Diamatic ULTRA BMG-780 RS User manual

www.diamaticusa.com

3

Table of contents

Maintenance log 2

1.

Introduction 4

2.

Machine description 4

Control keypad 6

3. Safety

7

3.1

Work area safety

7

3.2

Electrical safety

7

3.3

Personal safety

8

3.4

Machine safety

8

3.5

Maintenance safety

9

3.6

Dust collector safety

9

3.7

Grinding safety

9

3.8

Battery safety

10

3.9

Transport safety

10

3.10

Signs on the machine

11

4. Accessories

5. Initial

operation

12

5.1

Checkpoints of electrical safety

12

5.2

Checkpoints of machine safety

12

5.3

Battery drive system (option)

13

Remote controlled driving

14

AUTO DRIVE-mode

14

5.4

Manual moving of the machine

15

Diamag

16

5.5

Adjustable weights

16

5.6

Changing the wings

17

5.7

Before start-up

19

6. Operating 20

6.1 Switching the machine on 20

6.2 Turning the machine off 20

6.3 Working with the remote control 21

6.4 Operating during grinding 23

6.5 Wet grinding 24

7. Maintenance 25

7.1 Buffers 27

7.2 Control keypad 28

7.3 Remote control maintenance 31

8. Troubleshooting 31

9. Technical data 33

10. Warranty 34

4

www.diamaticusa.com

1. Introduction

Before use, operators must be provided with information, instruction and training for the use of the machine

and the substances for which it is to be used, including the safe method of removal and disposal of the

material collected. All persons who are working with or maintaining this machine must read the manual

carefully and understand it fully. In case you sell the unit, hand it on to the next owner.

Keep this manual always with the machine, to enable it to be referred to at any time.

Any other work not covered by this operating manual must not be carried out.

This machine is designed for industrial use by professionals. Only authorized and trained personnel may

operate this machine. This machine is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge. Diamatic offers a course on

the use of the machine in order to make the operating and maintenance personnel familiar with all elements

of the machine. Always use common sense when working with machines.

2. Machine description

The BMG-780 RS is an electrical driven planetary grinding machine. This is a three headed machine for

leveling and polishing of indoor floors. The 3 planetary rotating discs are Ø 240 mm. It can be used for dry

and wet applications. The BMG-780 RS can be used on almost any floor to plane, to make ready for coatings,

or to remove coatings or glue residues. The machine may not be used without an adequate dust extraction

system. A specially designed Diamatic dust collection system ensures dust-free operation of the machine and

clean air at the workspace. This machine may not be used on wood.

Due to the drive motors and the wireless Bluetooth control unit this machine is very effective and ergonomic

to operate. The 24V battery drive system enables the operator to drive the machine to the work area without

the use of the power supply cable. This feature will save precious time and contributes to the ease of use.

www.diamaticusa.com

5

1

Operating panel

12

Lower drive

2

Steer handle

13

Upper drive

3

Swing arm for dust hose

14

Grinding buffer

4

Electric control box

15

Floating shroud

5

Weight set

16

Brush for shroud

6

Tilting support

17

Dust cover

7

Drive wheel

18

Front support grinders

8

Drive wheel motor

19

Pin

9

Grinding head motor

20

Front support wheel

10

Protection cap

21

Wheel

11

Frame mounting eyes

22

Adjustable front wheel

BMG-780 RS

6

www.diamaticusa.com

23

24

25

26

8

Control keypad

27

1

28

29

6

30

31.

Main voltage

32.

Amp of motor

33.

Disc speed

34.

Down Speed

35.

Up Speed

36.

Down / Up Speed

(by scrolling)

37.

Start grinding

40.

RDY = Ready

38.

Change turning

direction of discs

39.

Stop grinding

STO = EM-Stop activated

23

Key + Battery power indicator /

Hour counter

24

Fixing knob for ergonomic steer

25

Main power switch ON/OFF

26

Dusthose attachment

8

Drive wheel motor

27

Emergency stop button

1

Control keypad

28

Lever for adjusting steering

handle

29

Key + cord for dead mans switch

6

Tilting support

30

Integrated floor nozzle on

floating shroud

31

Main voltage indication

32

Ampere of grindmotor

33

Speed of the grinding discs

34

Grinding speed DOWN button

35

Grinding speed UP button

36

Down / Up grinding speed (by

scrolling)

37

Start grinding button

38

Change the turning direction of

grinding discs button

39

Stop grinding button

40

RDY = Ready

STO = EM-Stop activated

www.diamaticusa.com

7

Warning!

3. General Safety Rules

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire, explosions and / or serious

injuries.

Only authorized and trained personnel may operate this machine. This machine is not intended for use by

persons (including children) with reduced physical, sensory or mental capabilities, or lack of experience and

knowledge.

It is the responsibility of the user to analyse the surface to be treated. The surface may not contain any

substances which could pose a fire-, explosion- or health risk when treated. The user should make a risk

assessment on the basis of the information obtained about the surface to be treated and take proper

precautions for the work to be performed.

In case of any inappropriate usage, improper operation or repair, the producer shall be exempt from liability.

3.1

Work area safety

a) Do not use the machine in rain, damp or wet locations.

b) Avoid dangerous environments: do not work in the presence of explosive atmospheres, in the presence of

flammable liquids, gases or dust. Remove materials or debris that may be ignited by sparks.

c) In some cases sparks could be created by grinding.

d) The surface to be treated must be clean, make sure to remove all stones, screws etc..

Any stones, screws, bolts, pieces of wire etc. could cause serious damage if it gets inside the machine!

e) Make sure there is enough ambient light on the work area. Cluttered or dark areas invite accidents.

f) Do not use on wood.

g) Keep children and bystanders away while operating the machine. They are likely not to foresee the

potential dangers of the machine. Distractions could cause you to lose control of the machine.

h) Persons who are not operating the machine must not be permitted to stay in the surrounding area ofat

least 5 meter from the machine.

i) Never use the machine when the surface is not clear and if there is a risk of stumbling or tripping.

j) Make sure that there are no cables or hoses in the driving direction of the machine.

k) Make sure that there is nothing standing or situated on the surface to be treated.

l) Make sure the machine can travel over all inequalities on the surface, small inequalities like weld seams

or floor joints are no barriers for the machine.

m) Never stay in the rain with the machine.

n) Check if there are any obstacles that can snag the cables when the machine is moving.

o) Remove reinforcing steel or other objects protruding from the surface in order to prevent damage to the

machine.

p) Warning!

Make sure that the surface to be treated does not contain dangerous materials such as:

-combustible or explosive dusts or substances.

-carcinogenic or pathogenic substances.

q) Secure the work area around the machine in public areas providing an adequate safety distance from the

machine. Use a red and white safety chain and danger sign to enclose the work area.

3.2

Electrical safety

a) Use only extension cables for extending the main cable that are sized and marked in accordance with the

overall power consumption of the machine. Do not use damaged extension cables.

b) Make sure that the phases and the earth wire of the extension cable(s) are connected in the same order

as the supply cable of the machine and the power supply.

c) Electrical cables must be rolled entirely off of the reels.

d) Any damage to the electric cables and/or electrical components is not permitted.

e) The voltage on the identification plate must comply with the power supply.

f) Use an electrical power supply connection with earth connection and earth leakage circuit breaker.

g) The circuit breaker of the power supply must have a ‘’D’’ characteristic. Circuit breakers with a “C” or “B”

characteristic can give problems when switching the motor on.

h) Keep the machine original; The machine is always equipped with an earthed connection, do

not change this and always use earthed cables with an earthed plug.

i) Inspect and test the electrical components regularly. The electrical components have to satisfy with the

requirements set out in the harmonised norm EN60204-1.

8

www.diamaticusa.com

j) Always call a skilled electrician or your distributor when you have questions about the safety of the

electrical components.

k) Work on electrical equipment or operating materials may only be undertaken by a skilled electrician or by

trained persons under the guidance and supervision of a skilled electrician as well as in accordance with

the electrical engineering regulations.

l) Always use tools that are insulated against voltages.

m) Do not abuse the cables. Never use the cables for carrying, pulling or unplugging the machine. Keep

cables away from heat, oil, sharp edges or moving parts. Damaged or entangled cables increase the risk

of electric shock.

n) Be careful with water on the treated surface. Electrical cables must not come into contact with water.

o) The main power switch on the machine must be in the “Off” position before connecting to the power

supply. (Only if there is a main switch present on the electrobox.)

p) During a long standstill of the machine, pull out the main plug and cover it with plastic foil.

q) If the machine is to be operated using power from a generator, the generator must be operated in

accordance with the current legal regulations and directives in force. (this applies to the protective earth

conductor in particular) in order to ensure that all safety devices are functioning and to eliminate possible

damage to electrical components.

3.3

Personal safety

a) Always wear Personal Protective Equipment while working with the machine.

-Dust mask class FFP3 or higher

-Hearing protection

-Safety glasses with lateral protection

-Protecting gloves

-Safety shoes

b) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from

moving parts.

c) Stay alert, watch what you are doing and use common sense when operating the machine.

d) The cord of the deadmans switch key should always be fastened on your arm or on to your clothing.

e) Pull out the key of the deadmans switch before any inspections, adjustments and/or maintenance work

is started.

f) All persons in the proximity of the machine, must wear hearing protection and safety shoes.

g) Always seek professional medical attention immediately in case of injury.

h) All persons surrounding the machine should wear Personal Protective Equipment.

3.4

Machine safety general

a) Safety functions and operating functions must work correct.

b) No loose bolts and nuts permitted.

c) Never operate machine without the guards and/or safety devices in place.

d) Never change anything on the safety devices on the machine!

e) Do not use the machine when it is damaged.

f) Do not open or remove protective guards while driving gears are running.

g) The temperature of certain machine parts can be above 37° C.

h) The machine, specially the handle grips must be free of fats/oils and have to be dry.

i) If the length of the brushes is, due to wear, less than 5mm or they are extremely deformed, the brushes

have to be replaced. Check the Service Manual for the order numbers.

j) All repair work has to be done by qualified Diamatic personnel, this guarantees a safe and reliable

machine.

k) Always use original Diamatic spare parts, grinding disks, grinding wings and polishing pads.

This will ensure the best performance. Only original Diamatic parts meet the factory specifications and

quality. Otherwise Diamatic BV cannot guarantee the safety of the machine. The part numbers can be

found in the Service Manual.

l) Check the rotating direction of the motor before starting up.

m) If safety-critical changes occur to the machine or its working method, the machine must be shut

down immediately! The cause of the fault must be established, and rectified.

n) In the event of operational malfunctions the machine must be shut down immediately and secured!

3.5

Maintenance safety

a) Pull out the main plug and place it in sight, before starting inspections and repairing on the machine. Pull

out the key of the dead man’s switch and keep it in your pocket. Press the Emergency shutdown button.

b) Wait for standstill of all drives before any inspections, adjustments and/or maintenance work is started.

c) Block the machine in a stable position before doing any maintenance work.

www.diamaticusa.com

9

d) Failures due to inadequate or incorrect maintenance may generate very high repair costs and long

standstill periods of the machine. Regular maintenance therefore is imperative.

e) Operational safety and service life of the machine depends, among other things, on proper maintenance.

f) Prevent premature wear by keeping the machine as dust free as possible. Clean the machine for this

reason regularly with a dust collector and non-aggressive materials, especially the upper drive. Never use

a high pressure water cleaner to clean the machine.

g) It is advisable to stock all spare parts or wear parts that cannot be supplied quickly. As a rule, production

standstill periods are more expensive than the cost for the corresponding spare part.

h) Do not use any aggressive cleaning materials and use lint-free cleaning cloths.

i) To allow the user to carry out maintenance operations, the machine must be disassembled, cleaned and

inspected as far as reasonably possible, without causing hazards for the maintenance staff or other

people.

j) The suitable precautions include decontamination before disassembling the machine, adequate filtered

ventilation of the exhaust air from the room in which it is disassembled, cleaning of the maintenance area

and suitable personal protection equipment.

3.6

Safety regarding dust collectors

a) Always use a suitable Diamatic dust collector when working dry to ensure a dust-free operation of the

machine and clean air at the workspace. Also the airflow helps to cool the machine and prevents

overheating.

b) Read the operating instructions of the dust collector before using it.

c) The dust container/bag of the dust collector must be emptied or replaced regularly. Comply with the local

waste treatment regulations considering the removed material.

d) The dust hose must be connected properly with a hose clamp and industrial tape.

e) The dust hose must be undamaged and free of obstructions.

f) Always switch on the dust collector first!

3.7

Grinding safety

a) The machine contains rotating parts, which are protected with a sliding cover. Always leave the diamond

discs on the floor while the motor is turning.

b) The flexible couplings / buffers can become worn out with use, because of this there can be higher

vibrations than normal. Check for this reason the flexible couplings / buffers for deformation and damage

before every use.

c) Do not let the machine rest on the diamond disc or coupling when it is not in use, this will cause

deformation to the flexible coupling.

d) Make sure the brush seals are in good condition, this to avoid dust escaping.

e) Make sure the diamond tools (wings / discs / pads) are not damaged or worn out.

f) Always pull out the main plug before u start changing the wings, disks or pads.

g) When mounting or removing a diamond disc; lay the machine down backwards so it is lying on the

handle. Make sure the machine will not fall back down. A second person can hold the handle down to

make sure it will not fall back down.

h) For changing the disks/wings u should wear Personal Protective Equipment like a dust mask, safety

goggles, gloves, protective shoes, and close fitting protective clothing.

Use the vacuum cleaner to prevent excessive dust.

i) Caution! The grinding disks / wings will heat up during grinding, don’t risk getting burned, always wear

protective gloves when handling them.

j) The machine contains rotating parts; because of this never tilt the machine backwards with a turning

motor.

k) Be careful with the machine and pull or let down the machine slowly, big shocks can damage the

electrical parts.

l) Make sure the floating shroud is in transport mode when you transport the machine.

m) Be careful, the workfloor can get slippery when grinding wet.

n) Keep all electrical cables and connections away from water.

3.8

Battery safety (12V)

a) Only use Diamatic approved batteries. Diamatic cannot guarantee the safety of the machine when other

batteries are used.

b) Every service work on batteries should only be done by trained personnel.

c) The battery contains lead-acid, do not disassemble, heat above 60°C, or incinerate.

d) Immediately flush eyes with cold, fresh water for a minimum of 15 minutes if electrolytic acid comes in

contact with eyes. Seek professional medical attention immediately.

10

www.diamaticusa.com

e) For work with the battery you need to remove all metal jewelry like rings, watches, necklaces etc. They

can be a cause of serious burns.

f) The old battery should be recycled. Batteries contain harmful materials, like lead en sulphuric acid. These

materials form an environmental and health hazard. Therefore it is imperative that they are recycled

responsibly in accordance with local disposal and environmental regulations.

3.9

Transport safety

a) Be aware of your surroundings and machine operating level. Do not side hill, do not run on steep incline,

this could cause machine to tip over.

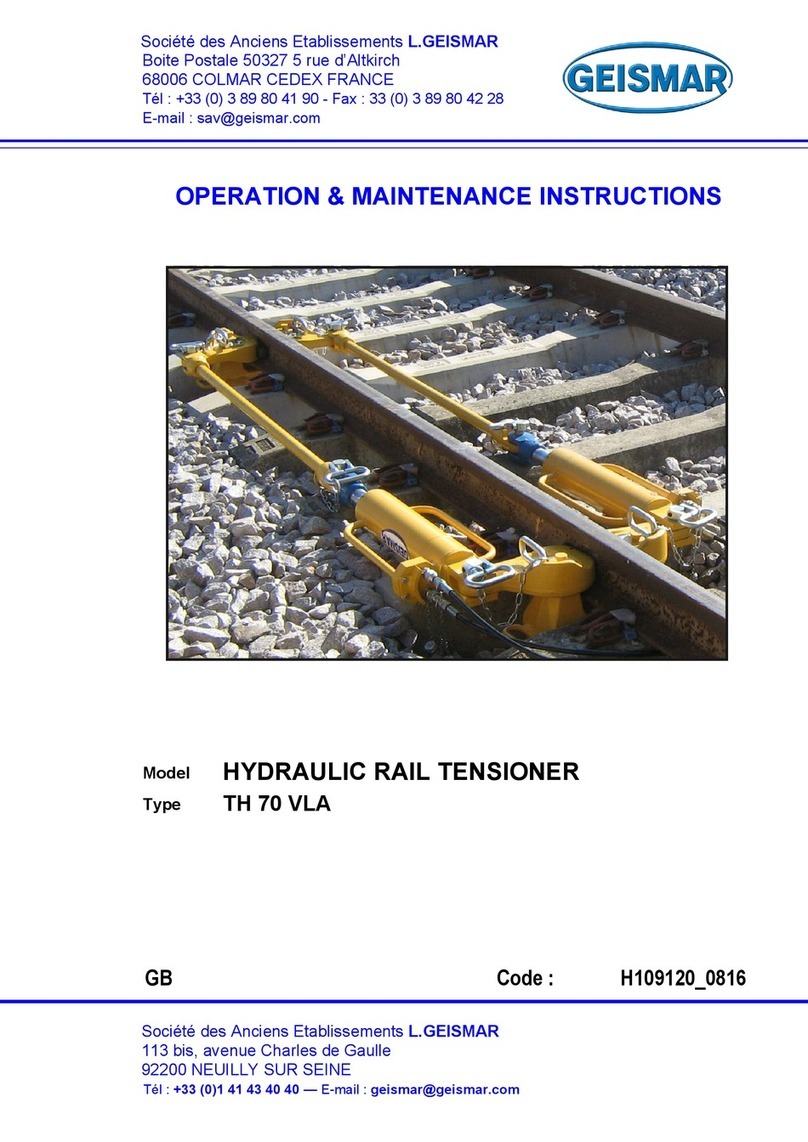

b) The weight of the grinding machine is between 399 and 639 kg. Use a crane or lift when transporting the

machine, use the lifting eyes of the machine.

c) Before every use check the lifting eyes and welds for: deformation, damages, cracks, corrosion and wear.

d) Only lift the machine as shown in the picture below.

e) When lifting the machine from the ground, always use the lowest lifting speed. The cables must firstbe

tensioned at this speed; they must not be slack when the machine is lifted from the ground.

f) During hoisting make sure to be at a safe distance from the machine with the most optimal view on the

machine and working environment.

g) Never stand directly below the machine.

h) When transporting the machine do so in such a manner that damage due to the effects of the use of

force or incorrect loading and unloading is avoided.

i) The lifting eyes can also be used to fasten the machine on a pallet or during transport.

j) Always drive backwards when driving up to a ramp or grade, and forwards when driving of the ramp.

k) Chock wheels for transport and keep control handle in neutral position.

l) Don’t leave the machine unsecured on jobsites.

m) Park the machine always on a flat horizontal and levelled surface.

n) Make sure the floating shroud is in transport mode when you transport the machine.

o) Make sure the electrical cable and dust hose are disconnected.

p) Store the cleaned and dry machine in a humid free room. Protect the electrical motor from moisture, heat

dust and shocks.

q) Never use the machine for lifting or transporting persons or items.

It is not allowed to lift the machine without appropriate appliances as a lift or crane, lift themachine

with a rope on the lifting eyes as showed in imagine mentioned below.

Make sure the floating shroud is in transport mode when you transport the machine.

65. Transport mode

www.diamaticusa.com

11

3.10

Signs on the machine

The following stickers are placed on the machine. Meanings of these symbols are:

Type plate:

Email address, Website, Telephone & fax number.

The serial number of the machine.

The year of manufacture.

The net weight of the machine in kilogram.

Wear a dust mask class FFP3 or higher.

Hearing protection is obliged.

Safety glasses with lateral protection are

obliged.

CE-mark on this machine.

Wear protecting gloves.

Safety shoes obliged.

Consult the manual before operating the

machine.

! Danger Hazardous voltage in motor even when

solid state controller is OFF. Disconnect main

power before servicing motor, controller or

associated wiring.

Name, address and CE mark.

The machine type.

12

www.diamaticusa.com

4. Accessories

Part

Description

Adaptor Plates

DIA-SUPERMAG-2

Heavy Duty Quick Change Plate

E10366

Resin Adaptor Full Round

E07240-2

(DIAMAG 780/735 Plates 2nd generation)

Buffalo Wings

BFL708320S-2

(18/20 Grit Extra Large Double Seg Soft (Red)) For Hard Concrete

BFL708340S-2

(30/40 Grit Extra Large Double Seg Soft (Red)) For Hard Concrete

BFL708380S-2

(60/80 Grit Extra Large Double Seg Soft (Red)) For Hard Concrete

BFL7083140S-2

(120/140 Grit Extra Large Double Seg Soft (Red)) For Hard Concrete

BFL708320-2

(18/20 Grit Extra Large Double Seg Medium (Green)) For Medium Concrete

BFL708340-2

(30/40 Grit Extra Large Double Seg Medium (Green)) For Medium Concrete

BFL708380-2

(60/80 Grit Extra Large Double Seg Medium (Green)) For Medium Concrete

BFL7083140-2

(120/140 Grit Extra Large Double Seg Medium (Green)) For Medium Concrete

BFL708320H-2

(18/20 Grit Extra Large Double Seg Hard (Blue)) For Soft Concrete

BFL708340H-2

(30/40 Grit Extra Large Double Seg Hard (Blue)) For Soft Concrete

BFL708380H-2

(60/80 Grit Extra Large Double Seg Hard (Blue)) For Soft Concrete

BFL7083140H-2

(120/140 Grit Extra Large Double Seg Hard (Blue)) For Soft Concrete

Poly Crystaline Diamonds

BG200995-2

(Wing PCD 1x1)

BG200997-2

(Wing PCD Split 18/20 Grit)

BG200999-2

(Wing PCD ¼ round)

Bush Hammering Tools

E09119/Set

(Replacement Bush Hammer/Specify set of 9 or 15)

E10240

(Cutter Plate with 5 Bush Hammers-Complete)

E09580

(Cutterplate Only 240mm for 5 tools)

E07240-2

(DIAMAG 780/735 Plates 2nd generation)

10 SEG Round

DIA18/20PLUG-S

(18/20 Grit 10 Seg Soft (Red)) For Hard Concrete

DIA30/40PLUG-S

(30/40 Grit 10 Seg Soft (Red)) For Hard Concrete

DIA60/80PLUG-S

(60/80 Grit 10 Seg Soft (Red)) For Hard Concrete

DIA120/150PLUG-S

(120/150 Grit 10 Seg Soft (Red)) For Hard Concrete

DIA18/20PLUG

(18/20 Grit 10 Seg Soft (Green)) For Medium Concrete

DIA30/40PLUG

(30/40 Grit 10 Seg Soft (Green)) For Medium Concrete

DIA60/80PLUG

(60/80 Grit 10 Seg Soft (Green)) For Medium Concrete

DIA120/150PLUG

(120/150 Grit 10 Seg Soft (Green)) For Medium Concrete

DIA18/20PLUG-H

(18/20 Grit 10 Seg Soft (Blue)) For Soft Concrete

DIA30/40PLUG-H

(30/40 Grit 10 Seg Soft (Blue)) For Soft Concrete

DIA60/80PLUG-H

(60/80 Grit 10 Seg Soft (Blue)) For Soft Concrete

DIA120/150PLUG-H

(120/150 Grit 10 Seg Soft (Blue)) For Soft Concrete

Resin Types

PA-103050

(#0 50 Grit 3” Transitional Diamond)

PA-103100

(#1 100 Grit 3” Transitional Diamond)

DIA3SUPERFLEX50

(50 Grit 3” Superflex Resin)

DIA3SUPERFLEX100

(100 Grit 3” Superflex Resin)

DIA3SUPERFLEX200

(200 Grit 3” Superflex Resin)

DIA3SUPERFLEX400

(400 Grit 3” Superflex Resin)

DIA3SUPERFLEX800

(800 Grit 3” Superflex Resin)

DIA3SUPERFLEX1500

(1500 Grit 3” Superflex Resin)

DIA3SUPERFLEX3000

(3000 Grit 3” Superflex Resin)

DIA3SEMI50

(50 Grit 3” Semi Metal Resin)

DIA3SEMI100

(100 Grit 3” Semi Metal Resin)

DIA3SEMI200

(200 Grit 3” Semi Metal Resin)

DIAITS800100-2

(100 Grit 3” 6mm resin Black)

DIAITS800200-2

(200 Grit 3” 6mm resin Black)

DIAITS800400-2

(400 Grit 3” 6mm resin Black)

DIAITS800800-2

(800 Grit 3” 6mm resin Black)

DIAITS801500-2

(1500 Grit 3” 6mm resin Black)

DIAITS803000-2

(3000 Grit 3” 6mm resin Black)

www.diamaticusa.com

13

5. Initial operations

Before using the machine it is important to inspect the machine.

It is not permitted to use the machine if the machine safety is not according the checkpoints below.

Before switching on the machine make sure that no-one can be endangered when the machine starts up!

5.1 Checkpoints of electrical safety

▪Use only extension cables for extending the main cable that are sized and marked in accordance with

the overall power consumption of the machine.

▪Electrical cables must be fully unwound of them reels.

▪No damage is permitted for electrical cables.

▪Use an electrical power supply connection with earth connecting.

▪The main switch of the machine should be put to ‘Off’ before connecting to the power supply. (Only if

there is a main switch present on the electrobox.)

▪Make sure the power supply is in accordance with the machine specifications.

▪If the machine is to be operated using power from a generator, the generator must be operated in

accordance with the current legal regulations and directives in force. (This applies to the protective

earth conductor in particular) in order to ensure that all safety devices are functioning and to

eliminate possible damage to electrical components.

5.2 Checkpoints of machine safety

5.2.1 Safety functions and operating functions must work correct.

5.2.2 Check the diamond wings for damages and/or wear.

5.2.3 Check all screws and other fasteners for tightness. No loose bolts and/or nuts are permitted.

5.2.4 Check the electrical components, cables and connections for wear and/or damages.

5.2.5 Dust hose connection must be reliable: use hose clamps and industrial tape.

5.2.6 Dust hoses must be undamaged and free of obstructions

5.2.7 Make sure that the dust bin / bigbag is empty and connected properly.

14

www.diamaticusa.com

5.3 Battery drive system (option)

19 20

54

66

67

65

68

The machine can be moved around on 3 wheels using the front wheel support and battery drive system.

The 24V battery drive system enables the operator to drive the machine to and from the work area without

the use of the power supply cable. This feature will save precious time and contributes to the ease of use.

•Make sure the bracket (20) is fastened correctly and secured with the pin (19).

•Use the lever (67) to lower the wheel to the ground and fasten the lever (67) tight.

•Turn the handle (66) clockwise to lift the front off the ground.

•Release the brake (68) and make sure the floating shroud is in transport mode (65).

•The traction wheels must be connected to the drive motors, use the locking pin of each rear wheel

(54) to connect the wheels to the drive motors.

62

63 64

•Make sure the key of the dead man switch is in place and the emergency stop button is not activated

(turn to unlock).

•Now turn the key on the electrobox to ACC (63), the battery power indicator and hour counter (64)

will light up.

•Turn the remote control on (62) and push the connection button (41) for 2 seconds.

•The machine and remote control should now be linked, indicated by a little green light (45) on top of

the remote control.

There are 2 ways of driving the machine using the remote control, the AUTO DRIVE-mode or manually

controlled.

www.diamaticusa.com

15

Remote controlled driving

-Push the joystick (42) in the desirable direction to the drive the machine. The further the joystick is

pushed into the desirable position, the faster the machine moves.

-The SPEED FORWARD button (50) & the TRACKING button (51) don’t work in the manually controlled

mode, these functions only work in AUTO DRIVE-mode.

-You can turn the machine around its axle by pushing the joystick totally to the right or totally to the

left.

-The machine can also turn around one wheel, this can be done by pushing the joystick to the left or

right upper corner.

45

42

41

50 51 52 53

AUTO DRIVE-mode

-Use the FORWARD/REVERSE-switch (52) to select forward or reverse driving.

-Use the SPEED FORWARD (50) to select the driving speed, always start slowly at first.

-Set the TRACKING (51) in the middle position.

-Now push the DRIVE-button (53), to drive the machine automatically.

-Steer the machine left or right with TRACKING (51) and change the driving speed with (50).

NOTE: The joystick does not work in AUTO DRIVE-mode.

Push the DRIVE-button (53) to stop the AUTO DRIVE-mode. The machine can now be controlled with the

joystick again.

WARNING! Always make sure all rotating parts have come to a complete standstill before moving around the

machine.

Be careful! Make sure nobodies feet get under the wheels. Wear appropriate safety shoes when you drive the

machine to or from the work area.

16

www.diamaticusa.com

5.4 Manual moving of the machine

There are 2 ways of moving the machine around manually, tilting the machine backwards or by using the

front wheel support system to push the machine around on 3 wheels.

19 20

54

66

67

65

68

•Make sure the bracket (20) is fastened correctly and secured with the pin (19).

•Use the lever (67) to lower the wheel to the ground and fasten the lever (67) tight.

•Turn the handle (66) clockwise to lift the front off the ground.

•Release the brake (68) and make sure the floating shroud is in transport mode (65).

•The traction wheels must be disconnected from the drive motors, pull out the locking pin of each rear

wheel (54) to disconnect the wheels from the drive motors.

The machine can now be pushed around manually.

Another way to move the machine manually is by putting the steering handle in the upright (vertical) position

and putting the side-weights slightly backwards. Disconnect the traction wheels by pulling out the fast locking

pins (54). Stand with one foot on the bracket and pull on the handgrips to tilt the machine backwards. It can

now be pushed around on its back wheels.

The machine should only be moved around when the dust

hose, water supply and power supply cable are disconnected.

Be careful when you let the machine tilt back on the grinding heads, let the machine down slowly, big shocks

can damage the electrical parts.

www.diamaticusa.com

17

e weight forward or backward to the desired

allows the operator to regulate the grinding

DIAMAG

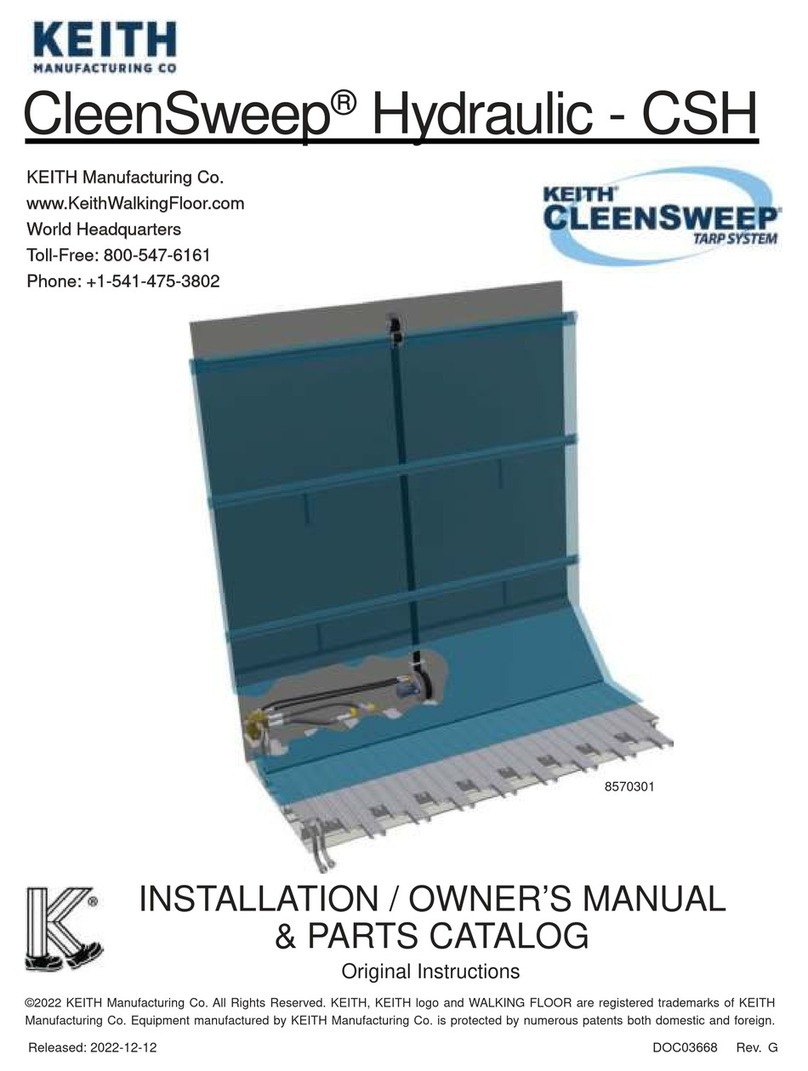

When using DIAMAG adapter plates, you can replace

the diamond wings without using any tools!

Because of the specially designed heat resistant magnets

and fixation pins, the diamond tools are fixed onto the

plate, but can still very simply be replaced by hand.

Contact your Diamatic distributor for more information

or check WWW.DIAMAG.EU

5.5 Adjustable weights

The machine has adjustable weights mounted at the sides, they can be set for high, medium or low grinding

pressure.

Hold the knob of the weight firmly in your hand.

Be careful! The adjustable weight is heavy!

With your other hand pull out the locking pin and adjust th

position.

Lock the locking pin back in position.

Repeat on the other side of the machine.

The position of the adjustable weights and steering handle

pressure very precise.

Grinding pressure BMG-780RS BD:

260 Kg = Steering handle horizontal and the adjustable weights backwards.

318 Kg = Steering handle up and the adjustable weights in the middle.

373 Kg = Steering handle to the front and the adjustable weights to the front.

16 www.diamaticusa.com

Hold the knob

Locking pin

www.diamaticusa.com

17

5.6 Changing the wings / discs

Warning! Always wear Personal Protective Equipment!

The dust can be hazardous to the health! Wear a dustmask!

The wings can get hot! Don’t risk burning your hands! Wear protective gloves!

Make sure all moving parts of the machine have come to a complete standstill before changing the wings.

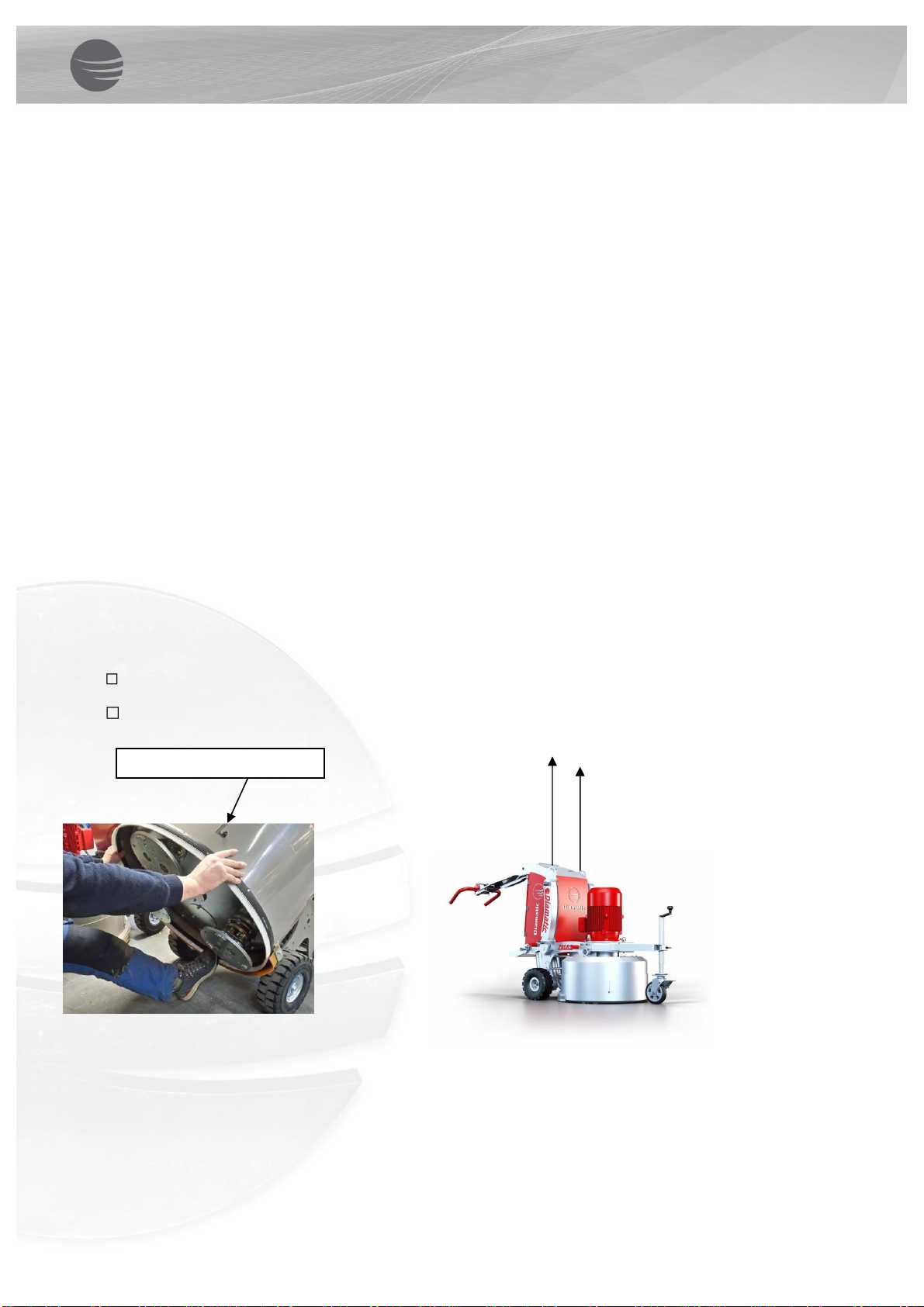

Correct position of the machine for changing tools.

Pull out the mains plug before you start

Always wear a dust mask of at least class FFP3 and gloves.

Use the vacuum cleaner in order to work as dust free as possible

18

www.diamaticusa.com

Remove the key of the dead man’s switch, press the red

stop button, and unplug the machine from the power

supply.

This is to prevent unintentional start-up of the machine.

Before you tilt the machine back, make sure the electrical

cable and dust hose cannot get damaged when you tilt the

machine back.

Put the steering handle in the upright (vertical) position,

stand with one foot on the bracket and pull on the

handgrips to tilt the machine backwards.

WARNING!

This is an unstable position of the machine.

Danger of tipping if the handle is not raised.

Tilt the machine back and lay down the machine so it is

laying on the metal support underneath the electrical box.

Make sure the machine will not fall back down. A second

person can hold the handle down, to make sure the

machine will not fall back down.

If there is a risk of damaging the floor-coating when tilting

the machine back, you can place a piece of cloth, a sheet,

a thin wooden board or something similar underneath the

metal supports.

WARNING! Danger of injury.

Do not let the machine rest on thick wedges or thick

wooden beams. This can cause the machine to fall back

down!

Use the vacuum cleaner to remove excessive dust.

A tool (spatula, screwdriver) makes it easier to release the

plate off the velcro.

Table of contents

Other Diamatic Industrial Equipment manuals