Dickey-John INTELLIAG ISO6 User manual

INTELLIAG®

ISO6

™

PLANTER DRILL CONTROL

VERSION 4 QUICK START GUIDE

Quick Start Guide

Add ISO6 WSMT Module

here (from spec sheet 2nd page)

SINCE 1966

®

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide / I

6011662 Rev B

Safety Notices.....................................................................................................3

Disclaimer..................................................................................................................................3

Basic Setup.........................................................................................................4

User Level 2 (Dealer) ................................................................................................................4

Basic Setup Steps .....................................................................................................................5

Modules...............................................................................................................7

Harness Select....................................................................................................8

Identify Harness Style................................................................................................................8

Selecting a Harness:...........................................................................................................8

Row Setup...........................................................................................................9

To Access Row Setup: ..............................................................................................................9

Controls.............................................................................................................10

Assign a Control Channel........................................................................................................10

To Create a Control Channel:...........................................................................................10

Enter Channel Parameters......................................................................................................11

Valve Calibration .....................................................................................................................12

Perform a Valve Calibration (Figure 9) .............................................................................13

Limit Output (Granular)............................................................................................................14

To Perform a Limit Output:................................................................................................14

Granular Spreader Calibration.................................................................................................15

Perform a Spreader Calibration ........................................................................................15

Spreader Constants Defined...................................................................................................17

Density ..............................................................................................................................17

Spreader Constant............................................................................................................17

Target Meter RPM.............................................................................................................18

Number (#) Meter Revs ....................................................................................................18

Pulse Count.......................................................................................................................18

New Spreader Constant....................................................................................................18

Amount Dispensed............................................................................................................18

Shaft Turn .........................................................................................................................18

Liquid Flow Calibration............................................................................................................18

Perform a Valve Calibration..............................................................................................18

Limit Output.......................................................................................................................19

K-Factor Calibration.................................................................................................................20

Method 1: 100% Catch Test .............................................................................................20

Perform a Liquid Flow Catch Test...........................................................................................21

Operations.........................................................................................................22

To Edit an Operation: ..............................................................................................................22

Configurations..........................................................................................................................23

To Activate/Change a Configuration:................................................................................23

To Edit a Configuration: ....................................................................................................24

To Change the Operation Product Class:.........................................................................25

To Change an Assigned Material:.....................................................................................25

To Change the Row Pattern: ............................................................................................25

Materials............................................................................................................26

To Create a Material:...............................................................................................................26

Setup Parameters For Planter Control....................................................................................27

Setup Parameters For Liquid Control......................................................................................28

Setup Parameters For Granular Control .................................................................................29

OPERATOR’S MANUAL

II / ISO6Version 4 Quick Start Guide

6011662 Rev B

Clutch Sections ................................................................................................30

Identify Sections and Outputs..................................................................................................30

Multiple Output Module Assignment.................................................................................30

To Enter # of Outputs per Module:....................................................................................30

Assign Channels/Rows/ Outputs/Switches....................................................31

To Assign Clutch Sections:......................................................................................................31

Geometry...........................................................................................................32

To Enter X/Y Coordinates:.......................................................................................................32

X and Y Coordinate Example..................................................................................................33

Row Sensors.....................................................................................................35

To Assign Sensors: .................................................................................................................35

Accessories ......................................................................................................39

Accessory Summary................................................................................................................39

Accessory Setup......................................................................................................................39

Accessory Alarm Setup...........................................................................................................41

Sensor Name....................................................................................................................41

High/Low Alarm Level.......................................................................................................41

High/Low Alarm Delay.......................................................................................................41

High/Low Alarm Gating.....................................................................................................41

High/Low Alarm Behavior .................................................................................................42

Pressure Sensor Setup ...........................................................................................................42

Hopper Sensor Setup..............................................................................................................43

RPM Sensor Setup..................................................................................................................44

Digital Sensor Setup................................................................................................................45

Task Controller.................................................................................................47

Task Controller Compatibility...................................................................................................47

To Disconnect Task Controller:.........................................................................................47

To Reconnect to the Task Controller:...............................................................................47

To Refine an Operation:....................................................................................................48

Ground Speed...................................................................................................49

To Select a Ground Speed Type:............................................................................................49

User Levels .......................................................................................................50

Lock To User Level 1 (Operator).............................................................................................50

To Set User Level 1 Mode: ...............................................................................................50

User Level 2 (Dealer) ..............................................................................................................50

To Unlock a Controller into User Level 2 (Dealer):...........................................................50

Frame Fold/Working Hydraulics......................................................................51

Fame Fold/Working Hydraulics ...............................................................................................51

Setting Up Frame Fold Controls: ......................................................................................51

Setting Up Working Hydraulics Functions:..............................................................................54

Adding Work Functions to the Work Screen: ..........................................................................55

Virtual Section Switches..................................................................................56

Setting Up Virtual Section Switches:.......................................................................................56

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide SAFETY NOTICES / 3

6011662 Rev B

SAFETY NOTICES

Safety notices are one of the primary ways to call attention to

potential hazards.

This Safety Alert Symbol identifies important safety messages

in this manual. When you see this symbol, carefully read the

message that follows. Be alert to the possibility of personal

injury or death.

WARNING

Use of the word WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury.

CAUTION

Use of the word CAUTION with the Safety Alert Symbol

indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CAUTION

Use of the word CAUTION without the Safety Alert Symbol

indicates a potentially hazardous situation which, if not

avoided, may result in equipment damage.

DANGER

Use of the word DANGER indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury.

DISCLAIMER

DICKEY-john reserves the right to make engineering refinements

or procedural changes that may not be reflected in this manual.

Material included in this manual is for informational purposes and

is subject to change without notice.

DANGER

OPERATOR’S MANUAL

4 / BASIC SETUP ISO6Version 4 Quick Start Guide

6011662 Rev B

BASIC SETUP

The ISO6Quick Start Guide provides the basic steps for user

level 2 and 3 administrators to setup a system.

The IntelliAg system is accessed by pressing the ISO6button in

the UT object pool selection box (location will vary with UT mfg).

Figure 1

Accessing IntelliAg IS06 Screens

USER LEVEL 2 (DEALER)

User Level 2 provides open access to all setup/configuration

screens excluding Factory Reset and the Alarm Log (User Level

3 access). To change from operator level to dealer level, a 6-digit

password is required. Password includes the five-digit serial

number found on the label of the ISO6module or on the

Version screen.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide BASIC SETUP / 5

6011662 Rev B

To Unlock to Dealer Access:

1. At the Version screen,

-Record the serial number of the ISO6module.

-Press the PASSWORD button.

2. On the Password screen, enter the 6-digit password as

follows:

-Enter the first digit as 2.

-For the next five digits, enter the last five digits of the

serial number taken from the ISO6module found on the

label or

-The last five digits found at the Version Information

screen (example: S/N 163210044 - use 10044).

3. Press the check button to accept password. At the Password

screen, text at screen bottom states “Dealer screens on” in

the User Level 2 (Full Access) mode.

Figure 2

Enter Password for User Level 3 Access

BASIC SETUP STEPS

The basic steps below are recommended in the listed order for

initial system setup:

1. Module Configuration (set module addresses)

2. System screen (select harness)

3. Rows (assign) Controls (define control channels)

4. Operations (define control/application configuration)

5. Materials (specify material type)

6. Row Clutch Setup (if applicable)

7. Liquid Section Setup (if applicable)

8. Geometry (implement layout)

OPERATOR’S MANUAL

6 / BASIC SETUP ISO6Version 4 Quick Start Guide

6011662 Rev B

9. Sensors (assign sensor type)

10. Accessory sensors

11. Work Screen layout setup

NOTE

Recommended Setup order is using the System Setup buttons

from left to right.

Figure 3

Home Menu Screen

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide BASIC SETUP / 7

6011662 Rev B

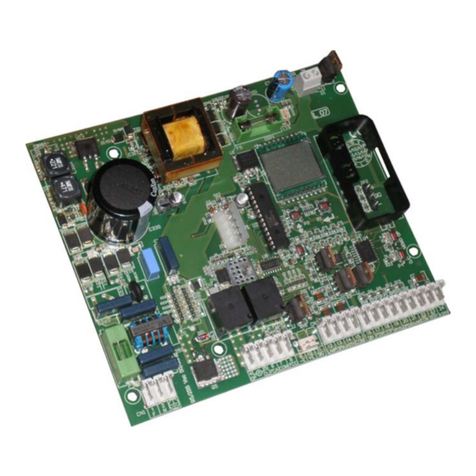

MODULES

The Modules screen displays what modules are currently

detected on the CAN bus. When a new module is added to the

system, the module appears as the last module and must be

placed in its correct position as installed on the implement.

To Add a New Module:

1. Press the Module Address input box of the new module.

2. Manually enter the correct module address location.

-The module location automatically adjusts to the correct

position and proceeding modules change to the new

module address.

Figure 4

Modules Screen

OPERATOR’S MANUAL

8 / HARNESS SELECT ISO6Version 4 Quick Start Guide

6011662 Rev B

HARNESS SELECT

IDENTIFY HARNESS STYLE

IM PORTANT

A harness style must be selected prior to channel setup.

The system default is set to “Monitor Only” with no control

channels enabled.

IM PORTANT

Harness selection changes the system configuration and

should only be done when changing physical harnesses.

It is recommended to perform a complete system setup after

changing the harness type.

SELECTING A HARNESS:

1. Press the SYSTEM button.

2. Press the Harness drop down box and select the

appropriate harness.

3. Press the SAVE button.

-Press the Cancel ‘X’ button to cancel the

selected changes.

4. A power cycle is required to reboot the system.

Figure 5

Select the Harness Type

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide ROW SETUP / 9

6011662 Rev B

ROW SETUP

Row Setup will allow the user to define the number of rows on

the implement and also set the row spacing. Total implement

width is calculated from these parameters.

TO ACCESS ROW SETUP:

1. Press the ROWS button to access the Row Setup screen.

2. Enter parameters on the setup screen shown in Figure 6.

NOTE

Applies to planter, granular, liquid, RPM, and Monitor

Only applications.

Figure 6

Row Setup

OPERATOR’S MANUAL

10 / CONTROLS ISO6Version 4 Quick Start Guide

6011662 Rev B

CONTROLS

NOTE

It is recommended that materials are created before

configuring control channels.

Up to eight control channels are available to control material

application based on the purchased feature set and installed

harness type.

ASSIGN A CONTROL CHANNEL

The Controls screen on initial setup is blank. Adding, deleting,

and editing channel setup parameters are defined at this screen.

As channels are configured and saved in sequential order, the

Controls screen identifies the channel type and material

assigned. A channel type cannot be changed after setup. The

channel must be removed and a new one created.

Once a channel is created, select the channel to edit setup

parameters.

TO CREATE A CONTROL CHANNEL:

1. Press the CONTROLS button.

2. Press the ADD button to select the control channel type.

3. Select the desired channel type button.

-The selected channel type now appears on the

Control screen.

4. Press to highlight and select the channel.

5. Press the EDIT button to open the channel and set

channel parameters.

The selected channel type now appears on the Controls screen.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide CONTROLS / 11

6011662 Rev B

Figure 7

Select a Control Channel Type

ENTER CHANNEL PARAMETERS

Enter in the desired channel parameters for each control type.

For more information on channel parameters please see the

Operators Manual.

OPERATOR’S MANUAL

12 / CONTROLS ISO6Version 4 Quick Start Guide

6011662 Rev B

Figure 8

Enter Channel Parameters

VALVE CALIBRATION

Performing a valve calibration is required for most channel

types to set system parameters and should be performed for

best results.

A VALVE CAL button appears on the control channel screen if

this step is appropriate for the assigned channel type.

TIP: Valve calibration steps 1-10 are the same when performing

for Planter, Granular, Liquid Flow, Fan and Shaft Control.

At the Liquid channel, a manual K-Factor calibration can also

be performed.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide CONTROLS / 13

6011662 Rev B

CAUTION

Hoppers are assumed to be empty for this calibration. If

loaded, material may dispense onto the ground.

PERFORM A VALVE CALIBRATION (FIGURE 9)

1. At the Controls screen, press the VALVE CAL button to

access the Valve Calibration screen.

2. Move the implement to the “raised” position.

3. Apply the tractor brakes and lock in the applied position.

4. Put the transmission in “park” or in a locked position.

-Verify disc speed high limit is set correctly. Valve

calibration will try and obtain the high disc speed.

DANGER

When the START key is engaged, the machine will become

operational. All necessary precautions must be taken to

ensure user safety. Failure to practice all necessary caution

may result in serious injury or death.

5. Start the tractor and engage the hydraulic system,

i.e. PTO or auxiliary lever.

6. Run the engine at normal operating speed until the

hydraulic fluid is at normal operating temperature.

7. Press the START button.

8. The valve calibration immediately starts.

9. Keep the hydraulics engaged until the calibration is

complete. The calibration may take a few minutes to

complete. Each calibration step is monitored on the lower

left corner of the display.

10. When the calibration is complete, the control shuts down

automatically. All calibration data is automatically stored.

CAUTION

DANGER

OPERATOR’S MANUAL

14 / CONTROLS ISO6Version 4 Quick Start Guide

6011662 Rev B

Figure 9

Valve Calibration

LIMIT OUTPUT (GRANULAR)

In certain instances, it is necessary to limit the output of the

control channel before running a valve calibration. System

capacities are greater than the actual desired capacities. These

features allow setting the maximum output of the channel to

prevent machine damage.

TO PERFORM A LIMIT OUTPUT:

1. At the Valve Calibration screen, press the LIMIT OUTPUT

button to access the Limit Output screen.

2. Move the implement to the “raised” position.

3. Apply the tractor brakes and lock in the applied position.

4. Put the transmission in “park” or in a locked, neutral position.

5. Engage hydraulic system.

6. Run engine at normal operating RPM until hydraulic fluid is

at normal operating temperature.

7. To change the valve position, press the Increment or

Decrement buttons repeatedly until the desired minimum or

maximum output value is reached.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide CONTROLS / 15

6011662 Rev B

8. Press the START button and the valve calibration

immediately begins. The calibration runs using the new max

flow value.

Figure 10

Limit Output (Granular)

GRANULAR SPREADER CALIBRATION

NOTE

Refer to the System Tests section for using a remote test

switch during a spreader calibration.

A Spreader Constant Calibration requires a catch test to

determine the spreader constant. This function is only

available for granular seed and fertilizer applications.

PERFORM A SPREADER CALIBRATION

IM PORTANT

A valve calibration should be performed before a

spreader calibration.

1. Load hopper with material.

2. Move implement to raised position.

3. Apply tractor brakes and lock in applied position.

4. Put transmission in park or in a locked, neutral position.

5. Engage hydraulic system.

6. Run engine at normal operating RPM until hydraulic fluid is

at normal operating temperature.

7. At the Controls screen, press the SPREAD CAL button.

OPERATOR’S MANUAL

16 / CONTROLS ISO6Version 4 Quick Start Guide

6011662 Rev B

8. Press the SHAFT TURN button to fill seed/fertilizer metering

system before starting calibration.

9. At the Calibration screen, enter the following values:

-Density - Enter product weight per volume in lbs/ft3.

-Target Meter RPM - Enter the RPM at which the output

meter shaft will turn during the calibration.

-# of Meter Revs - Enter number of total revolutions the

meter will turn during the calibration. This determines

the length of the test and is more accurate the higher

the number.

10. Place catch container to collect the dispensed material

to be weighed.

11. At the Calibration screen, press the START button.

12. Once calibration is complete, weigh and enter the lbs. of

material dispensed in the Amount Dispensed field.

13. Press the SAVE button.

The new spreader constant automatically calculates and is

entered for this material.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide CONTROLS / 17

6011662 Rev B

Figure 11

Spreader Calibration-Granular

SPREADER CONSTANTS DEFINED

DENSITY

Relative granular density as represented by the weight of

product per volume (lbs/ft3, lbs/bu.) If not known, enter a value

of 1 lb/ft3.

SPREADER CONSTANT

Determines how many pulses the application rate sensor

produces per volume of material discharged.

OPERATOR’S MANUAL

18 / CONTROLS ISO6Version 4 Quick Start Guide

6011662 Rev B

TARGET METER RPM

The speed at which the output meter shaft turns while the

calibration is performed.

NOTE

If performing a Spreader Calibration on a box type drill, catch

the output of a few seed meters, average the weight measured

from these meters, and multiply this average weight by the

total number of meters on the drill. Enter this weight for the

Amount Dispensed value.

NUMBER (#) METER REVS

The number of revolutions the meter turns during the calibration.

This will constitute the length of the test. The higher the number,

the more accurate the calibration.

PULSE COUNT

A pulse count that is produced from the feedback sensor. This

number is informational only.

NEW SPREADER CONSTANT

After the spreader calibration is performed and the amount is

entered, press the SAVE button to accept the new constant.

AMOUNT DISPENSED

Enter the amount (lbs/kg) dispensed after performing the

spreader constant calibration. The amount dispensed number

is used with pulse count and density to calculate the new

spreader constant.

SHAFT TURN

The SHAFT TURN (Figure 15) button turns the shaft one (1)

gear revolution and fills the seed meter for instant seed flow

when the control is turned on.

LIQUID FLOW CALIBRATION

Performing a Limit Output, Valve Calibration, and K-Factor

Calibration are recommended for a Liquid Flow control

channel type.

PERFORM A VALVE CALIBRATION

Follow valve calibration steps 1-10 listed in Planter and Granular

Control section.

OPERATOR’S MANUAL

ISO6Version 4 Quick Start Guide CONTROLS / 19

6011662 Rev B

Figure 12

Liquid Flow Valve Calibration

LIMIT OUTPUT

In certain instances, it is necessary to limit the output of the

control channel before running a valve calibration. System

capacities are greater than the actual desired capacities. These

features allow setting the maximum output of the channel to

prevent machine damage.

Perform a Limit Output:

1. At the Valve Calibration screen, press the

LIMIT OUTPUT button.

2. Move the implement to the “raised” position.

3. Apply the tractor brakes and lock in the applied position.

4. Put the transmission in “park” or in a locked, neutral position.

5. Engage hydraulic system.

6. Run engine at normal operating RPM until hydraulic fluid is

at normal operating temperature.

Table of contents

Other Dickey-John Control Unit manuals

Popular Control Unit manuals by other brands

DBA

DBA LaneWalker operating manual

AQUATROL

AQUATROL POWERFLO Series Service manual

Beijer Electronics

Beijer Electronics SER0060 quick start guide

oventrop

oventrop mote 420 Installation and operating instructions

Grafik Eye

Grafik Eye 3000 Series Installer's guide

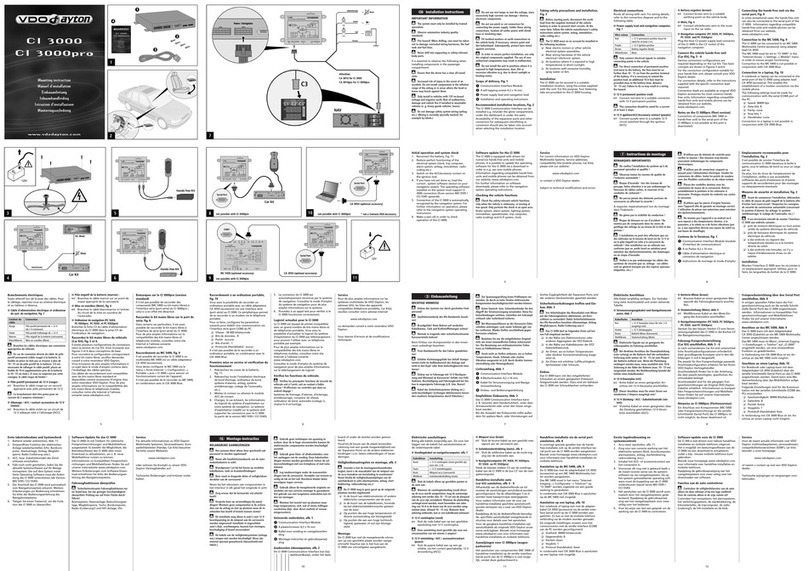

VDO

VDO CI 3000 - COMPATIBILITY LIST Mounting instruction