- 4 -

THE PRESENT MANUAL IS PROPERTY OF THE MANUFACTURER. ANY REPRODUCTION, EVEN PARTIAL, IS PROHIBITED.

The appliance must be installed in a su-

itable place, namely, one which allows

normal running, routine and extraordi-

nary maintenance operations. The ope-

rating area for maintenance must be set

up in such a way that the safety of the

operator is not endangered. The room

must also be provided with the features

required for installation, such as:

•

maximum relative humidity: 80%;

•

minimum cooling water temperature

> + 10 °C ;

•

the floor must be anti-slip, and devi-

ces positioned perfectly level;

•

the room must be equipped with a

ventilation system and lighting as

prescribed by standards in force in

the country of the user;

•

the room must be set up for draining

greywater, and must have switches

and gate valves which cut all types

of supply upstream the appliance

when needed;

•

The walls/surfaces immediately clo-

se/contact to the appliance must be

fireproof and/or isolated from possi-

ble source of heat

TEST INSPECTION AND WAR-

RANTY /

Testing: the equipment has

been tested by the manufacturer during

the assembly stages at the site of the

production plant. All certicates related

to the testing performed will be deli-

vered to the customer upon request.

Guarantee: the warranty is 12 mon-

ths from the date of invoicing of the

equipment, this period cannot be ex-

tended. It covers the faulty parts only.

Carriage and installation charges are

for the buyer’s account. Electric com-

ponents, accessories as well as other

removable parts are not covered by the

guarantee. Labor costs relating to the

intervention of authorized by the manu-

facturer at the customer’s premises, for

removal of defects under warranty are

charged to the dealer. Excluded are all

tools and supplies, possibly supplied by

the manufacturer together with the ma-

chines. Damage occurred in transit or

due to incorrect installation or mainte-

nance can’t be considered. Guarantee

is not transferable and replacement of

parts and appliance is at the nal discre-

tion of our company. The Manufacturer

is responsible for the equipment in its

original conguration and only for origi-

nal spare parts replacement. The ma-

nufacturer declines all responsibility for

improper use, for damages caused as a

result of operations not covered in this

manual or not authorized in advance by

the manufacturer.consideration in this

manual or without prior authorisation of

the manufacturer himself.

THE WARRANTY TERMINATES

IN CASE OF /

• Damage caused by

transport “ex works” (EXW) and / or by

handling, should this event occur, the

customer must inform the retailer and

the carrier via fax / mail or RR and write

down on the copies of the transport do-

cuments what It’s happened. The tech-

nician authorized to install the applian-

ce will evaluate the damage and decide

if the installation can be carried out.

The warranty also terminates in the

presence of: • Damage caused by in-

correct installation. / • Damage caused

by parts worn due to improper use. /•

Damage caused by use of non-origi-

nal spare parts. / • Damage caused by

incorrect maintenance and/or lack of

maintenance. / • Damage caused by

failure to comply with the procedures

described in this document.

AUTHORISATION /

Authorisation

refers to the permission to operate an

activity intrinsic to the appliance. Au-

thorisation is given to anyone who is

responsible for the appliance (manu-

facturer, purchaser, signer, dealer and/

or location owner).

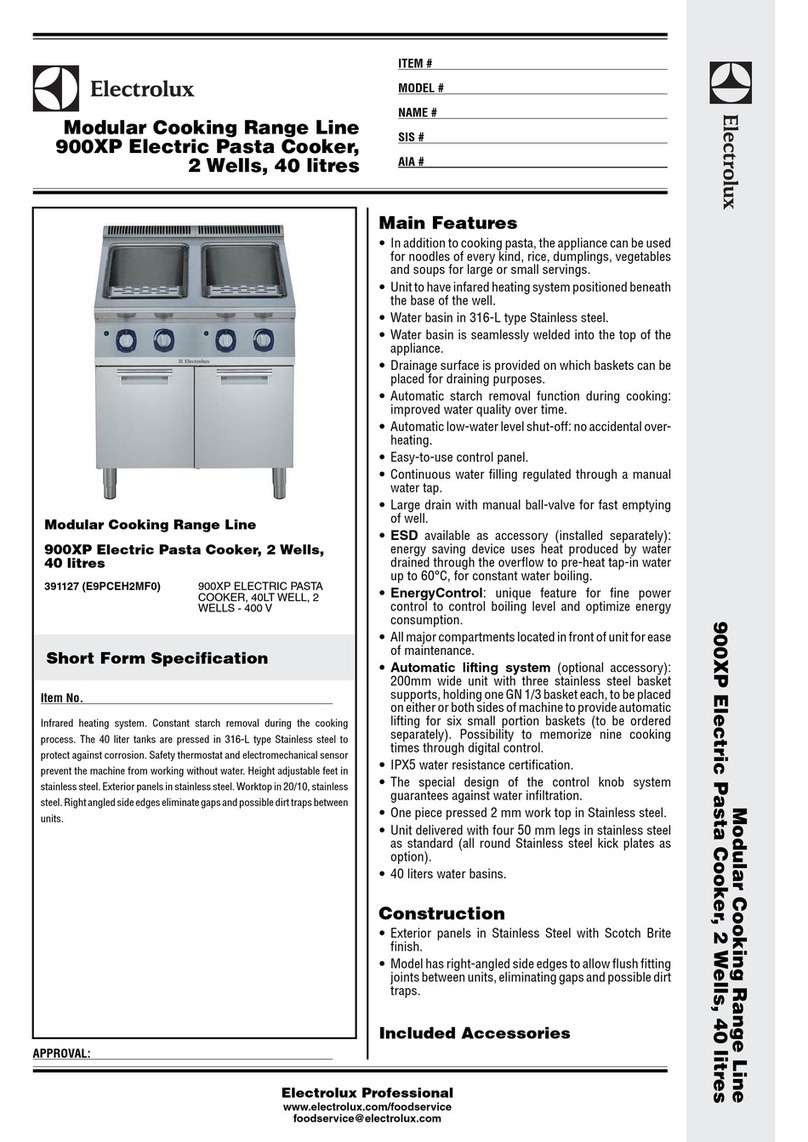

TECHNICAL DATA and IMAGES /

The section is at the ending of this

manual.

GENERAL AND SAFETY INFORMATION