Zakład Wytwórczy Aparatów Elektrycznych Sp. z o.o.

3

Table of contents

1. TRANSPORT AND STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1. Unpacking and inspection ..............................4

1.2. Transport and storage. ................................6

2. DESCRIPTION ........................................ 6

2.1. Application ...........................................6

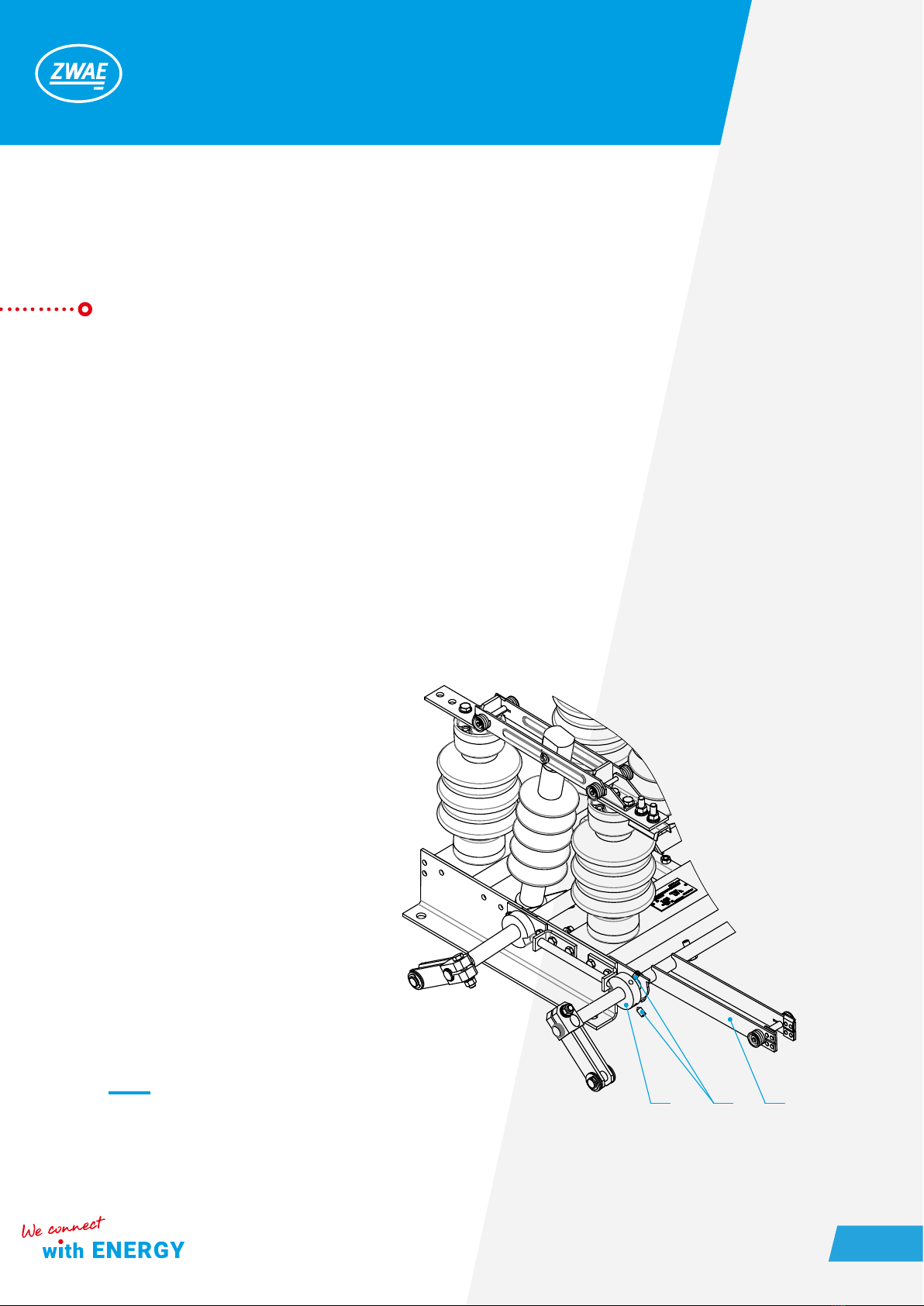

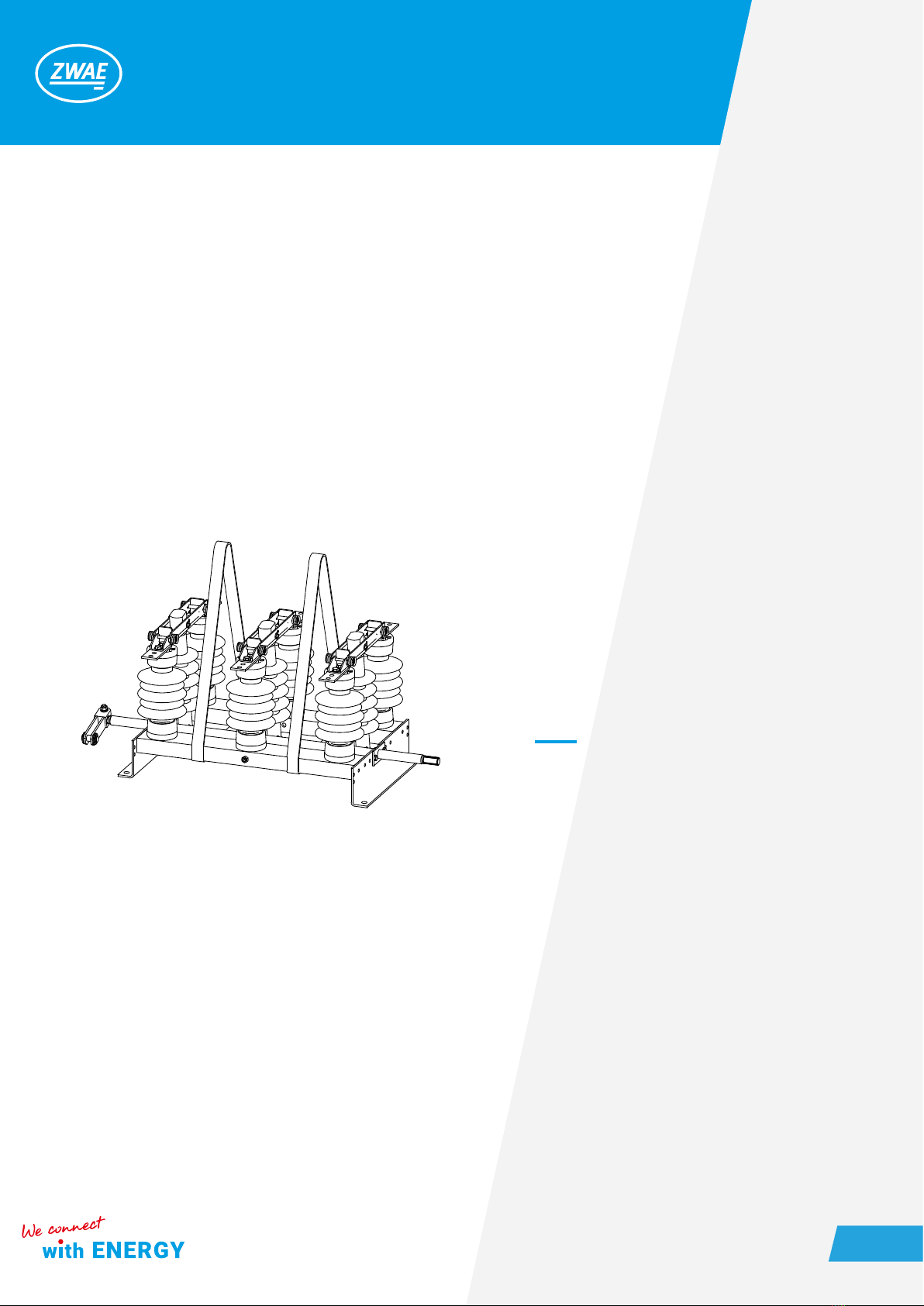

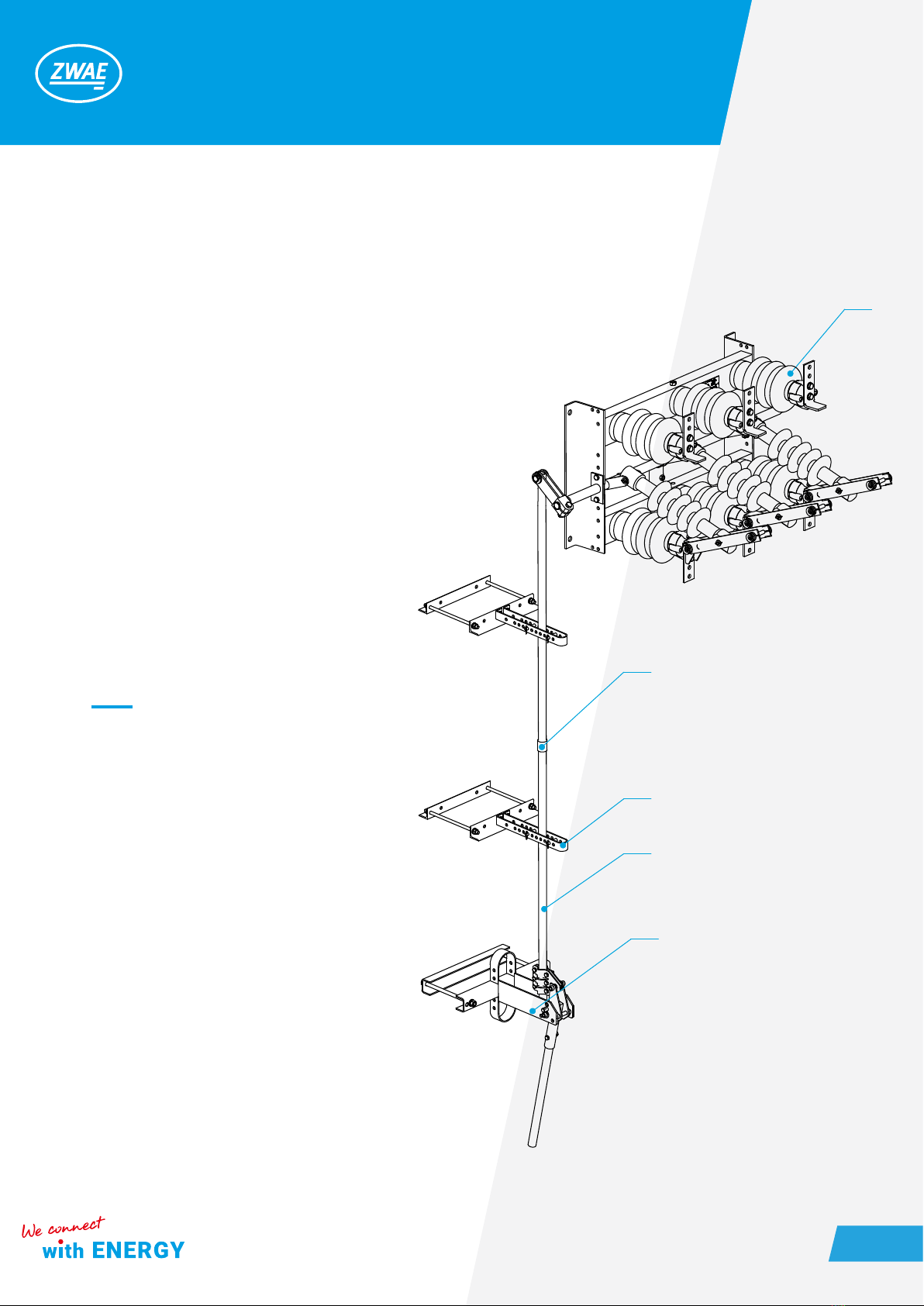

2.2. Construction and principle of operation. ..................7

2.3. Ambient conditions during operation .....................8

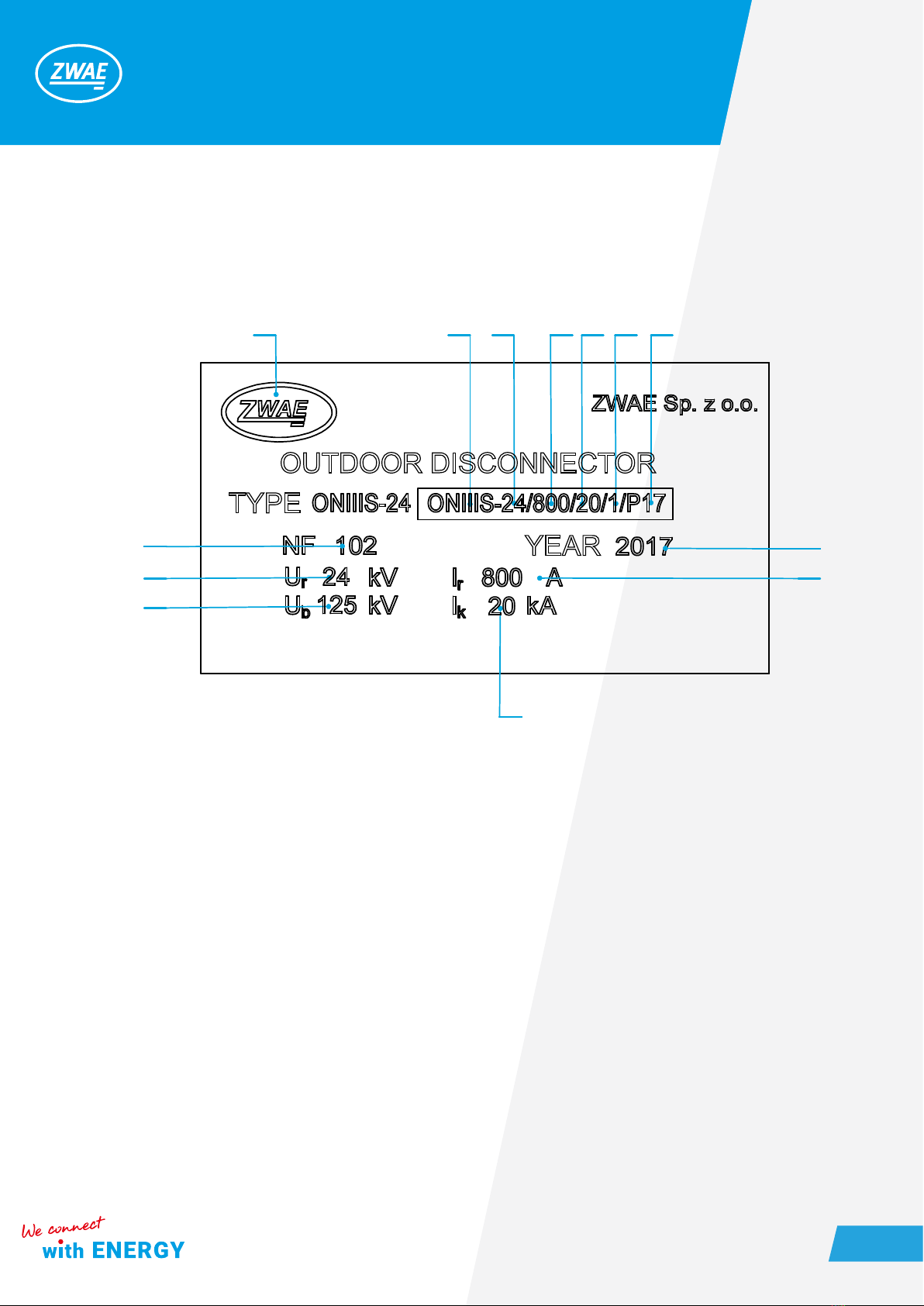

2.4 . Nameplate. ..........................................9

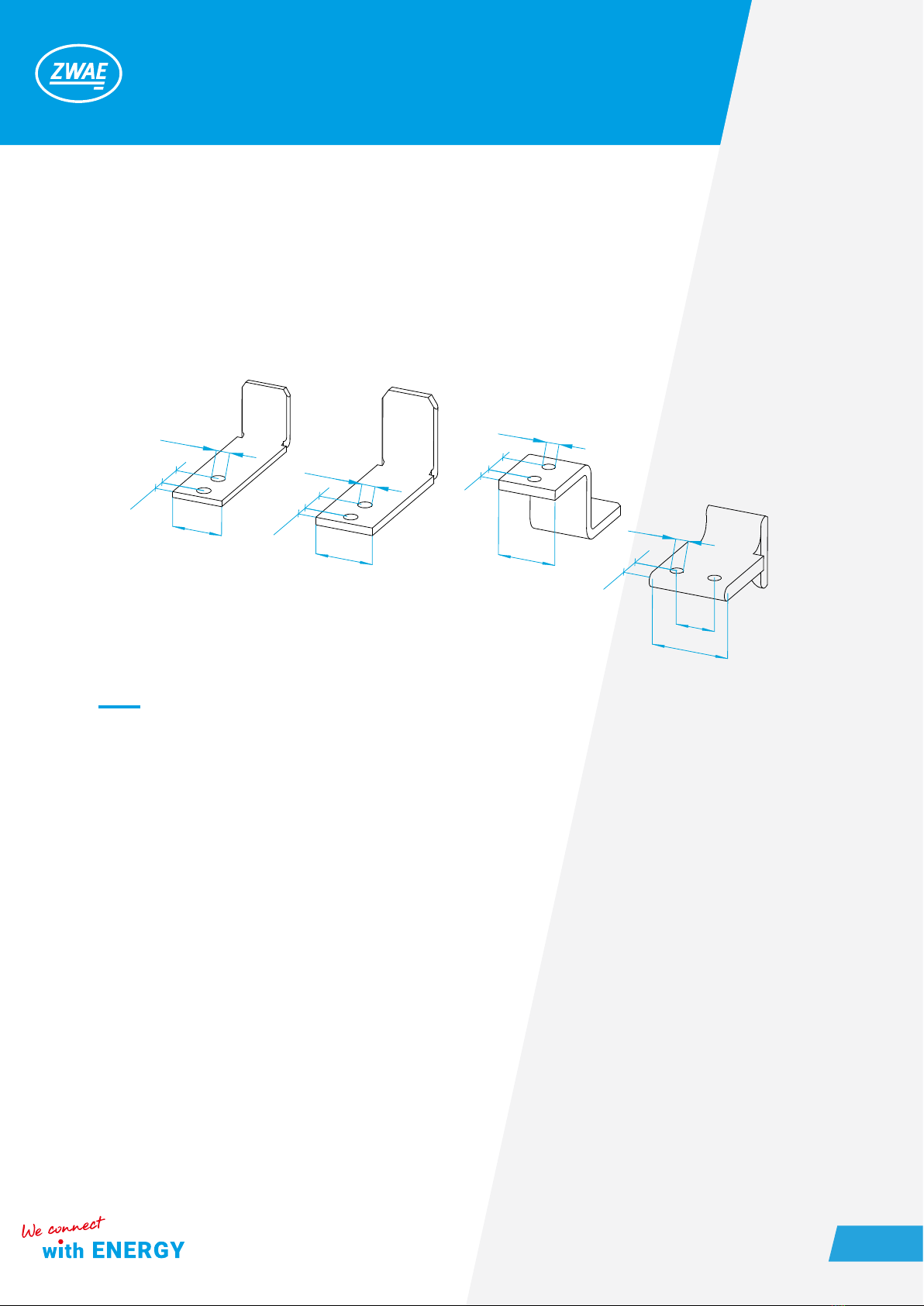

3. ACCESSORIES, ADDITIONAL EQUIPMENT ................. 10

4. INSTALLATION AND ADJUSTMENT ...................... 13

4.1. Preparation of the supporting structure and assembly

ot the disconnector........................................13

4.2. Connecting feeding wires and grounding wire .............14

5. OPERATING MANUAL ................................. 15

5.1. Periodic inspections ...................................15

5.2. Permitted repairs carried out by the user. .................16

6. MAINTENANCE ....................................... 16

6.1. Regular tests .........................................16

7. UTILIZATION ......................................... 17