Di-Acro 6 User manual

REV. A 11/12

1

DI-ACRO

#6 & #8 POWER BENDER

INSTRUCTION MANUAL

REV. A 11/12

2

TABLE OF CONTENTS

A. INTRODUCTION PG. 3

B. SAFETY INFORMATION PG. 3

C. SPECIFICATIONS PG. 4

D. INSTALLATION PG. 4-5

E. LUBRICATION PG. 5

F. CONTROL DESCRIPTION PG. 5-7

G. SETUP & RUN NO. 6 BENDER PG. 8-9

H. SETUP & RUN NO. 8 BENDER PG.9-10

I. TABLE ASSEMBLY PG. 11-13

J. 4” CYLINDER ASSEMBLY PG. 13

K. BASE ASSEMBLY PG. 14-15

L. NO. 6 TOOLING HEAD ASSEMBLY PG. 16-17

M. HANGER ASSEMBLY PG. 18

N. PRESSURE ROLLER ASSEMBLY PG. 19

O. NO. 8 TOOLING HEAD ASSEMBLY PG. 20-21

P. NOSE HOLDER ASSEMBLY PG. 22

Q. GAUGE GROUP PG. 23

R. FLOOR PLAN PG. 24

S. HYDRAULIC DIAGRAM PG. 25

T. ELECTRICAL DIAGRAM PG. 26

U. WARRANTY PG. 27

REV. A 11/12

3

A. Introduction

This instruction manual serves two purposes:

1. It outlines essential information for installation, operation and maintenance of the No. 6

and No. 8 Power Bender.

2. It gives a complete parts breakdown identified by number, should replacements be

required.

It is recommended that the operator become familiar with the bender’s instructions and operating

details. It is also recommended that the foreman or supervisor familiarize himself with the

operating details of the machine to insure its continued efficient service.

The Di-Acro Power Benders are designed to accommodate two different types of tooling.

The No. 6 Bender is designed to handle tubing to 1.125” diameter (.060 wall-mild steel) and

round bars up to .563” diameter.

The No. 8 Bender will handle round bar up to 1” diameter and tubing up to 1.500” diameter.

B. Safety –Caution

Always read and understand this instruction manual before operating the No. 6 or No. 8

Bender.

Always make certain that other individuals are not in the working area of this machine

before operating.

Always keep fingers, hands, arms, elbows, head, feet or other parts of the body clear of

swinging arm and out of tooling area while machine is in operation.

Always make certain power is off when installing or changing tooling.

Always make certain power is disconnected when servicing machine.

Never allow untrained personnel to operate this machine.

REV. A 11/12

4

C. Specifications

SPECIFICATIONS

No. 6 Tooling Head No. 8 Tooling Head

Capacity (Material) 1-1/4” OD Tube (.060 wall 1-1/2” OD Tube (.060 wall

mild steel mild steel

3/4” IPS 1” IPS

5/8” Rd (solid mild steel) 1” RD (solid mild steel)

1/4”x 2” Flat (easy way) 3/8”x4” (easy way)

1/4” x 1” Flat (hard way) 3/8” x 1” (hard way)

Radius Capacity 9” 24”

Degree of Bend 280 360

Hydraulic Pressure 1000 PSI 1000 PSI

Motor 3 HP 3 HP

Cylinder 4” 4”

Floor Space 18” x 62” 18” X 62”

Shipping Weight 1,150 lbs. 1,150 lbs.

Spindle Torque 3487 ft./lbs. 3487 ft./lbs.

Power Required 208, 230 or volt, 3phase, 60hz

D. Installation

During shipment, the bender may have accumulated a coating of dust or grit. Remove all

Dirt and rust preventative with cleaning solvent.

WARNING: To prevent serious bodily injury fasten machine to floor through 4 holes

(5/8” Dia) provided in the base of machine.

When shipped the gauge is removed for packing purposes. Install one of the two gauge groups

as illustrated below.

REV. A 11/12

5

NOTE: Install gauge group “A” for short or single length bends. Install group “B” for longer

or multiple length bends.

NOTE: It is suggested that all four stop arms be placed at right angles to each other even if

only one or two are needed so that the knurled knob can be easily turned in to position

the stops.

Connect electricity to a thee phase input power supply making certain the transformer and motor

are connected properly for power being supplied (208, 230, or 460).

Check pump rotation. Proper rotation is shown by the directional arrow on shroud located at the

top of the motor. To change pump rotation, interchange two supply lines.

Check pump reservoir and fill to the proper level in the sight gauge if needed. Reservoir is filled

at the factory.

E. Lubrication

Fill pump with anti-wear hydraulic oil such as Mobil DTE-26 or equivalent. A viscosity

between 120 and 250 SUS should be maintained. If this is not available, automotive oil SAE 20-

20W, type SC, SD, SE is an acceptable substitute when there is little or no water contamination.

Detergent dispersant additives in these oils hold water in a tight emulsion and prevent separation

of water, even after long standing periods. A minimum of lubrication is required on the No. 6

and No. 8 benders. A single grease fitting on the rack cam requires lubrication every 500 hours

of operation or every three months. The same schedule applies to the miscellaneous linkages on

the control and gauges. Use NLGI No. 2 grease on the grease fittings, and a No. 30 machine oil

on the linkages.

F. Control Description

1. Initial Power Up

After providing the proper power source to main electrical enclosure, rotate

disconnect switch to the “ON” position. This will provide power to the control

panel.

If needed rotate “E” stop mushroom button clockwise to deactivate.

Press “POWER ON RESET”

Press “START”, “STOP” buttons to control hydraulic pump. NOTE: Stop pump

when not running production. Running for extended periods of time can cause

overheating.

2. HMI Screen Displays

Three screen options are provided to operate the power bender. They are the

“Production” screen, “Manual/Homing” screen, and “Bend Value” screen. See page

7 for screen layout.

The “F4” button is used to toggle between the “Production” screen and

“Manual/Homing screen.

REV. A 11/12

6

The “F1” button (when in the “Production” screen is used to enter the “Bend Value”

screen “F1” (ESC) or <RET> is used to return back to the “Production screen.

3. Manual Operation

Start Hydraulic pump with the “START” button.

Go to the “Manual/Homing” screen; press “F4” if in the “Production” screen.

Toggle “F2” button between “Extend” & “Retract” to control the rotation

direction of the tooling head.

Position and hold fingers in the two hand safety switch to activate rotation.

Rotation will stop when fingers are removed from the safety switch or the

hydraulic cylinder has reached full stroke in either direction.

The “F2” button must be toggled back to rotate the tooling head in the other

direction.

NOTE: The bend value is displayed but cannot be reset. Also, the proximity switch

used for homing in “Auto” mode does not stop rotation in “Manual” mode.

4. Automatic Operation (Step 1-Homing)

Using the manual operation (Step 1) rotate the tooling head to the desired

“Home” position for making a bend.

Once properly positioned, press “F1” when in the ‘Manual/Homing” screen to

Toggle to the “Auto” mode.

Press “F3” to activate the “Homing” sequence. The “Homed” indicator circle

will turn off and the “Homing’ indicator circle will illuminate (turn dark)

Manually position the trip arm, under the left side of the machine, until the yellow

lights on the proximity switch illuminates on the base of the switch if necessary.

NOTE: The “Homing” operation will automatically zero the bend value.

Automatic Operation (Step 2 –Setting the Initial Bend Set Point)

(assuming the Homing sequence is complete and “Auto” mode is selected)

Press “F1” in the “Production” screen to go to the “bend Value” screen

Enter the desired bend angle using the numeric key pad. The set bend angle and

actual bend angle may differ by a few degrees and therefore the set bend angle

may need to be changed. Material spring back will also need to be considered.

Press the <RET> Key to save a bend value and return to the “Production” screen.

Press “F1” to escape from the “Bend Value” screen back to the “Production

screen. The bend value will default back to the previous value.

5. Automatic Operation (Step 3 –Test Bending and Bend Value Adjustment)

Position and hold fingers in the two hand safety switch to activate rotation.

Rotation will stop once the “Bend Value” has been reached.

NOTE: Rotation will stop anytime the two hand safety switch is deactivated (fingers m

removed). Rotation direction will not change until the “Bend Value” has been

reached.

Position and hold fingers in the two hand safety switch to activate rotation back

REV. A 11/12

7

to the Home position. Rotation will not stop once the Home position has been

reached.

If the desired bend angle is not obtained repeat Step 4 (above)

6. Cycle Counter

A cycle counter is available in the “Production” screen. It is activated in the

“Auto” mode when the “Bend Value” is reached.

Press “F3” in the “Production” screen to reset the counter.

CONTROL PANEL

REV. A 11/12

8

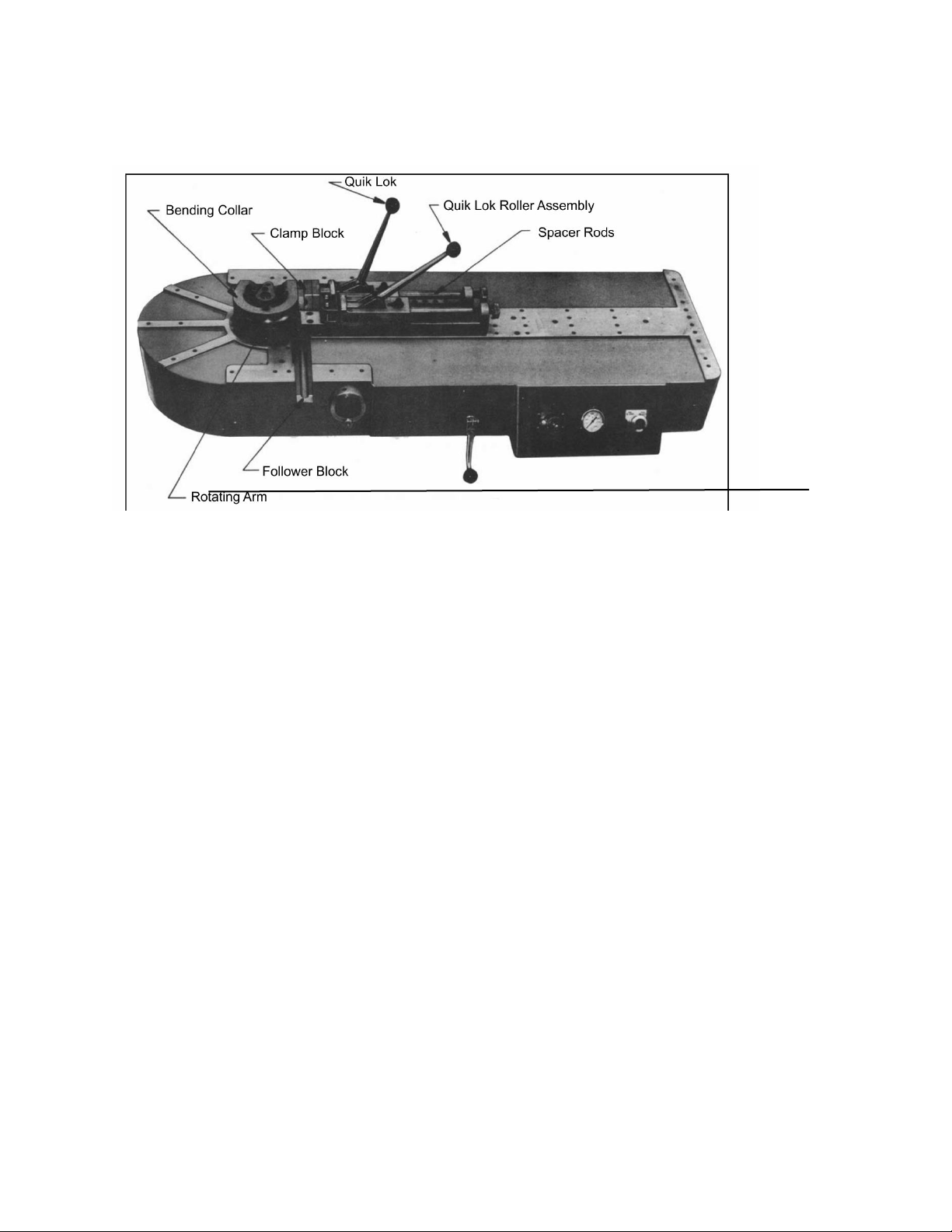

G. SET-UP & RUN NO. 6 BENDER

NOTE: This example set-up is of forming in the counter-clockwise direction.

When you first receive your machine and tooling head, make sure you have all the

proper

parts and quantity of parts. Refer to pages 16 and 17 for No. 6 tooling head

components.

1. Turn power on. Make sure that the rack assembly is fully retracted into the cylinder.

Once in position, turn power off.

2. Place rotating arm assembly on machine top as shown on this page.

3. Place slide bar adjacent to the rotating arm.

4. Insert the 3/8” socket head cap screws into the holes on the slide and loosely thread

them into the table top.

5. Insert the three 1/2” diameter dowels into the holes of the slide bar to they are flush at

the top. At this point tighten the 3/8” screws and secure the bar.

6. Turn power on and follow the manual operation instructions to rotate the pinion

assembly in a counter-clockwise direction. Rotate pinion assembly until threaded

holes line up with clearance holes on the rotating arm. Once the holes are aligned,

turn power off, insert and tighten the six 7/16” socket head cap screws.

7. Insert the holding pin and 1/2" radius pin into their proper positions on the rotating

arm.

8. Install the proper bending collar.

9. Attach the proper clamp block to the hanger assembly.

10. Adjust Quik-Lok slide that controls the clamp block.

A.. Bolt to the rotating arm at position where material can be held firmly between

bending collar and clamp block.

B. Add spacer rods as necessary to assure firm pressure between clamp block and

bending collar.

REV. A 11/12

9

11. Adjust Quik-Lok slide that controls follow block (excessive pressure not necessary).

12. Clamp material with clamp block.

13. Clamp material with follow block.

14. Follow Manual Operations Instructions to test bend a part.

NOTE: After desired part has been achieved, material stop indexes can be adjusted and

follow automatic operation instruction to set up for production.

To Set Up For Clockwise Bending

1. Remove Quik-Lok that controls clamp block from rotating arm.

2. Remove Quik-Lok that controls follow block.

3. Remove rotating arm and slide.

4. Remove and flip over screw support on the end of the rotating arm.

5. Turn power on and fully extend cylinder.

6. Turn power off.

7. Repeat steps 8 through 15 in set up for counter-clockwise bending.

H. SET-UP AND RUN NO. 8 BENDER

NOTE: This example is of forming in the counter-clockwise direction.

When you first receive your machine and tooling head make sure you have all the proper

parts

quantity of parts. Refer to pages 20 & 21 for No. 8 tooling head components.

REV. A 11/12

10

1. Turn power on. Make sure that the rack assembly is retracted fully into the cylinder.

Once

in position turn power off.

2. Place mounting plate on machine top as shown on this page.

3. Place nose holder slide on machine so that machine dowel and screws holes are

aligned.

4. Locate 3/8” socket head cap screws and insert through the slide and loosely thread

them

into the table top.

5. Insert the four 1/2” diameter dowels into the holes of the slide bar so they are flush at

the top. Tighten the 3/8” screws and secure the bar.

6. Place the nose holder assembly on slide. Do not bolt down at this time.

7. Insert desired center pin or radius collar.

8. At this time you need to determine the proper location of the locking pin. Place a

sample

piece of the material into the radius collar. Insert the locking pin into the mounting

plate

so that the material will be held in position when turning the locking pin in a counter-

clockwise rotation.

9. The mounting plate should be located so that the locking pin will be adjacent to the

forming side opposite the instrument panel when the cylinder rod is all the way back in

the cylinder. Follow Manual Operation instructions so that the pinion assembly rotates

in a counter clockwise direction. Rotate pinion assembly until threaded hole line up

with holes in the mounting plate. Insert the six 7/16” screws in the mounting plate and

tighten. When it becomes necessary to change position of mounting plate, remove the

six mounting screws in the top of the plate, which mount it to the spur pinion gear.

Position mounting plate in desired position and replace screws.

10. Rotate locking pin in a counter-clockwise direction and lock material against center pin

11. Adjust nose holder assembly.

a. Tighten bolts “B” securely

b. Finger tighten bolts “A”

c. Adjust nose holder support screw “C” until nose comes in contact with material.

d. Tighten bolts “A” securely.

12. Follow Manual Operation Instructions to test bend a part.

NOTE: After desired part has been achieved, and material stop indexes can be

adjusted. Follow automatic operation instructions to set up for production.

To Set Up For Clockwise Bending

1. Change position of pin to position shown on diagram for clockwise bending.

2. Repeat steps 7 thru 12 in set up for counterclockwise bending.

REV. A 11/12

11

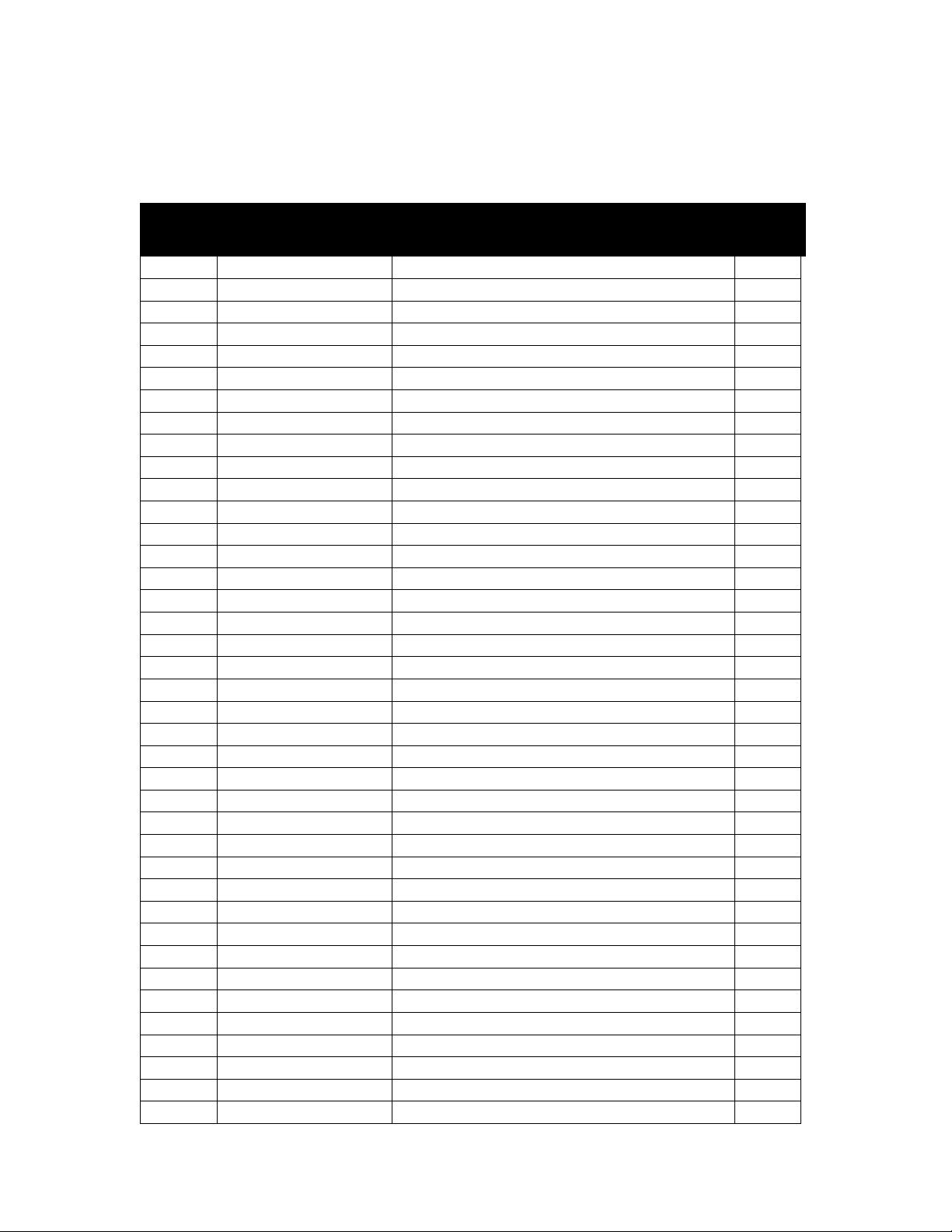

I. TABLE ASSEMBLY

REV. A 11/12

12

POWER BENDER

TABLE ASSEMBLY

PARTS LIST

8700000-060

ITEM

PART NUMBER

DESCRIPTION

QTY

1

8150110-505

TABLE

1

2

8156650-300

DANGER SIGN

1

12

899111-000

CYLINDER MOUNT

1

13

20A0508C2104

SCREW-SHCS 5/8-11X2-1/4

4

14

62X0508

LOCKWASHER 5/8

4

15

8150371-170

CYLINDER ASSEMBLY

1

16

120464-000

SHIM

1

19

8150390-108

PINION ASSEMBLY

1

20

8150120-308

LOCATING BUSHING

1

21

8310100-300

CONE

1

22

8310100-400

CUP

1

23

8150470-509

LOCKING RING

1

24

23A0104C0308

SCREW-SSS 1/4-20X3/8

2

25

8000110-608

GEAR CASE COVER

1

26

8310301-100

CAM FOLLOWER

1

27

8150110-808

CAM FOLLOWER SPACER

1

28

8150470-400

NUT

1

29

8690100-200

GREASE FITTING

1

30

21A0308C2000

SCREW-HHCS 3/8-16X2

6

31

8310100-100

CONE

1

32

8310100-200

CUP

1

33

19A0102X2104

PIN-DOWEL 1/2X2-1/4

4

34

8150111-008

TAKE-UP CAP

1

35

20B0516C0708

SCREW-BHSCS 5/16-18X7/8

4

36

8371005-600

OIL SEAL

1

38

8200130-108

TRIP CLAMP

1

39

20A0104C1104

SCREW-SHCS 1/4-20X1-1/4

1

40

8000130-108

TRIP ARM

1

*

23A0104C0304

SOC SET SCREW 1/4-20X1/2

1

73

8150120-805

INDEX KNOB

1

74

8151120-307

PIN

1

75

8200120-307

KNOB

1

76

8151510-206

SPRING

1

77

23A0104C1000

SCREW-SSS 1/4-20X1

2

78

8150130-400

CLAMP

1

79

20A0516C1102

SCREW-SHCS 5/16-18X1-1/2

1

80

8151142-007

STOP ROD SUPPORT

1

84

8300142-007

STOP ROD SUPPORT

2

85

23A0516C0104

SOC SET SCREW 5/16-18X1/4

4

REV. A 11/12

13

POWER BENDER

TABLE ASSEMBLY

PARTS LIST “CONTINUED”

ITEM

PART NUMBER

DESCRIPTION

QTY

86

62X0308

LOCKWASHER 3/8

6

90

62X0516

LOCKWASHER 5/16

4

92

8150110-800

SPACER

2

*

8150740-101

PROX. MOUNT

1

*

8150740-102

ENCODER FLEX PLATE

1

*

8150740-103

ENCODER ADAPTOR

1

*

23A0X10C0104

SCREW-SSS #10-24 X 1/4

2

*

23A0X10C0102

SCREW-SSS #10-24 X 1/2

1

*

20A0X08C0304

SCREW-SHCS #8-32X3/4

6

*

31X0X08C

NUT-JAM #8-32

6

*

61X0X10

WASHER-FLAT #10

10

*

62X0X10

WASHER-LOCK #10

6

* Parts shown above with (*) asterisk in Item column are not shown on assembly drawing

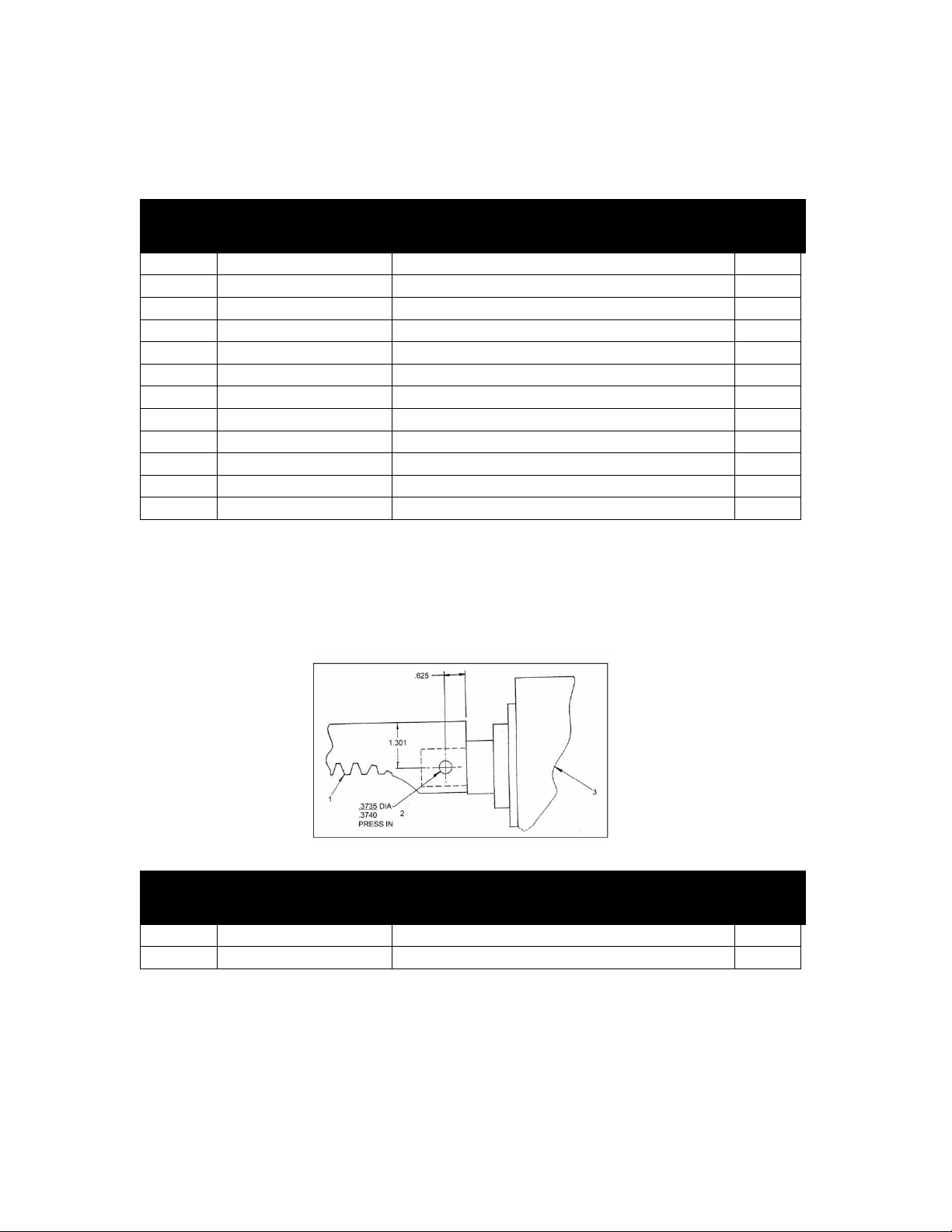

J. 4” CYLINDER ASSEMBLY

As of April 2011, the new style Rack (P/N 8150122-607) was threaded onto the cylinder piston

shaft and locked with a jam nut. Beginning December 2012 a ¼-20” set screw was used to lock

the thread.

Reflects old style Rack

ITEM

PART NUMBER

DESCRIPTION

QTY

1

8150122-607

RACK

1

3

8150372-100

CYLINDER

1

SEAL KITS (NOT SHOWN)

8150730-116 PISTON SEAL KIT

8150730-117 ROD SEAL KIT

NOTE: When replacing old style Rack (P/N 8150121-607), drill 3/8 dia. hole in rack and

align with hole in piston rod. Install 3/8” dowel pin.

REV. A 11/12

14

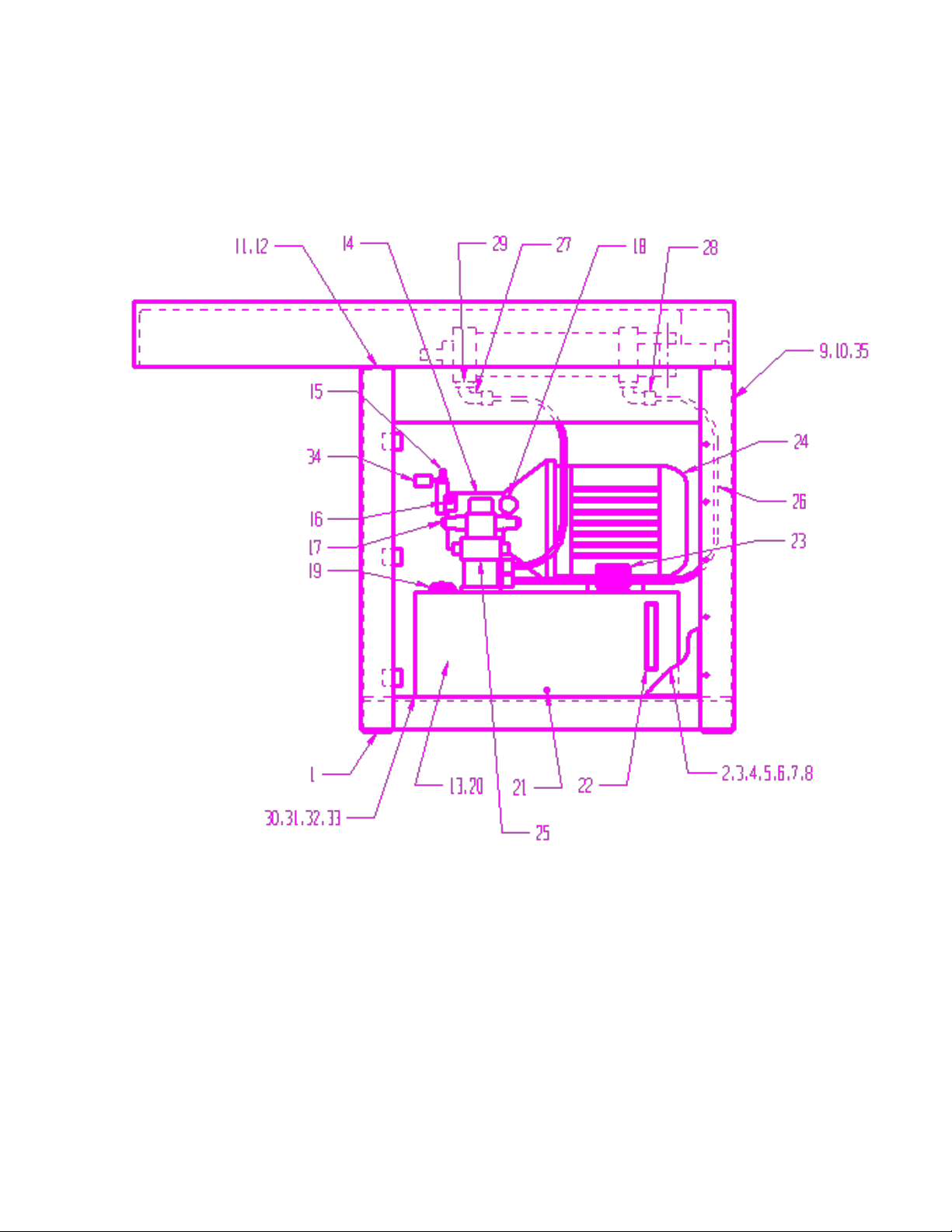

K. BASE ASSEMBLY

REV. A 11/12

15

POWER BENDER

BASE ASSEMBLY

PARTS LIST

121871-000

ITEM

PART NUMBER

DESCRIPTION

QTY

1

121871-100

BASE-SUB ASSY/PWR BENDER

1

2

121871-200

DOOR ASSEMBLY

1

3

8150720-108

DOOR

1

4

8150720-109

HINGE

1

5

803343-000

LATCH

1

6

20A0104C0304

SCREW-SHCS 1/4-20X3/4

5

7

62X0104

WASHER-LOCK 1/4

5

8

30X0104C

NUT-FULL 1/4-20

5

9

21A0308C0304

SCREW-HHCS 3/8-16X3/4

4

10

62X0308

WASHER-LOCK 3/8

4

11

20A0102C1104

SCREW-SHCS 1/2-13X1-1/4

4

12

62X0102

WASHER-LOCK 1/2

4

13

1000307-000

HYDRAULIC POWER SUPPLY

1

14

8150730-103

HYDRAULIC PUMP

1

15

8150730-104

PRESSURE ADJUSTMENT

1

16

8150730-105

FLOW ADJUSTMENT

1

17

8150730-106

DIRECTIONAL VALVE

1

18

8150730-107

PRESSURE GAUGE

1

19

8150730-108

RETURN FILTER

1

20

8150730-109

RESERVOIR

1

21

8150730-110

DRAIN PLUG

1

22

8150730-111

SIGHT LEVEL/TEMP GAUGE

1

23

8150730-112

FILLER/BREATHER CAP

1

24

8150730-113

MOTOR

1

25

8150730-115

PO CHECK VALVE

1

26

130-0221-P

HYDRAULIC HOSE

8’

27

130-0213-P

90° MALE ELBOW

2

28

130-0214-P

SWIVEL FITTING

4

29

8150730-114

BUSHING

2

30

20A0102C1304

SCREW-SHCS 1/2-13 X1-3/4

4

31

62X0102

WASHER-LOCK 1/2

4

32

61X0102

WASHER-FLAT 1/2

4

33

30X0102C

NUT-FULL 1/2-13

4

34

8150750-101

TAMPER PROOF LOCK

1

35

100-0135-P

NAMEPLATE

1

REV. A 11/12

16

L. NO. 6 TOOLING HEAD ASSEMBLY

REV. A 11/12

17

NO. 6 TOOLING HEAD

ASSEMBLY PARTS LIST

ITEM

PART NUMBER

DESCRIPTION

QTY

1

20A0716C1104

SOC HEAD CAP SCREW 7/16-14X1-1/4

6

2

8156120-302

HOLDING PIN

1

3

8130016-970

RADIUS PIN

1

4

20A0516C0508

SOC HEAD CAP SCREW 5/16-18X5/8

2

5

8156111-371

HANGER ASSEMBLY

1

6

61X0308

FLATWASHER 3/8

4

7

20A0308C2102

SOC HEAD CAP SCREW 3/8-16X2-1/2

4

8

8200111-371

ROTATING ARM ASSEMBLY

1

9

8400111-301

SPACER ROD C –4”

2

10

8300111-301

SPACER ROD B –2”

2

11

8156111-301

SPACER ROD A –1”

2

12

8700111-301

SCREW SUPPORT

2

13

20A0308C1000

SOC HEAD CAP SCREW 3/8-16X1

4

14

8500111-301

KNURL HEAD SCREW

2

15

20A0308C1102

SOC HEAD CAP SCREW 3/8-16X1-1/2

12

16

8910111-300

SLIDE

1

17

19A0102X1304

DOWEL PIN 1/2 X 1-3/4

3

18

8000111-371

ASSEMBLY COMP ROLLER

1

REV. A 11/12

18

M. HANGER ASSEMBLY

HANGER ASSEMBLY

PARTS LIST

ITEM

PART NUMBER

DESCRIPTION

QTY

1

85000111-300

HANDLE ROD

1

2

8120810-700

PLASTIC KNOB

1

3

61X0308

FLATWASHER 3/8

1

4

19A0102X2102

DOWEL PIN 1/2 X 2-1/2

1

5

19A0508X2102

DOWEL PIN 5/8 X 2-1/2

1

6

8156111-302

HANDLE WELDMENT

1

7

8920111-300

NOSE ASSEMBLY

1

7A

23A0104C0308

SCREW-SSS 1/4-20X3/8

1

8

8930111-300

LINK

2

9

8156120-301

LINK PIN

1

10

8400111-300

HANDLE BLOCK

1

10A

23A0104C0104

SCREW-SSS 1/4-20X1/4

2

REV. A 11/12

19

N. PRESSURE ROLLER ASSEMBLY

PRESSURE ROLLER ASSEMBLY

PARTS LIST

ITEM

PART NUMBER

DESCRIPTION

QTY

1

19A0508X2102

DOWEL PIN 5/8 X 2-1/2

1

2

8156111-302

HANGER WELDMENT

1

3

8100111-371

ROLLER ASSEMBLY

1

8600111-301

ROLLER HOLDER

1

8156111-300

ROLLER

2

8200120-301

ROLLER PIN

2

8690100-200

DRIVE FTG

2

3A

23A0104C0308

SCREW-SSS 1/4-20X3/8

1

4

8930111-300

LINK

2

5

8156120-301

LINK PIN

1

6

8400111-300

HANDLE BLOCK

1

6A

23A0104C0104

SCREW-SSS 1/4-20X1/4

2

7

19A0102X2102

DOWEL PIN 1/2 X 2-1/2

1

8

61X0308

FLAT WASHER 3/8

1

9

8120810-700

PLASTIC KNOB

1

10

8500111-300

HANDLE ROD

1

REV. A 11/12

20

O. NO. 8 TOOLING HEAD ASSEMBLY

Other manuals for 6

1

This manual suits for next models

1

Table of contents

Other Di-Acro Construction Equipment manuals