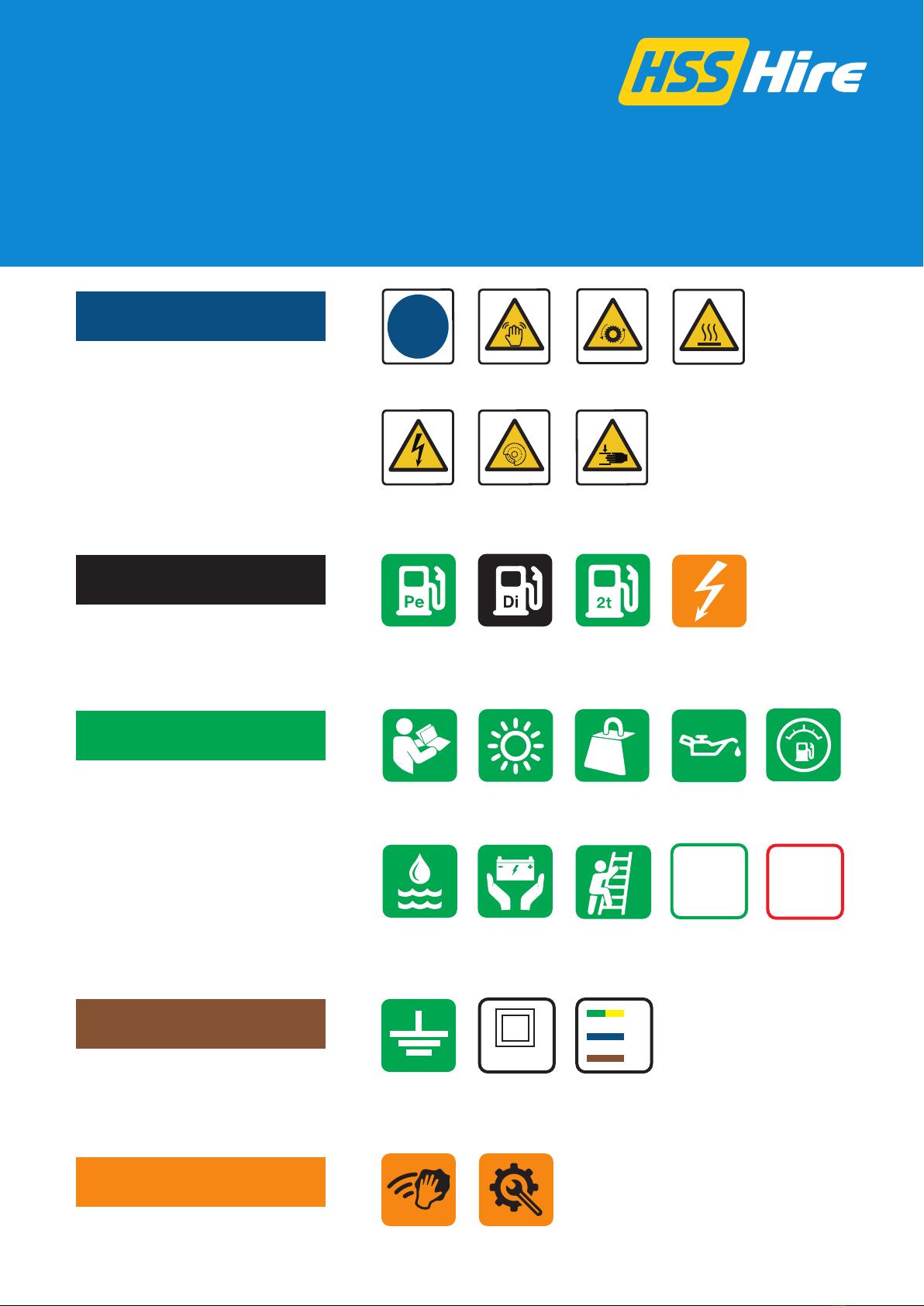

Inadmissible misuse

Do not use accessory tools that are not approved for this

product. This includes cut-off wheels, diamond cut-off

wheels and rotary wire brushes.

Do not use the product for wet grinding, do not

grind projecting objects such as nails or screws.

Do not use the product if slats on the dust hood

are worn; never use the product without a dust

extractor. Never use the grinding pad at a speed for

which it is not approved.

Preparations at the workplace

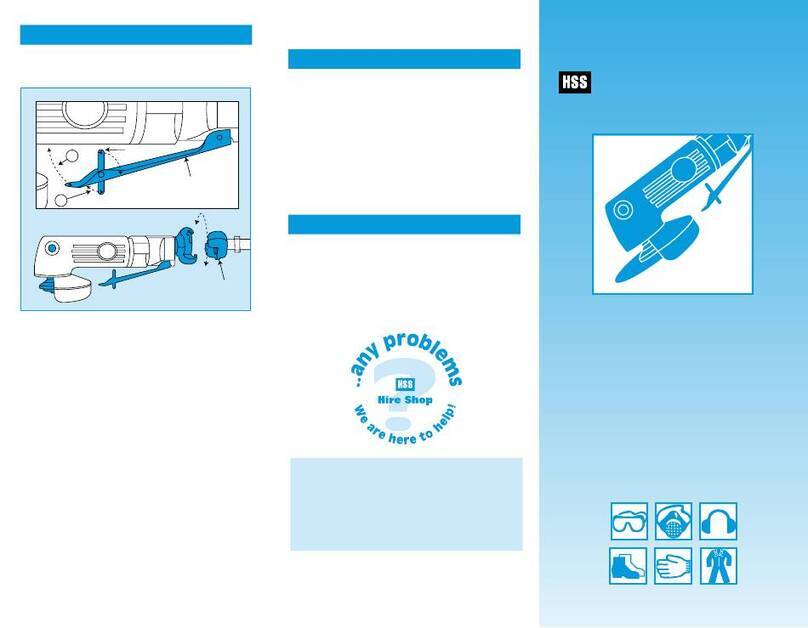

Installing an accessory tool

1. Clean the chuck

2. Slip the mounting flange on to the arbor and turn

the mounting flange until it engages

3. Position the accessory tool on the centering collar of

the mounting flange

4. Screw the quick-action clamping screw into the

arbor and tighten the screw

Removing the accessory tool

1. Slacken the clamping nut

2. Remove the accessory tool

Adjusting the side handle

1. To release the side handle, open the clamping lever

2. Adjust the side handle to the desired position

3. Close the clamping lever

Adjusting the guard

1. Switch the grinder off

2. Position the power tool on the grinding wheel

3. Use the height adjuster to adjust the height - Note:

The guard is at the optimum height when the

distance between the slats and the surface is

approximately 1mm.

4. If you are working along a wall, turn the segment

opening of the guard to the desired position

5. Be sure to close the segment opening when you

finish working along the wall

Selecting the gear

CAUTION - Risk of injury and damage. If speed is too

high, segments of the grinding accessory can come

loose. Use only gears 1 and 2 for fine grinding.

GETTING STARTED CONT. 1. Use the gear selector switch to select a gear to suit

the accessory tool you are going to use and the

hardness of the material to be worked

2. Use 1st gear for better dust control when grinding

off soft mineral materials, such as paint from cement

rendering, and to make the power tool easier to

guide when grinding off coatings from soft materials

3. Use 5th gear to apply full power of the tools when

grinding hard mineral materials such as concrete,

floor screeding or natural stone

Types of work

Switching on

CAUTION - Risk of injury. Inadequately secured accessory

tools can work loose. Before each use, always check that

the accessory tool is secure.

1. Connect the grinder to an industrial vacuum cleaner.

2. Lift the power tool clear of the work surface

3. Press and hold down the on/off switch - the status

LED of the locking button flashes

4. Press the locking button to switch on the grinder in

continuous-operationmode - the locking button has

to be pressed within one second

Trying out after fitting a new diamond cup wheel

CAUTION - Risk of injury. Damaged diamond cup wheels

can come loose.

Do not use a diamond cup wheel if it vibrates; protect the

cup wheel against impact, shock loading and grease.

Hold the power tool just clear of the surface you are

going to work on and allow it to run for at least 1 minute

without load.

Sanding

1. Select a gear

2. Switch the grinder on

3. Bring the power tool with the accessory tool into

contact with the work surface and keep the tool

moving with a steady back-and-forth action

4. Apply moderate pressure and do not dig the tool

into the material

5. The diamond cut wheel can overheat and suffer

damage when used to grind very hard mineral

materials such as concrete with a high gravel

content. Under these circumstances take frequent

breaks from grinding and, with the power tool idling,

allow the diamond cup wheel to cool down briefly

Switching off

To switch off the power tool, press the locking button

or the on/off switch

Always hold the planer with both hands and

switch ON before bringing the planer into contact

with the work.

Adopt a stable posture with both feet on firm level

ground, do not work in areas where you are forced to

stand on loose debris or on a slippery uneven surface.

BASIC TECHNIQUE

Never apply too much pressure. Keep the planer

moving either in a straight line or in a circular motion,

or it may rut the work.

Lift it clear before switching OFF, and wait for

moving parts to stop before putting it aside.

On first contact with the surface, the planer will

try to throw you off line. Take great care until you

become familiar with the tool.

Never push the equipment beyond its design

limits. If it will not do what you want with reasonable

ease, assume you have the wrong tool for the job. Ask at

your local HSS Hire Shop for advice.

Regularly check the condition of the diamond

wheel, if it show signs of excessive wear contact your

local HSS Hire Shop for a replacement.

Keep the equipment clean. You will find this less of a

chore if you clean up regularly, rather than wait unit the

end of the hire period.

When not in use, store the equipment somewhere

clean, dry and safe from thieves.

When using the dust extractor listen for the bleep

noise and view the lamp indicator as there could be

restricted air flow or the dust bag needs replacing.

Switch OFF and unplug the planer. Remove the

dust extractor hose from the tool dust port. Remove

and empty the dust collection bag

Thoroughly clean the machine and dust extractor,

ready for return to HSS.

EQUIPMENT CARE

FINISHING OFF