Henkel Loctite EQ ACCE D Series Technical Document

EQ ACCE Robot D-Series Junc Box 24V

IDH #: 2182205

Equipment Instructions

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

1

Table of Contents

1Please Observe the Following .............................................................................................. 3

1.1.Emphasized Sections ..................................................................................................... 3

1.2.For Your Safety .............................................................................................................. 3

1.3.Unpacking and Inspection .............................................................................................. 4

1.4.Items supplied ................................................................................................................ 4

2Description ............................................................................................................................ 4

3Technical Data ...................................................................................................................... 4

4Installation ............................................................................................................................. 4

5Operation .............................................................................................................................. 5

5.1.D-Series Junction Box Internal Layout ........................................................................... 5

5.2.Installation of Cord Grips or Strain Reliefs ..................................................................... 6

5.3.Junction Box D-Sub Connections ................................................................................... 6

5.4.Input Circuits ................................................................................................................... 7

Example 1: Sourcing Input (Negative Logic) with Dry Contact Switch .................................. 7

Example 2: Sinking Input (Positive Logic) with Dry Contact Switch ...................................... 8

Example 3: Proximity Sensor Input – Sourcing (Negative Logic) / Sinking (Positive Logic) 10

5.5.Output Circuits .............................................................................................................. 1 2

Example 4: Sourcing Output (Positive Logic, PNP) ............................................................ 12

Example 5: Sinking Output (Negative Logic, NPN). ............................................................ 14

5.6.Installation of Needle Calibration Kit (1569523) ........................................................... 16

7Troubleshooting .................................................................................................................. 16

9Accessories and Related Components ............................................................................... 16

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

2

10Connector Pin Assignments ................................................................................................ 17

10.1.ROBOT SUB-D CONNECTOR ................................................................................. 17

10.2.XS1 OUT SUB-D CONNECTOR .............................................................................. 17

10.3.XS2 IN SUB-D CONNECTOR .................................................................................. 17

10.4.SOL VLV SUB-D CONNECTOR ............................................................................... 18

10.5.RBT DISP SUB-D CONNECTOR ............................................................................. 18

11Warranty .............................................................................................................................. 1 9

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

3

1 Please Observe the Following

1.1. Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice:

A notice gives recommendations for better handling of the unit during operation or

adjustment as well as for service activities.

1.2. For Your Safety

For safe and successful operation of the unit, read these instructions completely.

If the instructions are not observed, the manufacturer can assume no

responsibility.

Do not expose the connecting cable to heat, oil, or sharp edges.

Make sure the Unit stands stable and secure.

Use only original equipment replacement parts.

Do not operate the Unit outside its design. Damage to the unit and robot can

occur.

Always disconnect the power supply before servicing the unit.

Observe general safety regulations for the handling of chemicals such as

Loctite® adhesives and sealants. Observe the manufacturer’s instructions as

stated in the Safety Data Sheet.

While under warranty, the unit may be repaired only by an authorized Loctite

service representative.

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

4

1.3. Unpacking and Inspection

Carefully unpack the Loctite® EQ ACCE D-Series Junc Box 24V and examine the

items contained in the carton. Inspect the unit for any damage that might have

occurred in transit. If such damage has occurred, notify the carrier immediately.

Claims for damage must be made by the consignee to the carrier and should be

reported to the manufacturer.

1.4. Items supplied

(1) EQ ACCE D-Series Junc Box 24V

(1) D-Sub 25 pin cable – male to female

(1) D-Sub 9 pin cable – male to female

(1) Equipment Instructions for EQ ACCE D-Series Junc box 24V

2 Description

EQ ACCE D-Series Junc Box 24 V, part number 2182205 provides isolated input and

output connections between Loctite 24 Volt D-series robots and external devices such as

solenoids and sensors.

The EQ ACCE D-Series Junc Box 24V is only compatible with the Loctite 24-volt

D-Series and Loctite 24-volt RB15, RB20, & RB40 D-Series robots.

Do not connect EQ ACCE D-Series Junc Box 24V to any other Loctite Robots.

3 Technical Data

Dimensions (L x H x W): 7” x 2” x 10” [177.8 mm x 50.8 mm x 254 mm]

Total weight: 4 lbs. (1.8 Kg)

Operating Voltage:

Input 1….4: 5 … 24 VDC

Input 5.…8: 24 VDC

Output 1….8: 24 V DC/AC-peak

Output Type: solid state relay, maximum(peak) current 2.5 Amperes;

1 through 4 normally open;

5 through 8 normally open & normally closed.

4 Installation

Before using the equipment for the first time check it carefully for signs of external

damage. If any shipping damage is found DO NOT USE THE EQUIPMENT – return it

to your supplier immediately.

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

5

5 Operation

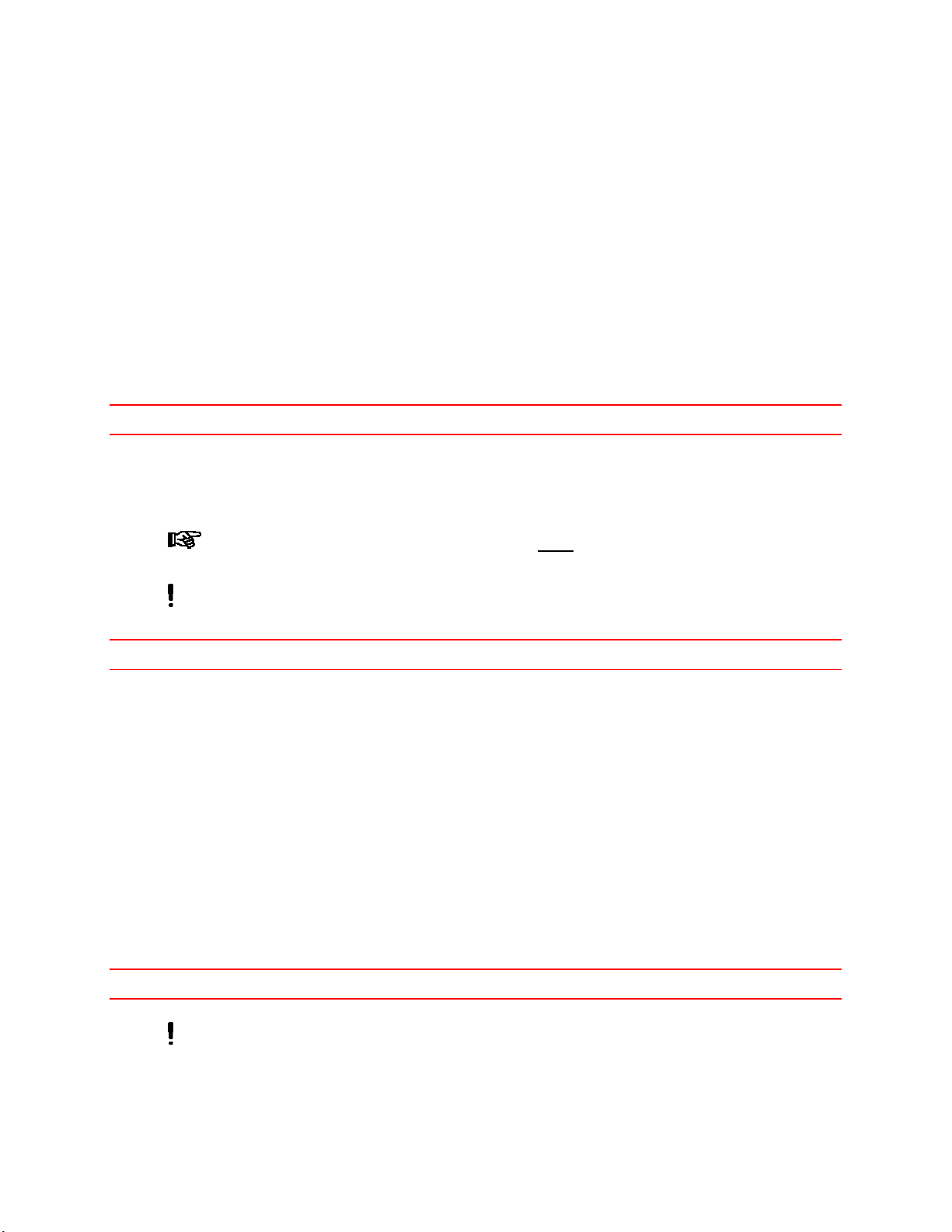

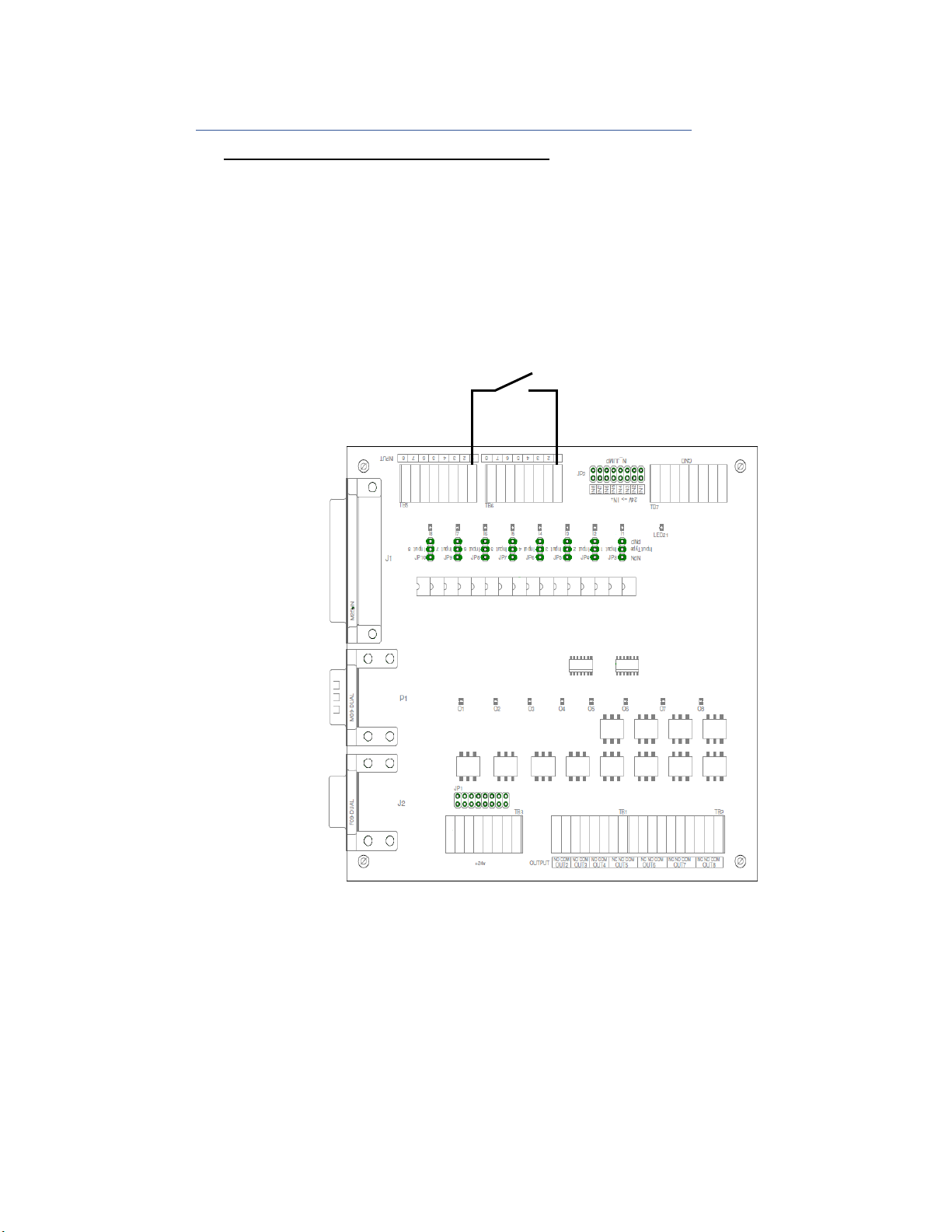

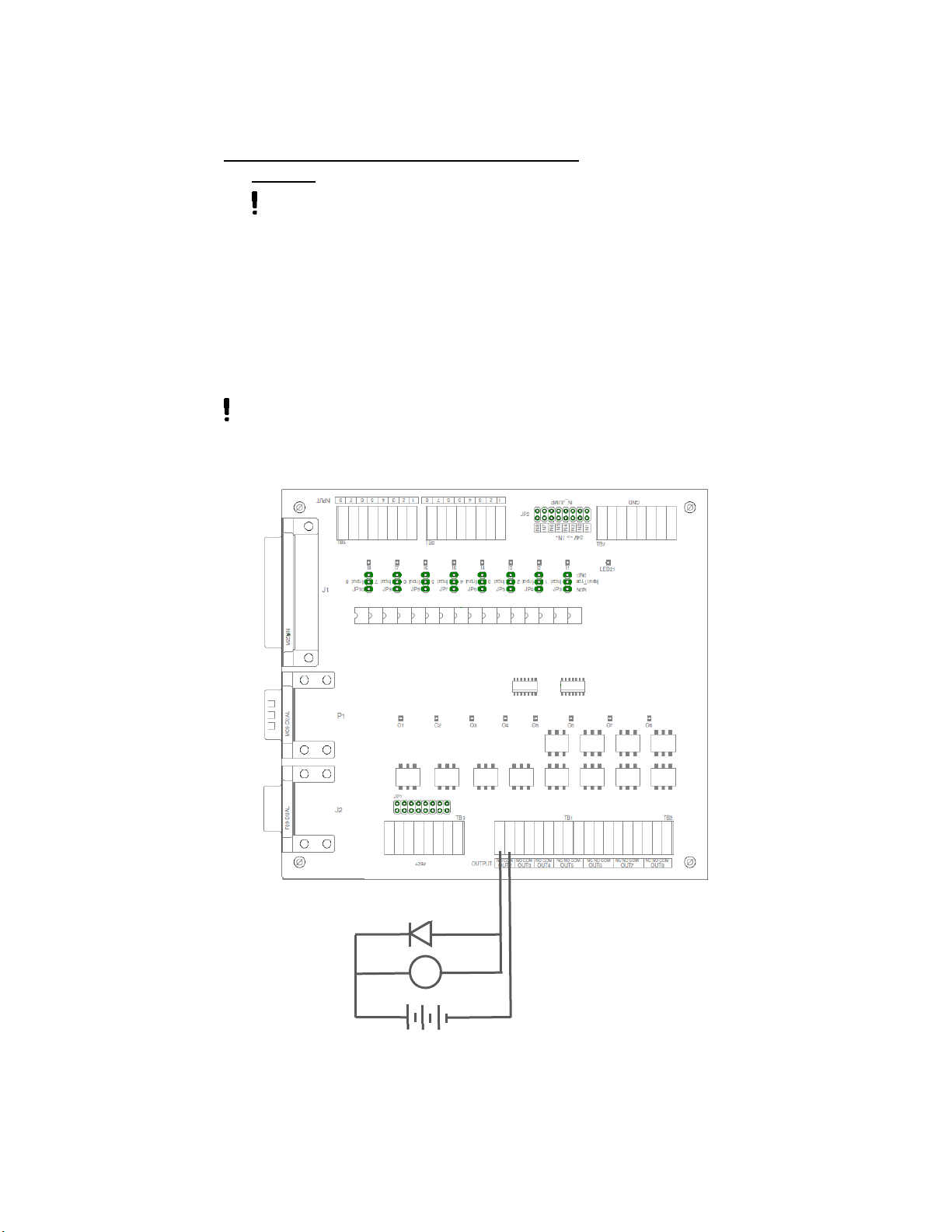

5.1. D-Series Junction Box Internal Layout

Input numbers 1 through 4 accept Vcc range +5 to +24 VDC.

When using external Vcc for any inputs, remove Jumpers from JP2 for that input

to avoid damaging the Junction box.

25-Pin I/O connector to Robot

Ground

from

Robot

Dual D-Sub 9 pin male connector

Upper for SX1 OUT for Loctite

Controllers (Output #1)

Lower for Robot Valve Solenoid

Assembly 988000

Dual D-Sub 9 pin female connector

Upper for XS2 IN (Input #7)

Lower for D-Series Robot Dispense Cable

Output LEDs -

RED

Input LEDs -

Green

Power LED -

Red

Jumpers pass

+24 V from

Robot to Input

Connector

+24 V from

Robot when

jumped.

(Input Vcc)

To Robot

Opto Input.

Jumpers Pass +24 Volts from

Robot to COM of Respective

SSR Output Solid State Relay Output

Connections

NOTE: # 1-4 SPST-NO, # 5-8 SPDT

Output 1 is accessible through D-Sub

9 pin connector on side of board.)

+24 Volts

Direct from

Robot

Input Type Jumpers

Set for NPN (Sink) or

PNP (Source).

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

6

5.2. Installation of Cord Grips or Strain Reliefs

Four capped locations are provided on the enclosure for customer supplied cord

grips.

Hole Diameter: 0.813” [20.7mm]

Number Holes: 4

5.3. Junction Box D-Sub Connections

There are 5 D-sub connectors on the Junction box for 24 Volt D-series robots.

D-SUB

Connector

pins & Type

Label on D-Series

Junction Box Connection Description

DB25-Male ROBOT I/O PORT TO 24 Volt D-Series Robot I/O Port connector

DB9-Male SOL VLV Dedicated connection for Solenoid Valve Module 24

VDC for D-Series Robot Material/IDH # 591031.

DB9-Male XS1 OUT TO Loctite Controller XS1 start input

(Robot Output #1)

DB9-Female RBT DISP Dedicated connection for D-Series

Dispenser Cable included with Robot

DB9-Female XS2 IN Robot Input # 7 typically used for

Loctite reservoir low level sensor.

ROBOT I/O PORT connection using a DB25 through cable to robot.

SOL VLV and RBT DISP dedicated for Solenoid Valve Module 24 VDC for D-Series Robot

(purchased separately) and D-Series Dispenser Cable (included with Robot).

Do not connect any other devices to these ports. Will cause damage.

XS1 OUT is robot OUTPUT#1 typically used as start signal to Loctite UV flood or CureJet

controllers. Can be used to control an external solenoid valve or relay.

there is no internal terminal block connection for robot OUTPUT #1.

XS2 IN is robot Input #7 typically used for Loctite product reservoir low level signal. Can also be

used with external switch or proximity sensor.

Do not use the internal terminal block connection for robot Input #7 when using this

D-sub connection. Will cause damage to the junction box and robot.

0.813” Diameter Holes

with covers

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

7

5.4. Input Circuits

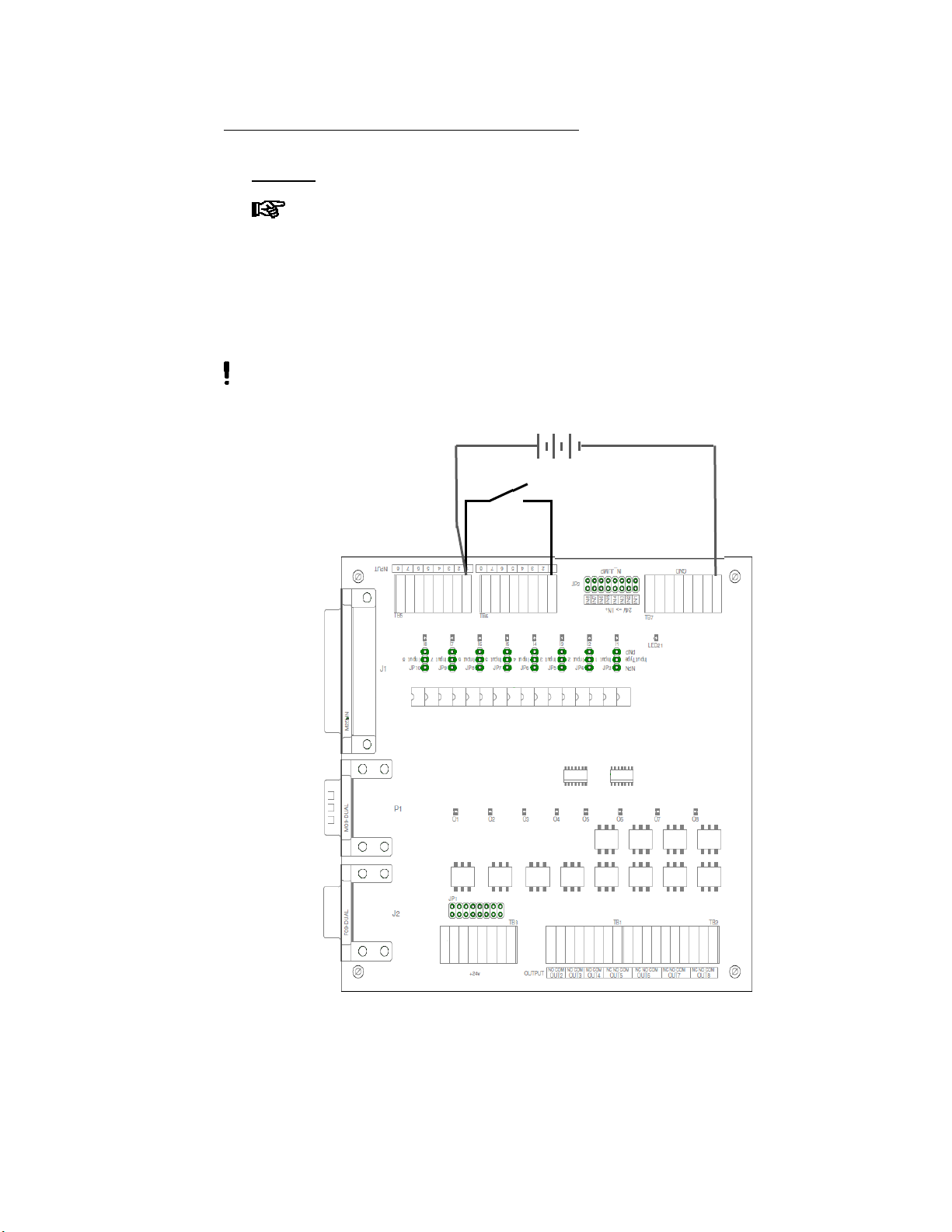

Example 1: Sourcing Input (Negative Logic) with Dry Contact Switch

Input #x type Jumper installed for NPN.

Jumper JP2-INx installed for Robot +24 VDC.

Connect one side of the external switch to TB6-x

Connect other side of the external switch to ground (TB7 “GND”).

Where x equals the input number (1 through 8).

Best to use robot internal 24 VDC for a dry contact switch. If an external

voltage source is needed, Remove the JP2-INx Jumper. Connect power

supply +24 VDC (+5…+24 VDC for inputs 1 through 4) to TB5-x. Connect

power supply 0 VDC to TB7-GND.

Do not use connect an external power supply on an input with jumper JP2-

INx installed.

Ground connection

(Use any position)

25-Pin I/O

connector to

Robot

External Switch

Connection to Robot Input # 1

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

8

Example 2: Sinking Input (Positive Logic) with Dry Contact Switch

USING ROBOT 24 VDC POWER SUPPLY

Input #x type Jumper installed for PNP.

Jumper JP2-INx installed for Robot +24 VDC.

Connect one side of the external switch to TB6-x

Connect other side of the external switch to TB5- x

Where x equals the input number (1 through 8).

JP2-IN1 Jumper

in place for Robot 24V

25-Pin I/O

connector to

Robot

External Switch

Connection to Robot Input # 1

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

9

USING EXTERNAL 24 VDC POWER SUPPLY

Input #x type Jumper installed for PNP.

Remove Jumper JP2-INx for External +24 VDC.

Inputs 1 through 4 accept 5…24 VDC. Inputs 5 through 8 are 24 VDC.

Connect one side of the external switch to TB6-x

Connect other side of the external switch to TB5- x

Connect power supply 0 VDC to Ground (TB7 “GND”)

Connect power supply +24 VDC TB5-x

Where x equals the input number (1 through 8).

Do not use connect an external power supply on an input with jumper

JP2-INx installed.

Remove JP2-IN1

Jumper for external 24V

25-Pin I/O

connector to

Robot

External Switch

Connection to Robot Input # 1

External 24 VDC

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

10

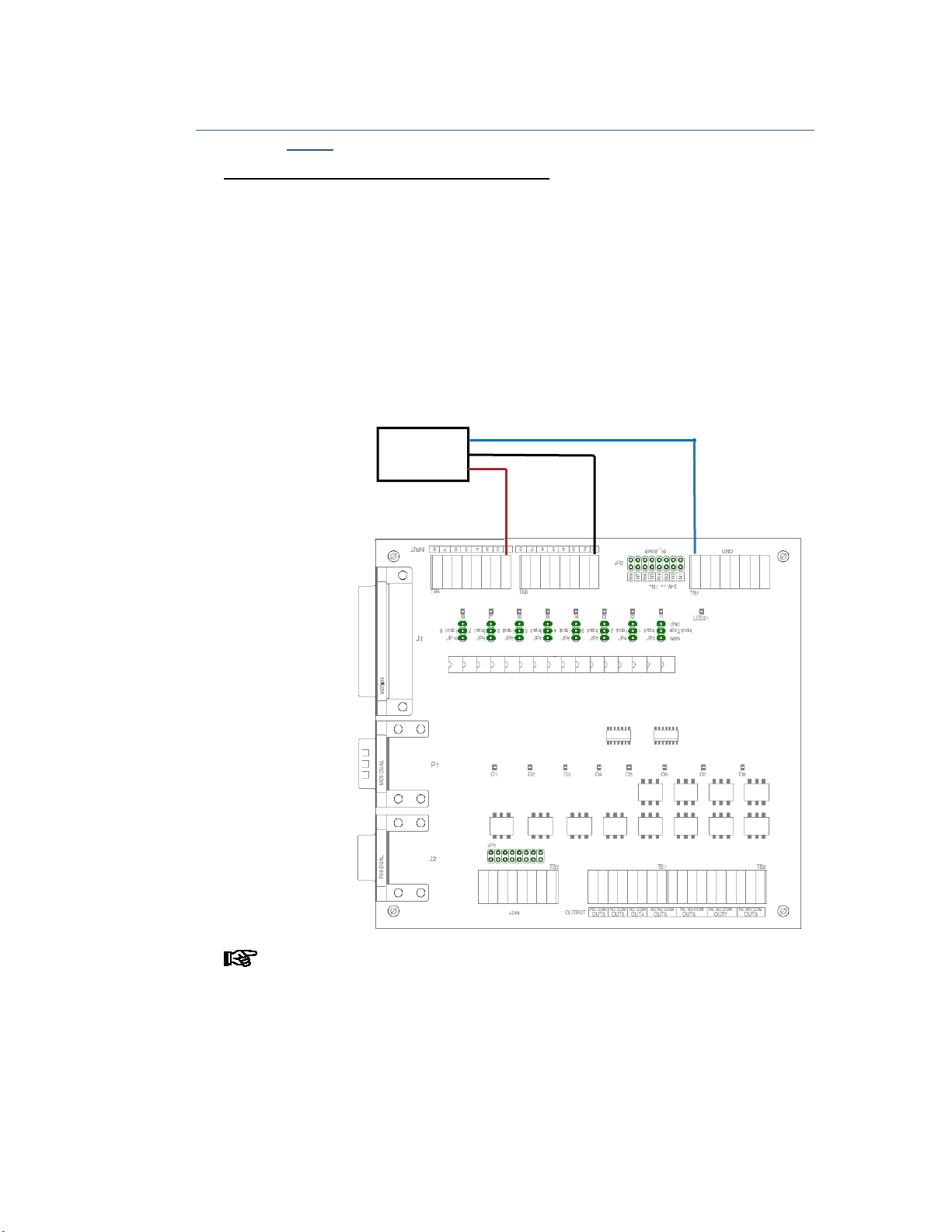

Example 3: Proximity Sensor Input – Sourcing (Negative Logic) / Sinking (Positive

Logic)

USING ROBOT 24 VDC POWER SUPPLY

Input #x type Jumper installed for PNP or NPN based on proximity sensor

type.

Jumper JP2-INx installed for Robot +24 VDC.

Place a Jumper across JP2 pins at “IN1” – Input 1 Internal Robot Voltage

Proximity Sensor (3-wire):

o Connect brown wire (+V) to TB5-x.

o Connect blue wire (0V) to TB7 “GND.

o Connect black wire (signal) to TB6-x.

Where x equals the input number (1 through 8).

If the robot input does not register the state change and junction box input

LED is registering the state change of the proximity sensor; Change jumper

for input type to the other position.

25-Pin I/O connector to Robot

Ground connection

(Use any position)

Proximit

y

Switch

Connection

to Robot

Input # 1

Connect +V to TB5-1 with

j

umper on JP2-“IN1” pins

for robot 24 VDC.

+24 Volts from Robot

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

11

USING EXTERNAL 24 VDC POWER SUPPLY

Input #x type Jumper installed for PNP or NPN based on proximity sensor

type.

Remove Jumper JP2-INx for External +24 VDC.

Inputs 1 through 4 accept 5…24 VDC. Inputs 5 through 8 are 24 VDC.

Proximity Sensor (3-wire):

o Connect brown wire (+V) to TB5-x.

o Connect blue wire (0V) to TB7 “GND.

o Connect black wire (signal) to TB6-x.

Connect power supply 0 VDC to Ground (TB7 “GND”)

Connect power supply +24 VDC TB5-x

Where x equals the input number (1 through 8).

Do not use connect an external power supply on an input with jumper

JP2-INx installed.

If the robot input does not register the state change and junction box input

LED is registering the state change of the proximity sensor; Change jumper

for input type to the other position.

25-Pin I/O connector to Robot

Ground connection

(Use any position)

Proximit

y

Switch

Connection

to Robot

Input # 1

Connect +V to

TB5-1 with NO

j

umper on

JP2-“IN1” pins

for external

DC voltage.

Volts DC from

External Supply

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

12

5.5. Output Circuits

Example 4: Sourcing Output (Positive Logic, PNP)

USING ROBOT 24 VDC POWER SUPPLY

Jumper JP1-x installed - robot +24 Volts at output x common terminal.

Connect solenoid control valve coil (+) to OUTx

Connect solenoid control valve coil (-) to ground (TB7 “GND”).

Where x equals the input number (1 through 8).

Suppression Diode is required for all coils or Inductive loads. Make sure that

these devices suppression diode. If the device does not have suppression diode,

an external suppression diode needs to be added.

Turn Robot Output 2 on

to energize solenoid.

Solid State Rela

y

Connections

Ground connection

(Use any position)

25-Pin I/O

connector

to Robot

+24 V

o

l

ts

fr

o

m R

obot

24 Volt DC Solenoid

Do Not Exceed Robot

Output Current Limit of

250 mA (total Current,

taking inrush into

account)

Diode

(

mandator

y)

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

13

USING EXTERNAL 24 VDC POWER SUPPLY

Remove Jumper JP1-x – External power at output x common terminal.

Do not use connect an external power supply with jumper JP1-x

installed.

Connect solenoid control valve coil (+) to external power supply +V.

Connect solenoid control valve coil (-) to OUTx-NO

Connect external power supply 0V to OUTx-COM

Where x equals the input number (1 through 8).

Suppression Diode is required for all coils or Inductive loads. Make sure that

these devices suppression diode. If the device does not have suppression diode,

an external suppression diode needs to be added.

Turn Robot Output 2 on

to energize solenoid.

Solid State Rela

y

Connections

25-Pin I/O

connector

to Robot

24 Volt DC Solenoid

Do Not Exceed Output Current Limit of

External Supply or Solid State Relay Rating.

Diode

(

mandator

y)

24 Volt DC External Power Supply

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

14

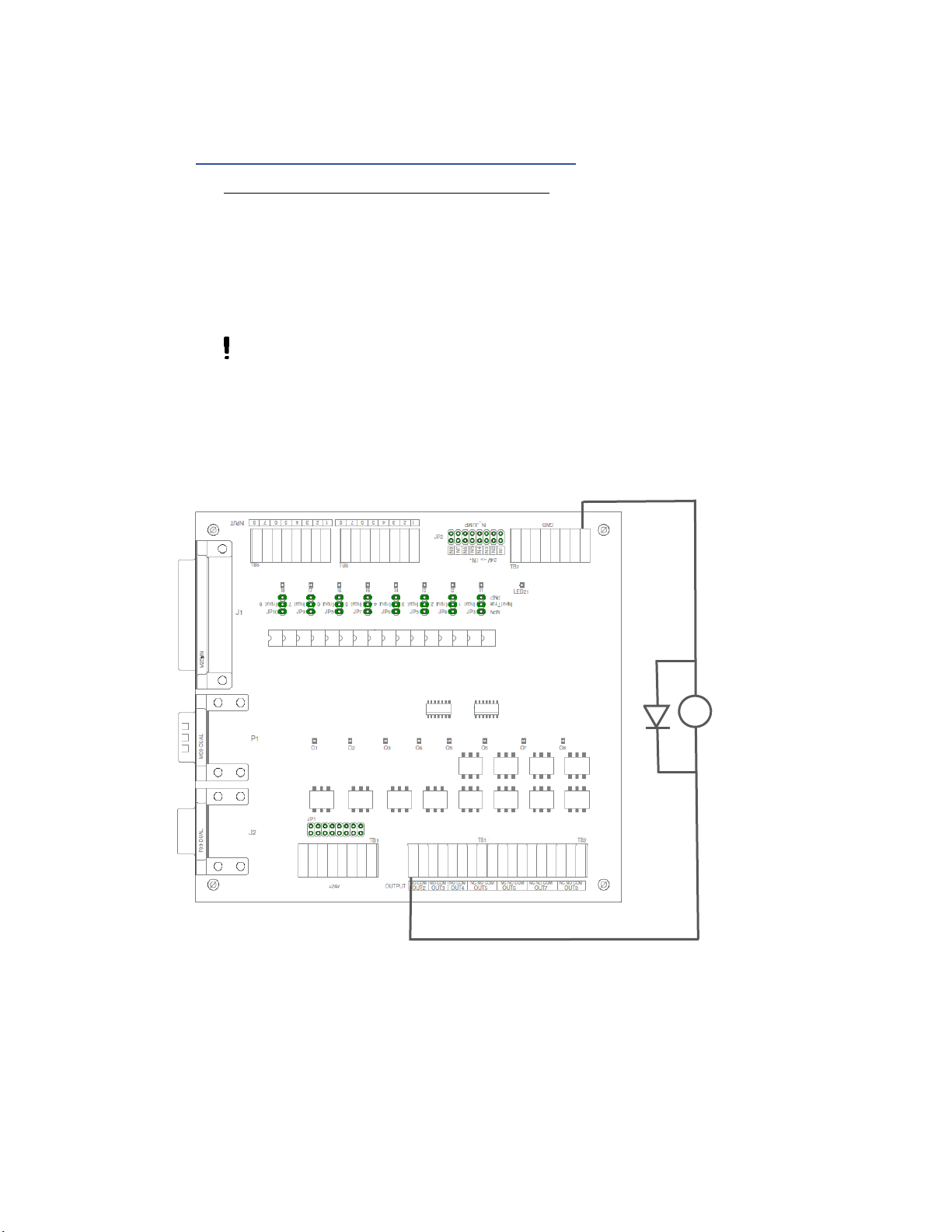

Example 5: Sinking Output (Negative Logic, NPN).

USING ROBOT 24 VDC POWER SUPPLY

Remove JP1-x installed - robot +24 Volts at output x common terminal.

Connect OUTx-COM to ground (TB7 “GND”).

Do not use connect an external power supply or connect to Ground

with jumper JP1-x installed.

Connect solenoid control valve coil (+) to TB3 robot +24VDC

Connect solenoid control valve coil (-) to OUTx-NO.

Suppression Diode is required for all coils or Inductive loads. Make sure that

these devices suppression diode. If the device does not have suppression diode,

an external suppression diode needs to be added.

Turn Robot Output 2 on

to energize solenoid.

Solid State Rela

y

Connections

Ground connection

(Use any position)

25-Pin I/O

connector

to Robot

+24 Volts from Robot

Diode

(

mandator

y)

24 Volt DC Solenoid

Do Not Exceed Robot

Output Current Limit of

250 mA (total Current,

taking inrush into

account)

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

15

USING EXTERNAL 24 VDC POWER SUPPLY

Remove Jumper JP1-x – External power at output x common terminal.

Do not use connect an external power supply with jumper JP1-x

installed.

Connect solenoid control valve coil (+) to external power supply +V.

Connect solenoid control valve coil (-) to OUTx-NO

Connect external power supply 0V to OUTx-COM

Where x equals the input number (1 through 8).

Suppression Diode is required for all coils or Inductive loads. Make sure that

these devices suppression diode. If the device does not have suppression diode,

an external suppression diode needs to be added.

Turn Robot Output 2 on

to energize solenoid.

Solid State Rela

y

Connections

25-Pin I/O

connector

to Robot

24 Volt DC Solenoid

Do Not Exceed Output Current Limit of

External Supply or Solid State Relay Rating.

Diode

(

mandator

y)

24 Volt DC External Power Supply

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

16

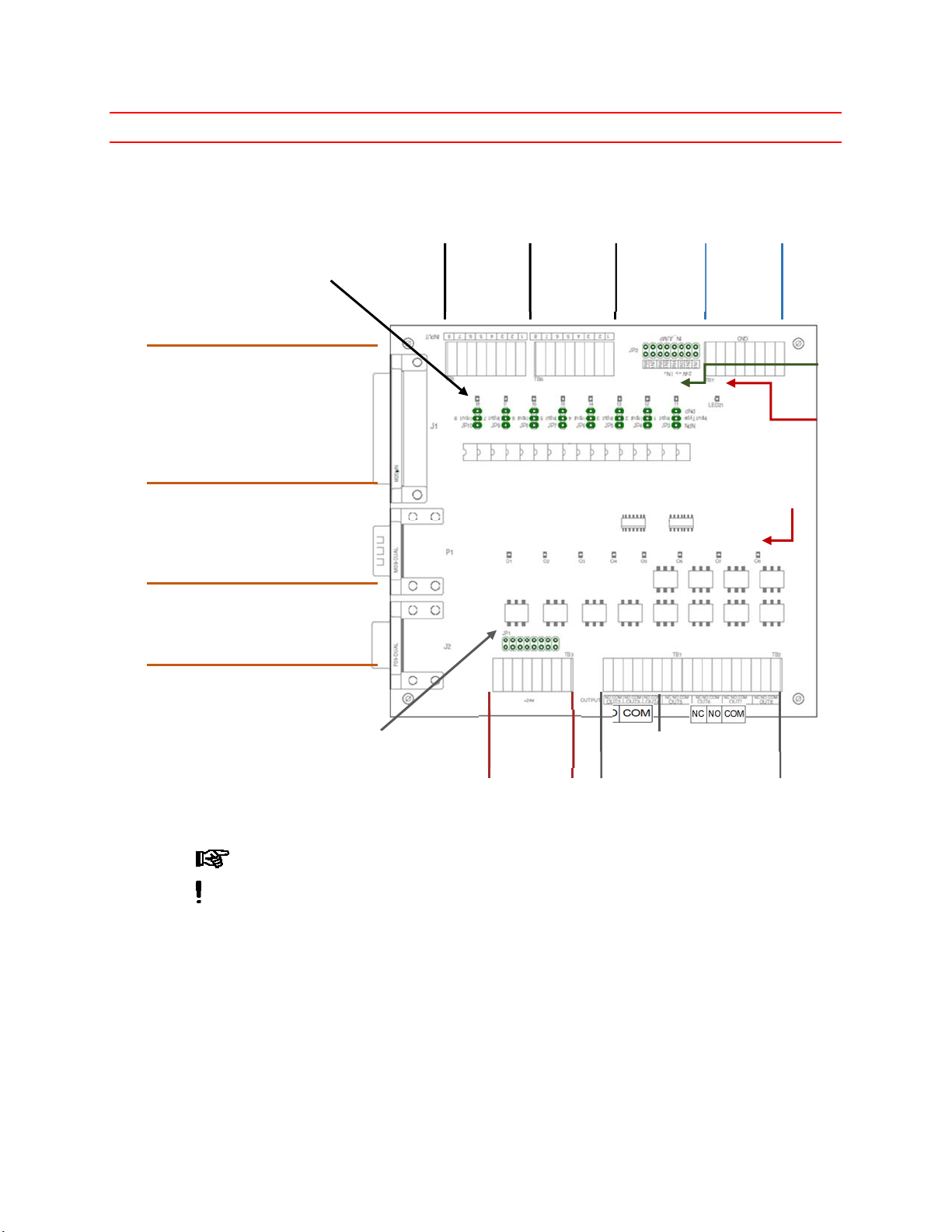

5.6. Installation of Needle Calibration Kit (1569523)

When adding the Needle Calibration Kit to a D-Series Robot with the

EQ ACCE D-Series Junc Box 24V, the Needle Calibration Kit needs to

be wired through the junction box.

Steps for wiring the Needle Calibration Kit to the EQ ACCE D-Series Junc Box 24V:

Remove the 25-Pin D-Sub Plug from the cable assembly.

The outer cable jacket is stripped back to expose 7” [178 mm] of the internal

wires.

Label wires based on D-Sub pin position (see 1

st

table below).

Add strain relief to junction box with appropriate sized cord grip.

Connect wires to the appropriate Junction Box Terminal Blocks (1

st

table)

Set Junction Box Jumpers as indicated on second table below.

25 Pin Connector Wire Junction Box – Terminal Block

Pin # Description Color Designation Description

25 24 VDC Red TB3 +24 VDC

1 X Signal Yellow TB6-1 IN1

13 GND Black TB7 GND

2 Y/Z Signal White TB6-2 IN2

Junction Box Jumper Settings for Needle Calibration

Designation Setting Description

JP2-IN1 Installed Internal +24 VDC

JP2-IN2 Installed Internal +24 VDC

JP3 NPN Sourcing Input (Negative Logic)

JP4 NPN Sourcing Input (Negative Logic)

7 Troubleshooting

Before proceeding with any repair or maintenance operation turn off and disconnect the

main electricity supply to the system.

9 Accessories and Related Components

Loctite Part No. Description

89XXXX Cable, Male to Female, D-Sub 25 pin

989432 Cable, Male to Female, D-Sub 9 pin

591031 Solenoid Valve Module 24 VDC for D-Series Robot

1569523 Needle Calibration Kit

25-Pin

D-Sub

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

17

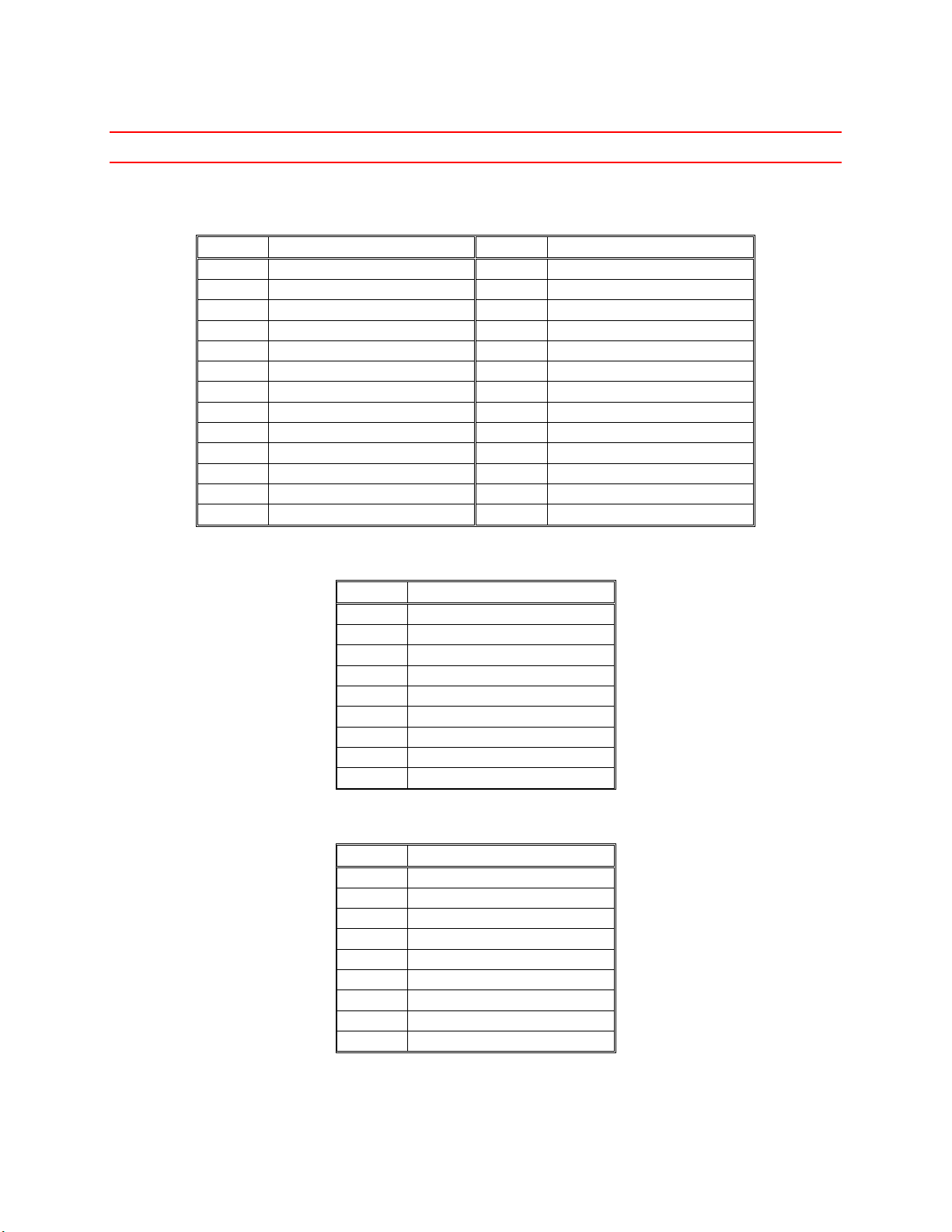

10 Connector Pin Assignments

10.1. ROBOT SUB-D CONNECTOR

Pin # Description Pin # Description

1 IN # 1 (X Signal) 14 OUTPUT # 1 (Disp Start)

2 IN # 2 (Y/Z Signal) 15 OUTPUT # 2

3 IN # 3 16 OUTPUT # 3

4 IN # 4 (Disp Ready) 17 OUTPUT # 4

5 IN # 5 18 OUTPUT # 5

6 IN # 6 19 OUTPUT # 6

7 IN # 7 (Low Level) 20 OUTPUT # 7

8 IN # 8 21 OUTPUT # 8

9 NC 22 NC

10 NC 23 NC

11 COM GND 24 +24V

12 COM GND 25 +24V

13 COM GND

10.2. XS1 OUT SUB-D CONNECTOR

Pin # Description

1 OUT1-NO

2 No Connection

3 No Connection

4 No Connection

5 Jumper to Pin # 8

6 No Connection

7 No Connection

8 Jumper to Pin # 5

9 OUT1-COM

10.3. XS2 IN SUB-D CONNECTOR

Pin # Description

1 IN7

2 No Connection

3 No Connection

4 No Connection

5 Robot 0 VDC

6 No Connection

7 No Connection

8 No Connection

9 Robot +24 VDC

EQ ACCE Robot D-Series Junc Box 24V IDH #: 2182205

Equipment Instructions

18

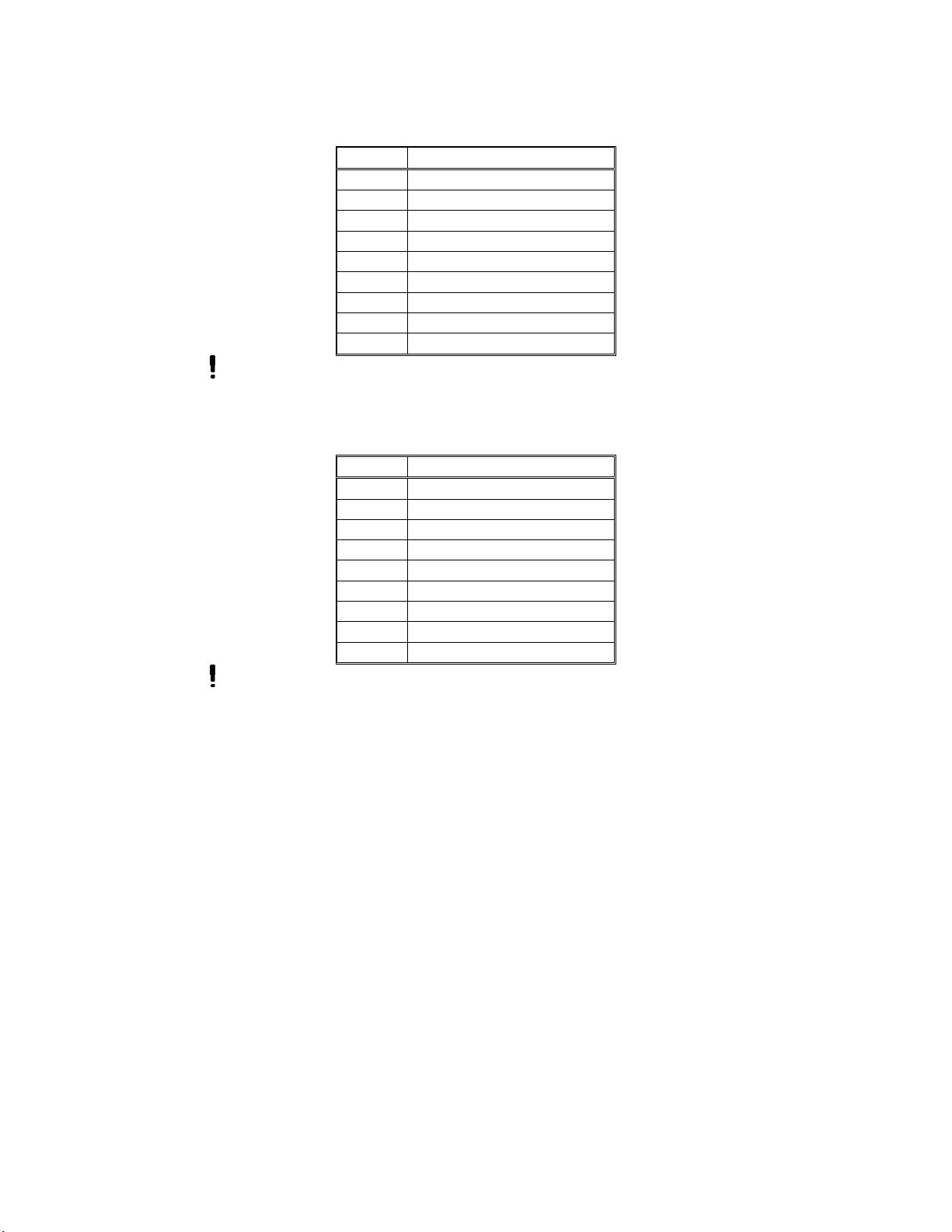

10.4. SOL VLV SUB-D CONNECTOR

Pin # Description

1 No Connection

2 No Connection

3 Robot 0 VDC

4 No Connection

5 No Connection

6 Robot 0 VDC

7 No Connection

8 No Connection

9 to RBT DISP Pin # 1

Do not use this connector with any other devices. This connection is only reserved

for the Solenoid Valve Module 24 VDC for D-Series Robot, Material/IDH # 591031.

10.5. RBT DISP SUB-D CONNECTOR

Pin # Description

1 to SOL VLV Pin # 1

2 No Connection

3 No Connection

4 No Connection

5 No Connection

6 No Connection

7 No Connection

8 No Connection

9 Robot +24 VDC

Do not use this connector with any other devices. This connection is only reserved for the

for D-Series Dispenser Cable (included with Robot).

This manual suits for next models

1

Table of contents

Other Henkel Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

PCB Piezotronics

PCB Piezotronics TORKDISC 5309D-01A Installation and operating manual

LNS

LNS QL Servo 80 S2 Service manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN SKM 470S user manual

Alfalaval

Alfalaval IsoMix External Drive instruction manual

GSI Group

GSI Group SCR Series instruction manual

GAPOSA

GAPOSA P200 Series Reference manual