3

ENGLISH

r ) After finishing the cut, release the switch, hold the saw head down and wait for

the blade to stop before removing the cut-off piece. Reaching with your hand near the

coasting blade isdangerous.

s ) Hold the handle firmly when making an incomplete cut or when releasing the

switch before the saw head is completely in the down position. The braking action of

the saw may cause the saw head to be suddenly pulled downward, causing a risk ofinjury.

Additional Safety Rules for Miter Saws

WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace

safety rules. Always remember that a careless fraction of a second is sufficient to inflict

severeinjury.

WARNING: Never modify the power tool or any part of it. Damage or personal injury

couldresult.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed according to

the instructions. A machine incorrectly assembled can cause seriousinjury.

• OBTAIN ADVICE from your supervisor, instructor, or another qualified person if you are not

thoroughly familiar with the operation of this machine. Knowledge issafety.

• FOLLOW ALL WIRING CODES and recommended electrical connections to prevent shock

or electrocution. Protect electric supply line with at least a 15 ampere time-delay fuse or a

circuitbreaker.

• MAKE CERTAIN the blade rotates in the correct direction. The teeth on the blade should point in

the direction of rotation as marked on thesaw.

• TIGHTEN ALL CLAMP HANDLES, knobs and levers prior to operation. Loose clamps can cause

parts or the workpiece to be thrown at highspeeds.

• BE SURE all blade and blade clamps are clean, recessed sides of blade clamps are against blade

and arbor screw is tightened securely. Loose or improper blade clamping may result in damage

to the saw and possible personalinjury.

• DO NOT OPERATE ON ANYTHING OTHER THAN THE DESIGNATED VOLTAGE for the saw.

Overheating, damage to the tool and personal injury mayoccur.

• DO NOT WEDGE ANYTHING AGAINST THE FAN to hold the motor shaft. Damage to tool and

possible personal injury mayoccur.

• NEVER CUT FERROUS METALS or masonry. Either of these can cause the carbide tips to fly off

the blade at high speeds causing seriousinjury.

• NEVER PLACE HANDS CLOSER THAN 4" (100 mm) FROM THEBLADE.

• NEVER HAVE ANY PART OF YOUR BODY IN LINE WITH THE PATH OF THE SAW BLADE.

Personal injury willoccur.

• NEVER APPLY BLADE LUBRICANT TO A RUNNING BLADE. Applying lubricant could cause

your hand to move into the blade resulting in seriousinjury.

• DO NOT place either hand in the blade area when the saw is connected to the power source.

Inadvertent blade activation may result in seriousinjury.

• NEVER REACH AROUND OR BEHIND THE SAW BLADE. A blade can cause seriousinjury.

• DO NOT REACH UNDERNEATH THE SAW unless it is unplugged and turned off. Contact with

saw blade may cause personalinjury.

• SECURE THE MACHINE TO A STABLE SUPPORTING SURFACE. Vibration can possibly cause

the machine to slide, walk, or tip over, causing seriousinjury.

• USE ONLY CROSSCUT SAW BLADES recommended for miter saws. For best results, do not

use carbide tipped blades with hook angles in excess of 7 degrees. Do not use blades with deep

gullets. These can deflect and contact the guard, and can cause damage to the machine and/or

seriousinjury.

• USE ONLY BLADES OF THE CORRECT SIZE AND TYPE specified for this tool to prevent

damage to the machine and/or seriousinjury.

• INSPECT BLADE FOR CRACKS or other damage prior to operation. A cracked or damaged

blade can come apart and pieces can be thrown at high speeds, causing serious injury. Replace

cracked or damaged bladesimmediately.

• CLEAN THE BLADE AND BLADE CLAMPS prior to operation. Cleaning the blade and blade

clamps allows you to check for any damage to the blade or blade clamps. A cracked or damaged

blade or blade clamp can come apart and pieces can be thrown at high speeds, causing

seriousinjury.

• DO NOT USE WARPED BLADES. Check to see if the blade runs true and is free from vibration. A

vibrating blade can cause damage to the machine and/or seriousinjury.

• DO NOT use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the plastic

guard. The polycarbonate material used in the guard is subject to attack by certainchemicals.

• KEEP GUARD IN PLACE and in workingorder.

• ALWAYS USE THE KERF PLATE AND REPLACE THIS PLATE WHEN DAMAGED. Small chip

accumulation under the saw may interfere with the saw blade or may cause instability of

workpiece whencutting.

• USE ONLY BLADE CLAMPS SPECIFIED FOR THIS TOOL to prevent damage to the machine

and/or seriousinjury.

• CLEAN THE MOTOR AIR SLOTS of chips and sawdust. Clogged motor air slots can cause the

machine to overheat, damaging the machine and possibly causing a short which could cause

seriousinjury.

• NEVER LOCK THE SWITCH IN THE “ON” POSITION. Severe personal injury mayresult.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionallycontacted.

• ADDITIONAL INFORMATION regarding the safe and proper operation of power tools (i.e., a

safety video) is available from the Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH

44115-2851 (www.powertoolinstitute.com). Information is also available from the National

Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201. Please refer to the American

National Standards Institute ANSI 01.1 Safety Requirements for Woodworking Machines and the

U.S. Department of Labor OSHA 1910.213Regulations.

WARNING: Cutting plastics, sap coated wood, and other materials may cause melted

material to accumulate on the blade tips and the body of the saw blade, increasing the risk

of blade overheating and binding whilecutting.

WARNING: ALWAYS use safety glasses. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED

SAFETYEQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratoryprotection.

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicalsare:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treatedlumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specially designed to filter out microscopicparticles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with

soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin may promote

absorption of harmfulchemicals.

WARNING: Use of this tool can generate and/or disperse dust, which may cause serious

and permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles away from face andbody.

WARNING: Always wear proper personal hearing protection that conforms to ANSI

S12.6 (S3.19) during use. Under some conditions and duration of use, noise from this

product may contribute to hearingloss.

• Air vents often cover moving parts and should be avoided. Loose clothes, jewelry or long

hair can be caught in movingparts.

• An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is,

16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The lower the gauge number, the heavier thecord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet

(meters)

120 V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240 V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

Ampere Rating

American Wire Gauge

More

Than

Not

More

Than

0 6 18 16 16 14

610 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

The label on your tool may include the following symbols. The symbols and their definitions are

asfollows:

V.........................volts

Hz .......................hertz

min.....................minutes

or DC......direct current

......................Class I Construction (grounded)

…/min..............per minute

BPM....................beats per minute

IPM.....................impacts per minute

RPM....................revolutions per minute

sfpm ...................surface feet per minute

SPM....................strokes per minute

A.........................amperes

W........................watts

or AC........... alternating current

or AC/DC....alternating or direct current

......................Class II Construction (double insulated)

no.......................no load speed

n.........................rated speed

......................earthing terminal

.....................safety alert symbol

.....................visible radiation

.....................wear respiratory protection

.....................wear eye protection

.....................wear hearing protection

.....................read all documentation

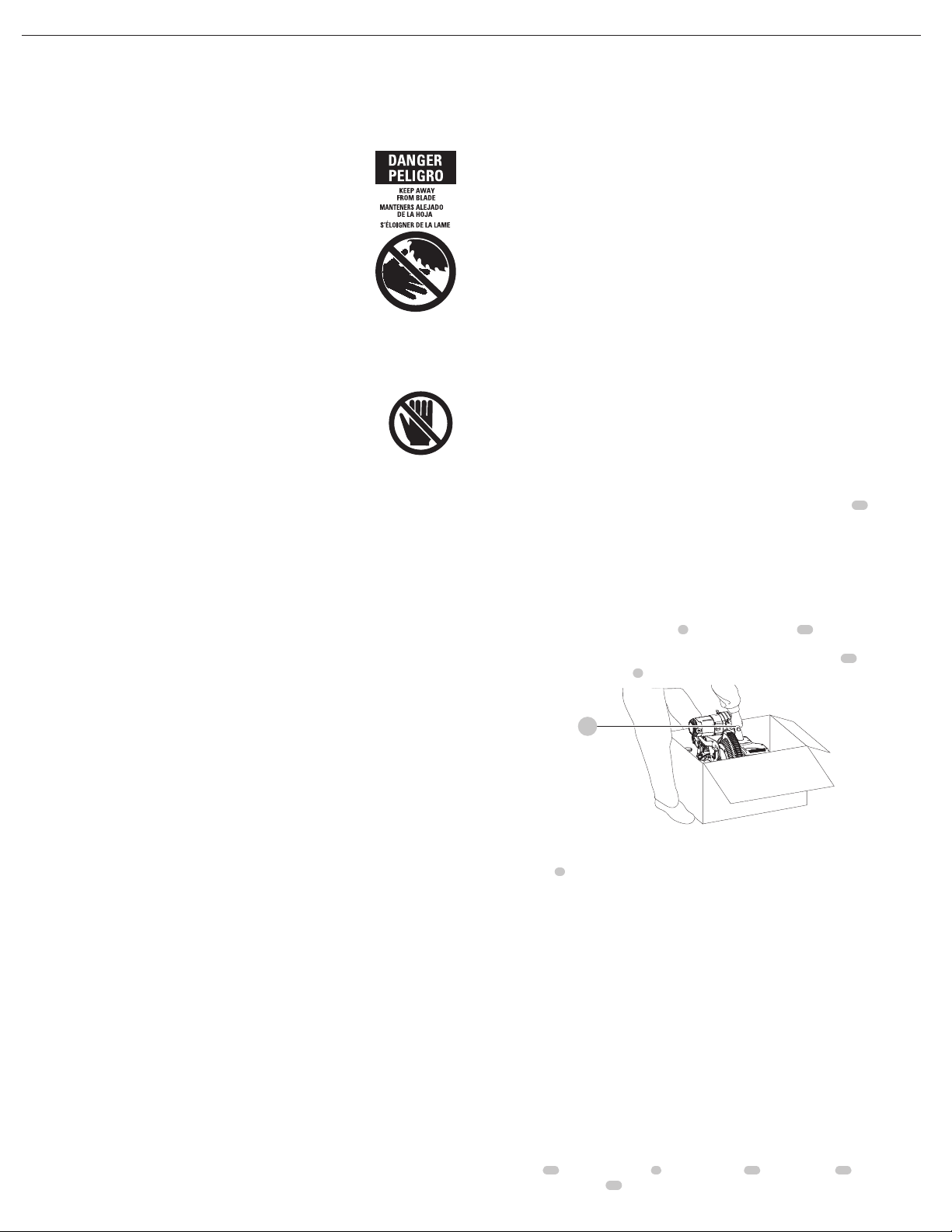

For your convenience and safety, the following warning labels are on your mitersaw.