Di-Acro 36 User manual

REV. D 9/12

1

DI-ACRO

#36 FINGER BRAKE

INSTRUCTION MANUAL

REV. D 9/12

2

TABLE OF CONTENTS

A. SAFETY INFORMATION PG. 3

B. ANGLE ADJUSTMENT PG. 4

C. #36 FINGER BRAKE BREAKDOWN AND PARTS LIST PG. 5-7

D. MICROMETER BACK GAUGE PG. 8

E. OPTIONAL STAND PG. 9

WARRANTY PG. 10

REV. D 9/12

3

A. SAFETY INFORMATION

Before brake is set up for operation, mount on work bench or stand*

with brake base flush with the front edge of stand or work bench and

bolt in place.

*IF BRAKE IS MOUNTED ON ITS OWN STAND, SECURE STAND TO FLOOR

REV. D 9/12

4

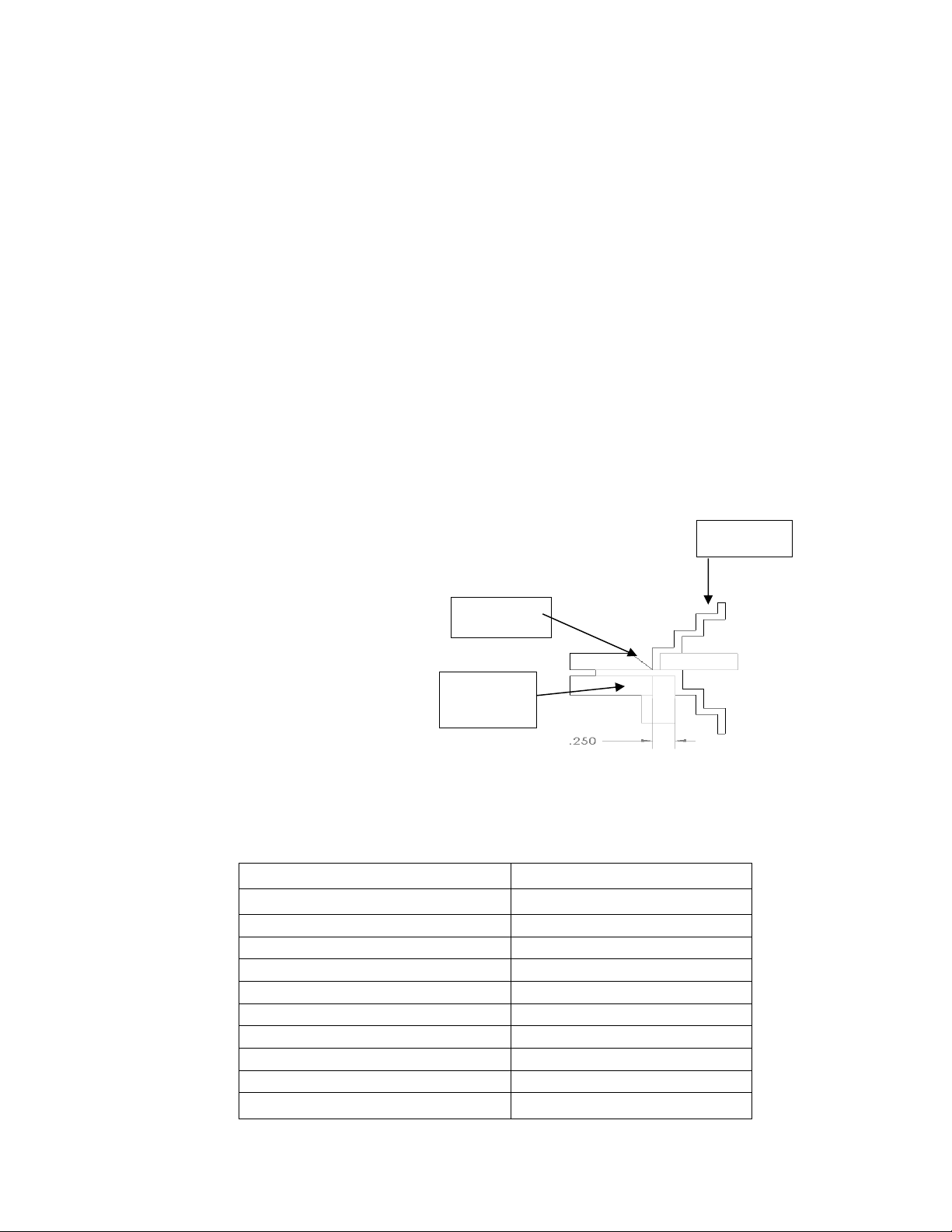

B. ANGLE ADJUSTMENT

To adjust Brake for bending clearance, raise folding blade 90 degrees,

insert material between edges of folding blade and leading edge of fingers

(for heavy material, clearance should be twice the thickness, less for

lighter gauge or if sharper bend is desired). Adjust finger mount

weldment by turning arm adjustment bolts (item 48). To adjust clamping

pressure, insert material under fingers and turn arm adjustment bolts

until material is held securely when fingers are lowered. To adjust

degree of bend, pins (item 44) located on both ends of folding blade for

desired degree of bend.

Reverse Bends

Remove the five Hex head cap screws 3/8-16x1 (item 67) the support bar

(item 64and adjust Brake as shown.

NOTE: 16 GAUGE CAPACITY (with support bar in place)

MINIMUM LENGTH OF BEND WHEN

FORMING A REVERSE BEND = 1/4

NOTE: Di-Acro Brakes are rated for 1” minimum flange when bending

full capacity. Caution should be used if necessary to bend heavier gauge

material in short widths.

SPECIFICATIONS

No. 36

in. mm

Max. Capacity, Mild Steel

16 ga. 1.5

Max. Forming Width

34 914.4

Clearance thru Top Opening

1 25.4

Max. Depth of Box or Pan

3 76.2

Min. Reverse Bend

¼ 6.4

Max. Angle Bend (one operation)

135°

Max. Back Gauge Adjustment

24 609.6

Shipping Weight

470# 123 kg

Stand, Shipping Weight

140# 63 kg

FINGERS

PART

BOTTOM

PLATE

REV. D 9/12

5

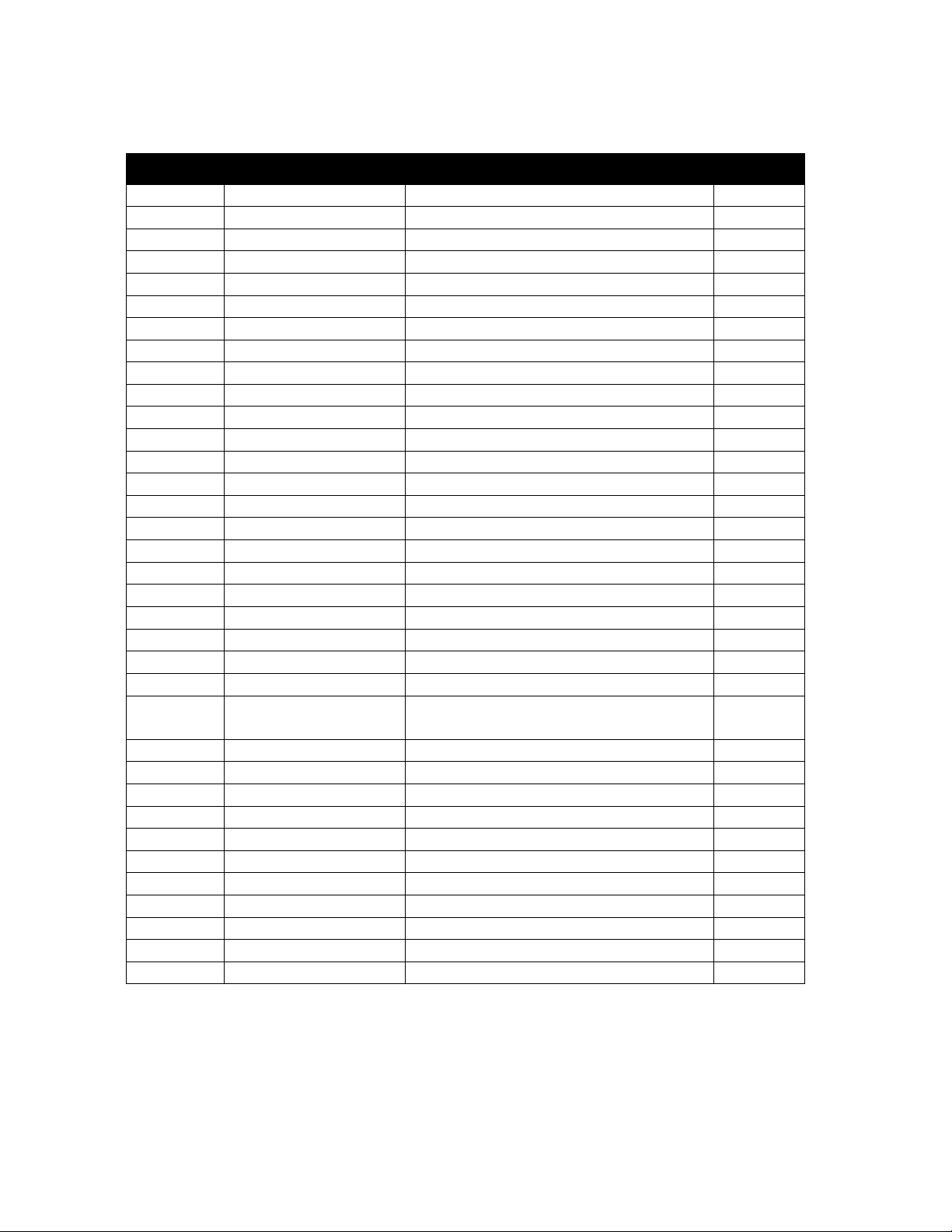

#36 FINGER BRAKE BREAKDOWN

8348820-080

REV. D 9/12

6

Parts List

8348820-080

ITEM

PART NUMBER

DESCRIPTION

QTY

1

30X0102C

NUT-FULL 1/2-13

2

2

8490500-100

WASHER SET

2

3

23A0104C0308

SCREW-SSS 1/4-20X3/8

2

4

8348111-000

FINGER MOUNT

1

5

8348310-700

THRUST BRG

4

7

8348510-200

SPRING

2

8

21A0104C0102

SCREW-HHCS 1/4-20X1/2

4

9

8348140-700

SPRING BRACKET

2

10

8348121-100

STUD

2

11

8348121-200

CONNECTING ARM

2

12

8120810-700

PLASTIC KNOB

1

14

8310300-900

NEEDLE BEARING

2

15

346-1208030

CLAMP HANDLE BLOCK

1

15A

8500111-300

CLAMP HANDLE ROD

1

16

21A0516C1104

SCREW-HHCS 5/16-18X1-1/4

1

17

21A0516C1308

SCREW-HHCS 5/16-18X1-3/8

16

19

8347110-203

FINGER CLAMP

16

20

8000122-203

FINGER STD 3/4

2

20

8100122-203

FINGER STD 1

2

20

8000122-204

FINGER STD 1-1/4

2

20

8200122-203

FINGER STD 3

2

20

8347122-204

FINGER STD 6

4

21

8700122-000

BRAKE SHAFT

1

22

8346110-302

BEARING ASSEMBLY (SEE

BELOW)

346-1103024

BUSHING HOUSING

2

8346110-302-1

BRONZE BUSHING

2

23

8690100-200

DRIVE FITTING

2

32

8348110-400

BOTTOM PLATE

1

33

20A0516X1000

SCREW-SHCS 5/16-18X1

7

34

8348110-100

BASE

1

35

21A0308C1304

SCREW-HHCS 3/8-16X1-3/4

2

36

31X0308C

NUT-JAM 3/8-16

2

37

8060510-205

SPRING

2

38

19A0508X3102

PIN-DOWEL 5/8X3-1/2

2

40

18A0308X2102

PIN-SPRING 3/8X2-1/2

1

REV. D 9/12

7

Parts List - Continued

8348820-080

ITEM

PART NUMBER

DESCRIPTION

QTY

44

19A0104X1000

PIN-DOWEL 1/4X1

2

46

8500122-000

FOLDING BAR STOP

2

47

31X0516C

NUT-JAM 5/16-18

2

48

8251470-101

ARM ADJUSTMENT BOLT

2

49

8400122-000

LEFT ARM

1

50

8310300-600

NEEDLE BEARING

2

52

8346120-300

TRUNION

2

53

21A0308C1104

SCREW-HHCS 3/8-16X1-1/4

4

54

8346120-801

HANDLE ARM

2

55

8348131-000

HANDLE BLOCK

2

56

23A0104C0308

SCREW-SSS 1/4-20X3/8

2

58

8348131-200

HANDLE CROSS BAR

1

59

23A0102C0102

SCREW-SSS 1/2-13X1/2

4

60

8348122-001

FOLDING BAR FRONT

1

60A

8348122-002

FOLDING BAR REAR

1

61

61X0104

WASHER-FLAT 1/4

2

62

21A0104C0102

SCREW-HHCS 1/4-20X1/2

2

63

20C0104C0304

SCREW-FHSCS 1/4-20X3/4

3

64

8600122-600

FOLDING BAR SUPPORT

1

65

21A0308C1304

SCREW-HHCS 3/8-16X1-3/4

4

66

19A0308X1102

PIN 3/8X1-1/2

2

67

21A0308C1000

SCREW-HHC 3/8-16X1

5

69

8346122-000

RIGHT ARM

1

70

21A0308F0304

SCREW-HHCS 3/8-24X3/4

2

72

30X0308F

NUT-FULL 3/8-24

2

76

21A0104C0102

SCREW-HHCS 1/4 -20X1/2

2

77

8346144-106

BLOCK

2

78

8348144-100

GAUGE

1

79

8346144-103

QUICK SET BRACKET

2

80

8210143-104

QUICK SET DIAL NUT

2

81

22B0104C0708

SCREW-FLHMS 1/4-20X7/8

2

82

8046144-103

QUIK SET ROD

2

82A

22D0516C0102

SCREW-THMS 5/16-18X1/2

2

83

8000143-104

QUIK SET DIAL SHOE

2

84

8000140-104

NAMEPLATE

1

86

8150650-110

SERIAL TAG

1

87

8210510-204

SPRING

2

REV. D 9/12

8

C. MICROMETER BACK GAUGE - #8348144-170

Typically the back gauge is assembled when the finger brake is shipped

from the factory. Occasionally it is removed for ease of palletizing. To

install and/or zero the gauge follow the instructions below.

1. Install quik set rod (item 82) in holes located in rear of the

base casting.

2. Hold quik set dial assemblies (items 79,80,83) on zero and

screw rods in until gage (item 78) lines up with folding blade.

Quik set rods can be locked in place by tightening screws

located behind folding blade.

3. To position micrometer back gauge rapidly, turn quik set dial

assemblies to zero. Depress dial and slide complete back gauge

assembly to desired position. For fine adjustment turn quik set

dial assemblies in regular manner.

REV. D 9/12

9

D. OPTIONAL STAND

Part Number: 838110-900

Stand Dimensions: 48” WIDE, 15” DEEP, 33-1/4” HIGH

CALL DI-ACRO FOR PRICE AND AVAILABILITY

Fasteners needed to attach Finger Brake to stand are the following:

Fasteners to attach stand to floor are not included

PART NUMBER

DESCRIPTION

QTY

21A0102C4102

SCREW-HHCS 1/2-13X4-1/2

4

61X0102

WASHER-FLAT 1/2

4

30X0102C

NUT-FULL 1/2-13

4

REV. D 9/12

10

Warranty & Limitation of Liability

Defective parts, of a product manufactured by DI-ACRO, will be replaced or repaired at

no charge for twelve (12) months following delivery to the original purchaser. Labor is

included for the first 90 days. This warranty becomes void when products have not

been used according to instructions furnished by DI-ACRO, nor does it cover any

altered parts or unauthorized repairs. We cannot be responsible for the cost of repairs

made or attempted outside of our factory. All other warranty claims are made FOB our

plant, providing such items(s) is returned freight prepaid to our plant for examination.

This warranty does not apply to parts, components or systems not manufactured by DI-

ACRO. These products are covered instead by the existing warranties, if any, of their

manufacturers. Normal service items with a reasonable life expectancy of less than one

year are warranted only to the extent of the reasonable life under normal use and

service.

Authorization must be obtained from DI-ACRO before returning parts or equipment to

the factory. DI-ACRO will satisfy this warranty by replacing the product or refunding the

purchase price upon receipt, inspection and defect identification.

DI-ACRO’s liability under this warranty shall not exceed the amount paid for the product.

THIS IS DI-ACRO’S SOLE WARRANTY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED, WHICH ARE HEREBY EXCLUDED, INCLUDING IN

PARTICULAR ALL WARRANTIES OF MERCHANTABILITY, FITNESS OR ANY

LOSS, DAMAGE OR EXPENSES DIRECTLY OR INDIRECTLY RELATED TO THE

USE OF ITS PRODUCT OR FROM ANY OTHER CAUSE OR FOR CONSEQUENTIAL

DAMAGES INCLUDING, WITHOUT LIMITATION, LOSS OF TIME AND LOSS OF

PRODUCTION.

IT IS EXPRESSLY UNDERSTOOD THAT DI-ACRO IS NOT RESPONSIBLE FOR

DAMAGE OR INJURY CAUSED TO OTHER PRODUCTS, MACHINERY, PROPERTY

OR PERSONS BY REASON OF THE USE OF ITS PRODUCTS.

©Copyright 2012

Other manuals for 36

1

Table of contents

Other Di-Acro Construction Equipment manuals

Popular Construction Equipment manuals by other brands

RDI

RDI PORCH RAIL installation instructions

Tractel

Tractel Tractelift Type II Installation and maintenance instructions

Atlas Copco

Atlas Copco LPD LPD-LD Safety and operating instructions

McElroy

McElroy DynaMc 28 Operator's manual

Allied

Allied Hy-Ram HR175 Safety, operation and maintenance

POP UP

POP UP MI TOWER STAIRS Assembly guide