8

ENGLISH

explode in a fire. Toxic fumes and materials are created when

lithium-ion battery packs are burned.

• If battery contents come into contact with the skin,

immediately wash area with mild soap and water. If

battery liquid gets into the eye, rinse water over the open eye

for 15 minutes or until irritation ceases. If medical attention

is needed, the battery electrolyte is composed of a mixture of

liquid organic carbonates and lithium salts.

• Contents of opened battery cells may cause respiratory

irritation. Provide fresh air. If symptoms persists, seek

medicalattention.

WARNING: Burn hazard. Battery liquid may be flammable

if exposed to spark or flame.

WARNING: Never attempt to open the battery pack for

any reason. If battery pack case is cracked or damaged,

do not insert into charger. Do not crush, drop or damage

battery pack. Do not use a battery pack or charger that

has received a sharp blow, been dropped, run over or

damaged in any way (i.e., pierced with a nail, hit with

a hammer, stepped on). Electric shock or electrocution

may result. Damaged battery packs should be returned to

service centre for recycling.

WARNING: Fire hazard. Do not store or carry the

battery pack so that metal objects can contact

exposed battery terminals. For example, do not place

the battery pack in aprons, pockets, tool boxes, product kit

boxes, drawers, etc., with loose nails, screws, keys, etc.

CAUTION: When not in use, place tool on its side on

a stable surface where it will not cause a tripping

or falling hazard. Some tools with large battery packs

will stand upright on the battery pack but may be easily

knocked over.

Transportation

WARNING: Fire hazard. Transporting batteries can

possibly cause fire if the battery terminals inadvertently

come in contact with conductive materials. When

transporting batteries, make sure that the battery

terminals are protected and well insulated from materials

that could contact them and cause a short circuit.

batteries comply with all applicable shipping

regulations as prescribed by industry and legal standards which

include UN Recommendations on the Transport of Dangerous

Goods; International Air Transport Association (IATA) Dangerous

Goods Regulations, International Maritime Dangerous Goods

(IMDG) Regulations, and the European Agreement Concerning

The International Carriage of Dangerous Goods by Road (ADR).

Lithium-ion cells and batteries have been tested to section 38.3

of the UN Recommendations on the Transport of Dangerous

Goods Manual of Tests and Criteria.

In most instances, shipping a

battery pack will be

excepted from being classified as a fully regulated Class 9

Hazardous Material. In general, only shipments containing a

lithium-ion battery with an energy rating greater than 100 Watt

Hours (Wh) will require being shipped as fully regulated Class 9.

All lithium-ion batteries have the Watt Hour rating marked on

the pack. Furthermore, due to regulation complexities,

does not recommend air shipping lithium-ion battery packs

alone regardless of Watt Hour rating. Shipments of tools with

batteries (combo kits) can be air shipped as excepted if the Watt

Hour rating of the battery pack is no greater than 100 Whr.

Regardless of whether a shipment is considered excepted

or fully regulated, it is the shipper's responsibility to consult

the latest regulations for packaging, labeling/marking and

documentation requirements.

The information provided in this section of the manual is

provided in good faith and believed to be accurate at the time

the document was created. However, no warranty, expressed or

implied, is given. It is the buyer’s responsibility to ensure that its

activities comply with the applicable regulations.

Transporting the FLEXVOLTTM Battery

The

FLEXVOLTTM battery has two modes: Use and

Transport.

Use Mode: When the FLEXVOLTTM battery stands alone or is in

a

18V product, it will operate as an 18V battery. When

the FLEXVOLTTM battery is in a 54V or a 108V (two 54V batteries)

product, it will operate as a 54V battery.

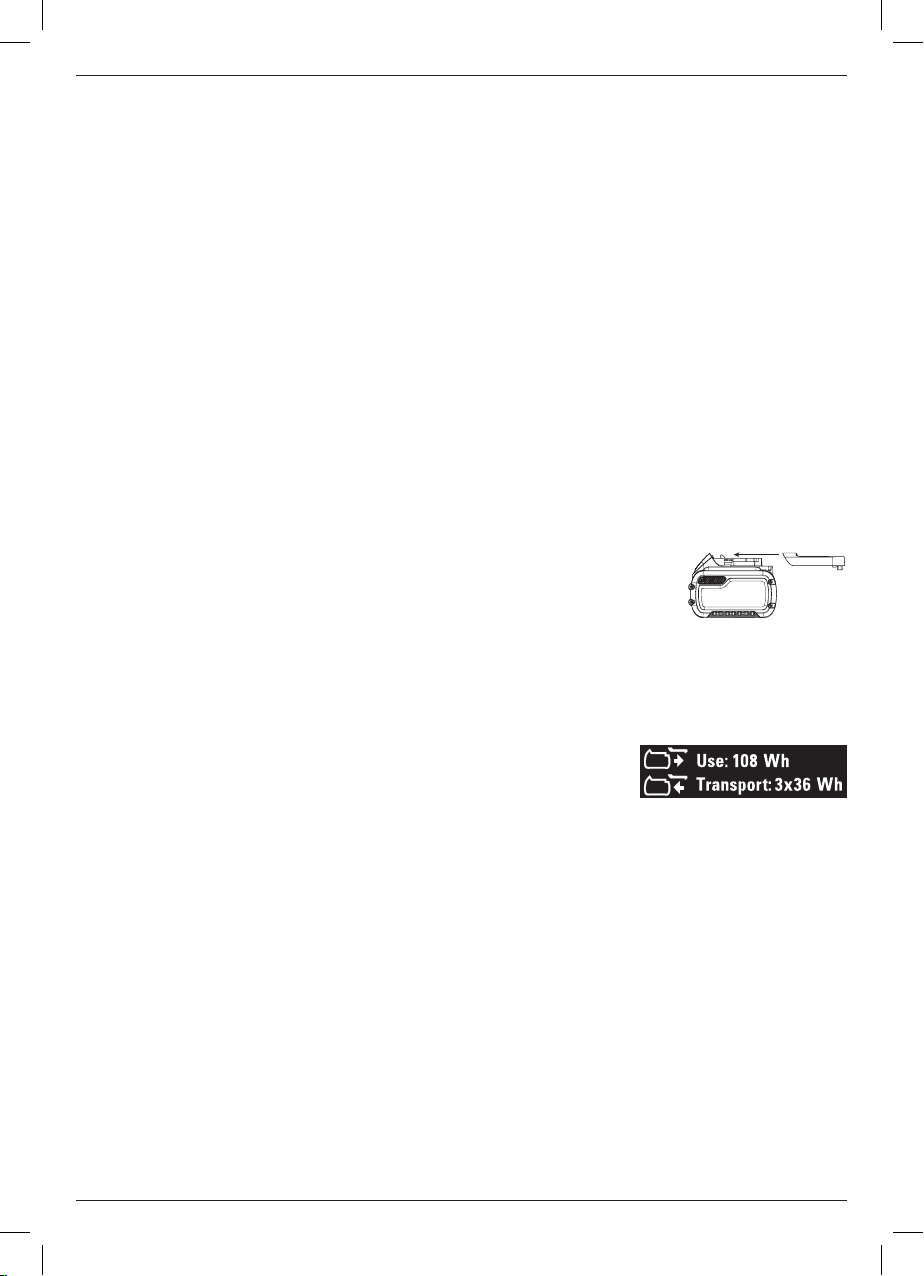

Transport Mode: When the cap is attached to the FLEXVOLTTM

battery, the battery is in Transport mode. Keep the cap for

shipping.

When in Transport mode, strings

of cells are electrically

disconnected within the pack

resulting in 3 batteries with a

lower Watt hour (Wh) rating as compared to 1 battery with a

higher Watt hour rating. This increased quantity of 3 batteries

with the lower Watt hour rating can exempt the pack from

certain shipping regulations that are imposed upon the higher

Watt hour batteries.

For example, the Transport

Wh rating might indicate

3x36 Wh, meaning 3

batteries of 36 Wh each.

The Use Wh rating might

indicate 108Wh (1battery implied).

Storage Recommendations

1. The best storage place is one that is cool and dry away

from direct sunlight and excess heat or cold. For optimum

battery performance and life, store battery packs at room

temperature when not in use.

2. For long storage, it is recommended to store a fully charged

battery pack in a cool, dry place out of the charger for

optimal results.

NOTE: Battery packs should not be stored completely

depleted of charge. The battery pack will need to be recharged

beforeuse.

Labels on Charger and Battery Pack

In addition to the pictographs used in this manual, the labels

on the charger and the battery pack may show the following

pictographs:

Example of Use and Transport Label Marking