2 — Warnings and Cauons

to large cubic airow requirements, exhaust temperature, and

velocity. Do not point exhaust at any nearby surface or object

that may be adversely aected by high temperature. is in-

cludes but is not limited to painted surfaces, tar paper and

asphalt roofs, water sprinkler heads, re alarms, and volatile

material.

• Do not use in conned spaces. e load bank may have to

compete with cooling air requirements of a nearby running

engine generator set where cooling air intake to a conned

space may not be adequate for both engine and load bank.

Be especially careful not to bounce hot exhaust air o nearby

obstructions for re-circulation through the load bank.

• Verify that all control switch positions are set correctly for

your intended usage before connecting the load bank to the

source to be tested.

• e load cables carry high amperage. Be constantly aware of

possibility of inductively heating adjacent ferrous objects to

temperatures sucient to damage cable insulation.

• Always connect the safety ground cable to a proper ground.

Do not rely on a possible grounded neutral somewhere else

in the system.

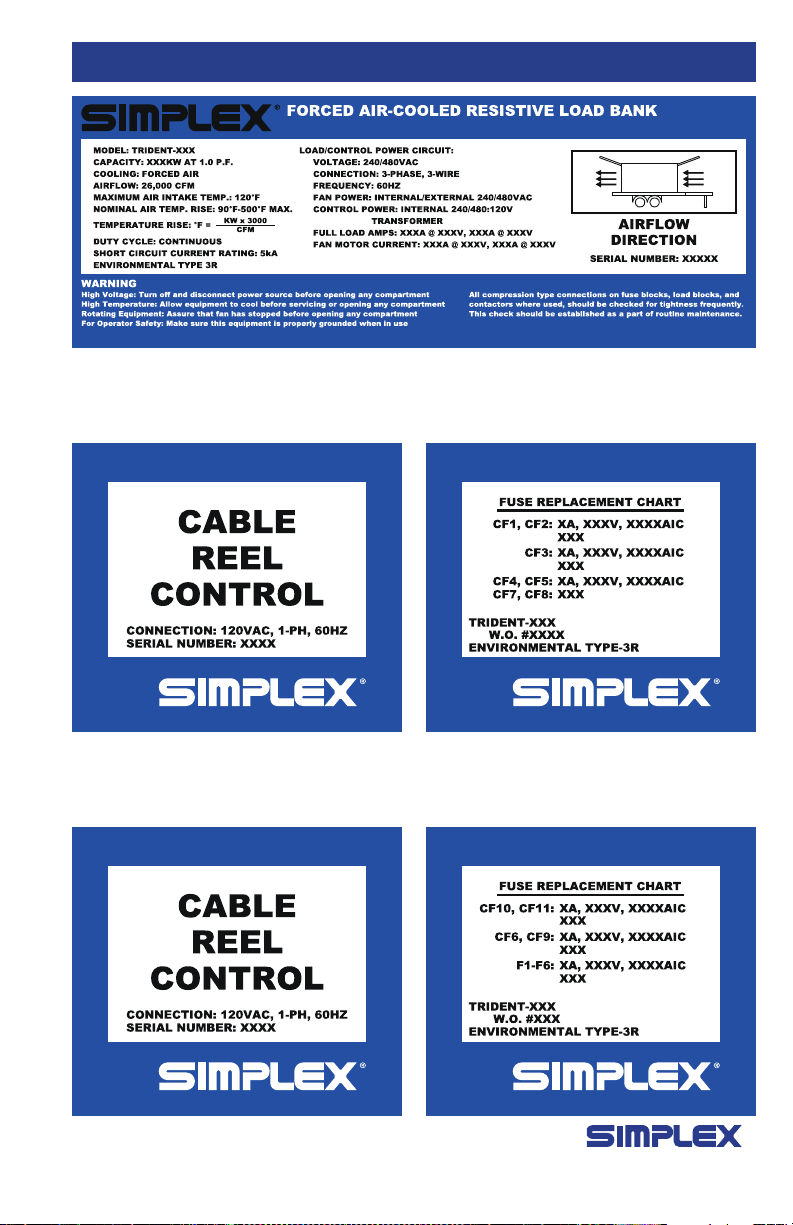

• Routinely inspect all components and electrical connections

for tightness and integrity.

• Repair any damaged or degraded components and wiring

without delay.

• If technical assistance, service, or parts are needed, please call

800-837-8603 (24 Hours).

• All hardware covered by this manual have dangerous elec-

trical voltages and can cause fatal electrical shock. Avoid

contact with bare wires, terminals, connections, etc. Ensure

all appropriate covers, guards, grounds, and barriers are in

place before operating the equipment. If work must be done

around an operating unit, stand on an insulated dry surface

to reduce the risk of electrocution.

• Do not handle any kind of electrical device while standing

in water, while barefoot, or while your hands or feet are wet.

• If people must stand on metal or concrete while installing,

servicing, adjusting, or repairing this equipment, place insu-

lative mats over a dry wooden platform. Work on the equip-

ment only while standing on such insulative mats.

• e National Electrical Code (NEC), Article 250 requires the

frame to be connected to an approved earth ground and/or

grounding rods. is grounding will help prevent dangerous

electrical shock that might be caused by a ground fault condi-

tion or by static electricity. Never disconnect the ground wire