2. INSTALLATION

Page 13 © 2007 DH Instruments, a Fluke Company

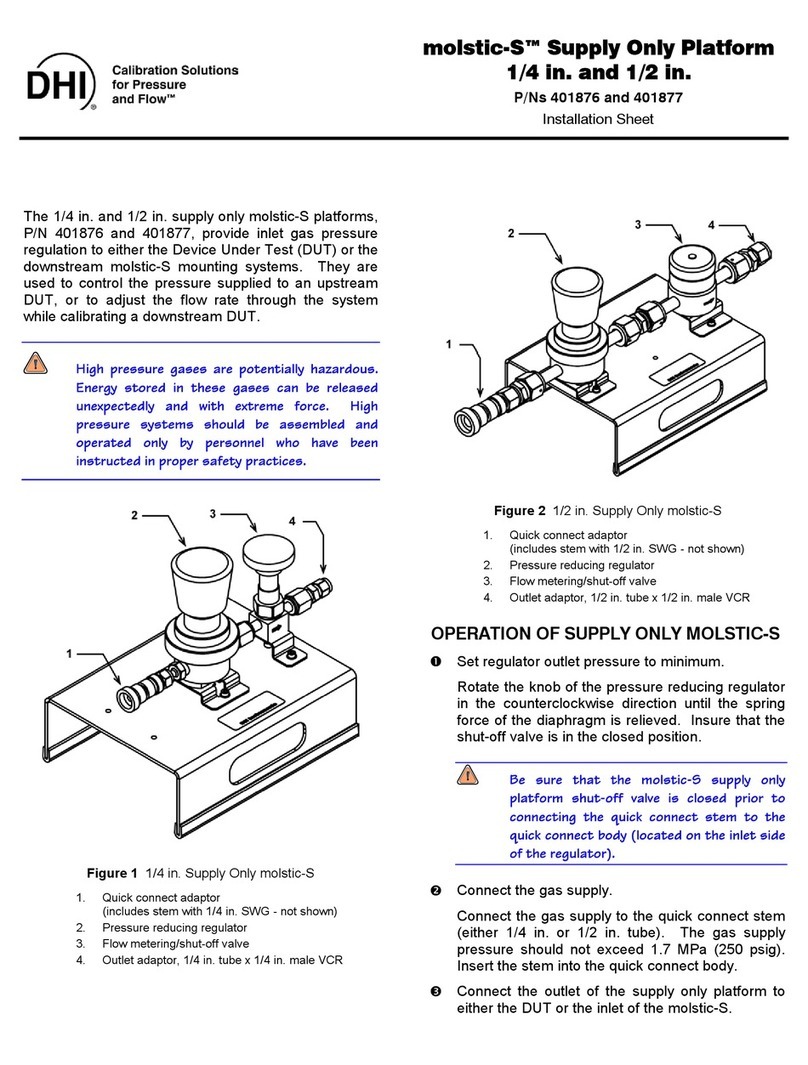

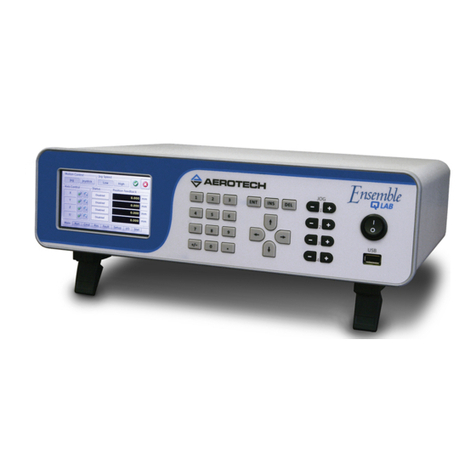

GPC1 TEST port

DH500 nipple with

glands and collars

installed

Adaptor, DH500 F to

1/4 in. M, 1/4 in. F,

1/8 in. M, AN4 M

or other

Connection to DUT

GPC1 TEST port

DH500 nipple with

glands and collars

installed

Adaptor, DH500 F to

1/4 in. M, 1/4 in. F,

1/8 in. M, AN4 M

or other

Connection to DUT

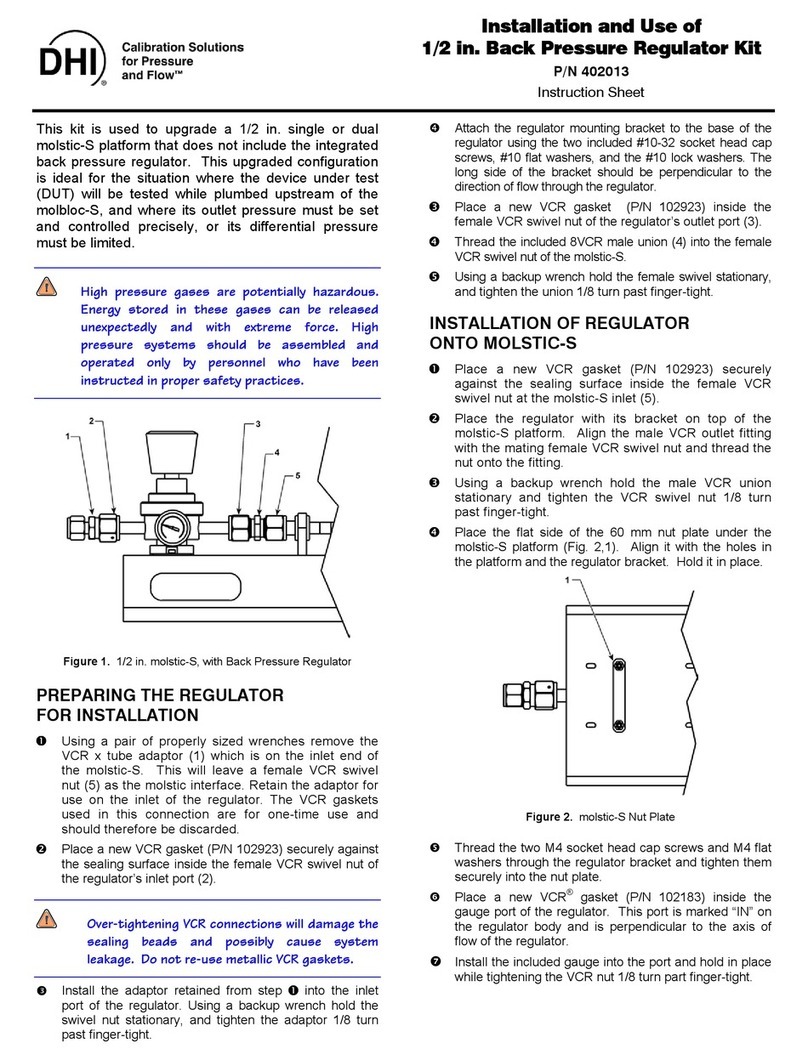

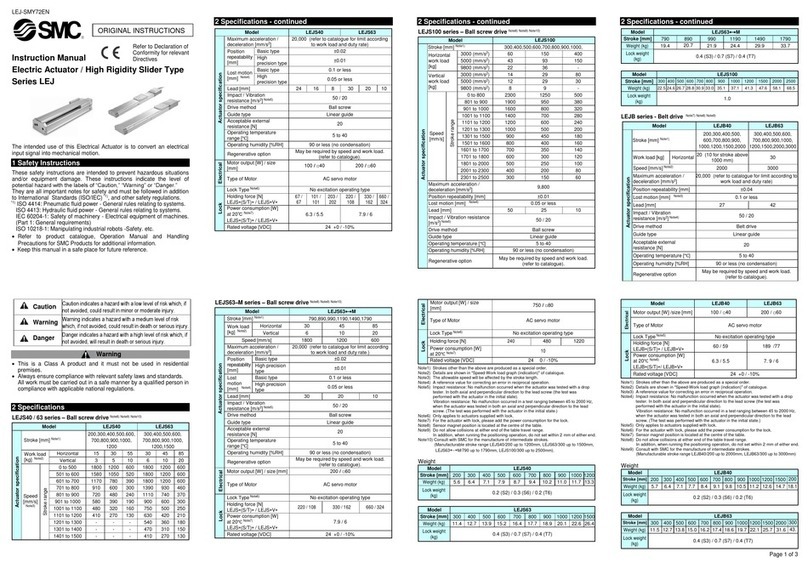

The PGC-10000-AF fittings accessory kit includes adaptors to convert the DH500 F

TEST connection to other commonly used fittings. The adaptors are made by

combining a DH500 F adaptor with a 2.75 in., 6 in. or 12 in. DH500 nipple. The

nipple/adaptor assembly is then

installed on the DUT. Finally, the

nipple/adaptor/DUT assembly is

installed on the GPC1’s DH500 F TEST

connection. Note that the gland nut on

the DH500 nipple assembly can be

tightened into the DH500 F connection

without rotating the nipple or DUT.

Adaptors included in the GPC1

accessory kit are:

•1/4 in. NPT F

•1/4 in. NPT M

•1/8 in. NPT M

•37 degree flare M (AN4 M)

Figure 6. Adapting TEST port to connect a

device under test

Highly pressurized gas can be extremely hazardous. Before applying pressure

to GPC1 and/or the system connected to it, be sure that all pressure vessels and

connections are rated for the pressure levels that will be applied and that all

connections have been properly tightened (see Section 2.5.5).

2.4.4.3 CLEANLINESS CONSIDERATIONS WHEN CONNECTING DUTS

Special design features are included in GPC1 to avoid excessive contamination

of GPC1 if liquids should return from a DUT to which it is connected.

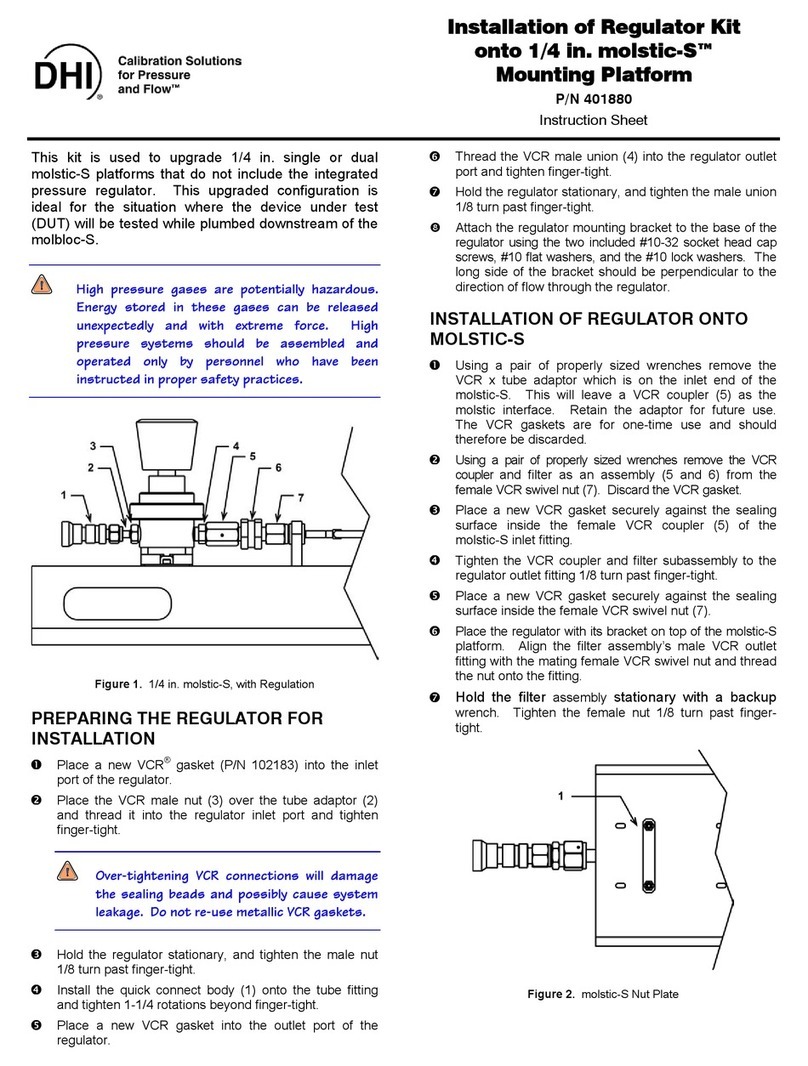

For this purpose, GPC1 is equipped with an inclined manifold that serves as a

liquid sump (see Figure 77). A DRAIN port is provided at the low point so that

the sump can be easily purged. The TEST ports all go directly through the sump

so that any liquids returning from the system under test will collect there rather

than being carried throughout GPC1. The top, rear TEST1 port is supplied

directly from the SUPPLY port so that it is always filled with clean gas from the

supply. Even if liquids are present in the sump, they will not enter the TEST1

port as gas that may have been exposed to liquids never flows into the port from

GPC1

(see Figure 77).

Below are recommendations for use of the three (3) GPC1 TEST ports.

If there is no risk of return of liquids from the devices that will be connected to

GPC1, it is not necessary to discriminate TEST port usage.

•TEST1 port (top, rear): This port is supplied directly with clean gas from the

SUPPLY port and should be reserved for connecting devices that are known

to be liquid free and must be protected from any risk of liquid contamination.

If no such devices will be connected to GPC1, then this port may be used as

any TEST port would.

•TEST2 port (left lateral): Normally, the system reference pressure

measurement device is connected here. In a PGC-10000-AF Pneumatic

Gauge Calibrator, this is an RPM4/HPMS A70M/A20M-AF.