2. Safety instructions

-Do not charge the Li-ion battery at temperatures below 0°C. First transport the Li-ion battery

and the BTS to a location where the temperature is higher and then start the test/charging

procedure.

-Charge specified batteries only. Do not recharge non-rechargeable batteries.

-Charge the batteries only if there is proper ventilation. Especially around the batteries. While

charging, a small amount of explosive gasses can be generated in the batteries.

inadequate ventilation in combination with open fire or sparks can lead to dangerous situations.

-Do not connect or disconnect the battery while the BTS is testing the battery. E.g. to reduce risk

of sparking.

-Batteries are capable of providing a lot of energy in a short time span. Prevent short circuits in

any way. For example walking over the cables or damaging the cables or connector by improper

use.

-Only use cables supplied with the BTS.

-Do not use the BTS if the cables are damaged.

-If the power cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualified persons in order to avoid a hazard. If the BTS is defective, do not try to repair

it.

-The BTS should never be used in a very damp or wet environment (for instance outdoors), never

poor fluids over it or submerge it in water.

-The system must not be exposed to chemical substances or vapours.

-Make sure the BTS is positioned stable.

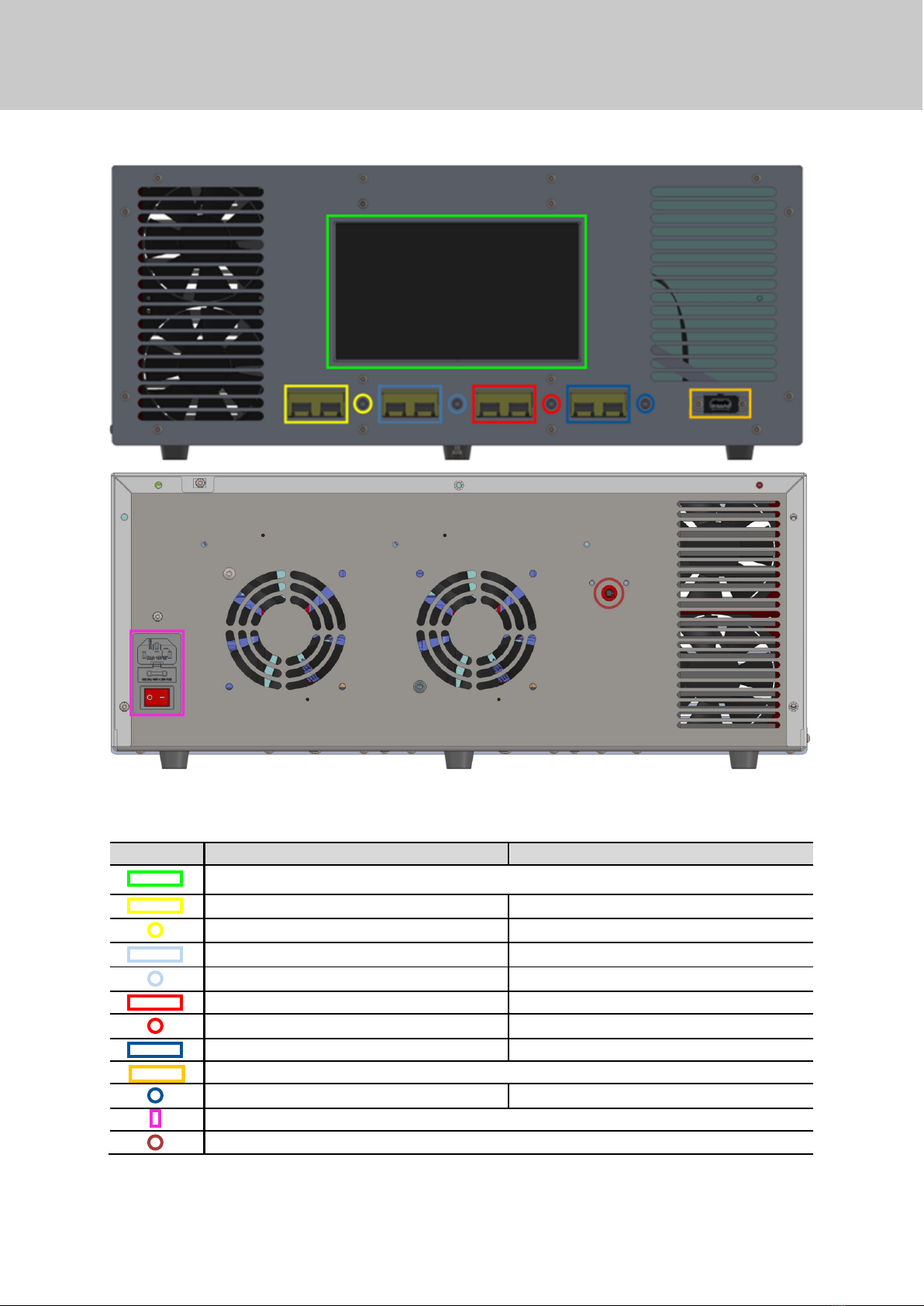

-Keep a free zone of 20cm around the BTS to ensure that heat, generated during operation, can

be removed.

-Do not place the BTS in direct sunlight.

-Do no place the BTS in an environment that contains mechanical vibrations(i.e. Compressors,

etc.) or where a lot of heat is generated(Heaters, Ovens, etc.).

-The ventilation slots of the BTS have to be kept free of excessive dust built up.

-Make sure the BTS is connected to an appropriately earthed wall outlet.