8

ENGLISH

Congratulations!

You have chosen a

tool. Years of experience, thorough product development and

innovation make

one of the most reliable partners for professional power toolusers.

Technical Data

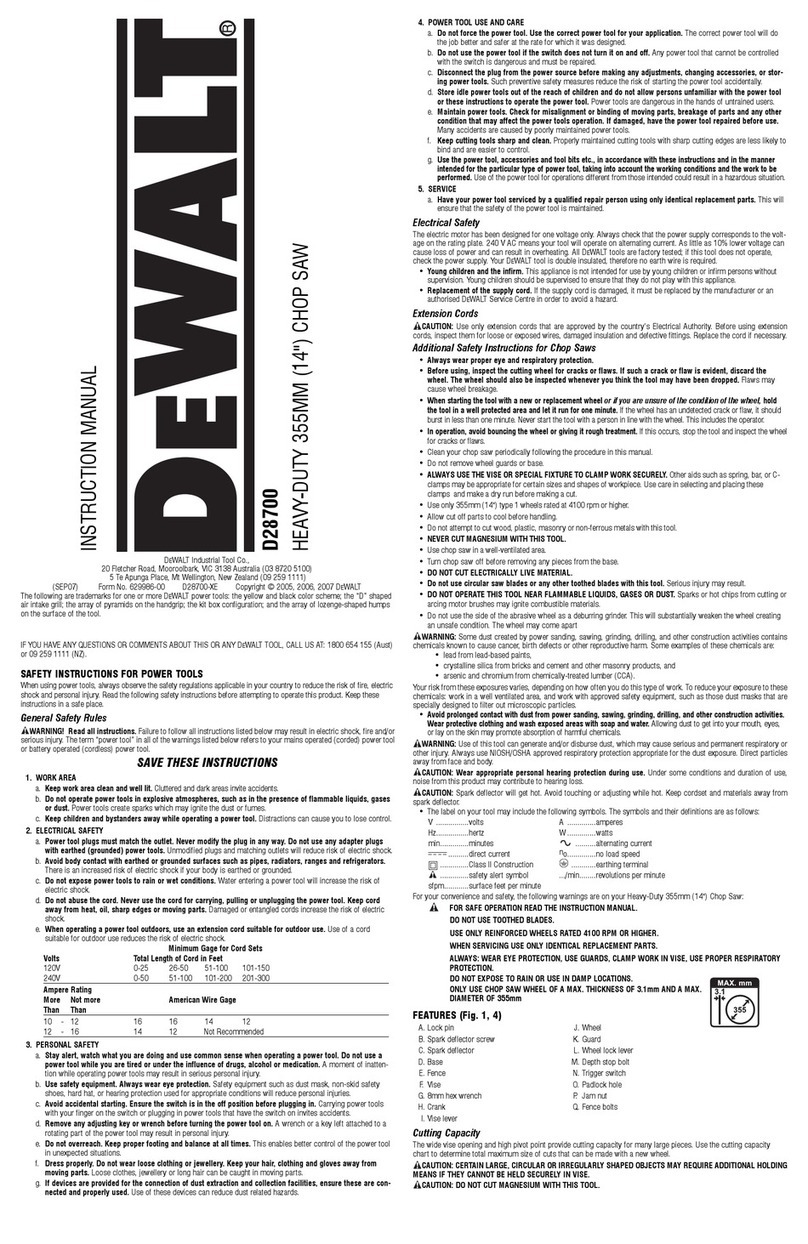

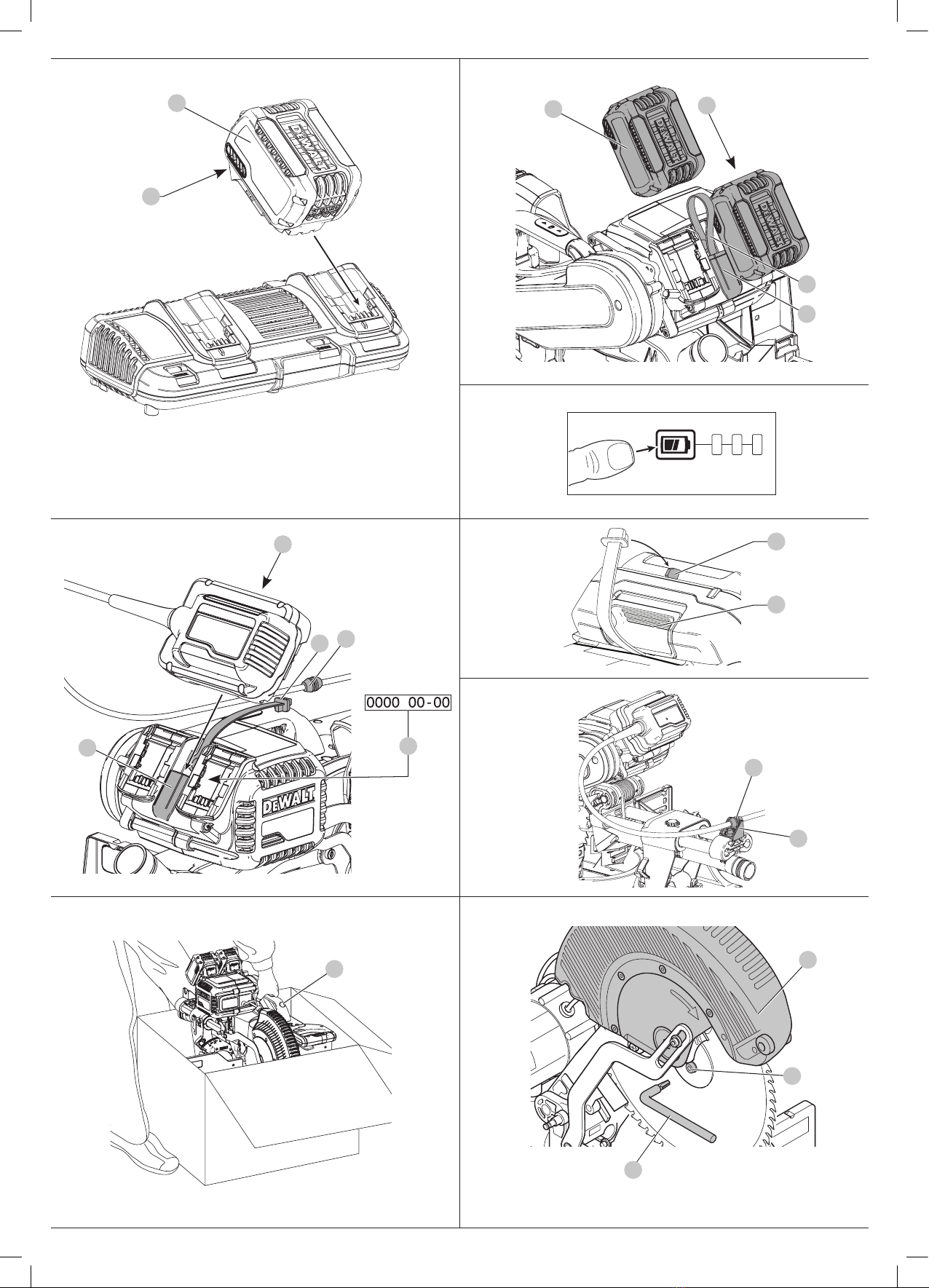

DHS780 DHS780-XE

Voltage VAC 230 230

UK & Ireland VAC 230/115 –

Type 21 21

Current AAC 8/15 8

Battery Type Li-Ion Li-Ion

Battery Voltage VDC 2 x 54 2 x 54

Blade diameter mm 305 305

Blade bore mm 30 25.4

Blade body thickness mm 1.6 1.6

Max kerf thickness mm 12 12

Max. blade speed min-1 3 800 3 800

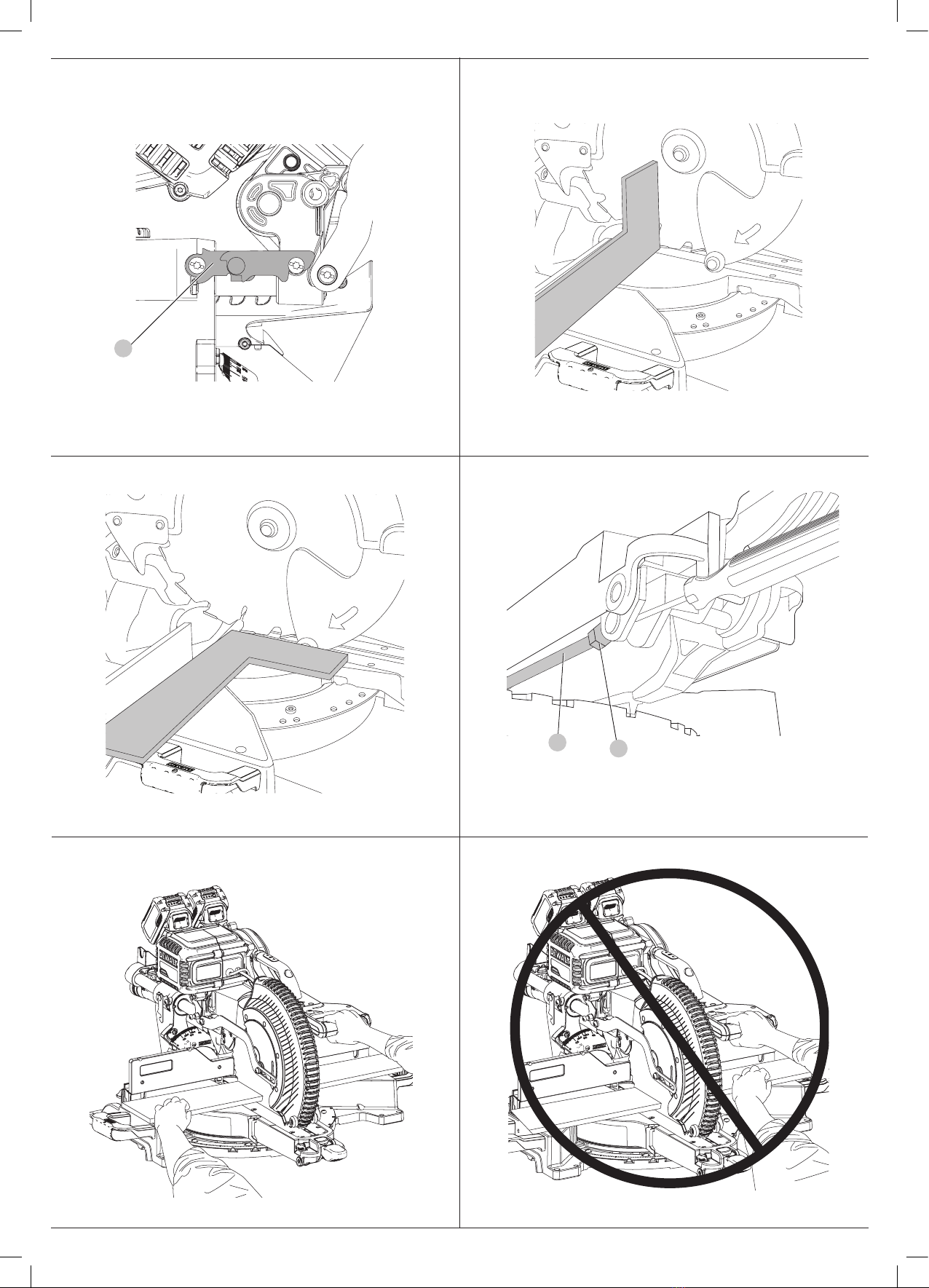

Max. cross-cut capacity 90° mm 345 345

Max. mitre capacity 45° mm 244 244

Max. depth of cut 90° mm 112 112

Max. depth of bevel cross-cut 45° mm 56 56

Mitre (max. positions) left 50° 50°

right 60° 60°

Bevel (max. positions) left 49° 49°

right 49° 49°

0° mitre

Resulting width at max. height 112 mm mm 299 299

Resulting width at max. height 110 mm mm 303 303

Resulting height at max. width 345 mm mm 76 76

45° mitre left

Resulting width at max. height 112 mm mm 200 200

Resulting height at max. width 244 mm mm 76 76

45° mitre right

Resulting width at max. height 112 mm mm 211 211

Resulting height at max. width 244 mm mm 76 76

45° bevel left

Resulting width at max. height 63 mm mm 268 268

Resulting height at max. width 345 mm mm 44 44

45° bevel right

Resulting width at max. height 62 mm mm 193 193

Resulting height at max. width 345 mm mm 28 28

Automatic blade brake time s< 5 < 5

Weight (without battery packs or corded power

supply) kg 26 26

Noise values and/or vibration values (triax vector sum) according to EN62841-3-9

LPA (emission sound pressure level) dB(A) 102 102

LWA (sound power level) dB(A) 91 91

K (uncertainty for the given sound level) dB(A) 3 3

The vibration and/or noise emission level given in this information sheet has been measured in

accordance with a standardised test given in EN62841 and may be used to compare one tool

with another. It may be used for a preliminary assessment ofexposure.

WARNING: The declared vibration and/or noise emission level represents the main

applications of the tool. However if the tool is used for different applications, with different

accessories or poorly maintained, the vibration and/or noise emission may differ. This may

significantly increase the exposure level over the total workingperiod.

An estimation of the level of exposure to vibration and/or noise should also take

into account the times when the tool is switched off or when it is running but not

actually doing the job. This may significantly reduce the exposure level over the total

workingperiod.

Identify additional safety measures to protect the operator from the effects of vibration

and/or noise such as: maintain the tool and the accessories, keep the hands warm

(relevant for vibration), organisation of workpatterns.

EC-Declaration of Conformity

Machinery Directive

Mitre Saw

DHS780

declares that these products described under Technical Data are in compliance with:

2006/42/EC, EN62841-1:2015/AC:2015; EN62841-3-9:2015 + AC:2016 + A11:2017.

These products also comply with Directive 2014/30/EU and 2011/65/EU. For more information,

please contact

at the following address or refer to the back of themanual.

The undersigned is responsible for compilation of the technical file and makes this declaration

on behalf of

.

Markus Rompel

Vice President of Engineering, PTE-Europe

, Richard-Klinger-Straße 11,

D-65510, Idstein, Germany

06.09.2019

WARNING: To reduce the risk of injury, read the instructionmanual.

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to thesesymbols.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or seriousinjury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result

in death or seriousinjury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in minor or moderateinjury.

NOTICE: Indicates a practice not related to personal injury which, if not avoided, may

result in propertydamage.

Denotes risk of electricshock.

Denotes risk offire.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING: Read all safety warnings, instructions, illustrations and specifications

provided with this power tool. Failure to follow all instructions listed below may result

in electric shock, fire and/or seriousinjury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTUREREFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) powertool.

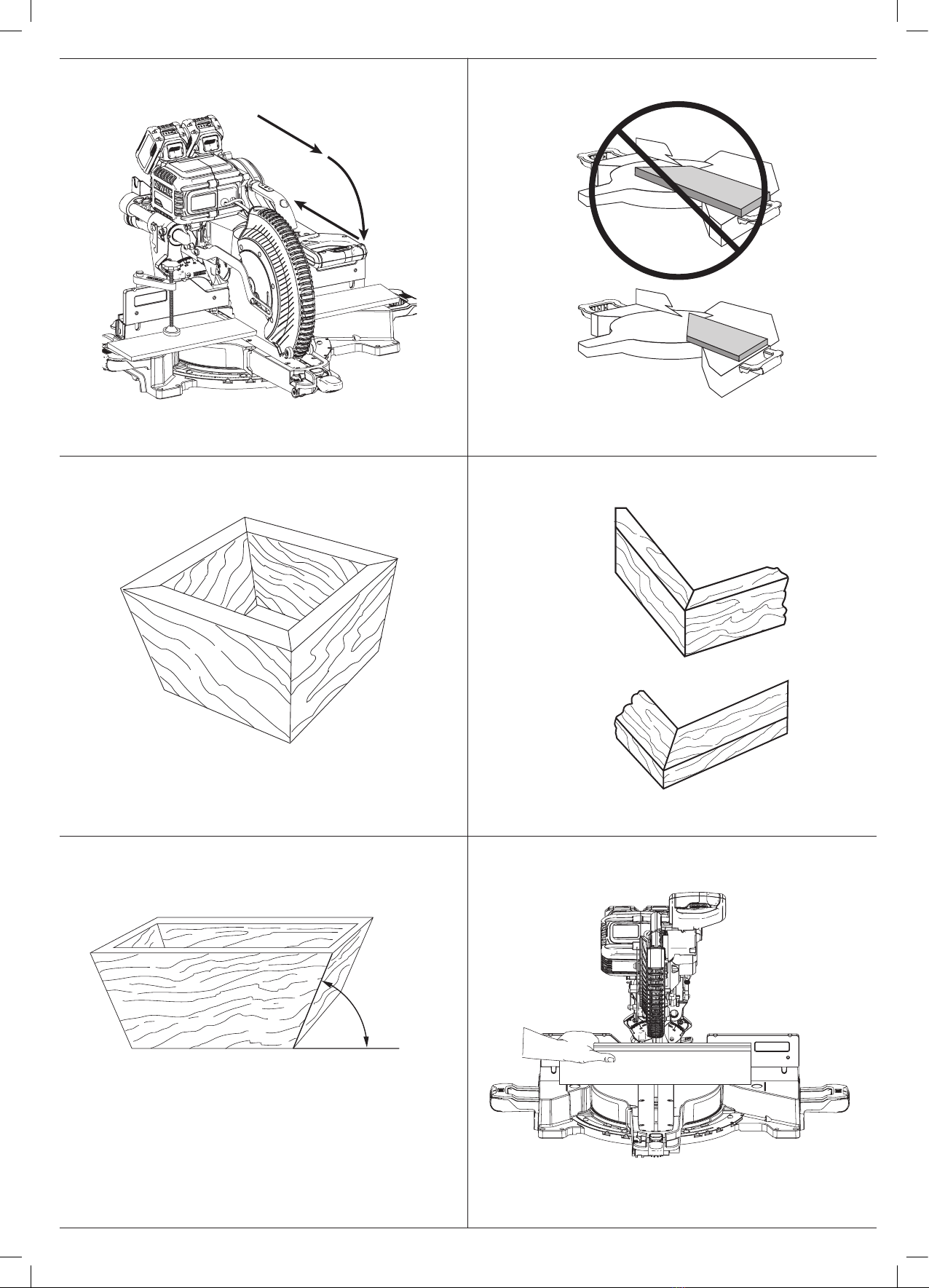

1) Work Area Safety

a ) Keep work area clean and well lit. Cluttered or dark areas inviteaccidents.

b ) Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

orfumes.

c ) Keep children and bystanders away while operating a power tool. Distractions can

cause you to losecontrol.

2) Electrical Safety

a ) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electricshock.

b ) Avoid body contact with earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is

earthed orgrounded.

c ) Do not expose power tools to rain or wet conditions. Water entering a power tool

will increase the risk of electricshock.

d ) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electricshock.

e ) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electricshock.

f ) If operating a power tool in a damp location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of electricshock.

English (original instructions)

MITRE SAW

DHS780