E170701X.01_ENG 16/04/18

6

when the machine is working.

Dryer must always be used by trained

personnel and with at least two operators in

the room!

READ CAREFULLY THE INSTRUCTION FOR

OPERATING IN CASE OF BLACK OUT, AND

INFORM ALL THE USERs ABOUT THEM.

ELECTROCUTION DANGER

Only qualified personnel must operate any

service of the electrical parts. Before working

on the machine, cut off the electrical supply.

Only manufacturer personnel can modify

power and controlled circuits, on the contrary

the warranty conditions expire.

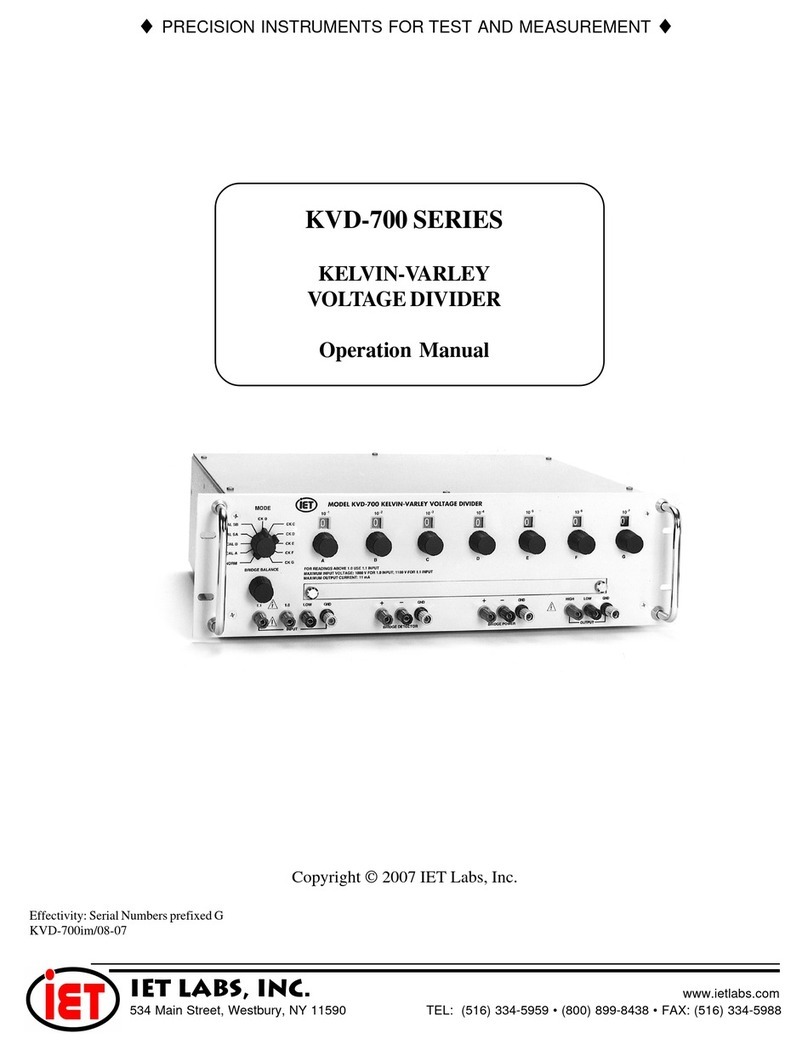

On the electric board, the here below warning

label was stuck. If this label should be damaged

or unstuck, an identical one must replace it.

OPERATOR PSYCHOPHYSICAL

CONDITIONS

User must be in perfect psychophysical condition;

during the working cycle, the user must always

assume a vertical posture in front of the machine.

Sudden or not controlled movement must be

avoided because of the risks of dangerous knocks

against the dryer chassis, i.e.: during the dryer

unloading.

The other people present on the laundry room

must not distract the operator, who is working on

the dryer.

While working, the operator must not be distracted

by TV, radio or any other source of distraction.

LIGHTING

In the room where the machine is installed,

lighting must be at least of 300-500 lux intensity;

unpleasant flashing must be avoided.

ATTENTION!

These instructions do not cover all possible risks.

User must always pay high attention and respect

carefully the rules.

The machine in not previewed to be used by

persons with reduced phisical or mental capacities

or with missing or reduced experience and

knowledge.

3. MANUFACTURER LIABILITY

The instructions written in this manual are not

replacing, but completing the duties deriving from

the safety and accident prevention laws.

With reference to what is written in this manual,

the manufacture is not responsible when:

- The machine user does not respect safety and

accident prevention laws in force;

- The machine was not correctly installed;

- Periodical and/or programmed maintenance is

missing;

- Manual instruction was not respected;

- Defects occur in the power supply;

- Non authorized modification made on the

machine;

- Non-authorized personnel use the machine.

4. UNPACKING

During tranportation or storage the machine must

stay within the following conditions:

- temperature: -15°C÷50°C

- humidity: 0%÷90% (without condensation)

The machine must be inspected at the delivery

moment, any external or internal damage due to

the transport, must be reported immediately to the

forwarder.

Machine must be completely unpacked next to the

installation place. Straps must be cut and the

covering packing material must be taken off.

Packing materials must be disposed following the

rules in subject of environment protection.

Using a key, take away the fixings on the machine

base which are attaching the dryer to the pallet

(frontal and back).

ATTENTION!

Check the machine net and gross weight on the

technical data sheet sent with the machine: it

must comply with the available lifting means.

ATTENTION!

Pallet cannot be used as normal dryer support!

The machine must always be installed without