02 03

Comgrow was founded in 2017 by people who have a serious passion for technology that helps

you make things. With this deep-rooted dedication, we wanted to make the digital manufacturing

process more accessible, giving educators, engineers, manufacturers, small businesses and tinkerers

the power to make anything.

Headquartered in Southern China,Shenzhen, Comgrows’ dedicated staff is committed to

providing the kind of service that makes you say"wow." We offer the highest quality materials,

machines, and accessories - from industrial-grade 3D printers to DIY laser cutters - all of which have

been tested and approved by our in-house experts. Our amazing gals and guys in customer service

are here Monday through Saturday to help with anything you may need, from finding the right

material to package your specific product, to discussing which printer is best for new users. Bottom

line is, we're here to make 3D printing, laser cutting, and CNC (will release in May. 2021) milling magic

happen. Contact us.

Thanks again for using our CNC engraving products, if you encounter any problems during the use, we

will reply you at the first time.

Service Email: service@comgrow.com

For related installation files, please check: https://www.comgrow.com

Join our Facebook support group: https://www.facebook.com/groups/comgrow/

WELCOME TO COMGROW!

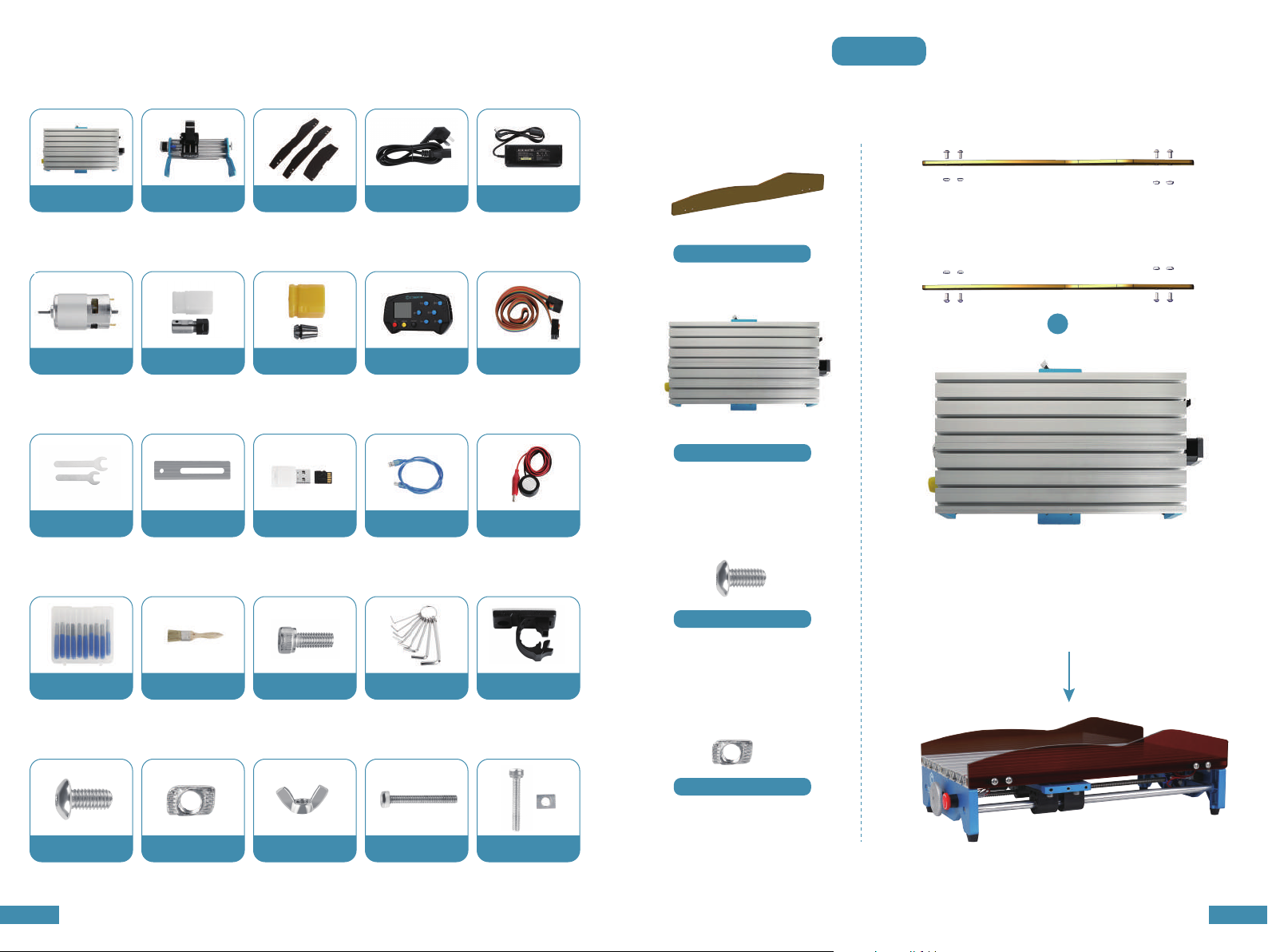

Product exterior size 400*275*268mm(motor not included)

Characteristics

Milling size 300*180*45mm

Weight 7.5KG

Drive motor 42 stepper motor,0.48 N.m.

Spindle 775 motor, 12V~24V,10000RPM

System Windows XP, Windows 7 32/64 bits,

Windows 8, Windows 10, Linux system.

Composed of aluminum, the overall structure is stable to meet the

needs of milling a wider range of materials; available for engraving

and cutting wood, plastic, acrylic, PCB, soft aluminum and so on;

unavailable for hard metals, jade and other hard objects

Acrylic baffle prevents from dust and make it easier to clean up;

equipped with emergency stop button, stop milling with one press

Operating by GRBL software or offline control handle;