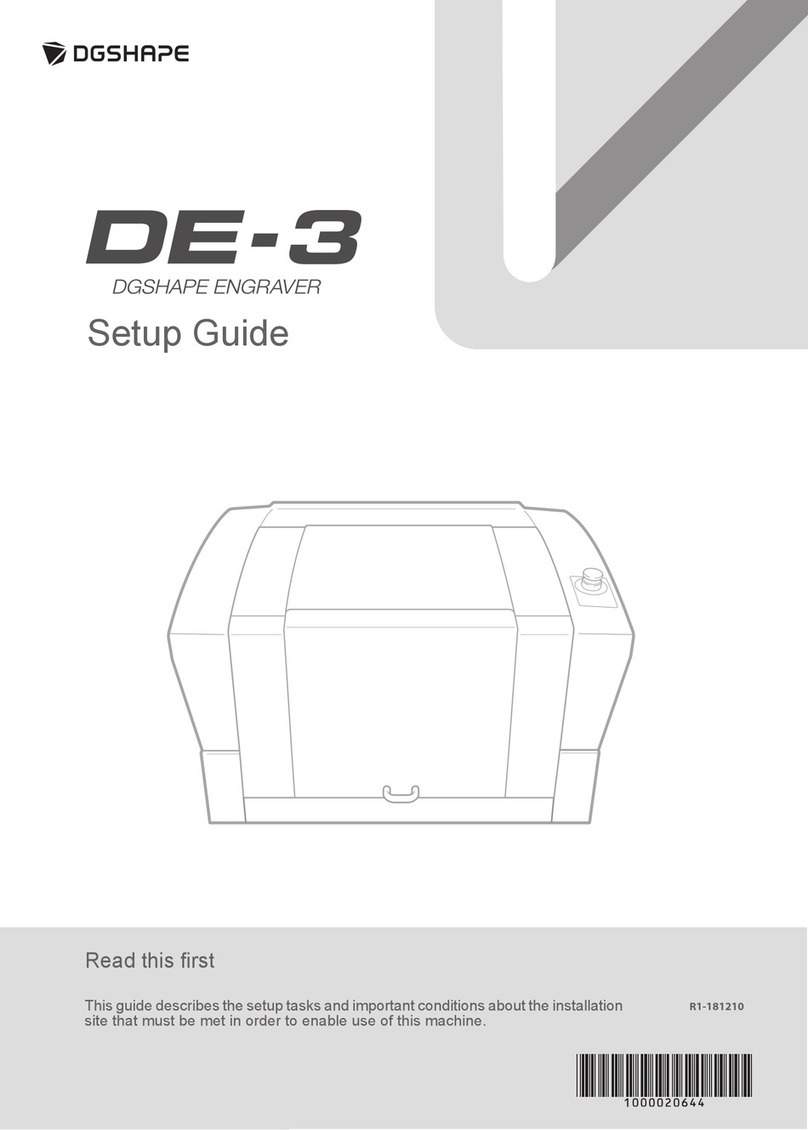

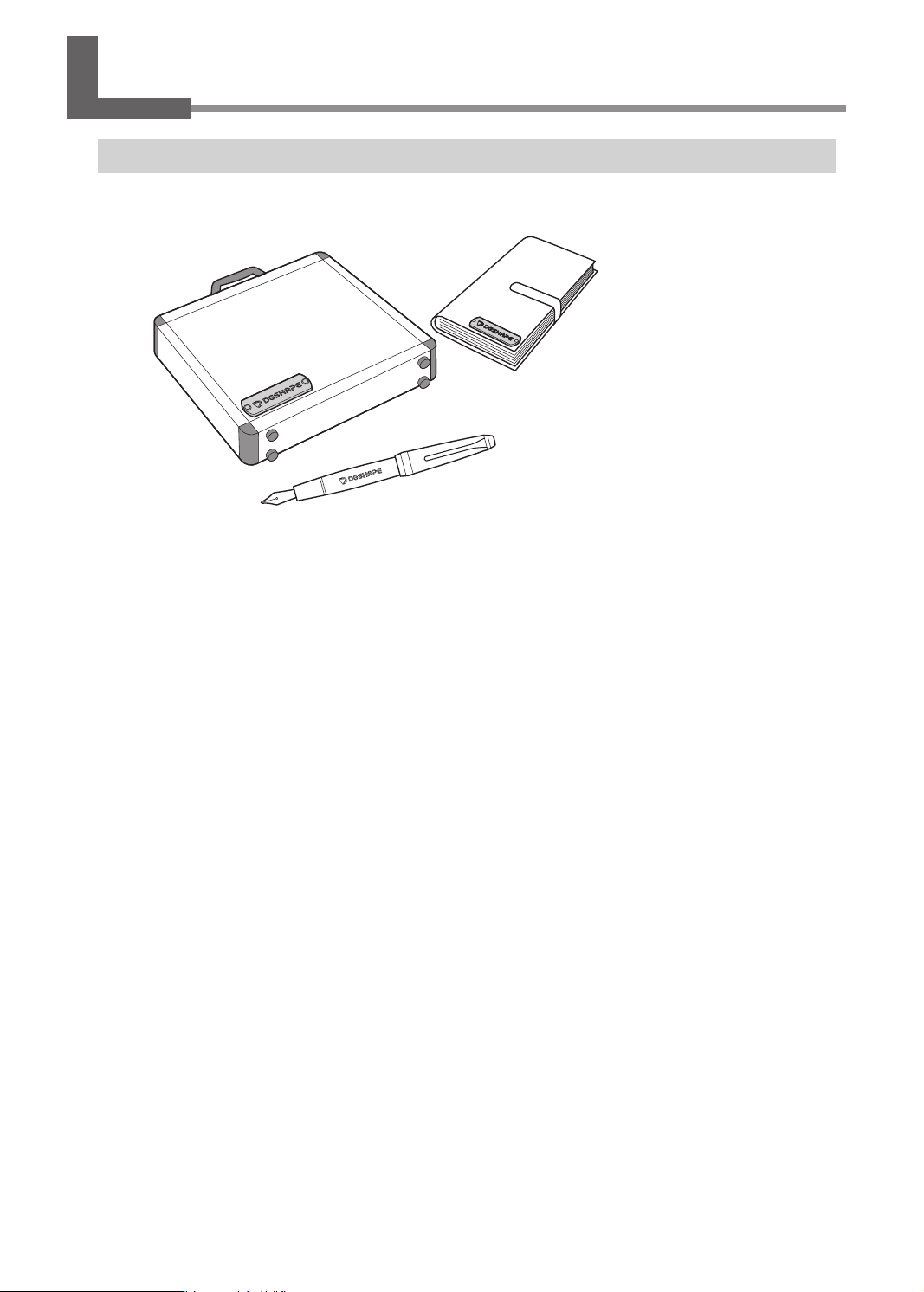

DGSHAPE DE-3 User manual

• To ensure safe use with a full understanding of this machine's performance, please be sure to read through this

manual completely.

• Store this manual in a safe place where it can be referred to when needed.

• Reproduction, citation, or translation, in whole or in part, of this manual is prohibited without the express written

consent of DGSHAPE Corporation.

• The contents of this operation manual and the specications of this product are subject to change without notice.

• DGSHAPE Corporation assumes no responsibility for any damage that may occur through use of this product,

regardless of any failure to perform on the part of this product or of any errors in this document. Damage includes

but is not limited to damage caused by the specications or performance of the product, damage caused by non-

use of the product, and damage caused by deliverables obtained through use of this product. Such damage can be

either direct or indirect.

Contents

Contents..............................................................................................................................................................................................1

Chapter 1 Getting Started ................................................................................................4

About This Machine ........................................................................................................................................................................5

Features of This Machine..............................................................................................................................................5

Part Names and Functions............................................................................................................................................................6

Front and Interior............................................................................................................................................................6

Side.......................................................................................................................................................................................7

Handy Panel......................................................................................................................................................................8

Viewing the Handy Panel Screen ..............................................................................................................................9

Menu List.......................................................................................................................................................................................... 10

Main Menu ..................................................................................................................................................................... 10

File Menu......................................................................................................................................................................... 11

Origin-setting Menu ................................................................................................................................................... 11

Chapter 2 Basic Operation.............................................................................................12

Emergency Stop to Ensure Safety........................................................................................................................................... 13

How to Perform an Emergency Stop .................................................................................................................... 13

Canceling an Emergency Stop................................................................................................................................ 13

Switching the Power On or O ................................................................................................................................................ 16

Switching the Power On............................................................................................................................................ 16

Switching the Power O............................................................................................................................................ 17

Moving the Tool............................................................................................................................................................................. 18

Terms of Tool Position................................................................................................................................................. 18

Display Example of Tool Position............................................................................................................................ 18

Moving to the Desired Position .............................................................................................................................. 19

Moving to the Specied Position ........................................................................................................................... 20

Pausing and Aborting ................................................................................................................................................................. 21

Pausing and Resuming Engraving......................................................................................................................... 21

Aborting Engraving..................................................................................................................................................... 23

Chapter 3 Basic Engraving Methods ............................................................................24

Checks and Preparation before Engraving.......................................................................................................................... 25

Checking the Flow of Engraving Operation....................................................................................................... 25

Checking Engravable Workpieces.......................................................................................................................... 26

Determining the Item to Create and Required Material and Tool.............................................................. 27

Creating Engraving Data ............................................................................................................................................................ 28

Step 1: Starting Dr. Engrave Plus ............................................................................................................................ 28

Step 2: Creating a Shape ........................................................................................................................................... 30

Step 3: Loading an Image ......................................................................................................................................... 31

Step 4: Entering Text ................................................................................................................................................... 33

Step 5: Setting the Engraving Parameters .......................................................................................................... 35

Step 6: Saving Engraving Data ................................................................................................................................ 37

Starting Engraving........................................................................................................................................................................ 38

Step 1: Setting the Workpiece................................................................................................................................. 38

Step 2: Setting the XY Origin ................................................................................................................................... 39

Step 3: Installing a Character Cutter/Parallel Cutter........................................................................................ 41

Step 4: Checking the Engraving Parameters...................................................................................................... 51

Step 5: Starting Engraving........................................................................................................................................ 54

1

Other Basic Operations............................................................................................................................................................... 56

Adjusting the Tool Feeding Speed and the Number of Rotations during Engraving (Override).... 56

Attaching the Vacuum Adapter .............................................................................................................................. 58

Setting the Lock Lever................................................................................................................................................ 62

Changing the Operation Mode............................................................................................................................... 63

Setting the Avoidance Height of the Tool to Match the Workpiece Shape ............................................ 64

Chapter 4 Maintenance ..................................................................................................66

Maintenance Precautions .......................................................................................................................................................... 67

Daily Care......................................................................................................................................................................................... 68

Cleaning after Engraving Finishes ......................................................................................................................... 68

Cleaning Inside the Spindle Unit Cover............................................................................................................... 69

Storing the Cutter........................................................................................................................................................ 70

Replacing Consumable Parts.................................................................................................................................................... 71

Replacing the Spindle Unit....................................................................................................................................... 71

Replacing the Resin Nose Cone.............................................................................................................................. 73

Correction........................................................................................................................................................................................ 75

Distance Correction..................................................................................................................................................... 75

Laser Correction ........................................................................................................................................................... 75

When Moving the Machine....................................................................................................................................................... 78

When the Machine Has Not Been Used for a Prolonged Period.................................................................................. 80

Spindle Run-in (Warm-up)........................................................................................................................................ 80

Chapter 5 Various Engraving Methods .........................................................................82

Nose Unit Overview and Precautions.................................................................................................................................... 83

The Role of the Nose Unit ......................................................................................................................................... 83

Nose Unit Limitations................................................................................................................................................. 83

When Using Nose Unit............................................................................................................................................... 84

Using Various Tools....................................................................................................................................................................... 85

Determining the Item to Create and Required Material and Tool.............................................................. 85

Considering Engraving Parameters....................................................................................................................... 87

Using a Diamond Scraper ......................................................................................................................................... 88

Using an End Mill ......................................................................................................................................................... 97

Using a Character Cutter/Parallel Cutter (without Nose Unit)...................................................................104

Surface Leveling of the Workpiece Table............................................................................................................................114

Previewing before Engraving .................................................................................................................................................118

Checking the Cutting Path of the Tool (Path Preview)..................................................................................118

Checking the Four Corners of the Engraving Area (Area Preview) ..........................................................119

Checking Any Point on Engraving Data Using a Workpiece (Point Preview) .......................................121

Repeating the Same Engraving .............................................................................................................................................123

Things You Can Do When Creating Engraving Data.......................................................................................................124

Making Use of Layers................................................................................................................................................124

Chapter 6 Appendix ......................................................................................................125

Troubleshooting (Machine Problems).................................................................................................................................126

The Power Does Not Turn On ................................................................................................................................126

Initial Operations Are Not Performed or Fail....................................................................................................126

The Operation Button Does Not Respond When Pushed ...........................................................................126

The USB Cable/LAN Cable Has Come Loose during Engraving.................................................................126

Contents

2

The Machine Does Not Move When Engraving Data Is Sent......................................................................127

The Spindle rotates but Does Not Move From Its Position When Engraving Data Is Sent ..............127

The Spindle Does Not Rotate.................................................................................................................................127

Descent Does Not Stop............................................................................................................................................128

Loud Noise or Unpleasant Noise during Engraving ......................................................................................129

Troubleshooting (Engraving Quality Problems) ..............................................................................................................130

Engraving Is Not Performed on the Expected Position................................................................................130

Cutting-in Depth Is Not Uniform (When Nose Unit Is Used)......................................................................130

Cutting-in Depth Is Not Uniform (When Nose Unit Is Not Used)..............................................................130

The Tool Leaves Tracks at Places Where Cutting-in Starts or Where Lines Change Direction ........131

An Engraved Bottom Surface Is Rough or Burring Remains ......................................................................131

Engraved Lines Are Uneven or Wavy ..................................................................................................................132

Troubleshooting (Installation)................................................................................................................................................133

Driver Installation Is Impossible............................................................................................................................133

Uninstalling the Driver.............................................................................................................................................137

Installing the Driver Separately.............................................................................................................................140

Installing the Software and the Electronic-format Manual Separately..................................................142

Responding to an Error Message ..........................................................................................................................................144

"1000-000*" The % limit switch was not found...............................................................................................145

"1017-0000" The cover was opened during the spindle rotating.............................................................145

"1023-0000" (RML-1) The number of the parameters is incorrect. ...........................................................146

"1024-0000" (RML-1) The parameter is out of range. ....................................................................................146

"1025-0000" (RML-1) A wrong command is detected...................................................................................147

"1029-0000" The spindle experienced an overload.......................................................................................147

"102A-000*" The spindle experienced overcurrent. ......................................................................................148

"102B-0000" The spindle motor temperature is too high. ..........................................................................149

"102D-0000" The spindle cannot be turned.....................................................................................................150

"1044-0000" The automatic Z0 setting failed...................................................................................................150

Locations of the Power Rating and Serial Number Labels ...........................................................................................151

Connector Specications .........................................................................................................................................................152

Expansion Port............................................................................................................................................................152

Machine Specications.............................................................................................................................................................153

External View ...............................................................................................................................................................153

Work Area......................................................................................................................................................................154

Workpiece Table Installation Area Dimensional Drawing...........................................................................155

Laser Pointer Irradiation Area................................................................................................................................155

Main Specications ...................................................................................................................................................156

http://www.dgshape.com/

Copyright © 2018 DGSHAPE Corporation

Company names and product names are trademarks or registered trademarks of their respective holders.

Contents

3

4

Chapter 1 Getting Started

About This Machine............................................................................................................................5

Features of This Machine ......................................................................................................5

Part Names and Functions ...............................................................................................................6

Front and Interior ....................................................................................................................6

Side...............................................................................................................................................7

Handy Panel ..............................................................................................................................8

Viewing the Handy Panel Screen.......................................................................................9

Menu List............................................................................................................................................. 10

Main Menu.............................................................................................................................. 10

File Menu................................................................................................................................. 11

Origin-setting Menu............................................................................................................ 11

Chapter 1 Getting Started

Features of This Machine

This machine is a desktop engraving machine. It can be used in a variety of applications such as making

personalized gifts and accessories by engraving names and creating signboards and industrial products.

• Accommodates various engraving methods

This machine achieves expressive, high-quality engraving of a wide range of types, from contouring and ll,

to hollowing and scribing.

• Outstanding basic performance

The spacious operating area measuring 305 × 230 × 40 mm (W × D × H; 12.0 × 9.1 × 1.6 in.) and the high-

speed spindle that turns at up to 20,000 rpm make for rapid engraving.

• Preview function for preventing failures

You can conrm the engraving area in advance using the laser pointer. By conrming which area of the

workpiece will actually be engraved in advance, you can perform engraving on any location you want.

• Designed for ease of use

You control machine operation using a handy panel that is separate from the machine. This lets you control

the machine from a location aording a clear view of the workpiece and tool. You can also make settings for

the machine simply and easily while viewing the display screen on the handy panel.

• Automatic Z control feature

The machine oers an automatic Z control feature that makes possible engraving at a uniform depth, even

on workpieces with wavy surfaces.

(Trackable undulation height: gentle undulations of about 1 mm (0.04 in.))

• High levels of safety

A front cover and an emergency stop button are standard features of the machine.

About This Machine

5

Chapter 1 Getting Started

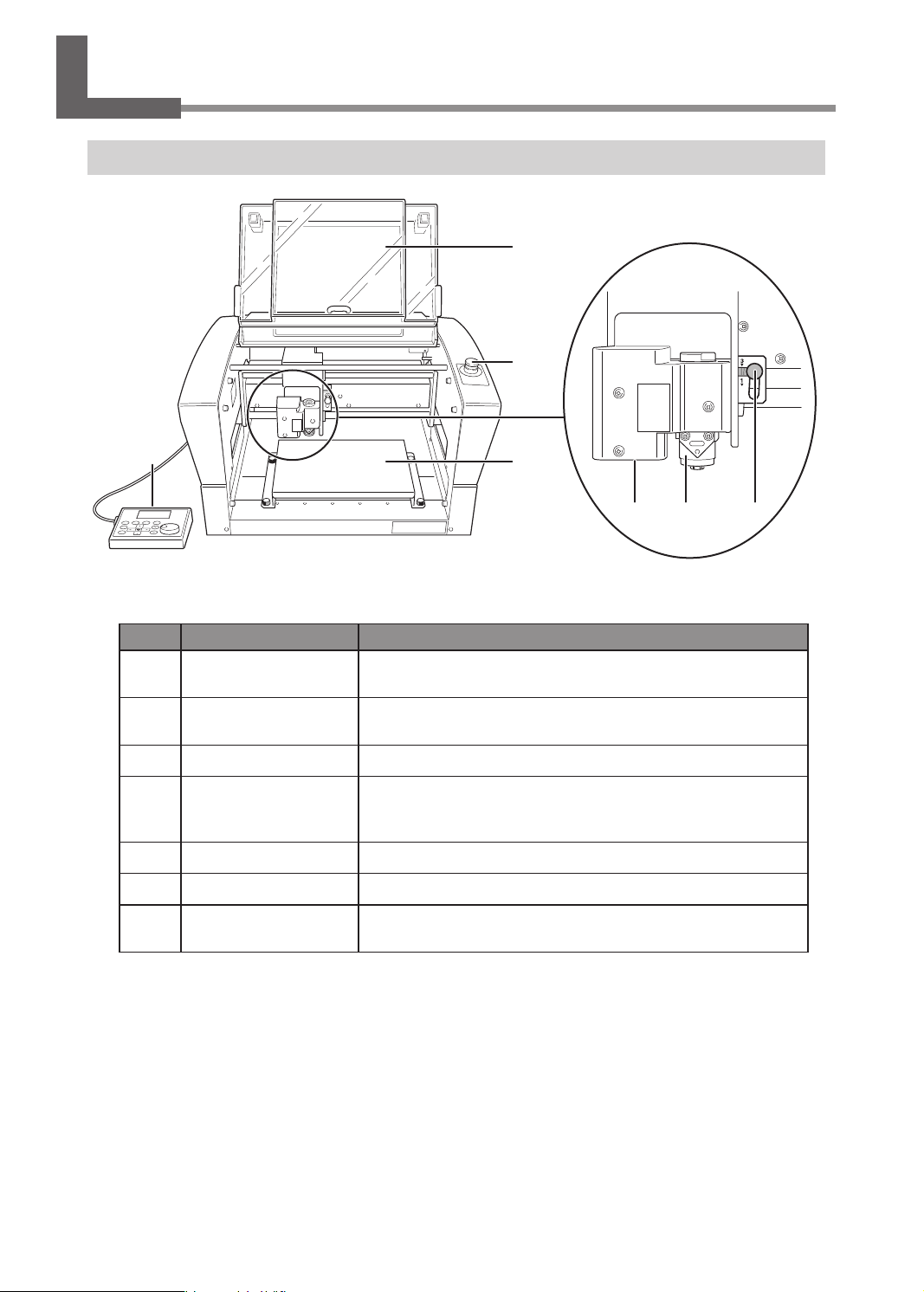

Front and Interior

Spindle head*

3

5

4

6 7

2

1

* In this document, the mechanisms around the spindle unit, including the spindle motor, are called the

"spindle head." Also, the rotary-axis area inside the spindle unit is called the "spindle."

No. Part Overview

1Front cover To ensure safety, opening this during engraving or spindle rotation

causes an emergency stop to occur.

2Emergency stop button Press this in an emergency to interrupt this machine's power supply.

"P. 13“Emergency Stop to Ensure Safety”

3Workpiece table The workpiece to be engraved is mounted on this table.

4Handy Panel

This is used to perform tool movement and other machine

operations, and to make various settings.

"P.8 “Handy Panel”

5Laser pointer Laser irradiation is applied from here.

6Spindle unit Install the tool here.

7Lock lever This locks or unlocks the spindle head.

"P. 62“Setting the Lock Lever”

Part Names and Functions

6

Chapter 1 Getting Started

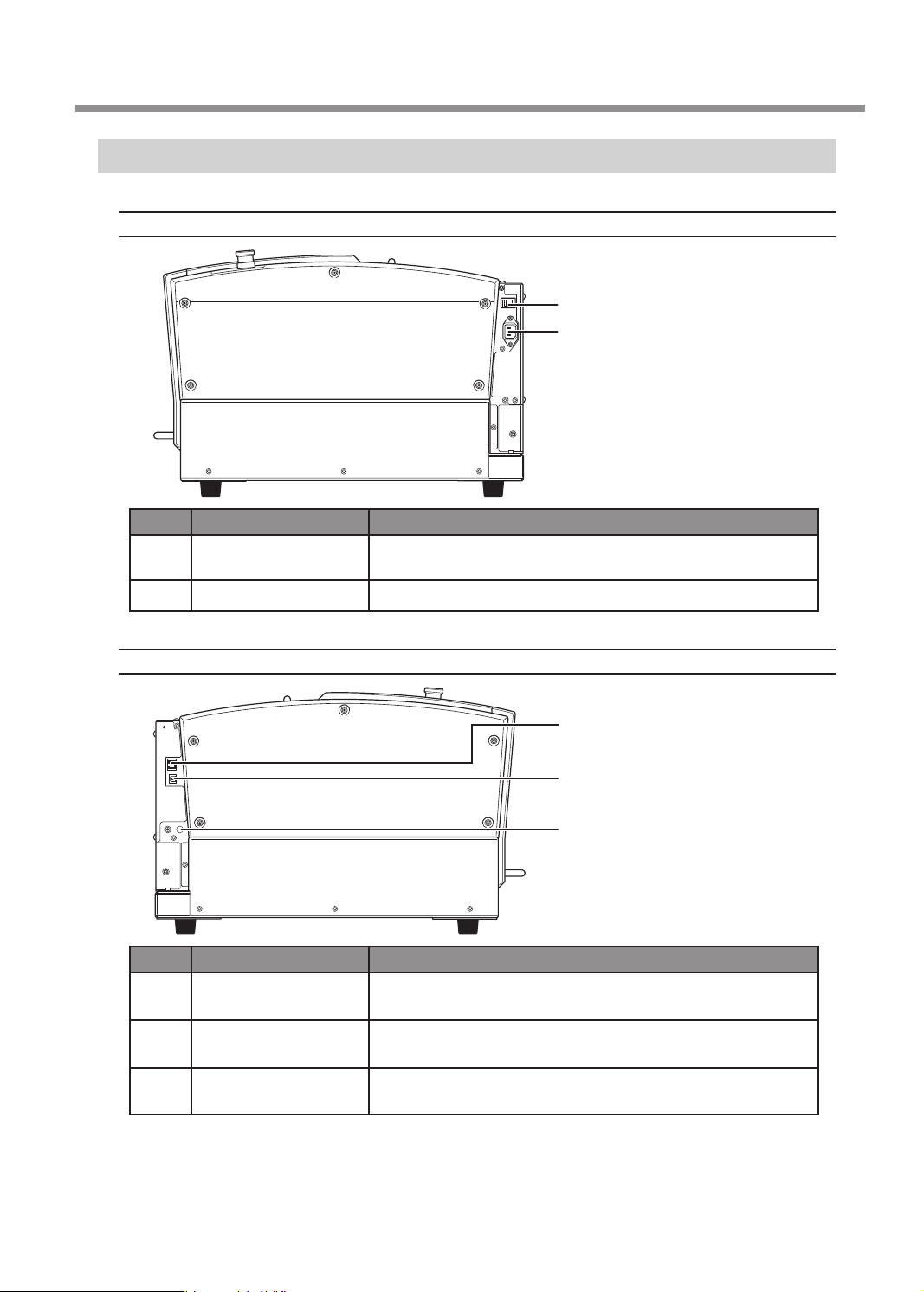

Side

Right Side

1

2

No. Part Overview

1Power switch This switches this machine's power on or off.

"P.16 “Switching the Power On or Off”

2Power cord connector This is for connecting a power cord.

Left Side

3

4

5

No. Part Overview

3LAN connector This is for connecting a LAN cable.

"Setup Guide "Connecting the LAN Cable"

4USB connector This is for connecting a USB cable.

"Setup Guide "Connecting the USB Cable"

5Expansion port This is a connector for external equipment.

"P. 152“Expansion Port”

Part Names and Functions

7

Chapter 1 Getting Started

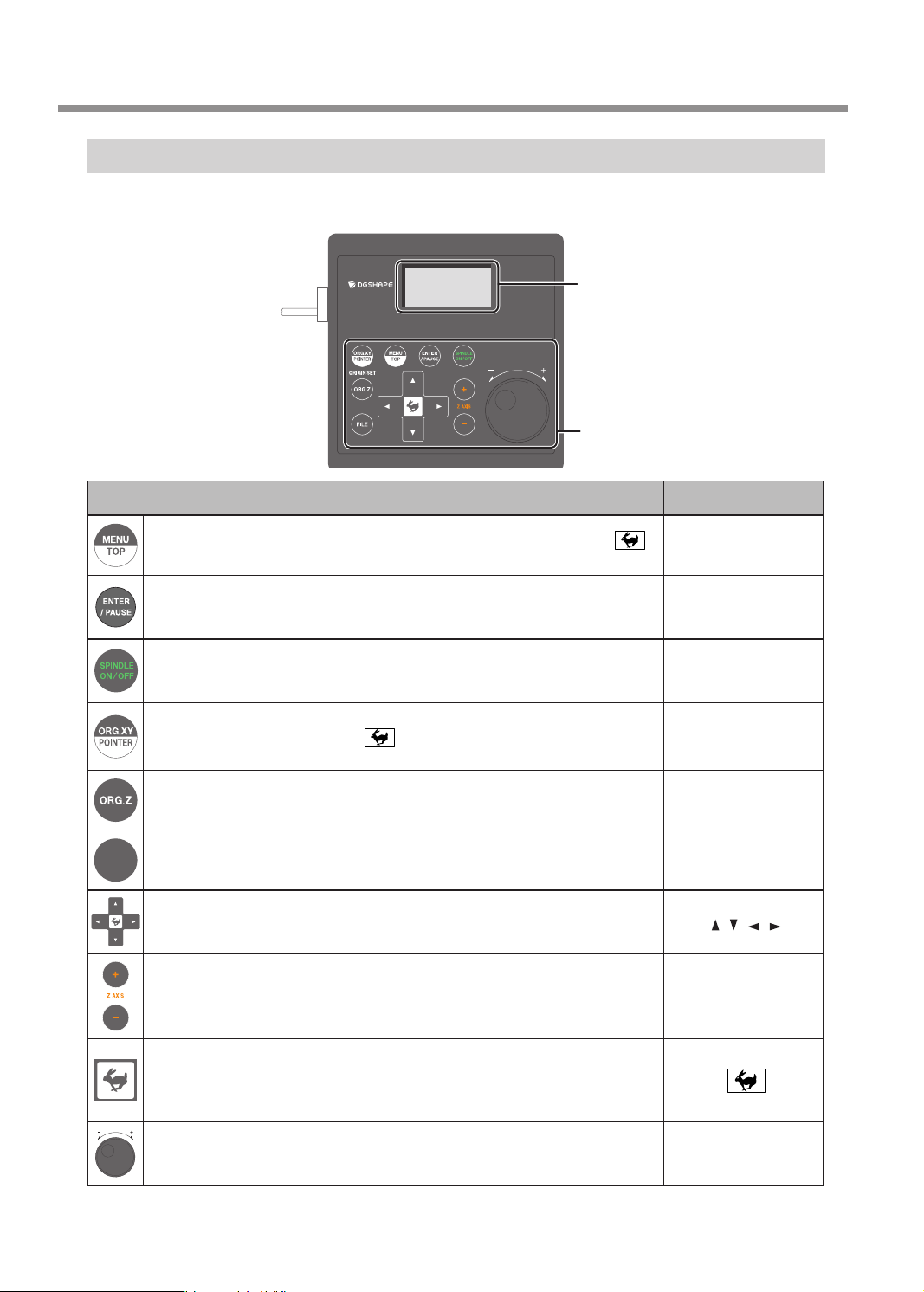

Handy Panel

This is used to perform tool movement and other machine operations, and to make various settings. Close the

front cover, then perform the operation of the handy panel.

Display screen

Menus, messages, etc. are displayed here.

"P.9 “Viewing the Handy Panel Screen”

Operation button

For details, see table below.

Operation button Functional overview Notation used in this

document

Menu/Top Pressing this changes the menu screen. Hold down

and press this button to return to the main screen.

[MENU/TOP]

Enter/Pause

This executes a selected on-screen item or conrms a

selected item or value. Pressing this during engraving

pauses operation and displays the PAUSE menu.

[ENTER/PAUSE]

Spindle

Holding this down for one second or longer while the

spindle is stopped makes spindle rotation start. Pressing

this during spindle rotation stops rotation.

[SPINDLE]

X/Y-axis Origin

Setting/Laser

Pointer

This sets the reference point for the engraving position.

Hold down and press this button to switch on and

off the irradiation from the laser pointer.

[ORG.XY/POINTER]

Z-axis Origin

Setting This sets the reference point for the engraving position. [ORG.Z]

FILE

File Operates the data in the memory of this machine. [FILE]

Move These move the tool forward and backward, and to the left

and right. [][ ] [ ] [ ]

Z-axis

Movement These move the tool up and down. [+Z]

[-Z]

Feed/Shift

Pressing a Movement or Z-axis Movement button while

holding down this button makes the tool move rapidly. This

is also used as a shift key by pressing it at the same time

as other buttons.

Dial

This adjusts the movement of the tool and the number of

rotations of the spindle. You use this to select items and

change settings on the menu screen.

[Dial]

Part Names and Functions

8

Chapter 1 Getting Started

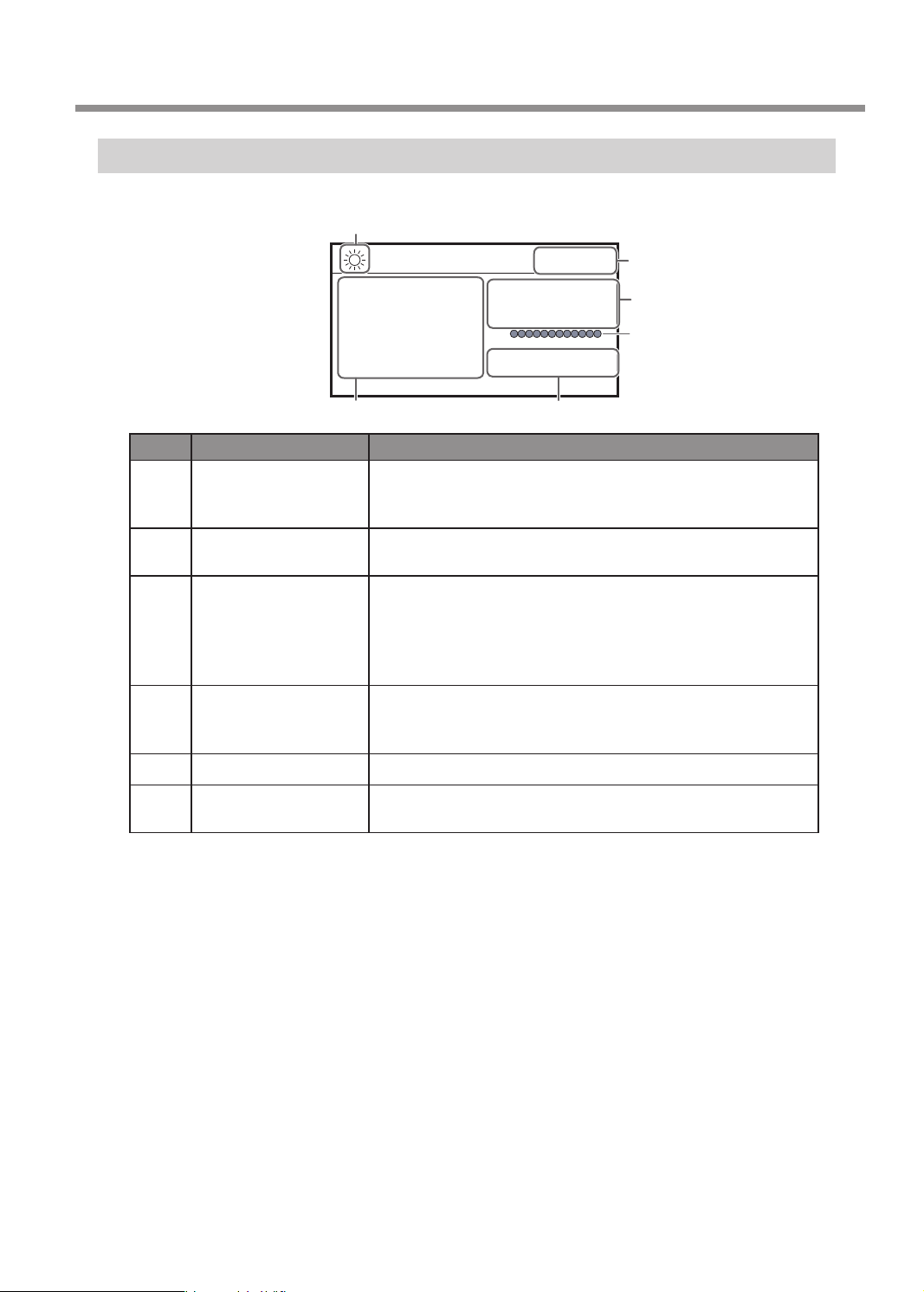

Viewing the Handy Panel Screen

XYZ 100%

S 100%

X 50.00mm

Y 30.00mm

Z 20.00mm S 5000rpm

012345678901234567 READY 2

5

1

6

4

3

(Main screen)

No. Part Overview

1Laser pointer on/off

When the laser pointer function is turned on, this icon appears. When

the laser pointer function is turned on, the current values of the laser

pointer are displayed on the handy panel.

2Status display Displays the status of the machine such as [READY], [BUSY], and

[PAUSE].

3Current values of the

tool/laser pointer

When the laser pointer function is off, this displays the current values

of the tool seen from the user origin. When the laser pointer function

is on, this displays the current values of the laser pointer seen from

the user origin.

"P. 39“Step 2: Setting the XY Origin”

4Override

Displays the ratio of change (unit: %) relative to the present feeding

speed (XYZ) and the spindle rotating speed (S). The override setting

is only displayed during engraving.

5Spindle load Indicates the increase in load as the gauge increases to the right.

6Number of rotations

of the spindle Displays the number of spindle rotations per minute.

Part Names and Functions

9

Chapter 1 Getting Started

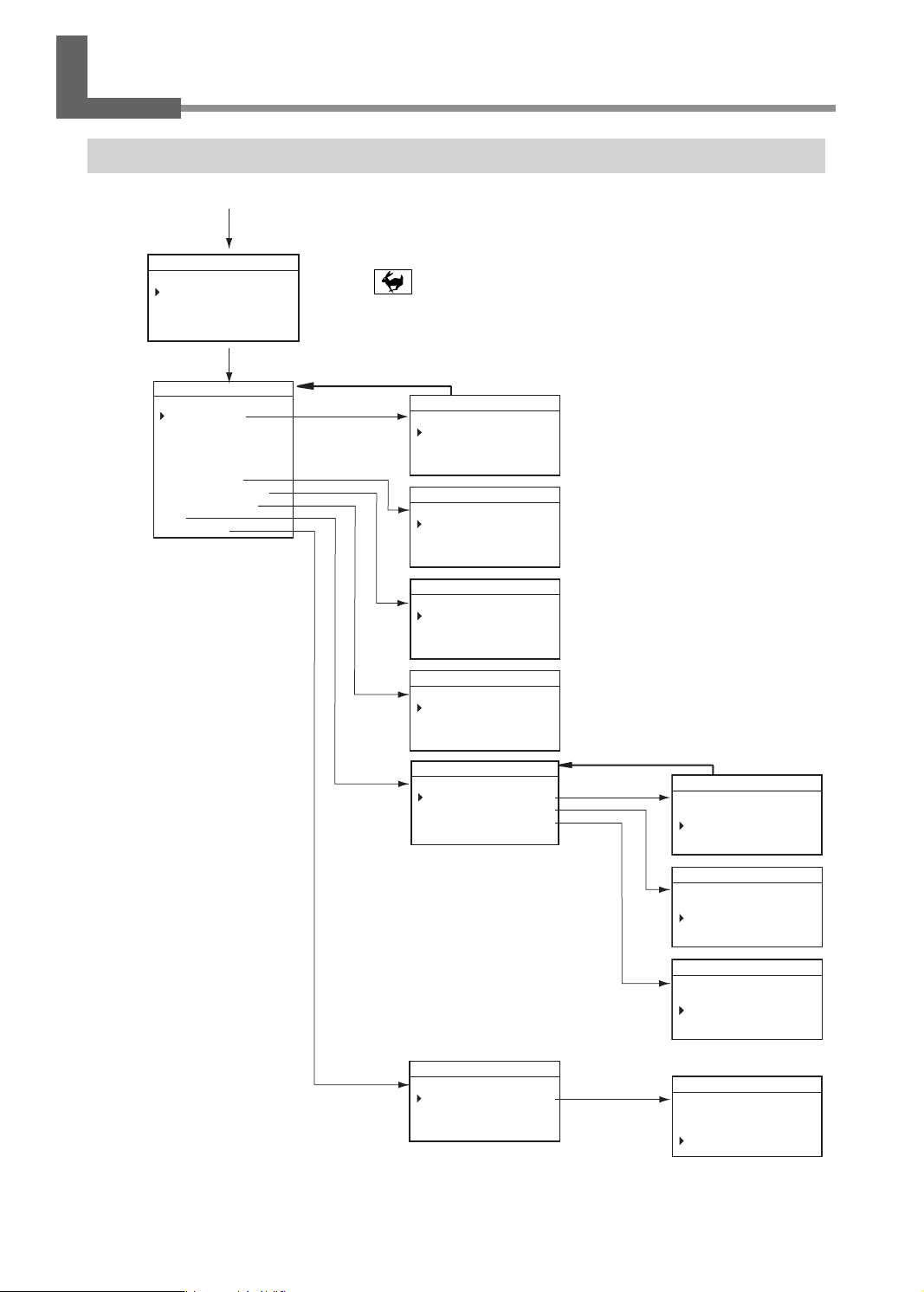

Main Menu

õöëøçúïôíÆóõêë

Æéûú

ÆöøëüïëýÆöçúî

ÆöøëüïëýÆçøëçÆÆÆÆÆÆÆÆÆÆ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

çûúõÆĀÆùëúúïôíÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆûöÆÆÆÛÔÖÖĒĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

SUBNET

255 . 255 . 255 . 000

012345678901234567 READY

GATEWAY

000 . 000 . 000 . 000

012345678901234567 READY

êïùúçôéëÆéõøøëéúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆþÆÆ×ÖÖÔÖÖË

ÆÿÆÆ×ÖÖÔÖÖË

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

òçùëøÆéõøøëéúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆþÆÆÆÖÖÔÖÖĒĒ

ÆÿÆÆÆÖÖÔÖÖĒĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

LAN

IP 192.168.001.254

SUBNET 255.255.255.000

GATEWAY 000.000.000.000

MAC 00:00:00:00:00:00

012345678901234567 READY

ïôìõøóçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùöïôêòëÆûôïúÆÆÆ×ßßßčÛÖĒ

ÆúõúçòÆýõøñÆÆÆÆÆØØÛÖčØÖĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

ïôìõøóçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùöïôêòëÆûôïúÆÆÆ×ßßßčÛÖĒ

ÆúõúçòÆýõøñÆÆÆÆÆØØÛÖčØÖĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

ïôìõøóçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùöïôêòëÆûôïúÆÆÆ×ßßßčÛÖĒ

ÆúõúçòÆýõøñÆÆÆÆÆØØÛÖčØÖĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

ïôìõøóçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùöïôêòëÆûôïúÆÆÆ×ßßßčÛÖĒ

ÆúõúçòÆýõøñÆÆÆÆÆØØÛÖčØÖĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

ïôìõøóçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùöïôêòëÆûôïúÆÆÆ×ßßßčÛÖĒ

ÆúõúçòÆýõøñÆÆÆÆÆØØÛÖčØÖĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

IP

192 . 168 . 001 . 254

012345678901234567 READY

SPINDLE UNIT

ÆýõøñÆúïóëÆÆÆÆÆÆ×ßßßčÛÖĒ

OK Clear

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆREADY

ùëúúïôíùÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆõöëøçúïôíÆóõêë

ÆùöïôêòëÆøëüõòûúïõôÆÆÆõô

ÆçûúõÆĀÆéõôúøõòÆÆÆÆÆÆõìì

ÆõüëøÆçøëçÆÆÆÆÆÆéõôúïôûë

ÆùúçøúÆóëùùçíëÆÆÆÆÆÆÆÆõô

ÆçûúõÆĀÆùëúúïôí

ÆêïùúçôéëÆéõøøëéúïõô

ÆòçùëøÆéõøøëéúïõô

Æòçô

Æïôìõøóçúïõô

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

óõüëÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆüïëýÆöõùïúïõô

Æéëôúëø

ÆûùëøÆõøïíïôÆþÿ

ÆóçéîïôëÆõøïíïôÆþÿ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

[MENU]

"P.20

"P.63

"P.75

"P.75

"P.71

"Setup Guide

"P.64

Main screen

[MENU]

[ENTER]

[ENTER]

[ENTER]

Turn the [Dial] to move the cursor on the screen or change the setting values.

* Press + [MENU] to return to the main screen.

Press [MENU] to return to the

previous screen.(*)

Press [MENU] to return to the

previous screen.(*)

Menu List

10

Chapter 1 Getting Started

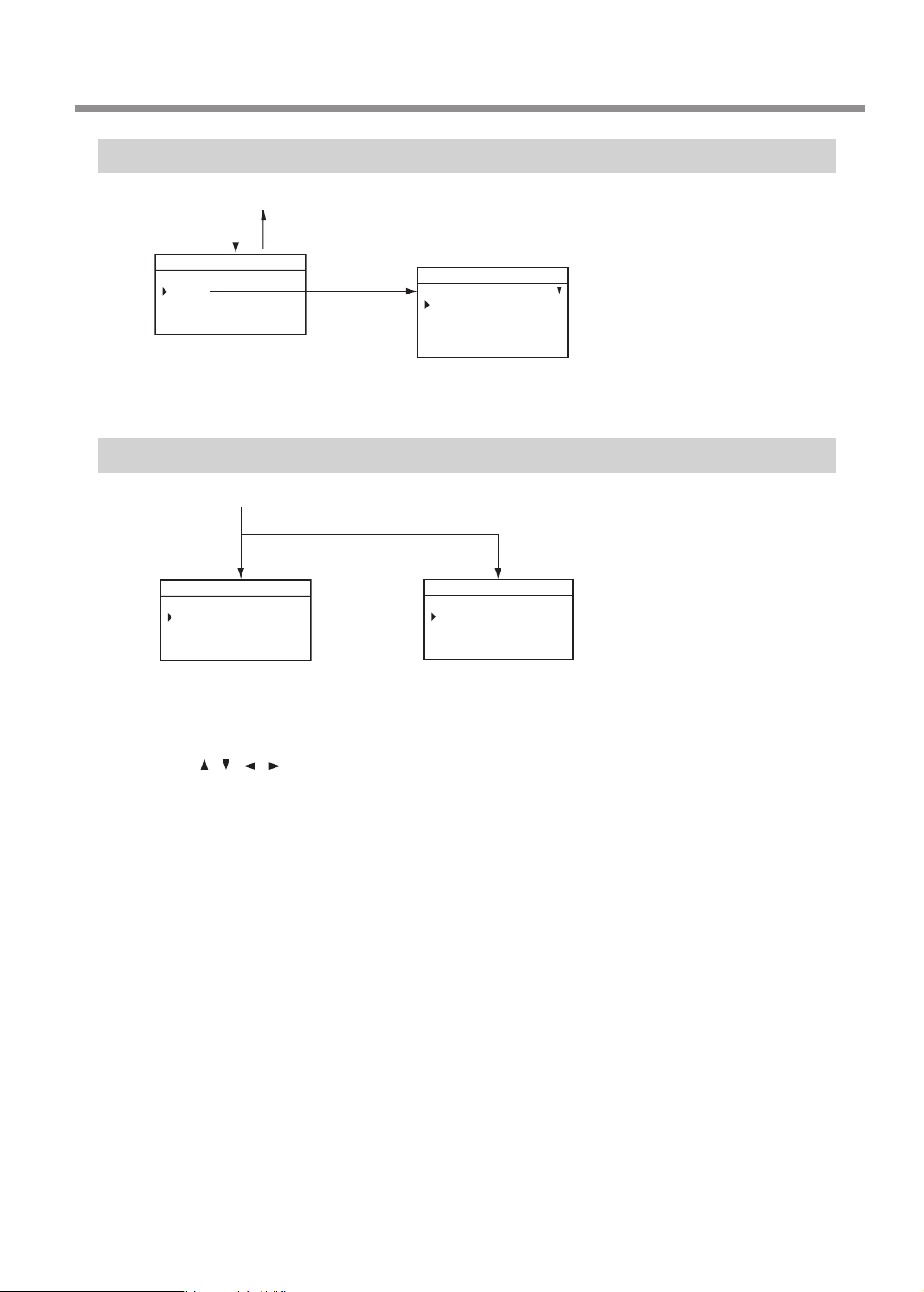

File Menu

ìïòëÆõöëøçúïõôÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

ÆùúçøúÆéûúúïôí

ÆùúçøúÆöøëüïëýÆöçúî

ÆùúçøúÆöøëüïëýÆçøëç

Æêëòëúë

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

ìïòëÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆÆ

Æéõöÿ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆøëçêÿ

Main screen

[FILE]

"P.123

[MENU]

Origin-setting Menu

• Turn the [Dial] to move the cursor on the screen.

• Use [ ], [ ], [ ], [ ], [+Z], and [−Z] to change the settings.

• Press [MENU] to return to the main screen.

ORIGIN SET Z

Z0

Z -30.00mm

012345678901234567 READY

ORIGIN SET XY

ÆþÿƄƄƄƄþƄƄƄƄÿ

ÆÆþƄÙÞÔÞÞĒĒ

ÆÆÿÆÆ×ÝÔÖÖĒĒ

Ö×ØÙÚÛÜÝÞßÖ×ØÙÚÛÜÝÆREADY

Main screen

[ORG.XY]

[ORG.Z]

"P.39

"P.108

"P.100

Menu List

11

Chapter 1 Getting Started

12

Chapter 2 Basic Operation

Emergency Stop to Ensure Safety .............................................................................................. 13

How to Perform an Emergency Stop............................................................................. 13

Canceling an Emergency Stop.........................................................................................13

Switching the Power On or O.................................................................................................... 16

Switching the Power On .................................................................................................... 16

Switching the Power O .................................................................................................... 17

Moving the Tool ................................................................................................................................ 18

Terms of Tool Position......................................................................................................... 18

Display Example of Tool Position.................................................................................... 18

Moving to the Desired Position....................................................................................... 19

Moving to the Specied Position ................................................................................... 20

Pausing and Aborting..................................................................................................................... 21

Pausing and Resuming Engraving ................................................................................. 21

Aborting Engraving............................................................................................................. 23

Chapter 2 Basic Operation

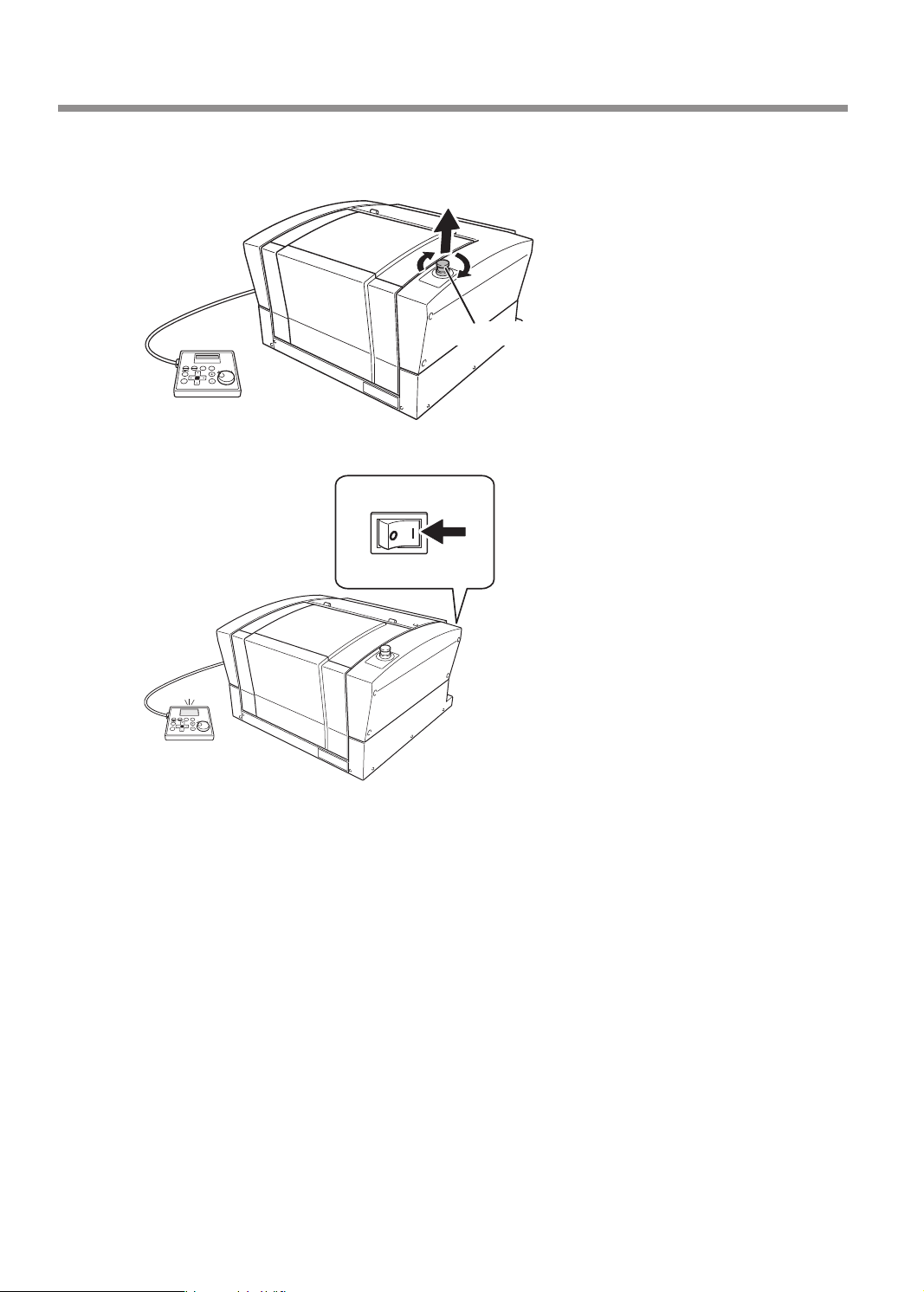

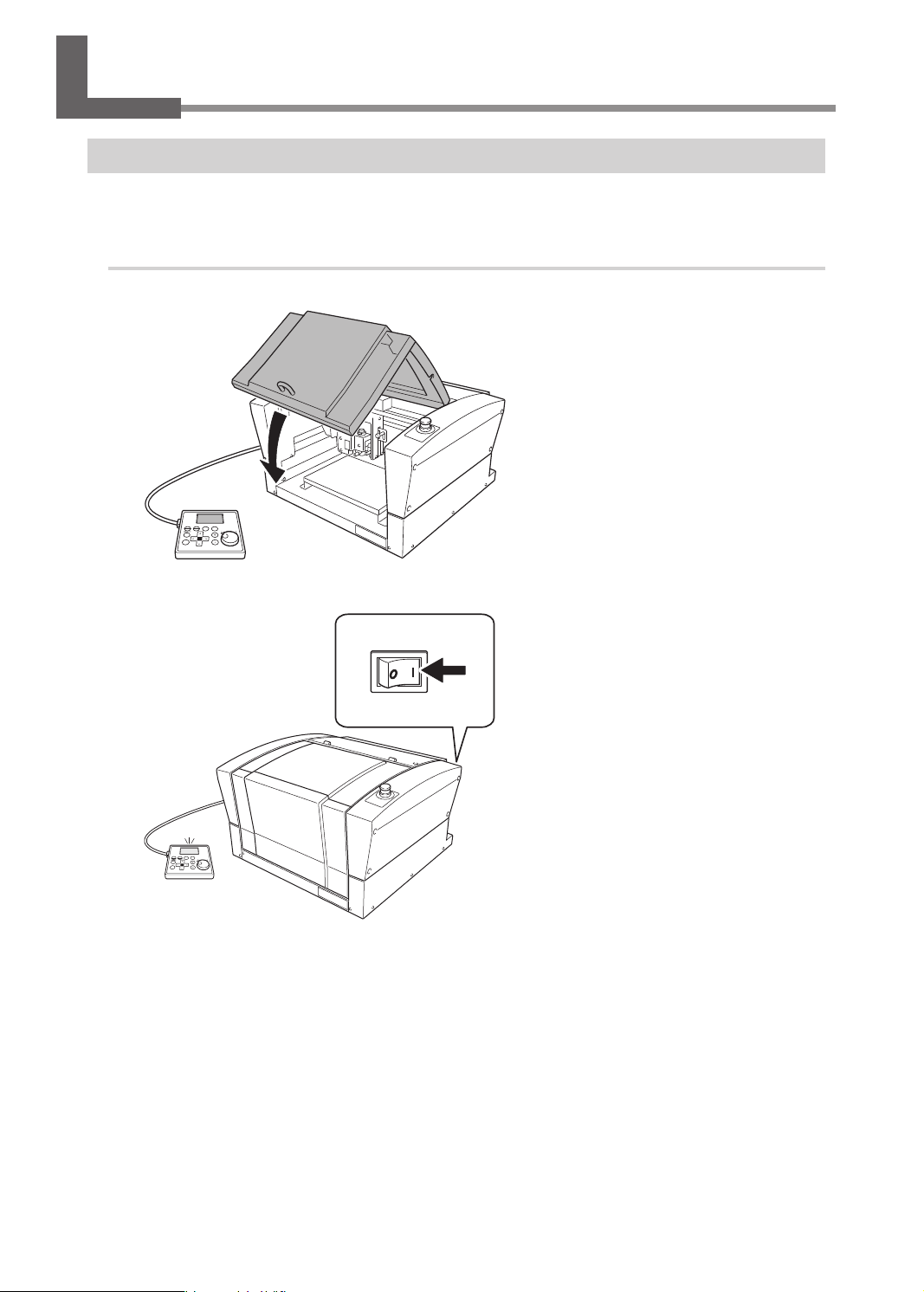

How to Perform an Emergency Stop

Procedure

Press the emergency stop button.

Operation stops immediately.

Emergency stop button

Canceling an Emergency Stop

Procedure

A Switch off the power switch.

OFF

Emergency Stop to Ensure Safety

13

Chapter 2 Basic Operation

B Turn the button in the direction of the arrows.

The button goes up, and the emergency stop is canceled.

Emergency stop button

C Switch on the power switch.

ON

Emergency Stop to Ensure Safety

14

Chapter 2 Basic Operation

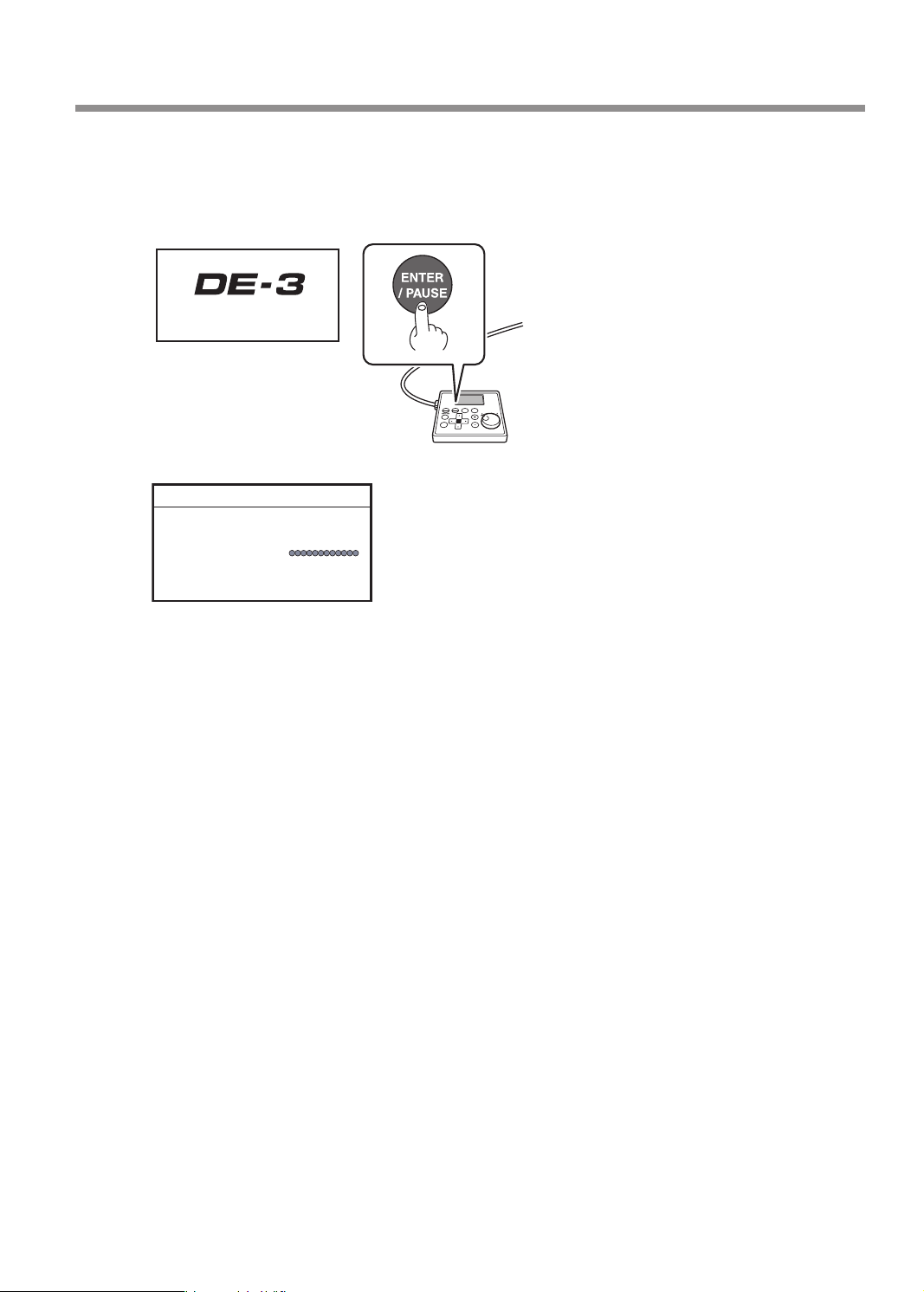

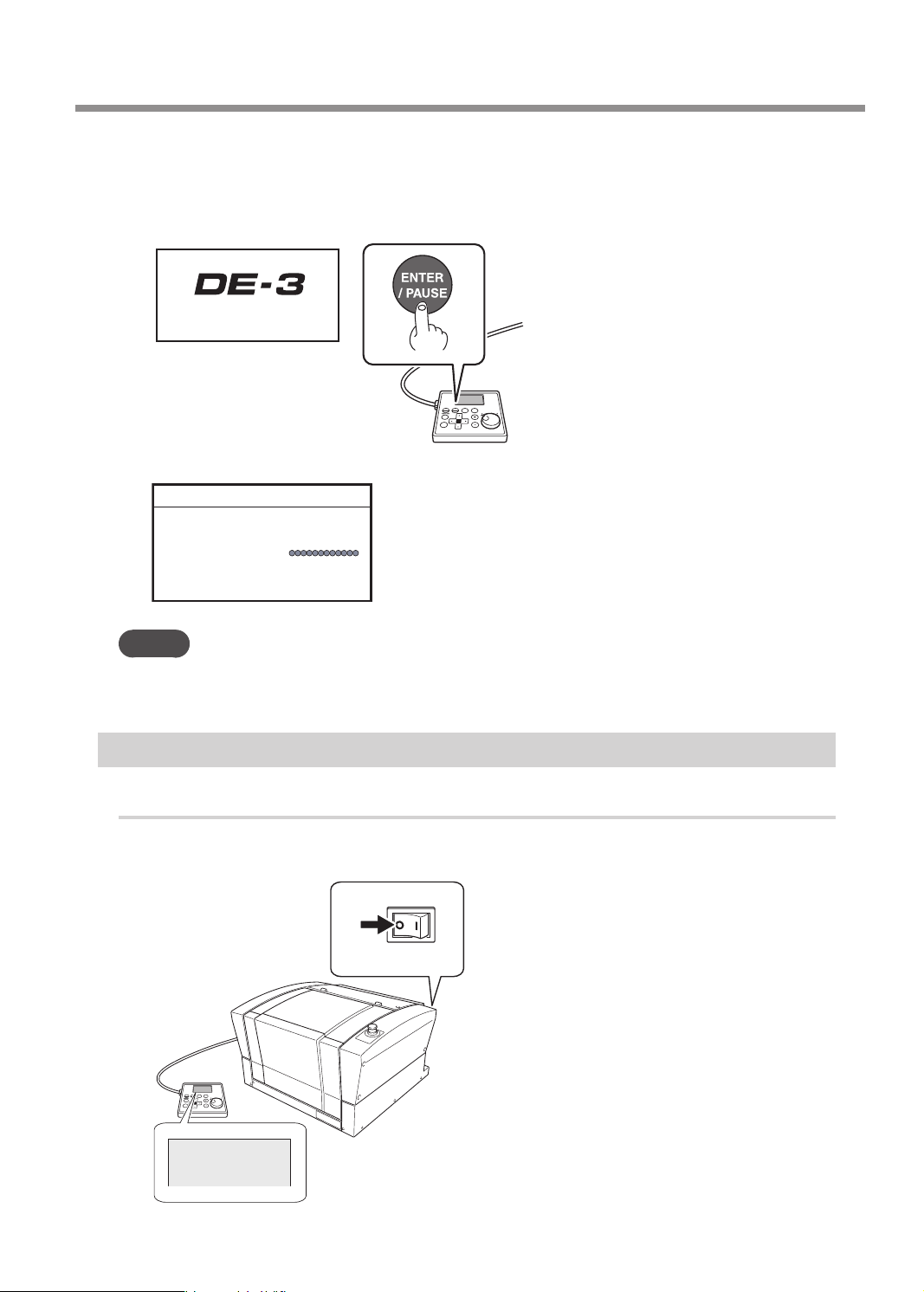

D When the screen shown below appears after approximately three seconds, press [ENTER/

PAUSE].

The spindle head moves to the left of the back of this machine (this movement at the machine's startup

is called the "initial operation").

* "XXX" indicates the version

number of the machine's

rmware.

Hit [ENTER] key.

Vxxx

When the initial operation is complete, the main screen appears.

X 15.00mm

Y 23.00mm

Z 0.00mm S 5000rpm

012345678901234567 READY

Emergency Stop to Ensure Safety

15

Chapter 2 Basic Operation

Switching the Power On

When the machine is connected to a computer, install the driver, and then turn on the power.

"Setup Guide "Installing the Software"

Procedure

A Close the front cover.

B Switch on the power switch.

ON

Switching the Power On or Off

16

Chapter 2 Basic Operation

C When the screen shown below appears after approximately three seconds, press [ENTER/

PAUSE].

The spindle head moves to the left of the back of this machine (this movement at the machine's startup

is called the "initial operation").

* "XXX" indicates the version

number of the machine's

rmware.

Hit [ENTER] key.

Vxxx

When the initial operation is complete, the following screen appears.

X 15.00mm

Y 23.00mm

Z 0.00mm S 5000rpm

012345678901234567 READY

MEMO

The factory default setting for the language used for on-screen display is English. For the method to

change the display language to Japanese, see the Setup Guide.

Switching the Power Off

Procedure

Make sure the machine is not in operation, then turn off the power switch.

The display screen on the handy panel goes dark.

OFF

O

Switching the Power On or Off

17

Chapter 2 Basic Operation

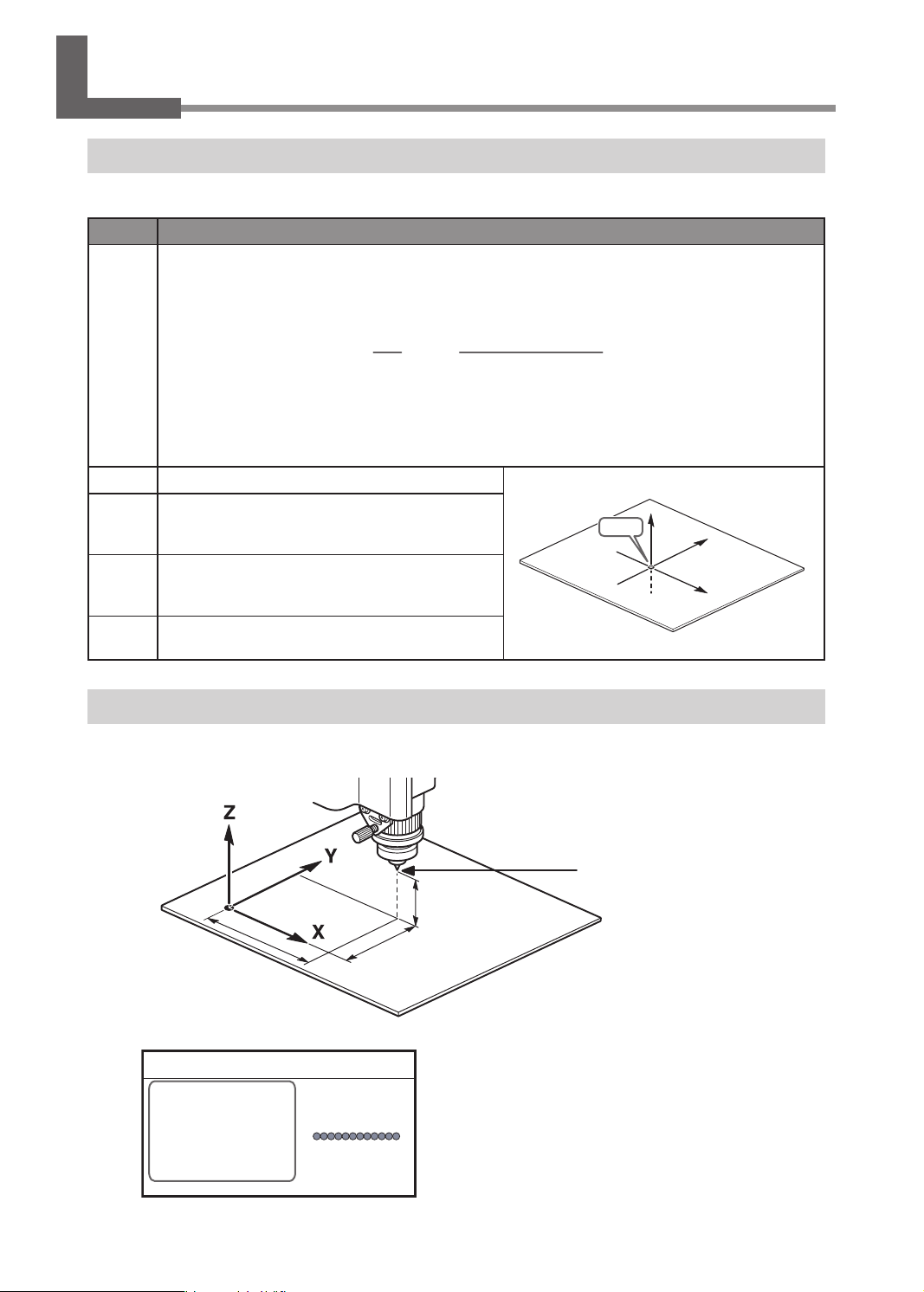

Terms of Tool Position

This manual uses the following terms to indicate the position of the tool.

Terms Overview

Coordinates

These refer to the numerical values that indicate the position of the tool on each of the X/Y/Z axis. They are represented

along with the axis, and the values are represented as positive or negative numbers.

Axis Distance from the origin

XYZ 100%

S 100%

X 35.00mm

Y 23.00mm

Z 0.00mm S 5000rpm

01234567890123456 待機中

(Representation)

The following are the two types of coordinates.

• "Machine coordinates": Coordinates whose origin is a machine-specic origin (machine origin) that

cannot be changed.

• "User coordinates": Coordinates whose origin is an origin that can be changed by the user (user origin).

Origin This refers to the origin ("0" position) of coordinates.

X

Y

Z

Origin

X-axis

coordinate

This refers to the distance from the origin of the X

axis direction (horizontal direction when the table is

seen from directly above).

Y-axis

coordinate

This refers to the distance from the origin of the Y

axis direction (vertical direction when the table is

seen from directly above).

Z-axis

coordinate

This refers to the distance from the origin of the Z

axis direction (height direction).

Display Example of Tool Position

¾When the tool has moved from the origin by 50 mm (2.0 in.) along the X axis, 30 mm (1.2 in.) along the Y

axis, and 20 mm (0.8 in.) along the Z axis.

50 mm (2.0 in.) 30 mm (1.2 in.)

20 mm (0.8 in.)

Origin

Actual tool position

This tool position is displayed on the handy panel's main screen as shown below.

X 50.00mm

Y 30.00mm

Z 20.00mm S 5000rpm

012345678901234567 READY

Moving the Tool

18

Chapter 2 Basic Operation

Other manuals for DE-3

1

Table of contents

Other DGSHAPE Engraver manuals