DH Instruments PPC3 User manual

© 2002-2007 DH Instruments, a Fluke Company

PPC3™

Pressure Controller/Calibrator

Operation and Maintenance Manual

© 2002-2007 DH Instruments, a Fluke Company

High pressure liquids and gases are potentially hazardous. Energy stored in these liquids and gases

can be released unexpectedly and with extreme force. High pressure systems should be assembled

and operated only by personnel who have been instructed in proper safety practices.

This instrument is not to be operated in any other manner than that specified by the manufacturer.

© 2002 - 2007 DH Instruments, a Fluke Company All rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the express written permission of DH Instruments, a

Fluke Company 4765 East Beautiful Lane, Phoenix AZ 85044-5318, USA.

DH Instruments makes sincere efforts to ensure accuracy and quality of its’ published materials; however, no warranty, expressed

or implied, is provided. DH Instruments disclaims any responsibility or liability for any direct or indirect damages resulting from the

use of the information in this manual or products described in it. Mention of any product or brand does not constitute an

endorsement by DH Instruments of that product or brand. This manual was originally composed in English and was subsequently

translated into other languages. The fidelity of the translation cannot be guaranteed. In case of conflict between the English version

and other language versions, the English version predominates.

Products described in this manual are manufactured under international patents and one or more of the following U.S. patents:

5,142,483; 5,257,640; 5,331,838; 5,445,035. Other U.S. and international patents pending.

AutoRange, AutoZ, DH Instruments,DH,DHI, COMPASS, PPC, PPC3, QDUT, Q-RPT, RPM, RPM4, SDS and SPLT are

trademarks, registered and otherwise, of DH Instruments, a Fluke Company.

Document No. 550128b-02

050815

Printed in the USA.

TABLE OF CONTENTS

Page I © 2002-2007 DH Instruments, a Fluke Company

T

TA

AB

BL

LE

E

O

OF

F

C

CO

ON

NT

TE

EN

NT

TS

S

TABLE OF CONTENTS...............................................................I

TABLES..................................................................................V

FIGURES................................................................................VI

ABOUT THIS MANUAL ............................................................VII

1. INTRODUCTION .................................................................1

1.1 PRODUCT OVERVIEW ...........................................................................................................................1

1.2 SPECIFICATIONS ...................................................................................................................................1

1.2.1 GENERAL SPECIFICATIONS.......................................................................................................................1

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS........................................................................................2

1.2.2.1 QUARTZ REFERENCE PRESSURE TRANSDUCER (Q-RPT)................................................................2

1.2.2.2 UTILITY SENSOR......................................................................................................................................4

1.2.2.3 ON-BOARD BAROMETER ........................................................................................................................4

1.2.3 PRESSURE CONTROL SPECIFICATIONS..................................................................................................4

2. INSTALLATION ..................................................................5

2.1 UNPACKING AND INSPECTION ............................................................................................................5

2.1.1 REMOVING FROM PACKAGING..................................................................................................................5

2.1.2 INSPECTING CONTENTS.............................................................................................................................5

2.2 SITE REQUIREMENTS............................................................................................................................6

2.3 SETUP .....................................................................................................................................................6

2.3.1 PREPARING FOR OPERATION ...................................................................................................................6

2.3.2 FRONT AND REAR PANELS........................................................................................................................7

2.3.2.1 FRONT PANEL ..........................................................................................................................................7

2.3.2.2 REAR PANEL.............................................................................................................................................7

2.3.3 POWER CONNECTION.................................................................................................................................8

2.3.4 REMOTE [ENTER/SET P] CONNECTION (FOOTSWITCH OR OTHER SWITCH) .....................................8

2.3.5 CONNECTING TO A PRESSURE SUPPLY (SUPPLY PORT).....................................................................8

2.3.6 CONNECTING A VACUUM PUMP (EXHAUST PORT) ................................................................................8

2.3.7 CONNECTING EXTERNAL Q-RPTS IN RPM4 REFERENCE PRESSURE MONITORS.............................9

2.3.8 CONNECTING TO THE DEVICE UNDER TEST (TEST(+) AND TEST(-) PORTS)....................................10

2.3.8.1 INSTALLING A SELF PURGING LIQUID TRAP (SPLT) .........................................................................11

2.3.8.2 INSTALLING A DUAL VOLUME UNIT (DVU), G15K AND BG15K Q-RPTS...........................................12

2.3.9 THE VENT PORT.........................................................................................................................................12

2.3.10 CHECK/SET SECURITY LEVEL.................................................................................................................12

2.3.11 TURN OFF ABSOLUTE AND NEGATIVE GAUGE MODE (AXXX RPT)....................................................12

2.4 POWER-UP AND VERIFICATION.........................................................................................................13

2.4.1 SWITCH POWER ON ..................................................................................................................................13

2.4.2 CHECK PRESSURE MEASUREMENT OPERATION.................................................................................13

2.4.2.1 CHECKING ABSOLUTE MODE PRESSURE MEASUREMENT.............................................................13

2.4.2.2 CHECKING GAUGE MODE PRESSURE MEASUREMENT...................................................................13

2.4.3 LEAK CHECK..............................................................................................................................................14

2.4.4 PURGE.........................................................................................................................................................14

2.4.5 CHECK PRESSURE CONTROL OPERATION...........................................................................................14

2.5 SHORT TERM STORAGE.....................................................................................................................14

3. OPERATION..................................................................... 15

3.1 USER INTERFACE................................................................................................................................15

3.1.1 MAIN RUN SCREEN....................................................................................................................................15

3.1.2 FUNCTION / DATA KEYPAD LAYOUT AND PROTOCOL.........................................................................17

3.1.3 DIRECT PRESSURE CONTROL KEYS......................................................................................................18

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page II

3.1.4 REMOTE [ENT/SET P] FOOTSWITCH.......................................................................................................18

3.1.5 SOUNDS......................................................................................................................................................19

3.2 GENERAL OPERATING PRINCIPLES .................................................................................................19

3.2.1 AUTOMATED PRESSURE CONTROL.......................................................................................................19

3.2.2 PRESSURE READY/NOT READY..............................................................................................................21

3.2.3 GAUGE AND NEGATIVE GAUGE MODES WITH AN AXXX (ABSOLUTE) Q-RPT, DYNAMIC

COMPENSATION FOR ATMOSPHERIC PRESSURE ...............................................................................22

3.2.4 MULTIPLE INTERNAL AND EXTERNAL Q-RPTS.....................................................................................23

3.2.5 MULTIPE RANGES (Q-RPTS, AUTORANGE AND INFINITE RANGING).................................................24

3.2.6 OPERATION WITH A PG7000 PISTON GAUGE........................................................................................25

3.2.7 DIRECT FUNCTION KEYS SUMMARY......................................................................................................25

3.3 DIRECT FUNCTION KEYS....................................................................................................................26

3.3.1 [RANGE] ......................................................................................................................................................26

3.3.2 [UNIT]...........................................................................................................................................................28

3.3.3 [MODE] ........................................................................................................................................................29

3.3.4 [AUTORANGE] ............................................................................................................................................30

3.3.5 [RPT]............................................................................................................................................................33

3.3.6 [AUTOTEST]................................................................................................................................................34

3.3.6.1 QUICK AUTOTEST..................................................................................................................................35

3.3.6.2 QDUT AUTOTEST...................................................................................................................................38

3.3.7 [HEAD].........................................................................................................................................................42

3.3.8 [PURGE] ......................................................................................................................................................43

3.3.9 [LEAK CK] ...................................................................................................................................................45

3.3.10 [ENT/SET P] (SET PRESSURE AUTOMATICALLY)..................................................................................47

3.3.10.1 INTERRUPTING AUTOMATED PRESSURE CONTROL........................................................................48

3.3.10.2 AUTOMATED PRESSURE COMMANDS FOR ZERO PRESSURE....................................................48

3.4 [SETUP].................................................................................................................................................49

3.4.1 <1RANGE> ..................................................................................................................................................49

3.4.1.1 SAVING AN AUTORANGE RANGE ........................................................................................................50

3.4.1.2 DELETING AUTORANGE RANGES........................................................................................................50

3.4.2 <2RES> (RESOLUTION).............................................................................................................................50

3.4.3 <3JOG>........................................................................................................................................................51

3.4.4 <4UL> (UPPER LIMIT) ................................................................................................................................52

3.4.4.1 OVER PRESSURE FUNCTION...............................................................................................................53

3.4.5 <5ATEST>....................................................................................................................................................54

3.4.6 <6CONTROL>..............................................................................................................................................55

3.4.6.1 <LIMITS> (CUSTOM CONTROL PARAMETERS) ..................................................................................56

3.4.6.2 TURNING-OFF CUSTOM CONTROL PARAMETERS............................................................................57

3.4.7 <7DRV> (DRIVERS) ....................................................................................................................................57

3.5 [SPECIAL] .............................................................................................................................................58

3.5.1 <1AUTOZ>...................................................................................................................................................58

3.5.1.1 EDIT AUTOZ............................................................................................................................................62

3.5.1.2 RUN AUTOZ.............................................................................................................................................62

3.5.2 <2REMOTE>................................................................................................................................................63

3.5.2.1 <1COM1> AND <2COM2>.......................................................................................................................64

3.5.2.2 <3IEEE-488>............................................................................................................................................64

3.5.2.3 <4FORMAT>............................................................................................................................................64

3.5.2.4 <5RS232 SELF-TEST>............................................................................................................................65

3.5.3 <3HEAD> .....................................................................................................................................................65

3.5.4 <4RESET> ...................................................................................................................................................66

3.5.4.1 <1SET> ....................................................................................................................................................66

3.5.4.2 <2UNITS...................................................................................................................................................67

3.5.4.3 <3ATEST>................................................................................................................................................67

3.5.4.4 <4CAL> ....................................................................................................................................................67

3.5.4.5 <5ALL>.....................................................................................................................................................68

3.5.5 <5PREFS> ...................................................................................................................................................68

3.5.5.1 <1SCRSVR> ............................................................................................................................................69

3.5.5.2 <2SOUND> ..............................................................................................................................................69

3.5.5.3 <3TIME>...................................................................................................................................................69

3.5.5.4 <4ID>........................................................................................................................................................70

3.5.5.5 <5LEVEL> (SECURITY)...........................................................................................................................70

3.5.6 <6PUNIT>.....................................................................................................................................................73

3.5.7 <7INTERNAL> .............................................................................................................................................75

3.5.7.1 <1CONFIG> .............................................................................................................................................75

3.5.7.2 <2CONTROL REF>..................................................................................................................................75

3.5.7.3 <3BARO>.................................................................................................................................................76

3.5.7.4 <4PURGE> ..............................................................................................................................................77

3.5.7.5 <5LO VNT> ..............................................................................................................................................77

3.5.8 <8CAL>........................................................................................................................................................79

3.5.9 <9LOG>........................................................................................................................................................79

TABLE OF CONTENTS

Page III © 2002-2007 DH Instruments, a Fluke Company

4. REMOTE OPERATION ....................................................... 81

4.1 OVERVIEW............................................................................................................................................81

4.2 INTERFACING.......................................................................................................................................81

4.2.1 RS232 INTERFACE.....................................................................................................................................81

4.2.1.1 COM1.......................................................................................................................................................81

4.2.1.2 IEEE-488..................................................................................................................................................82

4.2.1.3 COM2.......................................................................................................................................................82

4.3 PROGRAMMING FORMATS.................................................................................................................82

4.3.1 CLASSIC PROGRAM MESSAGE FORMAT...............................................................................................83

4.3.2 ENHANCED PROGRAM MESSAGE FORMAT ..........................................................................................83

4.3.2.1 USING COMMAND TYPE COMMANDS .................................................................................................83

4.3.2.2 USING QUERY TYPE COMMANDS...................................................................................................84

4.4 COMMANDS..........................................................................................................................................85

4.4.1 PROGRAMMING MESSAGES....................................................................................................................85

4.4.2 ERROR MESSAGES ...................................................................................................................................86

4.4.3 PROGRAM MESSAGE DESCRIPTION OVERVIEW..................................................................................87

4.4.4 PROGRAM MESSAGE DESCRIPTIONS....................................................................................................88

4.5 STATUS REPORTING SYSTEM.........................................................................................................114

4.5.1 ERROR QUEUE.........................................................................................................................................114

4.5.2 STATUS BYTE REGISTER .......................................................................................................................114

4.5.3 STANDARD EVENT REGISTER...............................................................................................................115

4.5.4 READY STATUS REGISTER ....................................................................................................................116

4.6 IEEE STD. 488.2 COMMON AND STATUS PROGRAM MESSAGES................................................117

4.6.1 PROGRAM MESSAGE DESCRIPTIONS..................................................................................................117

5. MAINTENANCE, ADJUSTMENTS AND CALIBRATION...........121

5.1 OVERVIEW..........................................................................................................................................121

5.2 CALIBRATION OF QUARTZ REFERENCE PRESSURE TRANSDUCERS (Q-RPTS) ......................121

5.2.1 PRINCIPLE ................................................................................................................................................121

5.2.1.1 PA AND PM COEFFICIENTS ................................................................................................................122

5.2.1.2 AS RECEIVED AND AS LEFT DATA ....................................................................................................122

5.2.2 EQUIPMENT REQUIRED..........................................................................................................................123

5.2.3 SET-UP AND PREPARATION...................................................................................................................124

5.2.4 RECOMMENDED CALIBRATION POINT SEQUENCE............................................................................124

5.2.4.1 STANDARD CLASS Q-RPTS ................................................................................................................125

5.2.4.2 PREMIUM CLASS Q-RPTS...................................................................................................................126

5.2.5 TURNING OFF ABSOLUTE AND NEGATIVE GAUGE MEASUREMENT MODES FOR AXXX

(ABSOLUTE) Q-RPTS .........................................................................................................................127

5.2.6 Q-RPT CALIBRATION USING CALTOOL FOR RPTS SOFTWARE........................................................128

5.2.7 EDITING AND VIEWING Q-RPT CALIBRATION INFORMATION............................................................128

5.2.8 Q-RPT CALIBRATION/ADJUSTMENT WITHOUT CALTOOL FOR RPTS SOFTWARE.........................130

5.3 ADJUSTMENT OF ON-BOARD BAROMETER...................................................................................131

5.4 ADJUSTMENT OF UTILITY SENSOR ................................................................................................131

5.5 PNEUMATIC CONTROL MODULE CONFIGURATION (<CONFIG>) ................................................132

5.6 OVERHAUL .........................................................................................................................................133

5.7 RELOADING EMBEDDED SOFTWARE INTO FLASH MEMORY......................................................134

5.8 SUBASSEMBLY DESCRIPTION AND LOCATION ............................................................................135

5.8.1 POWER SUPPLY MODULE......................................................................................................................135

5.8.2 MINI MICRO BOARD.................................................................................................................................135

5.8.3 Q-RPT MODULE........................................................................................................................................136

5.8.3.1 HI Q-RPT OR UTILITY SENSOR...........................................................................................................136

5.8.3.2 LO Q-RPT...............................................................................................................................................136

5.8.4 ON-BOARD BAROMETER........................................................................................................................136

5.8.5 VACUUM SENSOR....................................................................................................................................136

5.8.6 PRESSURE CONTROL MODULE ............................................................................................................137

5.8.7 DISPLAY....................................................................................................................................................137

5.8.8 DRIVER BOARD........................................................................................................................................137

5.9 PNEUMATIC SCHEMATICS................................................................................................................137

5.9.1 PRESSURE CONTROL MODULE ............................................................................................................137

5.9.2 Q-RPT MODULE CONFIGURATIONS (PRESSURE MEASUREMENT)..................................................138

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page IV

6. TROUBLESHOOTING .......................................................141

7. APPENDIX ......................................................................145

7.1 DRIVERS .............................................................................................................................................145

7.2 UNIT CONVERSION............................................................................................................................146

7.2.1 PRESSURE................................................................................................................................................146

7.3 REMOTE [ENT] ...................................................................................................................................146

8. WARRANTY ....................................................................147

8.1 OVERVIEW..........................................................................................................................................147

9. GLOSSARY.....................................................................149

TABLES & FIGURES

Page V © 2002-2007 DH Instruments, a Fluke Company

T

TA

AB

BL

LE

ES

S

Table 1. Reference Pressure Transducer (Q-RPT) Designations and Ranges..........................................2

Table 2. PPC3 Packing List .........................................................................................................................5

Table 3. Position Designators of Q-RPTs in a PPC3 System ...................................................................24

Table 4. Settings and What They Are Specific To (Range, Measurement Mode, Q-RPT, System).........25

Table 5. Summary of PPC3 Function Key Operation................................................................................26

Table 6. Settings Made by AutoRange......................................................................................................31

Table 7. Default Pressure Control Parameters..........................................................................................55

Table 8. AutoZ ON and OFF......................................................................................................................60

Table 9. Reset – Sets.................................................................................................................................67

Table 10. Reset – Cal ................................................................................................................................68

Table 11. Reset – All..................................................................................................................................68

Table 12. Security Levels...........................................................................................................................72

Table 13. UNIT Function - Available Units of Measure .............................................................................74

Table 14. COM1 Pin Designations and Connections................................................................................81

Table 15. COM2 DB-9F Pin Designations.................................................................................................82

Table 16. Program Message List...............................................................................................................85

Table 17. Error #s and Descriptions ..........................................................................................................86

Table 18. 8 Bit Status Byte Register........................................................................................................114

Table 19. 8 Bit Standard Event Register..................................................................................................115

Table 20. 8 Bit Ready Status Register.....................................................................................................116

Table 21. Program Message List.............................................................................................................117

Table 22. Calibration Point Sequence, Standard Class, Axxx and Gxxx Q-RPTs..................................125

Table 23. Calibration Point Sequence, Standard Class, BGxxx Q-RPTs................................................125

Table 24. Calibration Point Sequence, Standard Class, BA100K Q-RPT...............................................126

Table 25. Calibration Point Sequence, Premium Class, Axxx and Gxxx Q-RPTs ..................................126

Table 26. Calibration Point Sequence, Premium Class, BGxxx Q-RPTs................................................127

Table 27. Troubleshooting Guide.............................................................................................................141

Table 28. External Drivers Current Output ..............................................................................................145

Table 29. External Drivers Pin Outs.........................................................................................................145

Table 30. Pressure Unit of Measure Conversion Coefficients.................................................................146

Table 31. DHI Authorized Service Providers...........................................................................................147

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page VI

F

FI

IG

GU

UR

RE

ES

S

Figure 1. Front Panel ...................................................................................................................................7

Figure 2. Rear Panel....................................................................................................................................7

Figure 3. MAIN RUN Screen Display Fields..............................................................................................16

Figure 4. Keypad Layout............................................................................................................................17

Figure 5. Direct Pressure Control Keys .....................................................................................................18

Figure 6. Dynamic Pressure Control Operation.........................................................................................20

Figure 7. Static Pressure Control Operation..............................................................................................20

Figure 8. Ready/Not Ready in Dynamic Pressure Control Mode..............................................................21

Figure 9. Ready/Not Ready in Static Control Mode...................................................................................22

Figure 10. Status Register Schematic .....................................................................................................114

Figure 11. Internal View...........................................................................................................................135

Figure 12. Pressure Control Module Schematic......................................................................................137

Figure 13. Q-RPT Module Schematics for Various Configurations.........................................................139

Figure 14. Drivers Connector Schematic.................................................................................................145

Figure 15. Remote [ENT/SET P] Connector Schematic..........................................................................146

ABOUT THIS MANUAL

Page VII © 2002-2007 DH Instruments, a Fluke Company

A

AB

BO

OU

UT

T

T

TH

HI

IS

S

M

MA

AN

NU

UA

AL

L

This manual is intended to provide the user with the basic information necessary to operate a PPC3

pressure controller/calibrator. It also includes a great deal of additional information provided to allow you

to optimize PPC3 use and take full advantage of its many features and functions.

Before using the manual, take a moment to familiarize yourself with the Table of Contents structure:

Sections 1, 2 and 3 should be read by all first time PPC3 users. Section 3 is most important for those

using the local front panel interface but should be read over by all users to familiarize themselves with

general PPC3 operating principles. Section 4 is for remote operation from an external computer. Section 5

provides maintenance and calibration information. Section 6 is a quick troubleshooting guide. Use it to

troubleshoot unexpected PPC3 behavior based on the symptom of that behavior. Certain words and

expressions have specific meaning as they pertain to PPC3. The Glossary, Section 6, is useful as a

quick reference for exact definition of specific words and expressions as they are used in the manual.

For those of you who “don’t read manuals”, go directly to Section 2.3 to set up your PPC3 and then go

to Section 2.4 for power-up and verification. This will get you up and running quickly with a minimal

risk of causing damage to yourself or your new PPC3. THEN… when you have questions or start to

wonder about all the great features you might be missing, get into the manual!

Manual Conventions

(CAUTION) is used in throughout the manual to identify user warnings and cautions.

(NOTE) is used throughout the manual to identify operating and applications advice and

additional explanations.

[ ] indicates direct function keys (e.g., [RANGE]).

< > indicates PG7000 screen displays (e.g., <1yes>).

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page VIII

N

NO

OT

TE

ES

S

1. INTRODUCTION

Page 1 © 2002-2007 DH Instruments, a Fluke Company

1

1.

.

I

IN

NT

TR

RO

OD

DU

UC

CT

TI

IO

ON

N

1.1 PRODUCT OVERVIEW

PPC3 is a stand-alone, pressure controller intended to precisely set and control gas pressure into a

closed volume as is commonly needed for the calibration and testing of pressure measuring instruments.

It has been designed to provide very high performance combined with maximum versatility and ease of use.

PPC3 can be equipped with a low cost utility sensor for pressure monitoring or one or two Quartz Reference

Pressure Transducers (Q-RPTs) to allow it to set and measure pressure with very low measurement

uncertainty. Up to four external Q-RPTs in one or two external Reference Pressure Monitors (RPM4s),

can also be integrated into a PPC3 system. In some cases, a barometer is also included.

Pressure control is achieved by a patented pneumatic module based on digitally controlled solenoid

valves and differential pressure regulators.

PPC3 is controlled locally by the operator using a front panel display, keypad and function keys or

remotely by a computer using ASCII character command strings over an RS232 or IEEE-488.2 interface.

PPC3 models are available to measure and control pressure in ranges from as low as - 3 to 3 kPa (0.4 psi)

to as high as 0 to 10 MPa (0 to 1 500 psi) in absolute, gauge and compound gauge measurement modes.

1.2 SPECIFICATIONS

1.2.1 GENERAL SPECIFICATIONS

Power Requirements 85 to 264 VAC, 50/60 Hz, 30 VA max consumption

Operating Temperature Range 15 to 35 °C

Storage Temperature Range - 20 to 70 °C

Vibration Meets MIL-T-28800D

Weight 12.7 kg (28.2 lb) approx

Dimensions

Ventilation 18 cm H x 32 cm W x 40 cm D (7.1 in. x 12.6 in. x 15.8 in.)

To prevent product overheating, provide proper ventilation. Allow 10 cm

(4 in.) clearance from rear panel cooling fan.

Microprocessors Motorola 68302, 16 MHz

Communication Ports

Fuses RS232 (COM1), RS232 (COM2), IEEE-488.2

1 A, 250 VAC fuse, 5 x 20 mm, time lag type fuse

Internal power supply fuse not replaceable by operator: 2A, 250 V (UV 440-2

power supply), 3.15A, 250 V (NFS40-7612 power supply)

Pressure Ranges Six controller models from 200 kPa (30 psi) max to 10 MPa (1 500 psi) max.

Low uncertainty measurement provided by selection of quartz reference

pressure transducer(s) (Q-RPTs)

Operating Medium Any clean, dry, non-corrosive gas

Pressure Connections SUPPLY: 1/8 in. NPT F

TEST(+): 1/8 in. NPT F

TEST(-): 1/8 in. NPT F

ATM (Vent): 10-32 UNF

EXHAUST: 1/4 in. NPT F

Pressure Limits Maximum Working:Pressure: Controller or Hi Q-RPT maximum

Maximum Test Pressure:w/out Damage: 110 % controller or Hi Q-RPT

maximum

Recommended Supply:Pressure: Maximum control pressure + 10 %

Maximum Supply Pressure:w/out Damage: PPC3-10M: 14 MPa (2 000 psi)

PPC3 -7M: 9.6 MPa (1 400 psi)

PPC3-2M, -700K, -200K: 3.5 MPa (500 psi)

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page 2

1.2.2 PRESSURE MEASUREMENT SPECIFICATIONS

1.2.2.1 QUARTZ REFERENCE PRESSURE TRANSDUCER (Q-RPT)

Quartz reference pressure transducers (Q-RPTs) can be installed in PPC3 to obtain

low uncertainty pressure measurement. One or two Q-RPTs can be included in the

PPC3 and/or additional Q-RPTs can be used externally mounted in DHI RPM4

Reference Pressure Monitors (see Section 3.2.4).

The type (Axxx, Gxxx, BGxxx, BAxxx) and range of the Q-RPT module(s)

determines the PPC3 measurement specifications.

All Q-RPTs whose maximum pressure is over 200 kPa (30 psi) are of the absolute

pressure type (Axxx) using an evacuated, permanently sealed reference. Axxx Q-RPTs

can measure absolute, gauge and negative gauge pressure. Gauge pressure with

an Axxx (absolute) Q-RPT is obtained by offsetting atmospheric pressure and

applying dynamic compensation for atmospheric changes using the on-board

barometer (see Section 3.2.3). Gxxx (gauge) Q-RPTs can measure positive gauge

pressure only. BGxxx (bi-directional gauge) Q-RPTs can measure gauge and

negative gauge pressure. See Section 3.3.3, PRINCIPLE, for additional information on

absolute,gauge and negative gauge measurement modes.

PPC3s configured with two Q-RPT modules have only one TEST(+) and TEST(-) port.

PPC3 internal valves and logic handle switching between the two Q-RPTs as needed.

Q-RPTs are available with two different performance levels, STANDARD class

and PREMIUM class. See the product label on the PPC3 rear panel, the label

on the Q-RPT module on the rear panel and/or the product calibration

reports to determine the class of the Q-RPTs installed in PPC3.

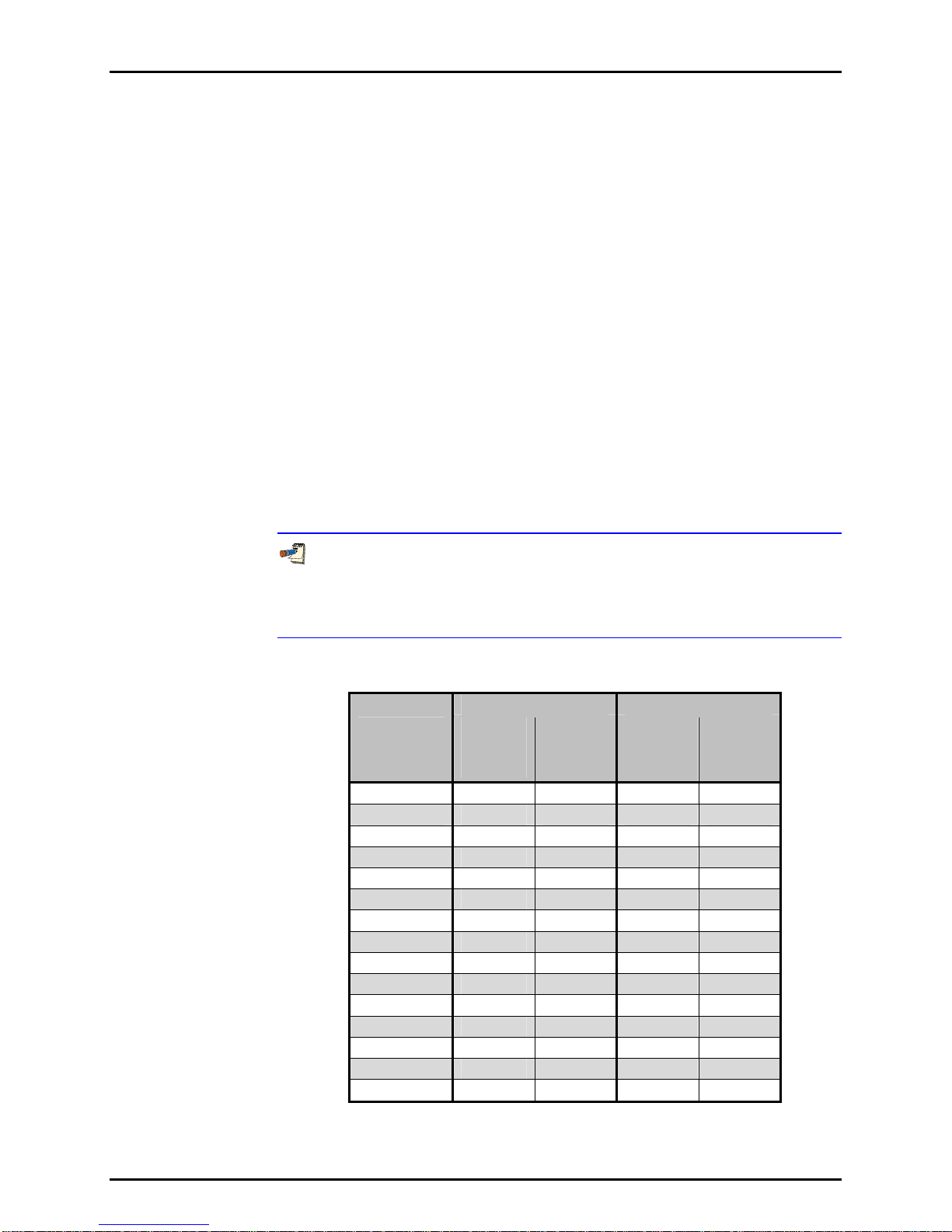

Table 1. Reference Pressure Transducer (Q-RPT) Designations and Ranges

SI VERSION US VERSION

RPT

DESIGNATION MAXIMUM

PRESSURE

Absolute

[kPa]

MAXIMUM

PRESSURE

Gauge

[kPa]

MAXIMUM

PRESSURE

Absolute

[psi]

MAXIMUM

PRESSURE

Gauge

[psi]

A10M110 000 10 000 1 500 1 500

A7M17 000 7 000 1 000 1 000

A3.5M13 500 3 500 500 500

A2M12 000 2 000 300 300

A1.4M11 400 1 400 200 200

A700K1700 700 100 100

A350K1350 250 50 35

A200K1200 100 30 15

A160K1 160 60 23 8

A100K1110 10 16 1.5

BA100K4110 - - 16 - -

G200K2- - 200 - - 30

G100K2- - 100 - - 15

G15K2- - 15 - - 2.2

BG15K3- - ±15 - - ±2.2

1. All AXXXX RPTs support absolute, gauge and compound (negative) gauge modes.

2. All GXXXX RPTs are positive gauge mode only.

3. BG15K is bi-directional gauge from - 15 to + 15 kPa (- 2.2 to + 2.2 psi).

4. BA100K is a barometric range whose low point is 70 kPa absolute (10 psi).

1. INTRODUCTION

Page 3 © 2002-2007 DH Instruments, a Fluke Company

Warm Up Time None required, 30 minute temperature stabilization

recommended for best performance from cold power up.

Resolution To 1 ppm, user adjustable

Compensated Temperature Range 5 to 35 °C

Acceleration Affect

Allows operation at ± 20° from

significant effect

Predicted One Year Stability1

± 0.008 % /g maximum, worst axis

Allows operation at ± 20° from reference plane without

significant effect

± 0.005% of reading

STANDARD CLASS PREMIUM CLASS

Precision2± 0.008% of reading or

0.0024% of Q-RPT span,

whichever is greater5

± 0.005% of reading, 0.0015%

of AutoRanged span, or

0.0005% of Q-RPT span,

whichever is greater6

Measurement Uncertainty3± 0.01% of reading or 0.0030%

of Q-RPT span, whichever is

greater5

± 0.008 % of reading, 0.0024%

of AutoRanged span, or

0.0007% of Q-RPT span,

whichever is greater6

Delivered Pressure Uncertainty4± 0.011 % of reading or

0.0033% of Q-RPT span,

whichever is greater5

± 0.009 % of reading,

0.0027% of AutoRanged span,

or 0.0008% of Q-RPT span,

whichever is greater6

1. Predicted Q-RPT measurement stability limit (k=2) over one year assuming regular use of AutoZero function. AutoZero

occurs automatically in gauge mode whenever vented, by comparison with barometric reference in absolute mode.

Absolute mode predicted one year stability without AutoZ is ± (0.005 % Q-RPT span + 0.005 % of reading).

2. Combined linearity, hysteresis, repeatability. Add + 1 Pa (0.00015 psi) in gauge mode with an Axxx (absolute) Q-RPT for

the resolution and short term stability of the on-board barometer.

3. Maximum deviation of the Q-RPT indication from the true value of applied pressure including precision, predicted one year

stability limit, temperature effect and calibration uncertainty, combined and expanded (k=2) following the ISO “Guide to the

Expression of Uncertainty in Measurement.”

4. Maximum deviation of the PPC3 controlled pressure from the true value including measurement uncertainty and dynamic

control hold limit.

5. % of reading value times measured pressure from 100 to 30 % of Q-RPT span. Under 30 % of Q-RPT span, % of reading

value times 30 % of Q-RPT span. For example, if the Q-RPT is a Standard A160K, the Measurement Uncertainty in

pressure is 0.010% times the measured pressure to 48 kPa (160 kPa span x 30%) and 0.0048 kPa (160 kPa span x 30%

x 0.01%) under 48 kPa.

6. % of reading value times measured pressure from 100 to 30 % of AutoRanged span. Under 30% of AutoRanged span, %

of reading value times 30% of AutoRanged span. If AutoRanged span is less then 30% of maximum Q-RPT span, % of

reading values times measured pressure, or % of reading times 9% of Q-RPT span, whichever is greater. For example, if

the Q-RPT is a Premium A160K and AutoRanged span is 160 kPa, the Measurement Uncertainty in pressure is measured

pressure x 0.008% to 48 kPa (160 kPa AutoRanged span x 30%) and 0.0038 kPa (160 kPa span x 30% x 0.008%) under

48 kPa. If the AutoRanged span is 100 kPa (greater than 30% of 160 kPa maximum Q-RPT span), the measurement

uncertainty in pressure is measured pressure x 0.008% to 30 kPa (100 kPa AutoRanged span x 30%) and 0.0024 kPa

(100 kPa span x 30% x 0.008%) under 30 kPa. If the AutoRanged span is 30 kPa (less than 30% of the 160 kPa

maximum Q-RPT span), the measurement uncertainty in pressure is measured pressure x 0.008% to 14.4 kPa (160 kPa

maximum Q-RPT span x 9%) and 0.0012 kPa (160 kPa maximum Q-RPT span x 9% x 0.008%) under 14.4 kPa.

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page 4

1.2.2.2 UTILITY SENSOR

Base PPC3 pressure controllers include a utility sensor. If a Hi Q-RPT

(see Section 3.2.4) is installed, there is no utility sensor.

Utility sensors are used for pressure control, system monitoring and safety functions.

They are intended for indication only, not to provide reference pressure

measurement. Q-RPTs (see Section 1.2.2.1) are used for reference measurement.

Warm Up Time None required

Range PPC3-10M: 10 MPa (1 500 psi) absolute and gauge

PPC3-7M: 7 MPa (1 000 psi) absolute and gauge

PPC3-2M: 2 MPa (300 psi) absolute and gauge

PPC3-700K: 700 kPa (100 psi) absolute and gauge

PPC3-200K: 300 kPa (45 psi) absolute;

200 kPa (30 psi) gauge

Resolution 0.001 % of span

Precision 0.1 % of span

1.2.2.3 ON-BOARD BAROMETER

The on-board barometer is used only to measure changes in atmospheric

pressure to provide dynamic compensation of the Q-RPT’s atmospheric pressure

offset when using an Axxx (absolute) Q-RPT to make gauge pressure

measurements.

Warm Up Time None required

Range 70 to 110 kPa (10 to 16 psi)

Resolution 0.001 % of span

Precision

Predicted Stability

0.1 % of span

0.05 kPa/yr (0.008 psi/yr)

The on-board barometer is only present in PPC3s that have an Axxx

(absolute) or BGxxx (bi-directional gauge) internal Q-RPT.

1.2.3 PRESSURE CONTROL SPECIFICATIONS

PPC3-200K PPC3-700K PPC3-2M PPC3-7M PPC3-10M

Control Precision ± 0.002 % of reading or of 2 % of controller span, whichever is greater.*

Q-RPT used must provide resolution higher than expected

control precision.

Lowest Controllable Pressure

(gauge mode) Zero set by automated venting. Lowest point above or below zero

limited only by Q-RPT resolution and control precision.

Lowest Controllable Pressure

(absolute, negative gauge modes) 1.5 kPa

(0.2 psia) 3 kPa

(0.4 psia) 5 kPa

(0.75 psia) 5 kPa

(0.75 psia) 10 kPa

(1.5 psia)

Ultimate Pressure

(absolute, negative gauge)

TEST(+) port is isolated and connected to vacuum

supply. Typically < 50 Pa (0.008 psia) depending on

vacuum source and test volume configuration.

5 kPa

(0.75 psia)

Typical Pressure Setting ReadyTime 15 to 30 seconds.

Optimum TEST Volume 500 cc 500 cc 500 cc 250 cc 250 cc

Default Dynamic Control Hold Limit ± 0.005 % of current range

* Control precision is reduced in absolute mode under 7 kPa (1 psi) absolute.

2. INSTALLATION

Page 5 © 2002-2007 DH Instruments, a Fluke Company

2

2.

.

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N

2.1 UNPACKING AND INSPECTION

2.1.1 REMOVING FROM PACKAGING

PPC3 is delivered in a corrugated container with high density polyethylene inserts to hold it in

place; or in the optional molded, medium density polyethylene shipping case with a custom

foam insert.

Remove the PPC3 and its accessories from the shipping container and remove each element

from its protective plastic bag.

2.1.2 INSPECTING CONTENTS

Check that all items are present and have no visible damage.

A standard PPC3 includes all items indicated in Table 2.

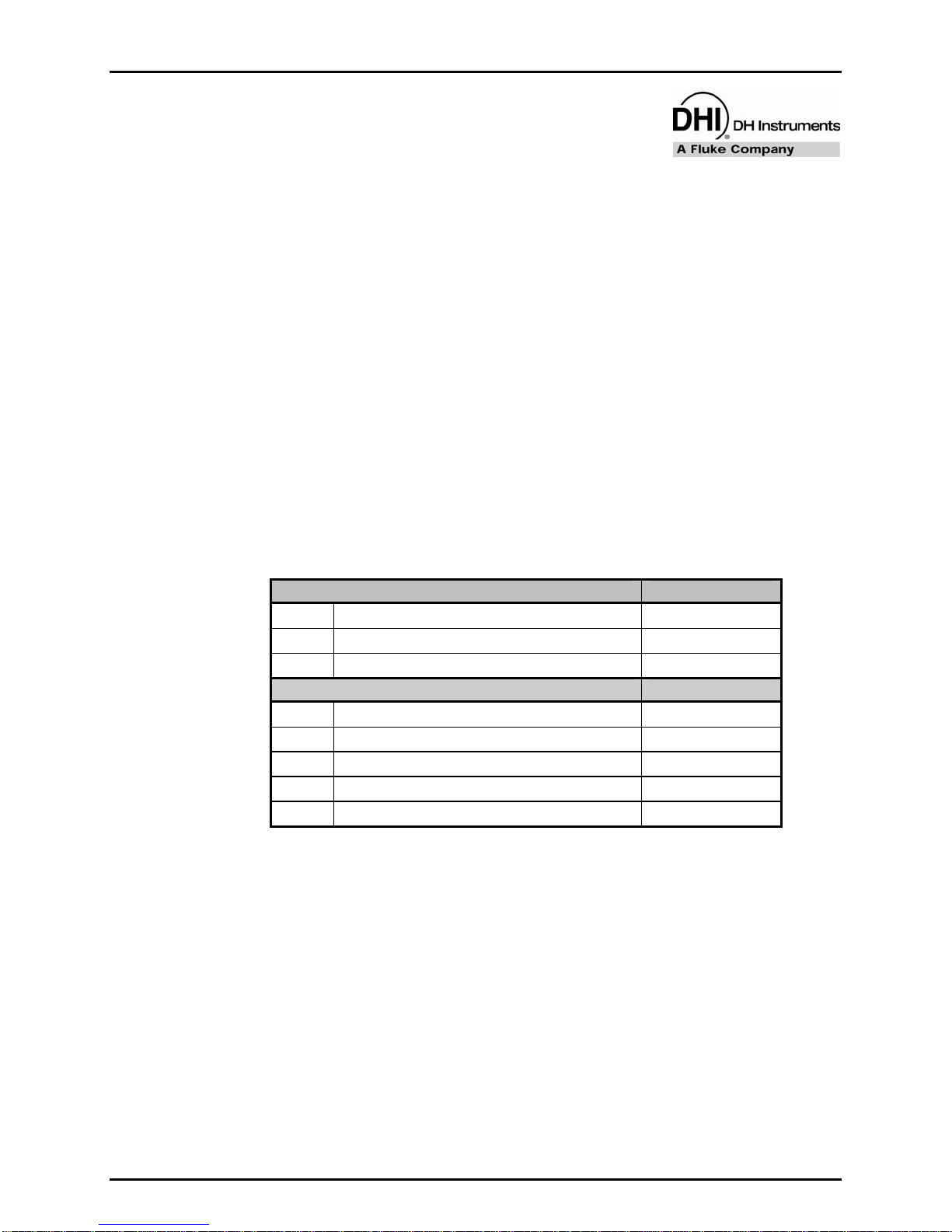

Table 2. PPC3 Packing List

DESCRIPTION PART #

1 ea. PPC3 Pressure Controller/Calibrator FAM007

1 ea. Calibration Report 550100

1 ea. Test Report 550200

ACCESSORIES: 401918 (401918-CE)

1 ea. Operation and Maintenance Manual 550128

1 ea. Power Cord (7.5 ft.) 100770 (100770-CE)

1 set (6) Rubber Feet Caps 400203

1 ea. Drivers Connector 401382

1 ea. General Accessories Disk (white CD) 102987

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page 6

2.2 SITE REQUIREMENTS

The PPC3 can be installed on any flat, stable surface at a convenient height. The front feet can be

extended so that the unit can be inclined slightly for easier viewing. The PPC3 can also be mounted in a

standard 19 in. rack using the optional rack mount kit.

Minimizing the distance between the PPC3 and the device or system under test will enhance control

performance and reduce pressure setting times.

Ready access to the PPC3 rear panel should be considered to facilitate making and breaking

pressure connections.

Pneumatic and RS-232 connections to RPM4s should be considered if RPM4s are to be used as

external reference pressure measurement devices (see Section 2.3.7).

The Self Purging Liquid Trap (SPLT), if used, should be mounted vertically at the low point of the

connection between the PPC3 TEST(+) port and the test (see Section 2.3.8.1).

If you are using a G15K or BG15K Q-RPT with a Dual Volume Unit (DVU), its location and

connections should be considered (see Section 2.3.8.2).

Support facilities required include:

•An electrical power source of 85 to 264 VAC, 50 - 60 Hz.

•A continuous, regulated pressure supply of clean, dry, non-corrosive gas at PPC3 maximum

control pressure + 10 % (at least 70 kPa (10 psi) in the case of a BG15K Q-RPT) to be connected to

the PPC3 SUPPLY port. Lower gas pressure supply can be used but should exceed the maximum

desired test output pressure by 10 to 20 %.

•A vacuum source of less than 1 psia (7 kPa) and with displacement of at least 3 cfm (90 lm)

if control of pressures under 3 psi (20 kPa) gauge is desired.

2.3 SETUP

2.3.1 PREPARING FOR OPERATION

To prepare PPC3 for check out and operation:

Remove the plastic caps from the PPC3 rear panel pressure connections.

Remove the protective plastic sheet from the front panel display.

Install the rubber feet caps onto the bottom case feet, if desired.

Familiarize yourself briefly with the front and rear panel (see Section 2.3.2).

Then proceed with Sections 2.3.3 to 2.3.11

2. INSTALLATION

Page 7 © 2002-2007 DH Instruments, a Fluke Company

2.3.2 FRONT AND REAR PANELS

2.3.2.1 FRONT PANEL

1. Ready/Not Ready Indicator

2. Display

3. Remote Activity Indicator

4. Cursor Control Keys

5. Multi-Function Keypad

6. Direct Pressure Control Keys

Figure 1. Front Panel

2.3.2.2 REAR PANEL

1. Label, Product

2. VENT port

3. COM2 Connector

4. IEEE-488 Connector

5. COM1 Connector

6. Drivers (12 V) Connector

7. Power Switch

8. Fuse

9. Electrical Power Connector (IEC-320-C13)

10. Remote [ENT] Connector

11. Pressure Connection, TEST(+)

12. Pressure Connection, TEST(-)

13. Pressure Connection, EXHAUST

14. Pressure Connection, SUPPLY

Figure 2. Rear Panel

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page 8

2.3.3 POWER CONNECTION

Check that the PPC3 power switch is OFF.

Connect the supplied power cable to the rear panel power module.

Connect the other end of the power cable to an electrical supply of 85 to 264 VAC, 50/60 Hz.

2.3.4 REMOTE [ENTER/SET P] CONNECTION (FOOTSWITCH

OR OTHER SWITCH)

Connect the optional remote ENTER footswitch, if available or a user supplied switch fitted to

the optional cable (see Section 7.3). Connect the cable to the PPC3 rear panel connection

labeled REMOTE ENTER. Activating the switch is equivalent to pressing the [ENT/SET P]

key on the front panel (see Section 3.1.4).

2.3.5 CONNECTING TO A PRESSURE SUPPLY (SUPPLY

PORT)

Using a pressure connecting hose or tube of appropriate pressure rating, connect the

pressure supply to the SUPPLY port on the rear panel of PPC3. The PPC3 SUPPLY port

connection is 1/8 in. NPT female.

The supply pressure should be equal to the maximum PPC3 control pressure + 10 % (or at

least 70 kPa (10 psi) for a BG15K Q-RPT). Lower gas pressure sources can be used but

should exceed the maximum desired test output pressure by 10 to 20 %.

Never connect a pressure supply greater than 20 % over the maximum control pressure of

the PPC3 model you are using (except models with a BG15K Q-RPT only). Be sure to

connect the pressure supply to the SUPPLY port. Connecting to another port is likely to

damage PPC3.

2.3.6 CONNECTING A VACUUM PUMP (EXHAUST PORT)

For PPC3 to set pressures under atmosphere and/or to reliably set pressure under 20 kPa (3 psi)

gauge (other than zero gauge), a vacuum supply must be connected to the EXHAUST port.

Never connect a pressure supply to or plug the PPC3 EXHAUST port.

To avoid building up pressure on the EXHAUST port or on a vacuum pump connected to

the EXHAUST port, the vacuum source should either be continuously ON or the EXHAUST

port should be bypassed to atmosphere when the vacuum source is OFF. This is because

when a supply pressure is applied to the PPC3 SUPPLY port and the PPC3 is NOT in the

vent ON condition, there may be a constant gas exhaust through the PPC3 EXHAUST port.

To assure optimum pressure control when changing the pressure applied to the EXHAUST

port from vacuum to atmosphere or vice-versa, be sure to change the control reference

setting if the setting is NOT in AUTO mode (see Section 3.5.7.2).

2. INSTALLATION

Page 9 © 2002-2007 DH Instruments, a Fluke Company

2.3.7 CONNECTING EXTERNAL Q-RPTS IN RPM4 REFERENCE

PRESSURE MONITORS

PPC3 can be connected pneumatically and by RS-232 to one or two RPM4 reference

pressure monitors to use up to four external Q-RPTs (two in each RPM4) as external

reference pressure measurement devices (see Section 3.2.4).

The PPC3 then manages communications and other RPM4 functions to integrate the RPM4

measurement capabilities into the PPC3 system. The RPM4 Q-RPT module’s Self Defense

System (SDS) is used to shut-off RPM4 Q-RPTs from the pressurized system when they are

not in use (see the RPM4 Operation and Maintenance Manual).

As a general rule, making the pneumatic connection between the PPC3 TEST port and the

remote Q-RPT as direct as possible favors good pressure control. As distance, volumes

and restrictions between the PPC3 TEST port and the remote Q-RPT are added, the

possibility of difficulty with pressure control when using the external Q-RPT increases.

To connect a PPC3 to an RPM4 to be used as part of the PPC3 system proceed as follows:

Set up the RPM4 for use as an external device to PPC3 following the instructions in

the RPM4 Operation and Maintenance Manual, Using RPM4 With a PPC3

Controller/Calibration Section.

Using tubing of appropriate pressure rating and a Tee, connect the RPM4 Q-RPT

TEST(+) port to the PPC3 TEST(+) port. The third leg of the Tee is for the connection to

the device or system under test. If there are two RPM4s, Tee the second RPM4 in series

with the first one. The order of the RPM4s on the test line is not relevant.

If an RPM4 Q-RPT will be used in a gauge pressure range of less than 100 kPa (15 psi),

consider connecting the RPM4 Q-RPT module TEST(-) port to the PPC3 TEST(-) port and

to the “low” connection of the DUT if available. This will improve pressure control and

stability when ambient pressure is unstable. If the Q-RPT is an Axxx designation Q-RPT,

this connection should be made but also be left open to atmosphere.

When external Q-RPTs are used with PPC3, the maximum set pressure is the maximum

pressure of the PPC3 controller/calibrator. The maximum pressure of the PPC3 is

determined by the PPC3 controller model or the Hi Q-RPT if one is installed (see Section 1.2.1).

Using a standard pin-to-pin DB-9M to DB-9F RS232 cable, connect COM2 of the PPC3

to COM1 of the RPM4 (see Section 4.2.1.3). If there are two RPM4s, connect COM2 of the

first RPM4 to COM1 of the second RPM4. The order of the RPM4 daisy chain is not

relevant.

Turn ON the PPC3 and RPM4(s).

Press [RPT] on the PPC3 key pad. This causes PPC3 to execute the Q-RPT search

function (see Section 3.3.5). Q-RPTs with whom communication is established will be

shown on the PPC3 display identified by their position (see Table 3).

PPC3™ OPERATION AND MAINTENANCE MANUAL

© 2002-2007 DH Instruments, a Fluke Company Page 10

For PPC3 to identify external RPM4s, the RPM4 COM1 port settings must be:

Baud rate: between 1200 and 19200

Parity: Even

Date bits: 7

Stop bits: 1

If PPC3 is not able to establish communications with RPM4s and their Q-RPTs, check

that the RPM4 COM1 port setting conform to the requirements above. If the COM1 port

settings are correct, check that the correct communications cable is being used

(standard pin-to-pin DB-9M to DB-9F RS232) and is connected to the correct

communications ports.

PPC3 COM2 > 1st RPM4 COM1; 1st RPM4 COM2 > 2nd RPM4 COM1

See the RPM4 Operation and Maintenance Manual for additional information on RPM4

RS232 communications and COM port settings.

2.3.8 CONNECTING TO THE DEVICE UNDER TEST (TEST(+)

AND TEST(-) PORTS)

If you are using a self purging liquid trap (SPLT), see Section 2.3.8.1 before proceeding to

connect the device under test.

If the PPC3 has a G15K or BG15K Q-RPT, a dual volume unit (DVU) should be installed for

very low pressure control. See Section 2.3.8.2 before proceeding to connect to the device

under test.

Using a pressure connecting hose or tube of appropriate pressure rating, connect the device or

system to be tested to the PPC3 TEST(+) port. The PPC3 TEST(+) connection is 1/8 in. NPT female.

PPC3 TEST(+) AND TEST(-) PORTS

All PPC3s have a TEST(+) and a TEST(-) port. See Figure 13 for PPC3 internal Q-RPT

TEST port configurations.

The TEST(+) port is connected to Axxx (absolute) Q-RPTs and to the high side of Gxxx or

BGxxx (gauge, bi-directional gauge) Q-RPTs.

The TEST(-) port is connected to PPC3s internal barometer, if present, and to the low side of

Gxxx or BGxxx (gauge, bi-directional gauge) Q-RPTs.

•When operating in absolute mode: The TEST(-) port is left open to atmosphere.

•When operating in gauge or negative gauge mode with a range greater than 50 kPa

(7.5 psi): The TEST(-) port is normally left open to atmosphere. A possible exception is

when the device or system under test is in an ambient pressure that may differ significantly

from the ambient pressure around the PPC3. For example, if the PPC3 is controlling

pressure into DUTs in an environmental chamber, the pressure in the environmental

chamber may be different from ambient pressure around the PPC3. In this case,

connecting a tube from the TEST(-) port to the inside of the chamber may improve

measurement results. If the Q-RPT in use is an Axxx Q-RPT, this tube must be left open to

the environment so that the pressure inside cannot deviate too far from ambient. When using

an Axxx Q-RPT, if this tube is connected to the low or reference side of DUTs, be sure to

open to the local environment as well.

•When operating in gauge or negative gauge mode with a range less than 50 kPa (7.5 psi):

As a general rule, it is preferable to connect the PPC3 TEST(-) port(s) directly to the low or

reference side of the device under test to assure that these are at the same pressure.

When using an Axxx Q-RPT, this connection must also be open to atmosphere. When using

a Gxxx or BGxxx Q-RPT, it is preferable that this connection not be open to atmosphere.

Table of contents

Other DH Instruments Test Equipment manuals