RTM-20 TEMPERATURE REGULATOR INSTRUCTION MANUAL

Zakład Mechaniki i Elektroniki

ZAMEL sp.j.

J.W. Dzida, K. Łodzińska

ul. Zielona 27, 43-200 Pszczyna, Poland

Tel. +48 (32) 210 46 65, Fax +48 (32) 210 80 04

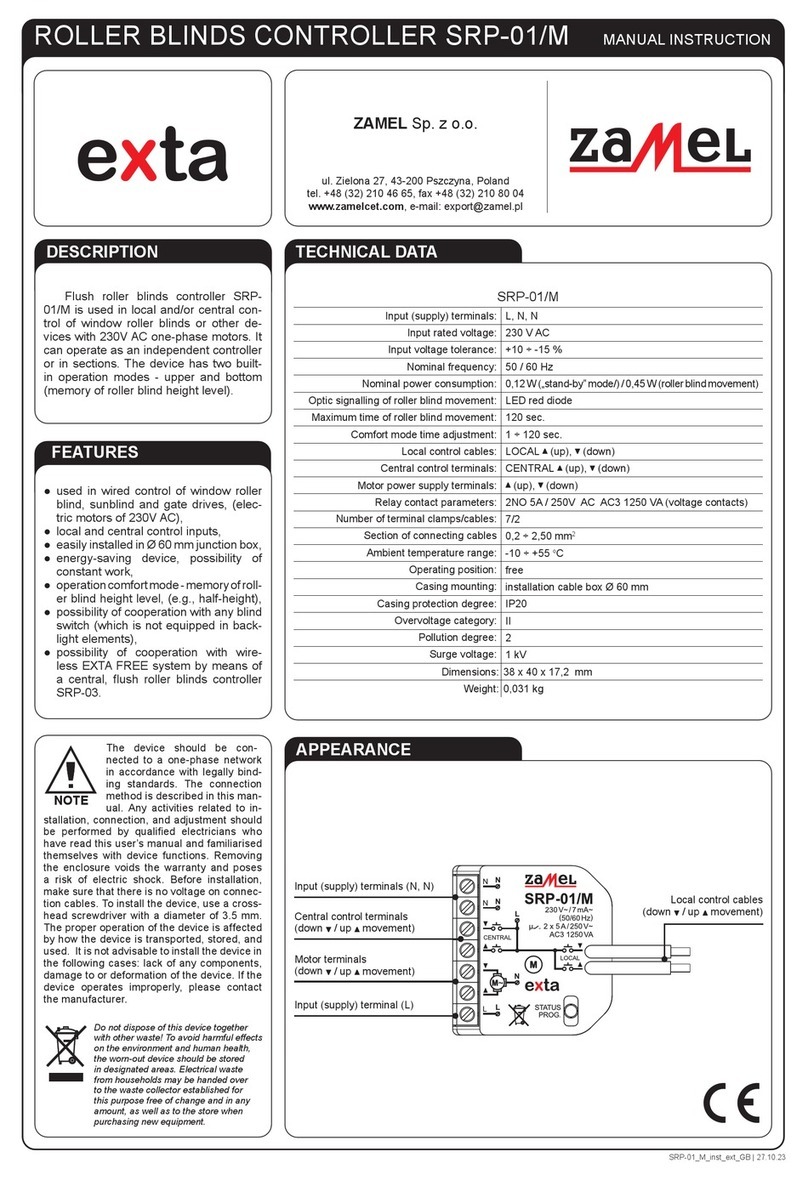

APPEARANCE

FEATURES

TECHNICAL DATA

DESCRIPTION

RTM-20

Power terminals : A1, A2

Rated voltage: 230 V~

Rated voltage tolerance: -15 ÷ +10 %

Rated frequency: 50 / 60 Hz

Rated power consumption: 2 W / 14 VA

NTC sensor terminals: NTC

Input terminals: IN, IN

Temperature adjustment range: 5 ÷ 60 oC

Hysteresis: ± 1 oC

Relay terminals: 12, 12, 11, 11, 14, 14

Load indicator: LCD

Colour of LCD panel lighting: amber

Parameters of transmitter contacts: 16A NO/NC 4000 VA AC1

Number of terminating clamps: 12

Intersection of terminating conductors: 0,2 ÷ 2,50 mm2

Temperature of work: -20 ÷ 60 oC

Temperatura pracy sondy: -20 ÷ 90 oC

Position of work: any

Fixing of casing: TH 35 rail (EN 60715)

Level of protection of casing: IP20 (EN 60529)

Protectivity class: II

Overvoltage category: II

Level of pollution: 2

Measurements: two-module (35 mm) 90x35x66 mm

Weight: 130 g

Compatibility with norms: EN 60730-1; PN-EN 60730-2-7

EN 61000-4-2,3,4,5,6,11

●Temperature control within the range

of 5°C ÷ 60°C,

●External NTC-03 probe,

●Led display + keyboard,

●Load control in dependence of am-

bient temperature,

●Double-module casing with a protec-

tion flap,

●Mounted on TH 35 rail,

●Relay output, 16 A maximum load.

The RTM-20 temperature digital regulator

is designed for load control (e.g. heaters,

floor heating systems) in dependence of

ambient temperature near an external

NTC sensor. It is possible to control

temperature within the range of +5°C ÷

+60°C.

The external NTC-03 probe is needed

for a correct device operation. The is

not part of the set and it is necessary to

purchase it separately. The probe lead is

3 m in length. It is possible to extend it up

to 50 m with 0,2 ÷ 2,5 mm2lead. Do not

join the probes.

CAUTION:

Before installing

the device in the

switchboard

or starting the

system operation

in order to

programme it,

the battery security

separator should

be removed

against

discharging.

The device should be con-

nected to a single-phase

system according to current

standards. The device con-

nections will be described in

this manual. Only qualified

electricians are allowed to

mount, connect and adjust the module. It is

necessary to read this manual before the de-

vice mounting. Do not disassembly the device

casing or you will lose any warranty rights and

expose yourself to the electric shock hazard.

Before mounting operation make sure of di-

sconnecting the connection wires from the

electric network. Use a cross-head screwdri-

ver of 3.5 mm diameter to mount the device.

The regulator should be carried, stored and

used in an appropriate way. Do not mount the

device in case of any regulator parts lack, da-

mage or deformation. In case of malfunction

please notify the manufacturer.

CAUTION

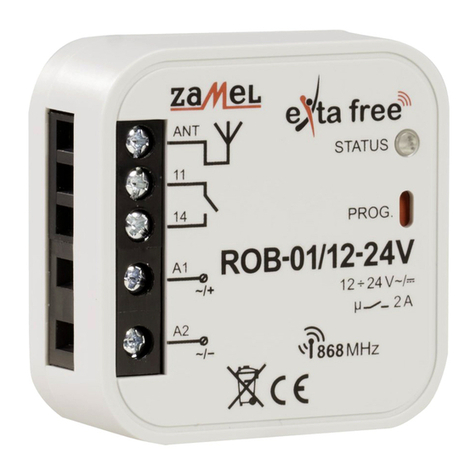

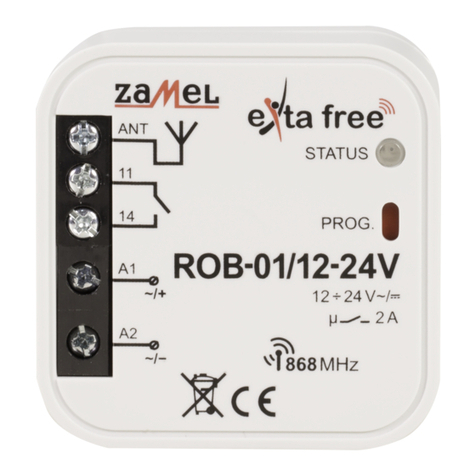

Display

Relay output terminals

(12, 12, 11, 11, 14, 14)

Control buttons

NTC terminals

(NTC)

Power terminals

(A1, A2)

Trigger terminals

(IN, IN)

VER. 004_31.03.2010

DESCRIPTION

MAIN MENU

DATE SETTING

- Current date setting; entry after pressing OK;

YEAR - choose adequate year with cursors confirm with OK, range of

years: 2000÷2099;

MONTH - choose month with cursors confirm with OK;

DAY - choose day with cursors confirm with OK; the system has a protec-

tion against introducing incorrect parameter of a day for a given month ( it

takes into account leap years and it automatically calculates the day of the

week on the basis of an arranged date);

Confirmation causes movement to a date setting window and set-up of cur-

rent summer/ winter time - if the option is arranged.

It is possible to exit every sub- menu window in any moment without

saving settings by pressing the button or .

Description of displayed fields and messages

From window no. it is possible to enter the info window (time and date) no. after

pressing the cursor or . The window will be closed after 15 seconds automatically.

Window Window

,

- relay state

- days of week

- automatic mode -

relay state

- manual mode - automatic mode

- output temperature - manual mode

- non-freeze temperature - winter time

- comfort temperature - current date

- econo temperature - current time

- temperature setting

- actual temperature

Other windows:

- day

- year

- automatic

- user’s

- ON/OFF

- NTC probe error (short circuit or break)

Button description

• the main window – entering the automatic op mode;

• ther windows – exit to a higher level without saving changes

entered;

• the main window – entering the manual op mode or the tem-

perature setting changing, if the manual mode set previously;

• other windows - exit to a higher level without saving

changes;

• the main window – entering the main menu;

• other windows – entering a submenu or the set value ac-

knowledgement;

• toggle between menu windows / options or the set value

increase / decrease.

Enter the menu by pressing OK in the main window;

scroll the menu by means of the following cursors .

Function Description

PROGRAM ASSIGNING

TEMPERATURE SETTING

PROGRAM SETTING

CURRENT TIME SETTING

CURRENT DATE SETTING

SUMMER / WINTER TIME SETTING

EXTERNAL OUTPUT SETTING

SENSOR ADAPTATION SETTING

RTM - 20

TIME SETTING

WINTER / SUMMER TIME SETTING

OPERATING MODE CHANGE (AUTOMATIC, MANUAL)

- setting the current clock time; entry after pressing

OK;

HOUR- choose adequate hour with cursor which you can

set in 1-24 or 1-12 (AM) and 1-12 (PM)format; confirm

with OK;

MINUTES - choose adequate parameter of minutes with cur-

sors confirm with OK;

Confirmation of the parameter of minutes causes simultane-

ous nullification of the parameter of seconds and movement to

the window of time setting.

It is possible to exit every sub- menu window in any moment

without saving settings by pressing the button or .

- choice of one of the two modes in which switching be-

tween winter and summer season time will occur. - switching

will take place in an automatic way, on the last Sunday of March, at

2.00 (for summer time) and on the last Sunday of October, at 3.00

(for winter time), - a user chooses between winter/ summer

time, entry after pressing OK;

setting the mode - choose mode or with cursors

, confirm with OK; after choosing the mode , the clock au-

tomatically sets the time as winter or summer one, depending on

the arranged date; after choosing the mode you go to another

window;

Choose time for winter/ summer one with cursors where is

winter time and is summer time, if change of marker has hap-

pened the system will change the current time by adding or sub-

tracting 1 hour, confirm the operation with OK;

After choosing the system moves to winter/ summer time shift win-

dow.

It is possible to exit every sub- menu window in any moment

without saving settings by pressing the button or .

MANUAL OP MODE TOGGLE - if the main window is open

and the device is in the automatic op mode

, pressing the

key will force the unit to toggle into the manual op

mode with active non-freeze temperature ; succes-

sive pressing the key will force the manual op mode

changeover as follows:

non-freeze temperature;

comfort temperature;

econo temperature;

output temperature.

If the unit is in one of the mentioned manual op modes

, pressing the key will force return to the automatic

mode .