Table of Contents

Chapter 1 - Safety..................................................................................................... - 1 -

1.1 Principles of a CO2Laser.................................................................................................... 2

1.2 Safety Ratings..................................................................................................................... 2

1.3 The Safety Interlock System............................................................................................... 2

1.4 Safety Labels...................................................................................................................... 2

1.5 Safety Measures............................................................................................................... 5

1.6 Operating Environment....................................................................................................... 6

Chapter 2 - Unpacking & Contents........................................................................ - 7 -

2.1 Unloading and Unpacking................................................................................................. 8

2.2 Contents and Accessories Checklist................................................................................. 10

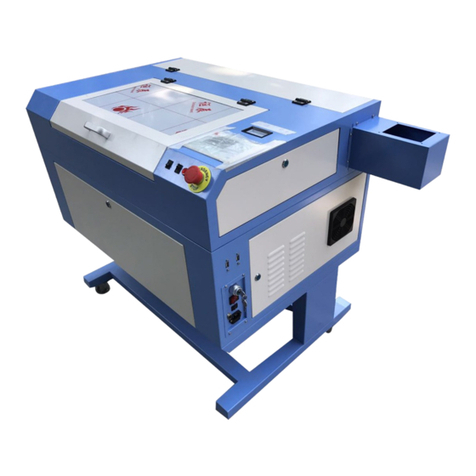

Chapter 3 - Mechanical Overview......................................................................... -11 -

3.1 Front View........................................................................................................................... 12

3.2 Top View.............................................................................................................................. 12

3.3 Right (Prole) View.............................................................................................................. 13

3.4 Left (Prole) View................................................................................................................ 13

3.5 Rear View............................................................................................................................ 14

3.6 Difference between C180 and C180S View......................................................................... 14

Chapter 4 - Setup and Installation........................................................................ - 17 -

4.1 Machine Setup.................................................................................................................... 18

4.1.1 Powering Up the Machine....................................................................................... 18

4.1.2 Power Cable Connection........................................................................................ 18

4.1.3 Connecting the Computer........................................................................................ 18

4.2 Graphics Software Setup.................................................................................................... 19

4.2.1 Recommended Computer Conguration................................................................ 19

4.2.2 Installation of the LaserPro USB Driver.................................................................. 20

4.2.3 Installation of the LaserPro Print Driver.................................................................. 26

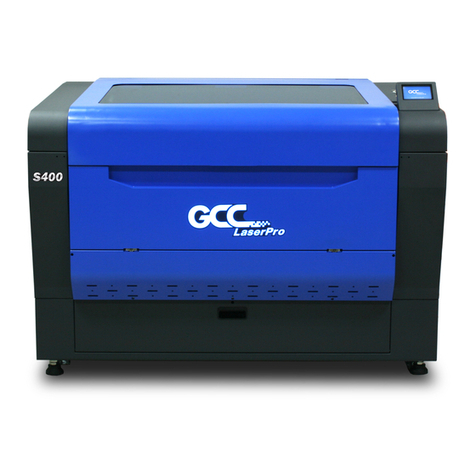

Chapter 5 - Operating the LaserPro C180 ............................................................ - 27 -

5.1 Using the Hardware............................................................................................................ 28

5.1.1 Adjusting the LCD Display Screen’s Contrast Setting............................................ 28

5.1.2 Graphic Control Panel Overview (Description)....................................................... 28

5.1.3 Graphic Control Panel Navigation Chart................................................................ 30

5.1.4 Graphic Control Panel Function Pages.................................................................. 31

5.2 The LaserPro C180 Print Driver.......................................................................................... 50

5.2.1 Page Setup and Orientation................................................................................... 50

5.2.2 Color Management................................................................................................. 52

5.2.3 Using the LaserPro C180 Print Driver..................................................................... 52

5.2.3.1 LaserPro C180 Print Driver >> Options Page......................................... 54

5.2.3.2 LaserPro C180 Print Driver >> Pen Page............................................... 59

5.2.3.3 LaserPro C180 Print Driver >> Advanced Page....................................... 61

5.2.3.4 LaserPro C180 Print Driver >> Paper Page............................................. 64

ii LaserPro C180 User Manual