Diablo Controls DSP-222 User manual

DSP222H_Manual_A Page 1 of 17

DSP-222 Operations Manual

Dual Channel Inductive

Loop Detector Sensor Unit

This manual contains technical information for the DSP-222 detector sensor unit.

Included are general description, general characteristics, installation procedure,

adjustment instructions, operational guide, maintenance procedures and technical

schematics and drawings.

DSP222H_Manual_A Page 2 of 17

1. General Description

The DSP-222 is a dual-channel inductive loop vehicle detector sensor unit designed to

meet the State of California, Department of Transportation, (Caltrans) specification

TSCES dated January of 1989 and the addendum dated July of 1991.

2. General Characteristics

The sensor unit incorporates a double-sided 44-pin edge connector for the connection

of power, loop inputs and call outputs and sensor unit reset. Each channel has

individual front-panel controls for setting sensitivity, frequency, and pulse/presence

mode. Each channel is also equipped with two high-intensity front-panel LEDs which

are used to indicate the detect state and fail condition of the individual channels. Call

outputs are optically isolated solid-state transistors. The sensor unit occupies one

position of a standard 170 input file. Each channel of the DSP-222 will automatically

tune to any loop and lead-in inductance between 50 and 750 microhenries with a loop

system “Q” as low as 5. The unit will detect inductance changes as small as 0.01%

∆L/L.

3. Installation and Adjustments

The sensor unit is factory shipped with all switches set to off signifying both channels

are disabled. The MIN PRESENCE jumper J1 located on the printed circuit board is

installed forcing all detection outputs to last a minimum of 100 ms in the presence

mode. The ALTERNATE jumper J2 located on the printed circuit board is installed

forcing both channels to operate in the non-scanning mode.

a) Remove the MIN PRESENCE jumper J1 on the circuit board to allow presence

outputs of times less than 100 ms, if so desired.

b) Remove the ALTERNATE jumper J2 on the circuit board to allow both channels to

scan sequentially, if so desired.

c) Make sure that the sensor unit is firmly seated into its position in the input file.

d) Set the PULSE switch on for pulse operation. Set the PULSE switch off for presence

operation.

e) Adjust sensitivity by setting switches S1, S2, and S4 to the desired position using

standard binary coding. Sensitivity 1 is the lowest setting and Sensitivity 7 is the highest

DSP222H_Manual_A Page 3 of 17

setting. If a channel is not used, it may be switched off (disabled) by setting it to

Sensitivity 0 (all three switches off).

f) Frequency setting needs to be changed only if crosstalk occurs between nearby

loops. Crosstalk usually manifests itself as chattering of the call output. Change the

frequency if crosstalk is encountered. Four frequency positions are available on each

channel to assist in alleviating interference. It may be necessary to reset the channel

after the frequency has been changed.

g) Check the front-panel indicators. If the Fault LEDs on either channel are flashing

there is a problem with the loop system on that channel. Observe the flash sequence to

determine the type of fault. A single flash followed by a pause indicates an open loop

system. A double flash indicates a shorted loop system. Check the loop connections

carefully. Reset both channels by momentarily selecting a different sensitivity or mode

and then return to the original setting.

h) Monitor operation and make adjustments to the sensitivity and frequency as

necessary.

4. Theory of Operation

The DSP-222 works on the principle that loop frequency is directly related to loop

inductance. However, the change in loop frequency is very small -- perhaps as little as

one hertz. It is easy to measure a change of one hertz simply by counting the number of

cycles in one second. Unfortunately, the minimum response time using this method is

easily greater than one second. To improve the response time, the measurement is

done by gating a high-speed stable oscillator with the loop frequency. This scheme,

called period measurement, provides high-resolution in a short period of time. This

measurement is compared to a previously established reference to determine whether

or not the frequency of the loop oscillator has changed sufficiently to indicate the

presence of a vehicle.

The high speed of the reference crystal oscillator ensures that the sample can be taken

within a very short period of time. For example, at sensitivities less than 4, a sample can

be taken within 2 ms which allows the sensor unit to respond to a vehicle presence (or

loss of presence) in the detection area with an accuracy of 1 ms. Note: This is true only

if the ALTERNATE jumper J2 is installed.

Sensitivity is a function of how long a sample is used for the determination of a vehicle

presence, i.e. the longer the sample time, the more sensitive the sample. Since the

sensor unit measures the minute changes in loop oscillations, it follows that low

frequency loops are innately more sensitive than high frequency loops. In order to keep

DSP222H_Manual_A Page 4 of 17

the sensitivity the same over the wide spectrum of loop frequencies, the sensor unit first

measures the loop frequency and calculates the number of complete cycles needed for

a sample. This value is then used for all subsequent loop measurements for this

channel.

The sensor unit checks the completed sample to confirm that it is still within acceptable

operating limits and then determines whether the sample has changed sufficiently with

respect to the stored reference to indicate the presence of a vehicle. It then controls the

output and indicators appropriately. Minor changes in period occurring over a relatively

long time are due entirely to environmental fluctuations. By altering the stored reference

slowly, these environmental changes are ignored. In this fashion, the sensor unit can

compensate for temperature changes and other long-term effects such as water on the

pavement.

5. Detailed Description of Circuit Operation

The following description is valid for both channels of the DSP-222. Reference

designators are shown for channel 1 with those related to channel 2 in parentheses.

Refer to section 8 for block diagram and schematic.

The loop oscillators consist of two PNP transistors in a basic Franklin type circuit. Q1

(Q4) is coupled to Q2 (Q5) to form the active oscillator. The loop is connected to the

oscillator circuit with the isolation transformer T1 (T2). The reflected roadway loop

inductance is resonated with the capacitor C5 (C11). Frequency modification capacitors

C3 (C9) and C4 (C10) are switched in via SW1 (SW2) and are used to change the

operating frequency of the loop circuit. Neon surge arrestor I1 (I2) provides high voltage

spike protection. When loops are connected to the oscillators and the unit is under

power, the oscillators will resonate at their natural frequency according to the

inductance of the roadway loop and the capacitance described above.

Surge protective diode D1 (D2) is used to limit voltage surges that may appear on the

circuit side of the loop transformer. The output signal from the oscillator is present on

the collector of Q1 (Q4) and is a sine wave at the oscillator frequency.

The loop frequency signals from the oscillators are routed to the squaring circuits

formed by transistor Q3 (Q6). The outputs of the squaring circuits are passed through a

low-pass filter network consisting of resistor R9 (R18) and capacitor C6 (C12). From

here, the square wave loop frequency is presented to the capture register input of the

microprocessor.

The Microchip PIC 16F73 U1 is an advanced RISC microcontroller using Harvard

architecture. The processor is being clocked with a 20 MHz crystal. This speed insures

fast instruction processing as well as a high-speed time base for the two independent

capture registers used in the period measurement of the loop frequencies.

DSP222H_Manual_A Page 5 of 17

The front-panel LED indication LED2 (LED1) is used to indicate the “Call” output of the

channels. LED3 (LED4) indicates the “Fail” condition of the loops. These outputs are

driven directly by the microcontroller. Monolithic voltage regulators provide a stable 12-

volt reference supply U3. Two additional 5-volt regulators provide stable 5-volt power to

the digital circuitry U2 and loop oscillators respectively U4.

An external reset signal is provided to reset the microcontroller with a low (ground true)

signal on pin C of the loop sensor unit. This is accomplished by using Q9 as an input

voltage comparator and phase inverter as well as a second phase inverter Q10. The

input signal is “noise” filtered with C15 and diode D5.

Front-panel switch S1 (S2) is used to input data to the microcontroller from the user.

The sensitivity setting and the choice of pulse or presence operation are routed directly

to the input ports of the microcontroller U1.

Transistor Q7 (Q8) is the high-current driver necessary to power the opto-isolator U5

outputs for external equipment.

The +24 volt input is protected with a power diode D6 to prevent damage to the unit if

power is connected incorrectly. In addition, an input resistor R36 is provided to reduce

inrush current when the unit is plugged into a “hot” card cage. The input voltage is well

filtered with C16.

6. Preventive Maintenance

Over the years, the electronic components used in inductive loop detectors have

become very reliable. Generally, most inductive loop sensor problems can be traced to

the loop system. The loop system is defined as the loop of wire(s) located in the street,

the lead-in wire(s) located between the street loop and the controller cabinet, and the

associated wiring in the controller cabinet itself.

The wire used in the street loop should be rated for direct burial. The wire should be of

the cross-linked polyethylene (XLPE) insulated type. PVC insulated type of wire should

always be avoided. The sealant should be carefully chosen to match the application and

pavement. A hard setting epoxy should never be used with asphalt.

The loop wires should be held into the bottom of the saw cut with backer rod. The loop

wire should be twisted with a minimum of 5 twists per foot between the loop itself and

the splice point. This is usually the hand hole or pull box at the side of the road.

At this point, the twisted loop wires must be soldered to the lead-in cable. If crimp type

connectors are used, they must be soldered after crimping. After soldering, the splices

must be protected with a moisture-proof seal.

DSP222H_Manual_A Page 6 of 17

The feeder cable used to extend the lead-in, must be a shielded, twisted pair with high-

density polyethylene insulation. The termination of the feeder cable in the controller

cabinet must also be soldered if crimp type terminals are used. The use of wire nuts and

other improper methods of connections will result in problems with the detection system.

7. Trouble Analysis

The following chart should be used to troubleshoot the sensor unit and installation. If the

DSP-222 itself is suspect, see section 8 for a complete internal testing sequence.

a) Neither channel responds to vehicles. Power supply fault.

The DSP-222 requires a 24 VDC nominal supply. The sensor unit will operate at

voltages as low as 16 volts. However, supply voltages below this may result in the

sensor unit entering a reset state. In this case, the unit will appear to be non-functional.

b) Reset line held low.

This fault is likely to affect all units in the rack since the external reset line is usually

common to every card rack position. Measure the voltage on the external reset line. If it

is below approximately 12 volts, remove each unit one by one until the reset line returns

to the power supply level (approximately 24 volts). The unit that was removed last

should be checked carefully for other faults. See section 8.

c) Channel does not detect all vehicles.

Sensitivity is too low. Increase sensitivity by one setting and observe operation.

d) Channel is noisy/chatters/gives false detect calls.

Two or more units are interfering with each other (crosstalk). Adjust the frequency

switches on all units that exhibit crosstalk. Continue this procedure until all affected

channels are corrected.

8. Troubleshooting Sequence

DSP222H_Manual_A Page 7 of 17

Apply 24 ±1 volt power to the unit. Connect a loop test box with an inductance of

approximately 115 microhenries to the loop inputs pins D and E (channel 1) and pins J

and K (channel 2) to simulate the connection of loops.

NOTE: All of the following signal measurements are referenced to logic ground.

a) Unregulated power supply.

Voltage across capacitor C16 should be 24 ±1 volt. This voltage can also be measured

at the input of regulator U3 and/or U2.

Possible component faults are diode D6 or resistor R36.

b) Regulated 12 volt power supply.

Voltage at output of U3 (across capacitors C17) should be 12 ± .2 volts. Possible

component fault is the voltage regulator U3.

c) Regulated 5 volt (logic) power supply.

Voltage at output of U2 should be 5 ± .2 volts.

Possible component fault is the voltage regulator U2.

d) Regulated 5 volt (oscillator) power supply.

Voltage at output of U4 should be 5 ± 0.2 volts.

Possible component fault is the voltage regulator U4.

e) Microcontroller clock

Waveform at pin 10 of U1 should be a sine wave at 20 MHz with a peak to peak voltage

of 1 to 2 volts. Note: This value will vary with the type of oscilloscope probe used. The

value stated here is obtained using a Tektronix scope probe with a capacitance of 20

pF.

DSP222H_Manual_A Page 8 of 17

Possible components at fault are the crystal X1 or microcontroller U1.

f) Reset input to microcontroller

Voltage at pin 1 of U1 should be 5 volts ± .2 volts. Check to insure pin C on the detector

is high--approximately 24 volts.

Possible components at fault are transistors Q9, Q10, or diode D5.

g) Loop oscillator output

Connect an oscilloscope to pin 13 (pin 12) of U1. Observe the square wave to be the

same frequency as the loop oscillator. At this point, a simulated call should be

introduced at the test box. Observe a slight frequency increase at this point.

If there is no square wave at this point a defective component in the oscillator circuit

may exist. Possible components at fault are Q1 (Q4), Q2 (Q5), Q3 (Q6), D3 (D4) or the

potcore isolation transformer T1 (T2).

h) Outputs and indicators

Verify that the opto-isolated outputs conducts only when the front-panel detect LEDs are

on.

Possible fault areas are: Transistor Q7 (Q8) or the dual opto-isolator U2 or LED2

(LED1)

DSP222H_Manual_A Page 9 of 17

9. Bill of Materials

Qty

Reference

Description

Manufacturing Part Number

2

C13, 14

22 pF 50V NPO SMD 805

Panasonic/ECU-V1H22OJCN

2

C6, 12

270 pF 50V X7R SMD 805

Kemet/C805C271M5RAC

2

C2, 8

.001uF 50V NPO SMD 805

Panasonic/ECU-V1H102JCX

10

C1,7,15,17-20,22-24

1uF 50V X7R SMD 1206

Kemet/C1206C104M5RAC

2

C3, 9

.022uF 50V PPS 1910

Panasonic/ECH-U1H223JB5

2

C4, 10

.047uF 50V PPS 1812

Panasonic/ECH-U1H473JB9

2

C5, 11

.1uF 50V PPS 1913

Panasonic/ECH-U1H104JB9

2

C25,26

.47uf X7R SMD 1206

AVX 12063C474KAT2A

2

C16, 21

220uF 35V elect SMD

Elna/RV-35V221MH10-R

1

—

–

DSP-222 alum. front panel

Diablo P/N CAS013

1

—

–

Oscillator plastic cover

Modar/JIT minibox

2

J1, 2

2 pins .025” sq. x .1” center

generic

7

D3-5, 7-10

1N914 SMD SOT-23

Motorola MMBD914LT1

1

D6

1N4004 1 amp 400V SMD SMA

Diodes, Inc S1G-13

2

Z1, 2

33V zener SMD SOD-123

Diodes, Inc MMSZ5257B

2

D1, 2

11V transorb SMD SMB

Diodes, Inc SMBJ11CA

2

LED3, 4

Right angle green LED

Bivar/H101CSGC

2

LED1, 2

Right angle red LED

Bivar/H101CSRC

2

I1,2

NE-2E neon indicator

Xenell

2

—

–

#4-3/8” Phil self-tap screw

generic

2

—

–

#4-40 5/16” screw w/ washer

generic

2

—

–

Right angle bracket

Diablo P/N HDW025

1

—

–

Handle

Diablo P/N HDW030

2

—

–

#6-3/8” Phil self-tapping screw

generic

2

U2, 4

+5V regulator SMD D2PAK

On Semi M7805CD2T

1

U3

+12V regulator SMD D2PAK

On Semi M7812CD2T

1

U5

Dual opto-coupler SMD SO-8

Fairchild MOCD223

1

U1

PIC microcontroller

Microchip PIC16F73-20/SO

1

—

–

2-channel oscillator box label

Diablo LBL032

1

—

–

Front panel label

Diablo LBL037

1

—

–

DSP-222 main PCB

Diablo PCB222

2

R1, 10

68 ohm 1/8 watt SMD 1206

generic

1

R36

10 ohm 1/2 watt SMD 1206

generic

6

R9, 18, 24, 25, 39, 40

330 ohm 1/8 watt SMD 1206

generic

2

R2, 11

510 ohm 1/2 watt SMD 1206

generic

6

R20-23, 37, 38

1K 1/8 watt SMD 1206

generic

16

R3, 5, 7, 8, 12, 14, 16, 17, 26-29, 31,

32, 34, 35

4.7K 1/8 watt SMD 1206

generic

4

R19, 30, 33, 41

12K 1/8 watt SMD 1206

generic

DSP222H_Manual_A Page 10 of 17

2

R4, 13

27K 1/8 watt SMD 1206

generic

2

R6, 15

56K 1/8 watt SMD 1206

generic

7

Q3, 6-8, 10-12

2N3904 NPN SMD SOT-23 transistor

Motorola MMBT3904LT1

5

Q1, 2, 4, 5, 9

2N3906 SMD SOT-23 transistor

Motorola MMBT3906LT1

2

S1, 2

6 position right angle DIP switch

Switronic DA06BTS

2

T1, 2

Potcore isolation transformer

Diablo P/N XFM060

1

X1

20 Mhz Xtal-parallel 20 pF HC-49UA

Fox 200-20-1

DSP222H_Manual_A Page 11 of 17

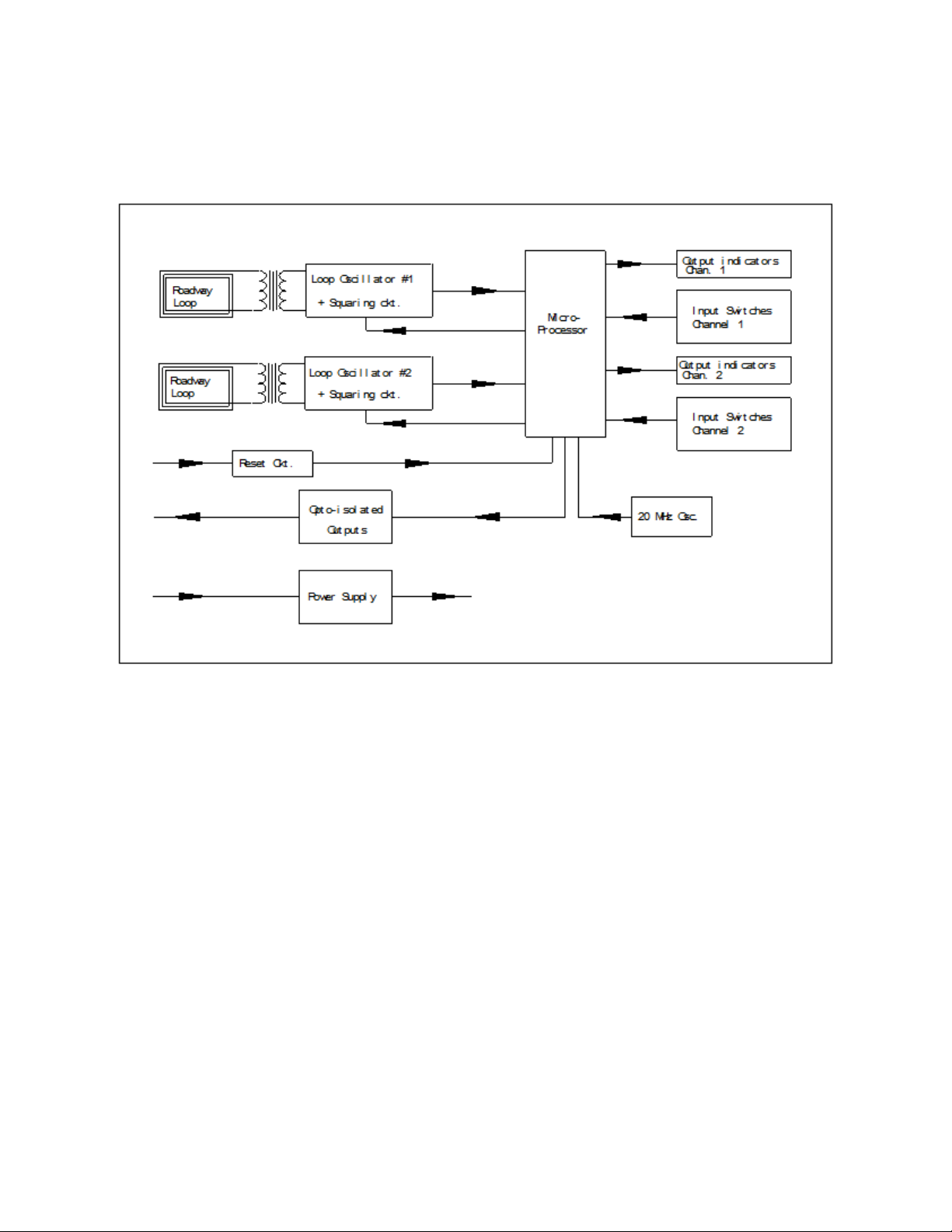

10. Block Diagram

11. Schematic (next page)

DSP222H_Manual_A Page 12 of 17

This page left intentionally blank.

Remove and insert B-size schematic.

DSP222H_Manual_A Page 13 of 17

12.Assembly Drawing

13. Specifications

Power Supply:

24 VDC ±20%, 80 ma maximum for both channels.

Loop Input:

The loop inputs incorporate lightning and transient protection devices and the loop

oscillator circuitry is transformer isolated. The lightning protection will withstand the

discharge of a 10 microfarad capacitor charged to 2,000V across the loop inputs or

between any loop input and earth ground.

DSP222H_Manual_A Page 14 of 17

Tuning:

Each channel of the DSP-222 series will automatically tune to any loop and lead-in

combination within the tuning range upon application of power or when a valid reset

signal is received. A channel can be reset by adjusting mode, sensitivity, or frequency.

Tuning Range:

50 to 750 µH with a “Q” greater than 5.

Lead-in Length:

The unit will operate with lead-in (feeder) lengths up to 2,000 feet with Caltrans types A,

B, or Q loops in all configurations as defined by California Standard Plan ES-5A & B.

Environmental Tracking:

The DSP-222 automatically and continuously compensates for environmental changes

and effects throughout the entire tuning range and operating temperature range.

Fault Monitoring:

Internal monitoring of the loop system is accomplished with the microcontroller. The

system is able to detect shorted or open loop systems, as well as a sudden change of

inductance exceeding 25 % of the nominal value. If a fault is detected on a channel, the

Fail LED will flash in a sequence related to the type of fault. The channel output will

remain in the detect (call) state. If the fault condition is removed, the detect LED and the

output will return to normal operation.

High-Intensity LED Indicators:

Each channel has a high-intensity red LED indicator to indicate the presence, or “call”

and a high-intensity green LED indicator to indicate a failure in the roadway loop

system.

DSP222H_Manual_A Page 15 of 17

Front Panel Controls:

Front panel mounted DIP switches allow the user to select sensitivity, pulse/presence

and frequency on each channel.

Operational Modes:

Pulse - 125 ms ±25 ms momentary output

Presence Time - Meets or exceeds the State of California (Caltrans) Specifications.

(Minimum presence = 10 minutes for a change of inductance of 0.06% and minimum

presence = 3 minutes for a change of inductance of 0.02%)

Note: When operating in the pulse mode, a vehicle remaining over a loop will inhibit

further pulse outputs from being issued for a period of 2 seconds after which time

vehicles passing over the loop will again be detected.

Sensitivity:

One of seven settings may be selected to optimize detection on varying loop and lead-in

configurations. Sensitivity is defined as the minimum percentage change in ∆L/L of the

total inductance (loop plus lead-in). Selecting level 0 will switch the channel off. In this

condition, the loop oscillator is de-energized, and the output will remain in the no call

state.

Sensitivity

∆

L%

Response Time (ms)

0Off Off

1.64 .5

2.32 1

3.16 2

4.08 4

5,04 8

6.02 16

7.01 32

DSP222H_Manual_A Page 16 of 17

Frequency:

One of four settings may be selected to eliminate crosstalk.

Reset Input:

The DSP-222 may be reset by applying a ground true logic level to the reset input pin C

for a period exceeding 15 microseconds.

Electrical Interconnection:

Edge Connector mates with connector types. Cinch 50-44A-30

Pins Function

A Power and logic common

B Input power (+24 volts DC)

C /Reset

D Loop 1

E Loop 1

F Output 1 (collector)

H Output 1 (emitter)

J Loop 2

K Loop 2

L Chassis ground

M N/C

N N/C

DSP222H_Manual_A Page 17 of 17

Output Ratings:

Optically Isolated Output Versions: the output transistor is rated for a maximum collector

voltage of 30 VDC. Maximum collector current is 50 mA.

Mechanical:

Dimensions 1.12 W x 4.5H x 7.0 (Excluding handle)

Environmental:

Temperature Range:

Storage: -55C to +85C

Operating: -37°C to +74°C

Humidity: 0 to 95% relative

Table of contents