6 © 2006 ITW Finishing Systems and Products

E

Installation

Important: To ensure that this equipment reaches you in first class condition, protective

coatings have been used. Flush the equipment through with a suitable solvent before use.

1. Attach air hose to connector (13). Recommended hose size 8 mm bore. The hose must be

conductive and electrical bond from the spray gun to earth should be checked with an

ohmmeter. A resistance of less than 106Ωis recommended.

2. Air supply should be filtered and regulated.

Operation

1. Mix coating material to manufacturers instructions.

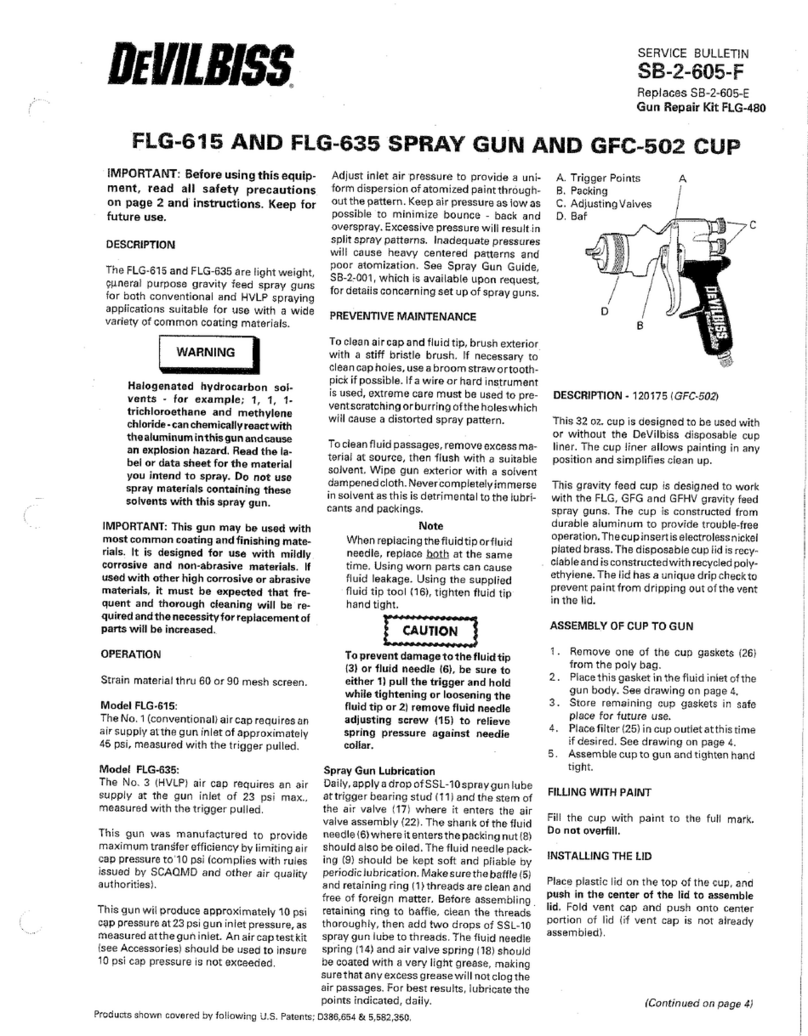

2. Turn needle adjusting screw (10) counter-clockwise until first thread shows.

3. Turn pattern valve (5) counter-clockwise to fully open.

4. Adjust inlet air pressure to give 2 bar (29psi) at the gun inlet with the gun triggered.

(pressure gauge attachment shown under Accessories is recommended for this).

5. Test spray. If the finish is too dry, reduce air flow by reducing inlet pressure. If finish is too

wet, reduce fluid flow by turning needle screw (10) clockwise. If atomisation is too coarse,

increase inlet air pressure. If too fine, reduce inlet pressure.

6. The pattern size can be reduced by adjusting valve (5).

7. Hold gun perpendicular to surface being sprayed. Arcing or tilting may result in uneven

coating.

8. The recommended spray distance is 150-200 mm (6”-8”).

9. Spray edges first. Overlap each stroke a minimum of 50%. Move gun at a constant speed.

10.Always turn off air supply and relieve pressure when gun is not in use.

Air Flow Valve (15)

1. If the air flow valve (15) is fitted this can be used to reduce the inlet pressure through the

gun. Screw the adjusting knob in to reduce pressure.

Preventative Maintenance

1. Turn off air supply and relieve pressure in the airline or, if using QD system, disconnect from

airline.

2. Empty coating material into a suitable container and clean the gun and cup, preferably in a

gun wash machine.

3. IMPORTANT– the cup must not be cleaned or rubbed with a dry cloth or paper. It is

possible to generate a static charge by rubbing which, if discharged to an earthed

object could create an incendive spark and cause solvent vapours to ignite. Only use

a dampened cloth or antistatic wipes if additional cleaning is required within a

hazardous area.

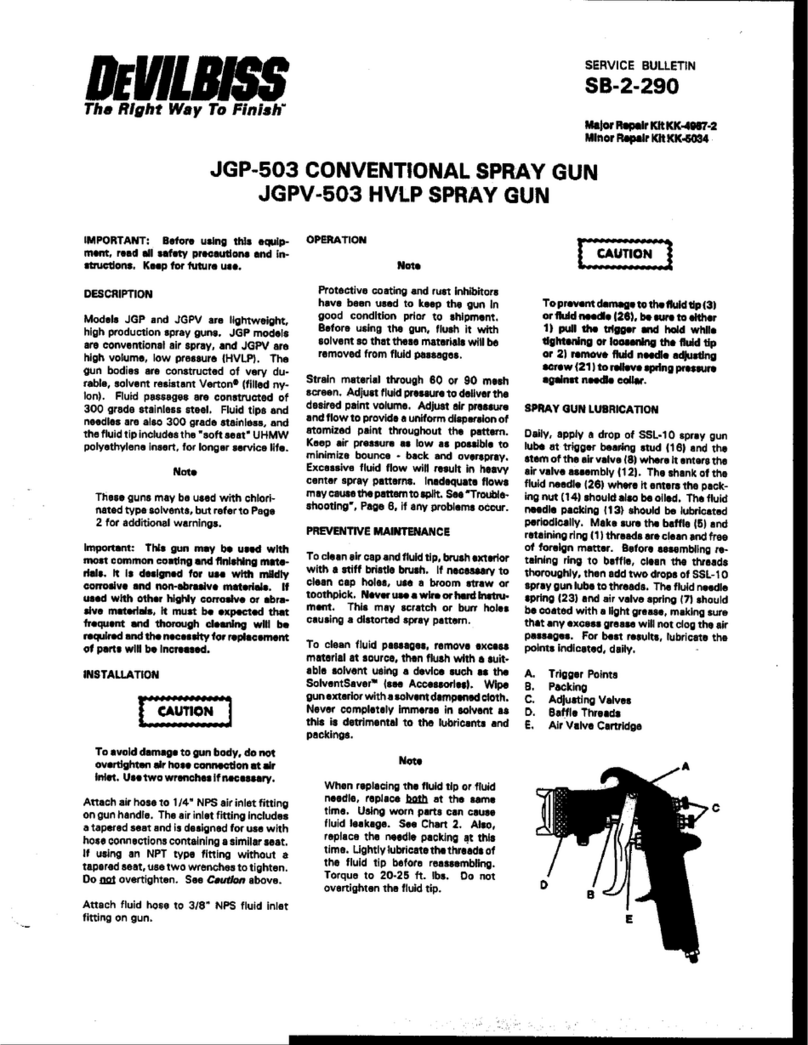

4. Remove air cap and clean. If any of the holes in the cap are blocked with coating material

use a toothpick to clean. Never use metal wire which could damage the cap and produce

distorted spray patterns.

5. Ensure the tip of the nozzle is clean and free from damage. Build-up of dried paint can

distort the spray pattern.

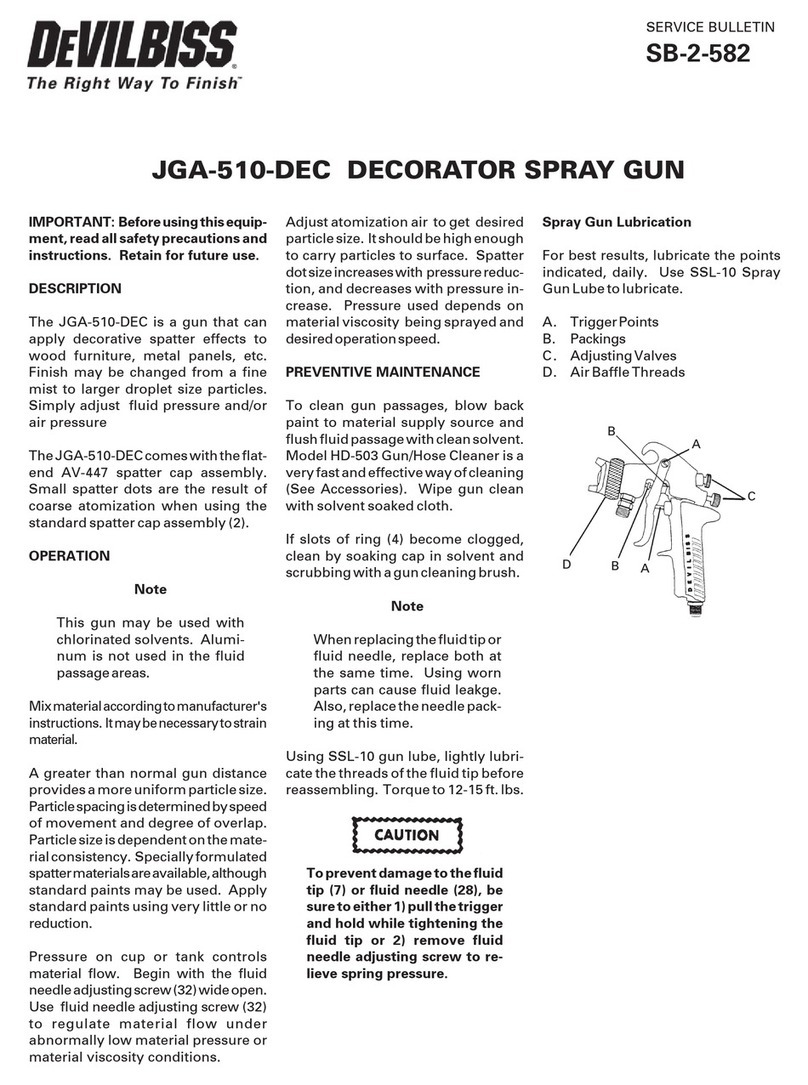

6. Lubrication – stud/screw (6), needle (7) and air-valve (11) should be oiled each day.