and out.

8. When installing Air Cap (3), make sure no foreign materials adhered on Retaining Ring (1) and thread of Baffle and then

oil one drop of Gun Lube SSL-10.

9. Apply non-silicone grease lightly on Needle Spring (13) and Air Valve Spring (10). Do not apply too much grease as it

may clog the air passage.

REPLACEMENT OF PARTS

Before replacing gun parts, remove materials from the gun for cleaning. Then release the air pressure in the gun and

disconnect air hoses. All repairs should be made on a clean flat surface. Use only appropriate tools indicated for replacement

of parts.

Fluid Tip (4) and Needle (12)

1. It is recommended to replace Fluid Tip (4) and Needle (12) as a set.

2. Loosen Pattern Valve (7) completely by turning the knob counterclockwise.

3. Remove Adjusting Screw (14) and Needle Spring (13) and then withdraw Needle (12) from the gun body.

4. Remove Retaining Ring (1) and Air Cap (3).

5. Remove Fluid Tip (4) by using socket wrench or offset wrench.

6. Recommended torque of Fluid Tip (4) is 8N・m.

Fluid Inlet (5) and Air Connector (21)

Fluid Inlet (5) and Air Connector (21) are fixed together with fluid packing. Use offset wrench for disassembling and

reassembling. When reassembling, apply fluid packing to threads of gun body.

Pattern Valve (7) and Cheater Valve (20)

When disassembling and reassembling Pattern Valve (7) and Cheater Valve (20), turn the knobs completely

counterclockwise and then disassemble or reassemble them.

Valve Seal Kit (8), Air Valve (9), Valve Spring (10) and Air Valve Bushing (11)

Valve Seal Inserting Tool (22) is required for replacing Valve Seal Kit (8). When replacing Valve Seal Kit (8), be careful

not to damage the surface of seals of Gun Body (6), Air Valve Bushing (11) and Air Valve (9)to prevent air leakage.

1. Remove Needle Adjust Screw (14) and Needle Spring (13) and then withdraw Needle (12) from the Gun Body (6).

2. Remove Air Valve Bushing (11) by using 17mm offset wrench.

3. Withdraw Valve Spring (10) and Air Valve (9) from the gun body.

4. Withdraw Valve Seal Kit (8), being careful not to damage where fitted to.

5. Insert each seat by using Valve Seal Inserting Tool (22).

6. Insert Air Valve (9) to the bottom end, being careful not to damage the seat, and then insert Air Valve Spring (10).

7. Install Air Valve Bushing (11) by using 17mm offset wrench.

Needle Packing (15)

1. Install Needle Packing (15) in the direction shown per drawing.

2. Adjust Needle Packing (15). Tighten the Packing Nut (16) gradually. To adjust the needle moving smoothly, untighten a

little where the Needle (12) is not well pulled back.