DH Instruments GB-152 User manual

©1998-2008 DH Instruments, a Fluke Company

GB-75™ and GB-152™

Gas Booster With Control Kit

Operation and Maintenance Manual

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company

This equipment described in this manual is designed and manufactured for the intended purpose of

generating high pressure gas. Certain precautions need to be followed during installation and operation of this

device. Reading and understanding the material is essential to the safe and correct operation of the unit.

Pressurized equipment is potentially dangerous. The equipment described in this manual generates and

controls very high gas pressures. It should not be operated by anyone who has not become thoroughly familiar

with this manual. Additional training in general and pressure specific safety procedures will help assure

protection from harm or damage to personnel or property. Responsibility for the proper and safe operation of

this instrument rests with the user.

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases can

be released unexpectedly and with extreme force. High pressure systems should be assembled and operated

only by personnel who have been instructed in proper safety practices.

© 1998-2008, DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane Phoenix AZ 85044-5318 USA.

DH Instruments makes every effort to ensure the accuracy and quality of its published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of subsequent translations cannot be guaranteed. In case of conflict between the

English version and another language version, the English version takes precedence.

DH Instruments, DH Instruments, a Fluke Company, DH, DHI, PPC, PPCK+, PPC2+, RPM3 and CalTool are trademarks,

registered and otherwise.

Swagelok is a registered trademark of the Swagelok Company.

Teflon is a registered trademark of the 3M Corporation.

Document No. 550038c

080423

Printed in the USA.

TABLE OF CONTENTS

Page I ©1998-2008 DH Instruments, a Fluke Company

T

TA

AB

BL

LE

E

O

OF

F

C

CO

ON

NT

TE

EN

NT

TS

S

TABLE OF CONTENTS...............................................................I

TABLES.................................................................................III

FIGURES................................................................................III

ABOUT THIS MANUAL .............................................................IV

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 LOCATION AND DESCRIPTION OF THE COMPONENTS....................................................................2

1.2.1 GAS BOOSTER.............................................................................................................................................2

1.2.2 DRIVE AIR CONTROL KIT............................................................................................................................3

1.3 SPECIFICATIONS ...................................................................................................................................5

2. INSTALLATION ..................................................................7

2.1 UNPACKING AND INSPECTION ............................................................................................................7

2.2 SITE REQUIREMENTS............................................................................................................................8

2.2.1 SITE................................................................................................................................................................8

2.2.2 GAS SUPPLIES.............................................................................................................................................8

2.2.2.1 DRIVE AIR SUPPLY ..................................................................................................................................8

2.2.2.2 HIGH PRESSURE INSTRUMENT GAS.....................................................................................................9

2.3 INSTALLATION AND SETUP..................................................................................................................9

2.3.1 GENERAL CONSIDERATIONS.....................................................................................................................9

2.3.2 INSTALLATION ...........................................................................................................................................10

2.3.2.1 BOOSTER INSTALLATION .....................................................................................................................10

2.3.2.2 DRIVE AIR CONTROL KIT INSTALLATION............................................................................................10

2.3.2.3 BOOSTER HIGH PRESSURE INSTRUMENT GAS SUPPPLY CONNECTION.....................................11

2.3.2.4 BOOSTER HIGH PRESSURE OUTPUT CONNECTION........................................................................11

2.4 INITIAL START UP................................................................................................................................12

3. OPERATION..................................................................... 13

3.1 GENERAL OPERATING PRINCIPLE AND INFORMATION.................................................................13

3.2 OPERATION..........................................................................................................................................13

3.2.1 SETTING THE BOOSTER OUTPUT PRESSURE ......................................................................................14

3.2.2 TURNING THE BOOSTER ON AND OFF...................................................................................................14

4. MAINTENANCE AND ADJUSTMENTS .................................. 15

4.1 MAINTENANCE.....................................................................................................................................15

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page II

5. TROUBLESHOOTING ........................................................ 17

5.1 GENERAL INFORMATION....................................................................................................................17

5.2 BOOSTER WILL NOT RUN...................................................................................................................17

5.3 BOOSTER RUNS TOO SLOWLY .........................................................................................................18

5.4 PRESSURE GENERATES TOO SLOWLY OR NOT AT ALL...............................................................18

5.5 BOOSTER RUNS (CYCLES) CONTINUOUSLY...................................................................................19

5.6 CANNOT ACHIEVE DESIRED PRESSURE..........................................................................................19

5.7 LEAKS...................................................................................................................................................20

5.8 GAS CONTINUOUSLY VENTS THROUGH EXHAUST MUFFLER......................................................20

6. WARRANTY STATEMENT .................................................. 21

6.1 WARRANTY STATEMENT....................................................................................................................21

TABLES AND FIGURES

Page III ©1998-2008 DH Instruments, a Fluke Company

T

TA

AB

BL

LE

ES

S

Table 1. GB-75 or GB-152 Parts List...........................................................................................................7

Table 2. DHI Authorized Service Providers...............................................................................................21

F

FI

IG

GU

UR

RE

ES

S

Figure 1. GB-152 Gas Booster....................................................................................................................2

Figure 2. Drive Air Control Kit .....................................................................................................................3

Figure 3. System Schematic .......................................................................................................................4

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page IV

A

AB

BO

OU

UT

T

T

TH

HI

IS

S

M

MA

AN

NU

UA

AL

L

Manual Conventions

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

1. INTRODUCTION

Page 1 ©1998-2008 DH Instruments, a Fluke Company

1

1.

.

I

IN

NT

TR

RO

OD

DU

UC

CT

TI

IO

ON

N

1.1 PRODUCT OVERVIEW

GB-75 and GB-152 are gas boosters with control kits intended to be used to provide a very high pressure

gas supply to systems using a GPC1 High Pressure Gas Controller and other high gas pressure test and

calibration systems.

Both models include a pneumatically driven, piston type, self-cycling gas booster. The gas booster

boosts a lower pressure, generally supplied from a bottle (2 MPa [300 psi] minimum), to higher pressure.

The booster is powered by drive air. The high pressure output is equal to the drive air input times the

boosting ratio of 75 or 152. The high pressure output is connected to the SUPPLY port of a GPC1 or

other system to which high pressure gas is to be supplied.

Both gas booster models include a drive air control kit and interconnecting tubing. The kit is on a bracket

that can be mounted at a convenient location remote from the booster itself.

GB-72 and GB-152 are not a good choice for supplying pressure to a PPCK+ high gas pressure

controller/calibrator. A different model, GB-K-75 and GB-K-175, with features specifically intended to support

PPCK+ is available for this application.

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 2

1.2 LOCATION AND DESCRIPTION OF THE COMPONENTS

1.2.1 GAS BOOSTER

1. High Pressure Instrument Gas Filter

2. High Pressure Instrument Gas Supply Port

3. Drive Air Supply Port (from Drive Air Control Kit)

4. Breather Port

5. Low Pressure Piston Body (50 % shorter in GB-75)

6. Muffler

7. High Pressure Piston Body

8. High Pressure Output Port

Figure 1. GB-152 Gas Booster

1. INTRODUCTION

Page 3 ©1998-2008 DH Instruments, a Fluke Company

1.2.2 DRIVE AIR CONTROL KIT

1. Drive Air Supply Connection (not visible)

2. Drive Pressure Adjust Regulator

3. Drive Pressure Indication Gauge

4. Drive Air Shut Off Valve

5. Drive Air Out Connection, to Booster (not visible)

Figure 2. Drive Air Control Kit

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 4

Figure 3. System Schematic

1. Drive Air Regulator 5. High Pressure Outlet Port

2. Drive Air Gauge 6. Booster Pump

3. Drive Air Shutoff Valve 7. 1/4 in. PFA Tubing

4. High Pressure Instrument

Gas Supply Port 8. Shop Drive Air Inlet Port

1. INTRODUCTION

Page 5 ©1998-2008 DH Instruments, a Fluke Company

1.3 SPECIFICATIONS

Dimensions: GB 75 Booster:

GB 152 Booster:

432 mm H x 241 mm W x 241 mm D (17 in. x 9.5 in. x 9.5 in.)

584 mm H x 241 mm W x 241 mm D (23 in. x 9.5 in. x 9.5 in.)

Weight: GB 75 Booster:

GB 152 Booster:

Drive Air Control Kit:

13.4 kg (29.4 lbs)

16.4 kg (36 lbs)

1.8 kg (4 lbs)

Pressure Supply

Pressure Range: Shop Drive Air:

High Pressure Supply Gas:

0.15 to 1 MPa (20 to 150 psi)

Maximum high pressure output is drive air pressure

times 75 (GB-75) or 152 (GB-152)

2 to 20 MPa (300 to 3 000 psi)

Maximum high pressure output is high pressure supply

times 25

Supply Flow

Rates: Shop Drive Air:

High Pressure Supply Gas:

425 to 2 125 slm (15 to 75 scfm)

140 to 560 slm (5 to 20 scfm)

Pressure

Connections: Drive Air Supply Inlet:

High Pressure Gas

Supply Inlet:

High Pressure Outlet:

1/4 in. NPT female

1/4 in. NPT female

DH 500 female (DH500 F is a gland and collar type fitting for

coned and left hand threaded 1/4 in. (6.35 mm) OD tube,

equivalent to AE F250C, HIP HF4, etc.)

High Pressure

Output: GB 75 Booster:

GB 152 Booster:

Drive air setting times 75, to 70 MPa maximum

Drive air setting times 152, to 110 MPa maximum

Booster Piston

Ratio: GB 75 Booster:

GB 152 Booster:

75:1

152:1

Due to a policy of continuous product improvement, all specifications are subject to change

without notice.

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 6

N

NO

OT

TE

ES

S

2. INSTALLATION

Page 7 ©1998-2008 DH Instruments, a Fluke Company

2

2.

.

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N

2.1 UNPACKING AND INSPECTION

GB-75 and GB-152 are delivered enclosed in plastic film and secured by foam in place in a

corrugated box. The Drive Air Control Kit and Interconnections Kit are included in the same box.

Remove all parts from the shipping box and plastic bag. Be sure not to lose or discard the Drive Air

Control Kit and Interconnections Kit.

Inspect all parts for damage. If damage is noted, report it to your Receiving Department for

appropriate action.

Inspect for any missing components or accessories using Table 1. Should any items be missing, contact

DHI or you local supplier.

Table 1. GB-75 or GB-152 Parts List

DESCRIPTION PART #

GB-75 Gas Booster 401002

GB-152 Gas Booster 400509

GB-75 Gas Booster, Hydrocarbon Free 401816

GB-152 Gas Booster, Hydrocarbon Free 401815

Accessories including:

1 ea. Operation and Maintenance Manual 550038

1 ea. Drive Air Control Kit 400998

Interconnections Kit: 401817

2 m (6 ft) 1/4 in. PFA tubing 101450-Z

1 ea. Tube weld, 1.5 m (60 in.) x 1/8 in. (3 mm) with DH500 tips (coiled) 402506

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 8

2.2 SITE REQUIREMENTS

2.2.1 SITE

There are no special site requirements.

The GB gas booster system is divided into two parts: the gas booster itself and the Drive Air

Control Kit. The two parts are separated so that they may be installed separately.

The gas booster, which is large and relatively noisy, does not need to be accessed regularly.

It is generally mounted out of the way, for example behind and under a work bench.

The booster may be set horizontally or vertically.

Connections of gas supplies and output need to be considered carefully when selecting the

installation site.

See Section 2.3.1 for additional recommendations.

2.2.2 GAS SUPPLIES

Two sources of compressed gas are required to operate the gas booster. They are drive air

(see Section 2.2.2.1) and high pressure instrument gas (see Section 2.2.2.2).

2.2.2.1 DRIVE AIR SUPPLY

The drive air supply provides power to operate the booster. The booster’s very

high pressure output is the drive air multiplied by either 75 (BG-75) or

152 (GB-152). This supply is usually “shop” or “factory” air.

Drive air requirements are:

Flow rate: 425 slm (15 scfm) minimum

Cleanliness: Not critical, use 60 micron filter

Humidity: 20 to 50 % RH. Do not use dry gas.

Approximate drive air pressures required to reach different high pressure

outputs are:

MODEL

BOSTER DRIVE AIR

[kPa (psi)] OUTPUT PRESSURE

[MPa (psi)]

GB-75 400 (60) 25 (3 500)

GB-75 700 (100

)

50 (7 500)

GB-75 1 000 (150

)

70 (10 000)

GB-152 450 (60) 50 (7 500)

GB-152 550 (80) 70 (10 000)

GB-152 900 (130

)

110 (16 000)

2. INSTALLATION

Page 9 ©1998-2008 DH Instruments, a Fluke Company

2.2.2.2 HIGH PRESSURE INSTRUMENT GAS

High pressure instrument gas is boosted by the booster and output from the

booster high pressure OUT port.

High pressure instrument gas supply requirements are:

Flow rate: 140 slm (5 scfm) minimum

Cleanliness: Use clean, dry instrument grade gases only.

Pressure: 2 MPa (300 psig) minimum, 20 MPa (3 000 psig) maximum.

Maximum boosted pressure output is high pressure supply

times 25.

2.3 INSTALLATION AND SETUP

2.3.1 GENERAL CONSIDERATIONS

The GB gas booster system is divided into two parts: the gas booster itself and the Drive Air

Control Kit. The two parts are separate so that they may be installed separately.

The gas booster, which is large and relatively noisy, does not need to be accessed regularly.

It is generally mounted out of the way, for example behind and under a work bench.

The booster may be set horizontally or vertically.

The Drive Air Control Kit allows local control of booster operation. The output pressure of the

booster can be set by adjustment of the drive air pressure and the SHUTOFF valve turns the

booster ON and OFF. The Drive Air Control Kit is presented on a bracket meant to be

mounted at a location convenient to the operator, for example on the front of a work bench.

When selecting the site for installation of the GB gas booster system, carefully consider

access for the connections that need to be made (drive air to the Drive Air Control Kit, high

pressure instrument gas to the booster, very high pressure gas output from the booster to the

test or calibration system).

The orientation of the booster is of no consequence to its operation. It may be installed

vertically, horizontally or any combination of the two with no affect on performance

or maintenance.

A variety of factors must be considered when determining where to locate the gas booster

and the Drive Air Control Kit. Factors include, but are not limited to:

•If control over booster operation by the operator is desired, locate the Drive Air Control

Kit where it can be easily accessed;

•The high pressure being generated and associated safety concerns;

•The source of gas supplies (drive air supply and high pressure instrument

gas supply);

•Point of use of output pressures;

•Noise levels. The booster operation is noisy;

•Vibration during use;

•Access to the unit for operation of the regulators and valve;

•Vents to atmosphere.

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 10

2.3.2 INSTALLATION

The installation of the gas booster system is broken down into four parts:

•Installation of the gas booster (see Section 2.3.2.1)

•Installation and connection of the Drive Air Control Kit (see Section 2.3.2.2)

•Connection of the booster high pressure instrument gas supply (see Section 2.3.2.3)

•Connection of the booster high pressure output (see Section 2.3.2.4)

2.3.2.1 BOOSTER INSTALLATION

To install the gas booster system, follow the steps below:

Place the gas booster in the appropriate location.

Consider the booster high pressure instrument gas supply and high pressure

output connections. The booster may sit vertically or horizontally.

Orientation does not affect operation.

Use the attached mounting brackets to secure the booster to a fixed location

if desired.

Due to the reciprocating nature of the booster, it is advised that shock mounts

be used when rigidly mounting the booster.

2.3.2.2 DRIVE AIR CONTROL KIT INSTALLATION

To install the Drive Air Control Kit, follow the steps below:

nIdentify an appropriate location for the Drive Air Control Kit bracket. If the

booster will regularly be turned ON/OFF and/or frequent adjustment of

booster output pressure is desired, the Drive Air Control Kit Bracket should

be readily accessible. Consider the routing of the PFA tubing connection

from the Control Kit bracket to the booster when selecting a location. The kit

bracket is often mounted on the front bottom surface of a work bench.

oMount the Drive Air Control Kit bracket onto the desired location using the

bracket mounting holes provided

pBack off (rotate counterclockwise) the DRIVE ADJUST regulator and put

the SHUTOFF valve in the OFF position.

qConnect the drive air supply to the 1/4 in. NPT F connection on the DRIVE

ADJUST regulator. Use tubing rated for at least 1 MPa (150 psig)

working pressure. See Section 2.2.2.1 for information on drive air

supply requirements.

Maximum input pressure to the DRIVE ADJUST regulator is 1 MPa (150 psig).

Pressures above this level may result in a failure that could damage the instrument

and/or cause personal injury.

rConnect the Drive Air Supply Kit SHUTOFF valve output to the booster

DRIVE AIR INPUT port using the 2 m (6 ft.) length of 1/4 in. PFA tubing

provided in the GB accessories. Both fittings are 1/4 in. swage.

2. INSTALLATION

Page 11 ©1998-2008 DH Instruments, a Fluke Company

2.3.2.3 BOOSTER HIGH PRESSURE INSTRUMENT GAS

SUPPPLY CONNECTION

To connect the booster high pressure instrument gas supply, follow the

steps below:

nConnect a high pressure gas supply to the gas booster high pressure

IN port. The IN port is a 1/4 in. NPT F fitting on the high pressure

gas filter. Use a thread sealer to seal the connection. The high pressure

gas supply should not exceed 200 MPa (3 000 psi). See Section 2.2.2.2 for

additional information on high pressure gas supply requirements.

Pressure present at the High Pressure IN port will be present at the high

pressure OUT port. Do not supply pressure to the high pressure IN port unless you

are prepared for there to be pressure at the high pressure OUT port.

2.3.2.4 BOOSTER HIGH PRESSURE OUTPUT CONNECTION

The booster high pressure OUT port is usually connected to the high pressure

inlet of a test or calibration system to which high pressure is to be supplied, such

as the DHI GPC1 Gas Pressure Controller. The booster high pressure OUT port

is connected to the SUPPLY port of the GPC1 (see the GPC1 Operation and

Maintenance Manual).

To connect the booster high pressure OUT port, proceed as follows:

-Connect the 1.5 m, 1/8 in. nipple with DH500 tips between the HIGH

PRESSURE OUT port and the GPC1 SUPPLY port. The DH500 glands and

collars are delivered installed in the female ports. Remove the orange plastic

plug, slip the gland onto the DH500 tip, install the collar onto the DH500 tip and

thread the gland into the female DH500 fitting. Torque gland to 15 Nm (11 lb ft).

Do not bend tubing with radius less than 50 mm (2 in.) or pressure capacity

may be reduced.

Depending on the drive pressure set by the DRIVE ADJUST regulator, GB-75 may

generate pressure over 70 MPa (10 000 psi) and GB-152 may generate pressure over

110 MPa (16 000 psi). Be sure to use fittings and tubing rated for the pressure that

is to be output from the booster. Always use a DH500 or equivalent tube on the

DH500 F high pressure OUT port connection. To limit the maximum pressure that

can be generated by the booster, limit the drive air supply to the Drive Air Control Kit

(see Section 2.2.2.1).

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 12

2.4 INITIAL START UP

After installing the gas booster (see Section 2.3.2), perform the initial start up as follows:

nSupply drive air: Check that the Drive Air Control Kit SHUTOFF valve is in the OFF position and

that the DRIVE ADJUST regulator is set to zero (fully counterclockwise). Apply drive pressure to the

SHUTOFF valve (see Section 2.2.2.1 for information on drive air supply requirements).

oSupply high pressure instrument gas: Check that all connections to the high pressure IN and OUT

ports are secure. Apply high pressure gas to the high pressure IN port (see Section 2.2.2.2 for

information on high pressure instrument gas).

Ensure the high pressure supply does not exceed 20 MPa (3 000 psi). Pressures above this range may

result in a failure that could damage the instrument and/or cause personal injury.

pAdjust the DRIVE ADJUST regulator: Rotate the DRIVE ADJUST regulator knob (clockwise)

while observing the set pressure on the DRIVE gauge. Set the drive pressure to the maximum

desired high pressure output divided by the booster ratio (75 for GB-75, 152 for GB-152).

For example, if the desired high pressure output of a GB-152 is 70 MPa (10 000 psi), set the drive air

pressure to 70 MPa/152 = 460 kPa (67 psi). Remember that when the SHUTOFF valve is in the ON

position, the booster will operate until the high pressure output is equal to the drive air setting times

the booster ratio.

The DRIVE ADJUST regulator is NOT self venting so it cannot be used to set pressure lower than the

current pressure when the SHUTOFF valve is OFF. If you overshoot the desired set point, set the SHUTOFF

valve to ON until the DRIVE pressure is lower than your desired setting. Then set the SHUTOFF valve to OFF

and use the regulator to adjust the pressure in the ascending direction.

qGenerate high pressure: Set the SHUTOFF valve to the ON position. The booster will begin to cycle

and will continue to cycle until it stalls. When it stalls, the high pressure output is roughly equal to the

drive pressure setting times the booster's ratio (75 or 152).

3. OPERATION

Page 13 ©1998-2008 DH Instruments, a Fluke Company

3

3.

.

O

OP

PE

ER

RA

AT

TI

IO

ON

N

3.1 GENERAL OPERATING PRINCIPLE AND INFORMATION

Refer to Figure 3.

The purpose of the GB booster is to automatically boost gas pressure to very high pressure.

The value of very high pressure that is generated depends on the drive air pressure setting. The unit

generates high pressure using a Pneumatically Operated Gas Booster Pump and a Drive Air

Control Kit.

GAS BOOSTER PUMP

The booster pump is a Pascal press utilizing two pistons connected together on the same axis having a

normal area ratio of 75:1 (GB-75) or 152:1 (GB-152). The booster is a two-stroke, single stage

reciprocating pump that generates gas pressures 75 or 152 times greater than the shop drive air applied

to the pump. The pump operates automatically, provided drive air is supplied to the

DRIVE ADJUST regulator and the regulator is set to at least 140 kPa (20 psig). Operation is continuous

until the outlet pressure is 75 (GB-75) or 152 (GB-152) times the shop drive air pressure.

At this point, the opposing forces within the pump reach equilibrium and the pump stalls. For example,

using a GB-75 with the drive air pressure set to 500 kPa (73 psig), the pump will run until the high

pressure output reaches 75 x 0.5 = 37.5 MPa (5 450 psig).

1. The Shop Drive Air section (low pressure) consists of a piston, cylinder, air cycling valve, pilot valve

and vent section. This section provides the reciprocating action and compression force needed to

operate the booster and generate the high pressure gas. Drive air is channeled to the appropriate

side of the piston (compression or suction stroke) by the air cycling valve. When the piston reaches

full stroke, a pilot valve is mechanically activated causing the air cycling valve to change position.

Shop drive air is routed to the opposite side of the piston reversing piston direction where a second

pilot valve is activated repeating the process.

2. The high pressure section (high pressure) consists of a small piston and an inlet/outlet check valve

assembly. The small piston moves forward and backward with the air drive piston. During the

suction stroke (backward movement), the outlet check valve closes and the inlet check valve opens

letting supply high pressure gas enter the compression chamber. During the compression stroke, the

inlet check valve closes and the outlet check valve opens letting boosted gas out of the pump.

The compression ratio of the high pressure piston is 25:1 (for both models). Maximum output

pressure is limited by the instrument gas supply pressure. For example, with 2 MPa (300 psi)

applied, maximum output pressure cannot exceed 2 x 25 = 50 MPa (7 500 psi).

3.2 OPERATION

Once the gas booster has been set up and the initial start up is completed, operation is very simple.

There are two possible operator actions:

•Setting the booster output pressure (see Section 3.2.1).

•Turning the booster ON and OFF (see Section 3.2.2).

GB-75™ AND GB-152™ OPERATION AND MAINTENANCE MANUAL

©1998-2008 DH Instruments, a Fluke Company Page 14

3.2.1 SETTING THE BOOSTER OUTPUT PRESSURE

The booster output pressure is determined by the value of the drive air pressure. The

approximate booster output will be the drive air pressure times 75 (GB-75) or 152 (GB-152).

To set the drive air pressure, adjust the DRIVE ADJUST regulator:

nWith the SHUTOFF valve in the ON position, observing the DRIVE gauge, adjust the

regulator counterclockwise to decrease pressure to a value lower than the desired

set pressure. This is necessary because the regulator is not self-venting.

oPut the SHUTOFF valve in the OFF position.

pRotate the DRIVE ADJUST regulator knob clockwise while observing the set pressure

on the DRIVE gauge. Set the drive pressure to the maximum desired high pressure

output divided by the booster ratio (75 for GB-75, 152 for GB-152). For example, if the

desired high pressure output of a GB-152 is 70 MPa (10 000 psi), set the drive air

pressure to 70 MPa/152 = 460 kPa (67 psi). Remember that when the SHUTOFF valve

is in the ON position, the booster will operate until the high pressure output is equal to the

drive air setting times the booster ratio.

To correctly set the pressure, gas flow must not occur. If flow is present in the circuit when

the regulator is adjusted, the pressure will increase when flow is reduced. If the setpoint is

exceeded, see Section 3.2.2.

The booster will run automatically, continuously until the high pressure output is equal to

the drive pressure times 75 (GB-75) or 152 (GB-152). Set the drive pressure very carefully to

avoid generating higher output pressures than desired which could be dangerous.

3.2.2 TURNING THE BOOSTER ON AND OFF

The booster is turned ON and OFF using the SHUTOFF valve of the Drive Air Control Kit.

The SHUTOFF valve controls the supply of drive pressure to the booster.

Set the SHUTOFF valve to the ON position to supply drive pressure to the booster and

cause it to operate.

Set the SHUTOFF valve to the OFF position to interrupt drive pressure to the booster and

cause it not to operate.

When the booster is OFF, the high pressure supply is still present at the high pressure gas

OUT port. This feature makes it easy to operate using the high pressure supply only when the

booster is not needed.

Emergency shut-down of the gas booster pump can be performed at any time by closing the

Drive Air Control Kit SHUTOFF Valve. This will prevent further generation of gas pressure by the

pump but WILL NOT NECESSARILY reduce pressure to high pressure point-of-use.

This manual suits for next models

1

Table of contents

Other DH Instruments Extender manuals

Popular Extender manuals by other brands

Lindy

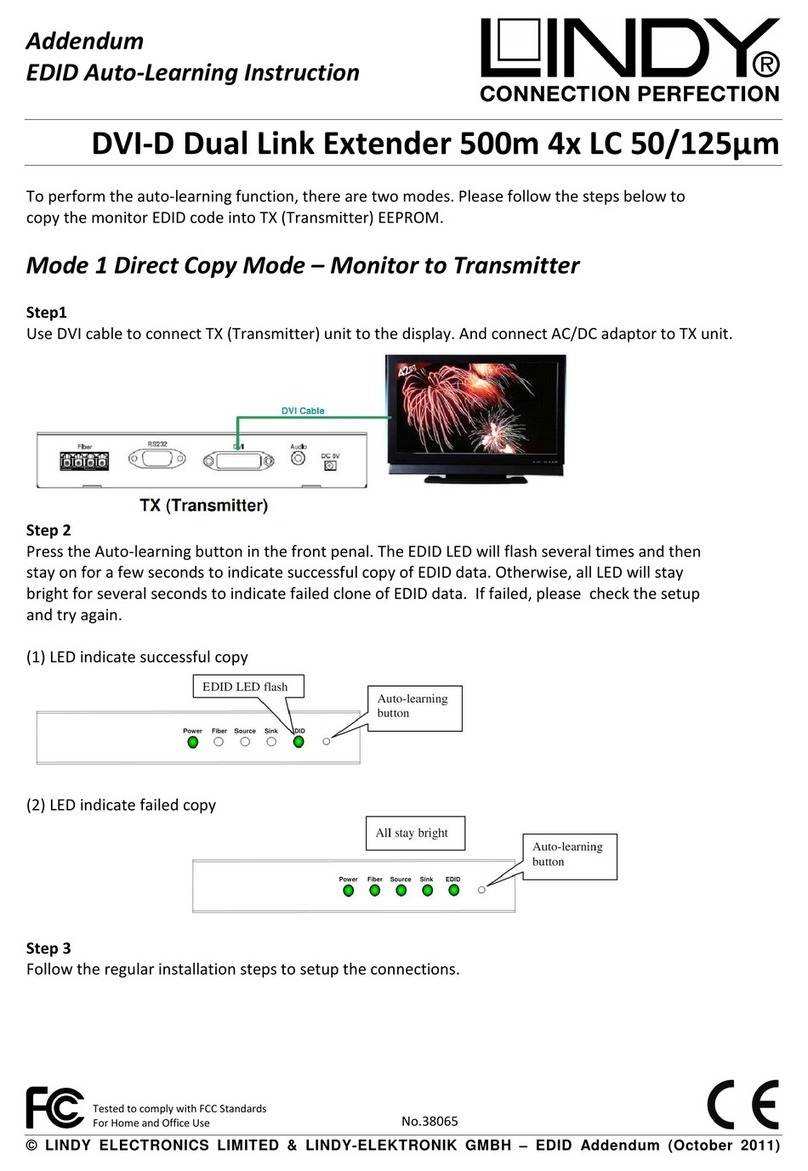

Lindy DVI-D Dual Link Extender 500m 4x LC 50/125um Instruction

KING

KING KX1000 user manual

Extron electronics

Extron electronics FOX T Plus MM user guide

Grandbeing

Grandbeing EX0101-U56 operating instructions

Abtus

Abtus CAT-HDX11T/AP2 User's operation guide

Nikrans

Nikrans LCD-300GW installation guide