9

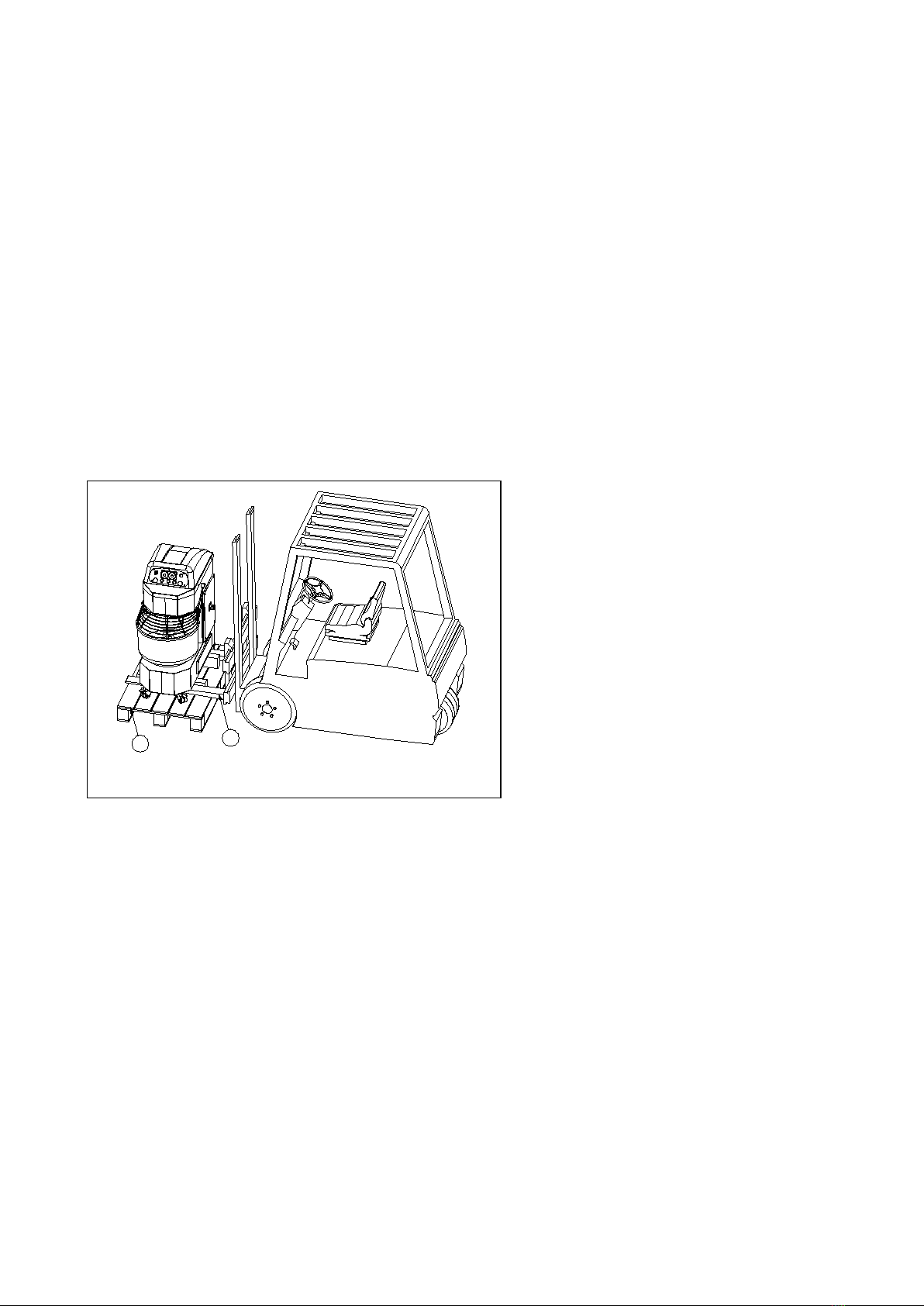

4.3 Installation and commissioning

Preparatory stages for the machine installation and commissioning:

-Identify an area suitable for food-processing that is completely accessible for cleaning in which collocate

the machine.

-It is not necessary to provide floor anchors but the floor must be well leveled because SP401,601 and

SP801 models do not have leveling feet, whereas the SP801 Gold model comes with frontal legs.

-Check that the power line is properly connected by means of a suitable outlet.

-Check that any command and removable safety protections work properly.

4.3.1 Installation

Once the machine has been transported to the chosen location, the installation is carried out following the

stages outlined below (see figs.3/4):

a) For SP401, SP601 and SP801 models, lock

the wheels by pressing on the lever with the

foot Pos.1 Fig.3a, until the lever remains

locked. For the SP801 Gold model the

positioning of the machine is done by

adjusting the front legs Pos.51 fig.3b through

the hand wheel Pos.53 and subsequently

blocking by tightening the nut, Pos.52.

b) Connect the machine to the power outlet,

turn the knob on Pos.3 and check that the ON

lights up, Pos. 4, Fig.4/5.

c) Check that the bowl protection is turned

down, Pos. 4, Figg.3a/3b.

d) Push on Start button, Pos. 5 Fig. 4/5

If the tank turns clockwise, ie opposite to the

one indicated by the arrow on the side of the

tank, the phases on the engine are incorrect,

then swap two of the three phases in the

socket.

The control panel Pos.2, figs.3/4/5 is

composed of:

Fig.3b : SP801- Gold Installation

Fig.3a : SP401/601-SP801 Installation