groove.

If the jaws appear to be coming out of the ball groove, release hydraulic pressure and re-tighten the

T-Handle by hand. This may be necessary when the puller is new to get the jaws to properly seat in

the cage.

5. Turn the T-handle clockwise to tighten the jaws firmly onto the component.

6. Makesurethatthepullerissquarewiththecomponenttobepulled.Advancetheplungeruntil

therampointcontactstheshafttoensurecorrectalignment.(Ifnecessary,refertothepump’s

instruction sheet.) The center of the ram point should be aligned with the center of the shaft.

Continue to advance the plunger slowly to pull the component off of the shaft. Do not re-tighten the

T-handleduringthepullingoperation.Neverexceedthemaximumtorqueratingofthepullers.

Maintenance

Alwayscleanthepullerafteruseandstoreinaclean,dryplace.

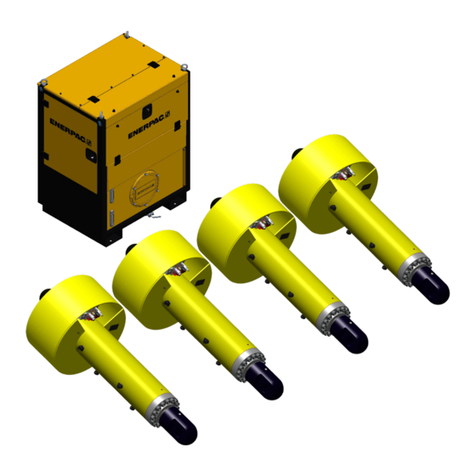

100-Ton Hydraulic Puller

WARNING

Do NOT stand on, under, or near puller while in use. Keep hands, feet and clothing

away from moving parts.

WARNING

When transporting puller, always place the puller in its lowest position and

remove ram extenders.

1. Make sure that all items being pulled are supported by a means other than the puller. Do not use the

puller for lifting or supporting objects.

2. Alignthepullertotheshafttoensureastraightpull.(Thepuller’sliftcartcanraisethepullerupto5

feet. For distances beyond 5 feet, the puller can be removed from the cart. See Removing Puller

from Lift Cart.)

Toraisethepuller,placethecylindercontrolvalveinthe“HoistOilSupply”position,openthepuller

hoistverticalcontrolvalve,andraisethepullerbyplacingtheremotejogswitchinthe“On”position.

When puller has reached the desired height, release the remote jog switch and close the vertical

control valve.

Tolowerthepuller,placethecylindercontrolvalveinthe“HoistLower”position,turnthehoist

vertical control valve counterclockwise, and close the hoist vertical control valve after the puller has

reached its desired height.

Note

The restrictor valve, located at the top of the hoist cylinder, is used to control the rate of puller

descent. This valve should be set at the desired rate and locked in place using the nut on the valve

shaft.(AnappropriatestartingpointisonefullturnfromtheclosedpositionThisrestrictorvalveis

only a one-way restrictor valve; it does not affect the rate at which the puller is raised.)

WARNING

Always keep the puller hoist vertical control valve closed when not adjusting the

vertical position.

(5)