DGSHAPE LD-300 User manual

Contents

Contents..............................................................................................................................................................................................2

Chapter 1 Getting Started ................................................................................................4

About the Machine..........................................................................................................................................................................5

Features ..............................................................................................................................................................................5

Names of Components.................................................................................................................................................5

Basic Operation.................................................................................................................................................................................9

Switching On the Power...............................................................................................................................................9

Switching O the Power...............................................................................................................................................9

Starting the Software ................................................................................................................................................. 10

How to Display Help for the Software.................................................................................................................. 10

Chapter 2 Imprinting.......................................................................................................11

Preparing for Imprinting............................................................................................................................................................. 12

Checking Imprint Workow ..................................................................................................................................... 12

Starting METAZAStudio............................................................................................................................................. 13

METAZAStudio Screen ............................................................................................................................................... 14

Specifying Output Destination for METAZAStudio ......................................................................................... 16

Preparing the Material ............................................................................................................................................... 17

Securing the Material .................................................................................................................................................................. 19

Selecting How to Secure the Material.................................................................................................................. 19

Loading the Material (Material Thickness: 0 to 26mm) ................................................................................. 20

Loading the Material (Material Thickness: 24 to 50mm)............................................................................... 22

Loading the Material (Material Thickness: 50 to 216mm) ............................................................................ 26

Creating Imprint Data.................................................................................................................................................................. 32

Step 1: Prepare to Create Imprint Data ................................................................................................................ 32

Step 2: Import the Image .......................................................................................................................................... 34

Step 3: Enter Text.......................................................................................................................................................... 36

Step 4: Match the Imprinting Position and Size................................................................................................ 37

Step 5: Save Imprint Data.......................................................................................................................................... 38

Imprinting........................................................................................................................................................................................ 39

Loading the Foil and the Light-absorbing Film................................................................................................. 39

Making Imprints ........................................................................................................................................................... 40

Stopping Imprint Operations ................................................................................................................................................... 44

Step 1: Stopping Imprinting Operations............................................................................................................. 44

Step 2: Deleting Data from the Imprint Queue................................................................................................. 45

Chapter 3 Maintenance and Adjustment ......................................................................47

Daily Care......................................................................................................................................................................................... 48

Points to Note on Daily Care .................................................................................................................................... 48

Cleaning the Machine ................................................................................................................................................ 48

Cleaning the Adhesive Sheet................................................................................................................................... 48

Cleaning the Film Frame ........................................................................................................................................... 49

Adjusting.......................................................................................................................................................................................... 50

Adjusting the Position of the Laser Pointer........................................................................................................ 50

Replacing Consumable Parts.................................................................................................................................................... 51

Checking the Lens Service Life................................................................................................................................ 51

Replacing the Light-absorbing Film...................................................................................................................... 52

2

Chapter 4 Detailed Operations/Settings .......................................................................55

Creating Data to Match the Film Frame................................................................................................................................ 56

Processing Images........................................................................................................................................................................ 59

Keeping Only the Required Portion of an Image (Trimming)...................................................................... 59

Adjusting the Location, Size, or Angle of an Image......................................................................................... 60

Enclosing an Image in a Frame ............................................................................................................................... 62

Tips and Tricks for Text Layout.................................................................................................................................................. 64

Changing the Location, Size, or Angle of Text................................................................................................... 64

Arranging Text to a Fan Layout ............................................................................................................................... 65

Laying Out Text along a Shape................................................................................................................................ 67

Filling Text....................................................................................................................................................................... 68

Creating/Editing a Stroke Character Font ............................................................................................................................ 70

About Stroke Characters and SFEdit2................................................................................................................... 70

SFEdit2 Window............................................................................................................................................................ 71

Creating a Stroke Character Font ........................................................................................................................... 72

Changing Entered Characters into a Stroke Character Font ........................................................................ 74

Editing Stroke Characters.......................................................................................................................................... 76

Creating Variable Imprint Data................................................................................................................................................. 78

Step 1: Create a Variable Field ................................................................................................................................. 78

Step 2: Place Text Inside the Variable Field ......................................................................................................... 81

Adjusting the Imprinting Conditions..................................................................................................................................... 82

Adjusting the Imprinting Pressure......................................................................................................................... 82

Registering the Foil and Adjusting the Imprinting Power ............................................................................ 83

Changing Basic Driver Settings................................................................................................................................................ 85

Other Operations Available with METAZAStudio.............................................................................................................. 87

Chapter 5 Appendix ........................................................................................................88

Troubleshooting............................................................................................................................................................................ 89

The [Power/Movement] Button Is Blinking ........................................................................................................ 89

The Machine Doesn't Run Even When Imprint Data Is Sent......................................................................... 91

You Cannot Select the Foil Using METAZAStudio ............................................................................................ 92

Materials and the Library Are Not Displayed in METAZAStudio ................................................................. 92

The Imprinted Location Isn't Where Desired ..................................................................................................... 92

The Imprinted Image is Unattractive (It Is Uneven or Shifted).................................................................... 96

The Imprinted Image Is Always Missing at the Same Location................................................................... 99

It Is Necessary to Remove the Unneeded Foil That Remains in Locations outside of the

Imprinting Location .................................................................................................................................................... 99

Laser Pointer Position Adjustment Failed (Head Manager).......................................................................... 99

Installing the Driver Separately............................................................................................................................... 99

Installing the Software and the Electronic-format Manual Separately.................................................... 99

Driver Installation Is Impossible.............................................................................................................................. 99

Uninstalling the Driver............................................................................................................................................... 99

Moving the Machine..................................................................................................................................................................100

Step 1: Removing the Material Retainers from the Machine .....................................................................100

Step 2: Attaching the Retainers to the Machine.............................................................................................101

Main Unit Specications...........................................................................................................................................................103

Work Area......................................................................................................................................................................103

Imprint Area.................................................................................................................................................................105

Laser Pointer Irradiation Area................................................................................................................................106

Locations of the Power Rating and Serial Number Labels ..........................................................................106

Copyright © 2019 - 2020 DGSHAPE Corporation

Contents

3

4

Chapter 1 Getting Started

About the Machine.............................................................................................................................5

Features.......................................................................................................................................5

Names of Components..........................................................................................................5

Basic Operation....................................................................................................................................9

Switching On the Power .......................................................................................................9

Switching O the Power .......................................................................................................9

Starting the Software.......................................................................................................... 10

How to Display Help for the Software .......................................................................... 10

Chapter 1 Getting Started

About the Machine

Features

This machine is a hot stamping printer that uses laser light. Using foil to imprint illustrations and text results in

high-class decorations on plastic products.

You can easily create imprint data using dedicated software.

Names of Components

Machine

Power-cord

connector

USB connector

Cover

Head

Base table

Head unit

Power/Movement button

Laser pointer

Lock lever

Laser unit

5

Chapter 1 Getting Started

Head

The foil is transferred onto the material by way of the laser light irradiated from the lens. Because the

lens is a consumable part, replace it at the appropriate time.

"P.51 "Checking the Lens Service Life"

Lens

Material Retainers

Material retaining frames

These frames secure thick material in place by clamping it. The orientation in which the frames are

secured can be changed to match the width of the material.

Knob (large)

Raising table

This table is installed on top of the base table to enable imprinting even on thin material by raising it.

Head detection holes

About the Machine

6

Chapter 1 Getting Started

Light-absorbing Film

Striking the light-absorbing lm with the laser light converts the light into heat. Note that if the lm is installed

with its front and back sides inverted by mistake, it will not be possible to convert the light to heat, so imprinting

will not be performed. For details, see P.52 "Replacing the Light-absorbing Film".

This heat transfers the foil onto the material.

A

A

Material

Laser light

Foil

Light-absorbing lm

Film frame

An adhesive sheet adhered to the bottom of the lm retainer is used to secure the light-absorbing lm.

Film frame

About the Machine

7

Chapter 1 Getting Started

Head Detection Jig

These jigs are used to detect the head. There are two types of jigs: a high one and a low one. Use these

jigs according to the thickness of the material.

About the Machine

8

Chapter 1 Getting Started

Basic Operation

Switching On the Power

Procedure

Press the [Power/Movement] button.

The head moves to the back left corner, and the lamp of the Power/Movement button is turned ON.

This operation is called initialization.

Important: When the power lamp remains blinking

An initialization error has occurred. Refer to the following section to eliminate the cause of the error, and then

press the [Power/Movement] button again.

"P.89 "The [Power/Movement] Button Is Blinking"

Switching O the Power

Procedure

Hold down the [Power/Movement] button for 1 second or longer.

The light turns o and the power is switched o.

9

Chapter 1 Getting Started

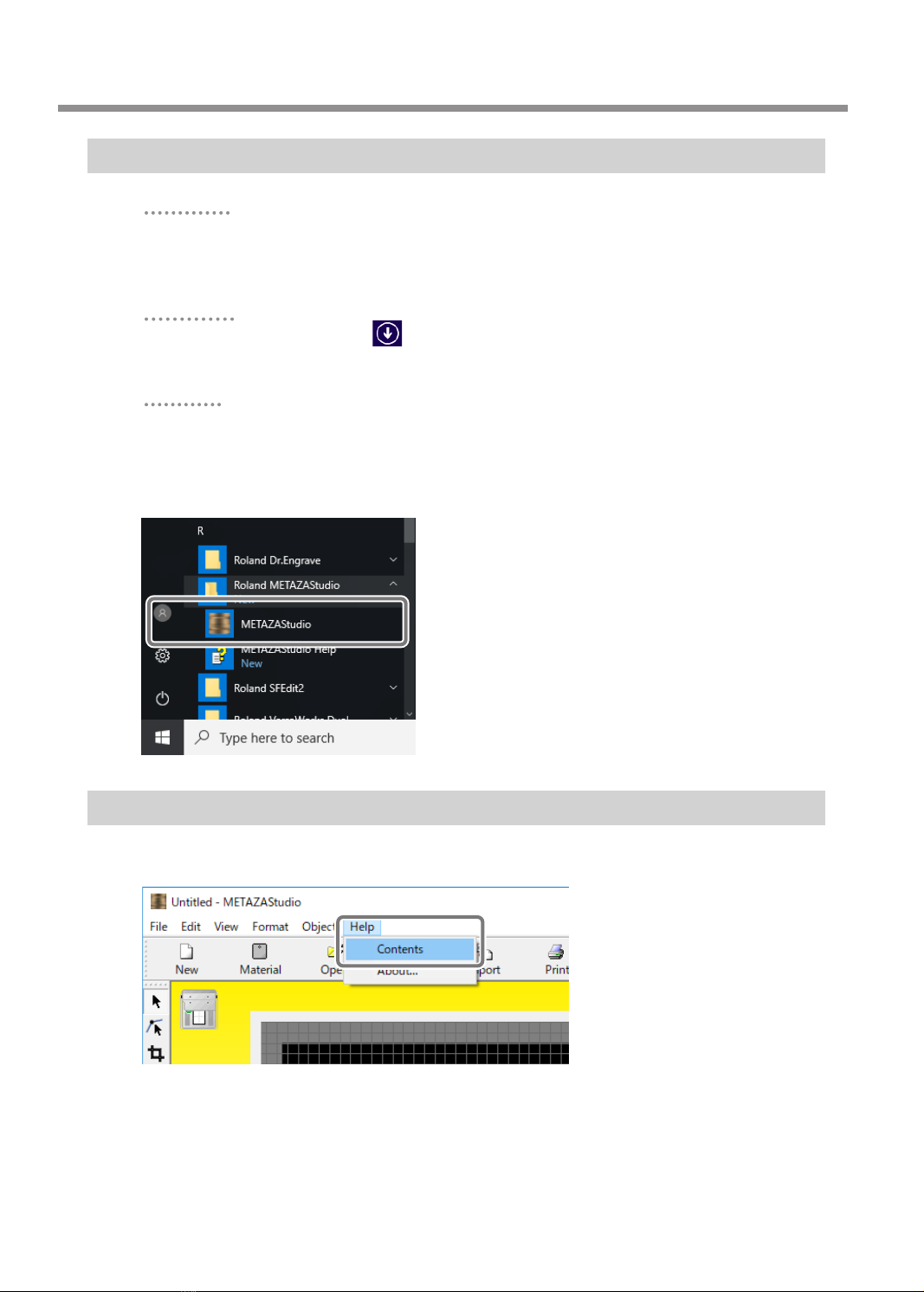

Starting the Software

Windows 10

1 Click the [Start] button.

2 Click the icon for [(Name of software to use)] under the [(Name of software to use)]

folder.

Windows 8.1

1 On the [Start] screen, click .

2 On the [Apps] screen, click the icon for [(Name of software to use)].

Windows 7

1 Click the [Start] button.

2 Click [All Programs] (or [Programs]).

3 Click the icon for [(Name of software to use)] under the [(Name of software to use)]

folder.

How to Display Help for the Software

Start the software, and then click [Help] - [Contents] from the menu.

"P.10 "Starting the Software"

Basic Operation

10

Chapter 1 Getting Started

11

Chapter 2 Imprinting

Preparing for Imprinting................................................................................................................ 12

Checking Imprint Workow.............................................................................................. 12

Starting METAZAStudio ..................................................................................................... 13

METAZAStudio Screen........................................................................................................ 14

Specifying Output Destination for METAZAStudio.................................................. 16

Preparing the Material........................................................................................................ 17

Securing the Material...................................................................................................................... 19

Selecting How to Secure the Material .......................................................................... 19

Loading the Material (Material Thickness: 0 to 26mm).......................................... 20

Loading the Material (Material Thickness: 24 to 50mm)....................................... 22

Loading the Material (Material Thickness: 50 to 216mm)..................................... 26

Creating Imprint Data..................................................................................................................... 32

Step 1: Prepare to Create Imprint Data......................................................................... 32

Step 2: Import the Image................................................................................................... 34

Step 3: Enter Text .................................................................................................................. 36

Step 4: Match the Imprinting Position and Size ........................................................ 37

Step 5: Save Imprint Data.................................................................................................. 38

Imprinting ........................................................................................................................................... 39

Loading the Foil and the Light-absorbing Film......................................................... 39

Making Imprints.................................................................................................................... 40

Stopping Imprint Operations....................................................................................................... 44

Step 1: Stopping Imprinting Operations......................................................................44

Step 2: Deleting Data from the Imprint Queue ......................................................... 45

Chapter 2 Imprinting

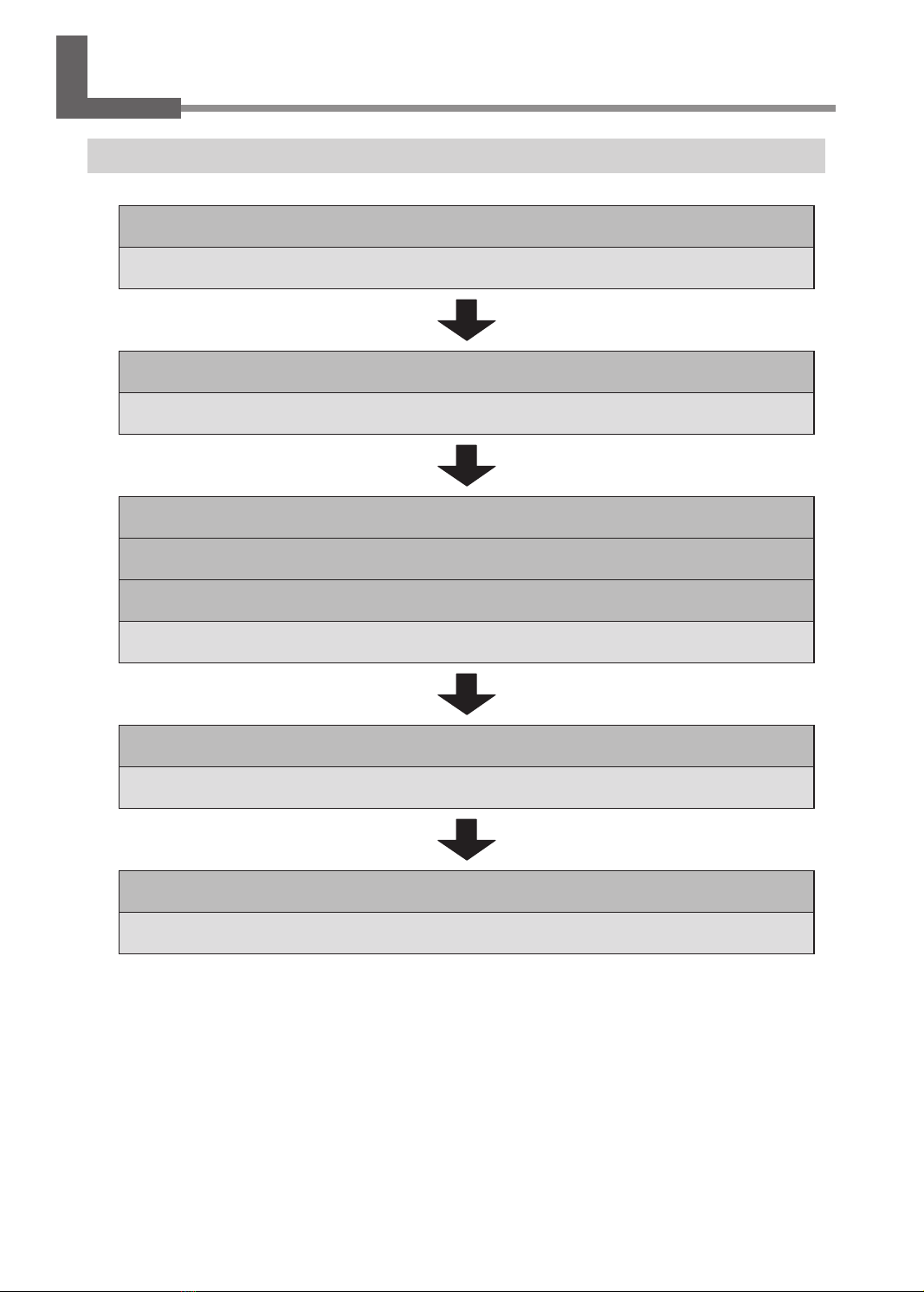

Checking Imprint Workow

P.16 "Specifying Output Destination for METAZAStudio"

Switch on the power of the machine and select it as the output destination for the computer.

P.17 "Preparing the Material"

Check several conditions such as the material type and thickness that must be met for a material to be imprinted.

P.20 "Loading the Material (Material Thickness: 0 to 26 mm)"

P.22 "Loading the Material (Material Thickness: 24 to 50 mm)"

P.26 "Loading the Material (Material Thickness: 50 to 216 mm)"

Set the material on the machine.

P.32 "Creating Imprint Data"

Create imprinting data using METAZAStudio.

P.39 "Imprinting"

Output the imprint data from METAZAStudio.

Preparing for Imprinting

12

Chapter 2 Imprinting

Starting METAZAStudio

Windows 10

1 Click the [Start] button.

2 Click the [METAZAStudio] icon under the [Roland METAZAStudio] folder.

Windows 8.1

1 On the [Start] screen, click .

2 On the [Apps] screen, click the [METAZAStudio] icon.

Windows 7

1 Click the [Start] button.

2 Click [All Programs] (or [Programs]).

3 Click the [METAZAStudio] icon under the [Roland METAZAStudio] folder.

METAZAStudio starts.

Preparing for Imprinting

13

Chapter 2 Imprinting

METAZAStudio Screen

No. Name Overview of function

1Menu bar Runs the various commands for METAZAStudio.

"METAZAStudio online help ("Commands")

2Toolbar

The toolbar is provided with buttons for running METAZAStudio commands such

as [Material] and [Open].

"METAZAStudio online help ("Commands" - "Toolbar Buttons")

3Page feed bar

When you have entered data into a variable eld, use this to specify the page

(record) that is displayed on the screen. Use this for variable imprinting.

"P.78 "Creating Variable Imprint Data"

"METAZAStudio online help ("Hints and Tips" > "Performing Variable Printing")

4Status bar

This shows the present location of the cursor, information about the shape, the

grid, and the view magnication. Moving the pointer to a toolbar button or pointing

to a menu command makes a brief explanation of the button or command appear

at the left edge.

Present cursor

position

This indicates the present location of the cursor. The

position at the center of the window (where the two

center lines intersect) is (0, 0).

Shape information

This appears when you click an on-screen object

(image, text, or shape). The center position and size

of the present shape are displayed, as shown in the

gure below.

Grid pitch

This displays the pitch (spacing) of the grid lines.

Clicking this displays menu items related to the

appearance of the grid.

View scaling factor

This displays the present scaling factor for the screen

view. Clicking this displays a menu that lets you

change the view scaling factor.

Preparing for Imprinting

14

Chapter 2 Imprinting

11

No. Name Overview of function

5Work area

This is the area in which the laser can move. The material size set with LD

Driver is shown here.

"P.85 "Changing Basic Driver Settings"

6LP movement

possible area You can move the laser pointer within this range.

7LP movement not

possible area

Do not move the laser pointer within this area. If you attempt to do so, laser

irradiation may occur in an unexpected position.

8Center line This indicates the vertical and horizontal centers of the window.

9Grid This is a grid of lines displayed in the work area. It serves as a guide for

positioning images and text.

0Margin

This blank area lies inside the edges of the work area and where no imprinting

is performed. The default setting upon installation of METAZAStudio is 2 mm

(0.08 in.). You can change the size of the margin by going to the [File] menu

and selecting [Preferences].

"P.32 "Step 1: Prepare to Create Imprint Data"

AHead detection

position

Perform operations within the window to display the head detection jig in the

same position as that where it is attached to the machine (back left corner/

front right corner).

"P.40 "Making Imprints"

Preparing for Imprinting

15

Chapter 2 Imprinting

Specifying Output Destination for METAZAStudio

Procedure

A Switch on the power to the machine.

"P.9 "Switching On the Power"

B Start METAZAStudio.

"P.13 "Starting METAZAStudio"

C Click [File] → [Set up the printer].

The [Print Setup] screen appears.

D Select the printer to which data will be output.

1 Select [DGSHAPE LD-300].

2 Click [OK].

Preparing for Imprinting

16

Chapter 2 Imprinting

Preparing the Material

In order for a material to be used for imprinting with this machine, the material must meet all of the following

conditions.

Material

• Acrylic

• Polypropylene

• Polystyrene

• ABS

• Leather

• Polyurethane

• Vinyl chloride

Thickness

Maximum: 216mm (8.5in.)

Size

Width: Maximum 323mm (12.72in.)

Size that can be stably xed in place.

With this machine, use the adhesive sheet and retainers to secure the material. It is acceptable for the material to

be of a size such that it protrudes from the adhesive sheet and retainers, but the essential requirement is that the

material can be rmly secured within the main unit.

When using the raising table: A material size such that one of the head detection holes is not covered

Head detection holes

When not using the raising table: A material size such that the head detection jig can be attached correctly

Preparing for Imprinting

17

Chapter 2 Imprinting

Shape

There must be no unevenness on the imprint surface.

Imprinting is not possible for material that comes into contact with the moving part of the machine when

being loaded or during imprinting.

The edge of the

material is too high.

Not OK

L-shape

Flat view:

Cross-sectional

view:

Gentle undulations of less than 0.5 mm (0.02 in.)

If the height displacement cannot be tracked by the head, correct imprinting will not be possible.

Preparing for Imprinting

18

Chapter 2 Imprinting

Securing the Material

Selecting How to Secure the Material

The securing method varies according to the thickness of the material. Standards are shown below.

Material

D

Material

D

C

B

Material

B

Material

A

Material

thickness Securing method

Place the included raising table on the base table,

and then x the material in place.

"P. 20 “Loading the Material (Material Thickness: 0 to

26mm)”

Items used

• Raising table A

• Base table B

Fix the material in place on the base table.

"P. 22 “Loading the Material (Material Thickness: 24 to

50mm)”

Items used

• Base table B

Remove the base table, and then x the material in

place with the material retaining frames.

"P. 26 “Loading the Material (Material Thickness: 50 to

216mm)”

Items used

• Height adjusting block C

* This is not included. Prepare it separately.

• Material retaining frames D

Remove the base table, and then x the material in

place with the material retaining frames.

"P. 26 “Loading the Material (Material Thickness: 50 to

216mm)”

Items used

• Material retaining frames D

0mm

24mm

(0.9in.)

26mm

(1.0in.)

50 mm

(2.0 in.)

190mm

(7.5in.)

216mm

(8.5in.)

Memo: When the thickness of the material is 24 to 26 mm (0.9 to 1.0 in.)

When imprinting is frequently performed on material whose surface is soft or whose thickness is less than 26mm

(1.0in.), use the raising table.

"P. 20 "Loading the Material (Material Thickness: 0 to 26 mm)"

19

Chapter 2 Imprinting

Loading the Material (Material Thickness: 0 to 26 mm)

Procedure

A Open the cover.

B Load the raising table on the base table.

Insert the positioning pins on the bottom of the raising table into the holes on the upper surface of the

base table.

Raising table

Hole

Positioning pins

C Set the adhesive sheet.

If the material is large, use two adhesive sheets.

Securing the Material

20

Chapter 2 Imprinting

Other manuals for LD-300

1

Table of contents

Other DGSHAPE Printer manuals