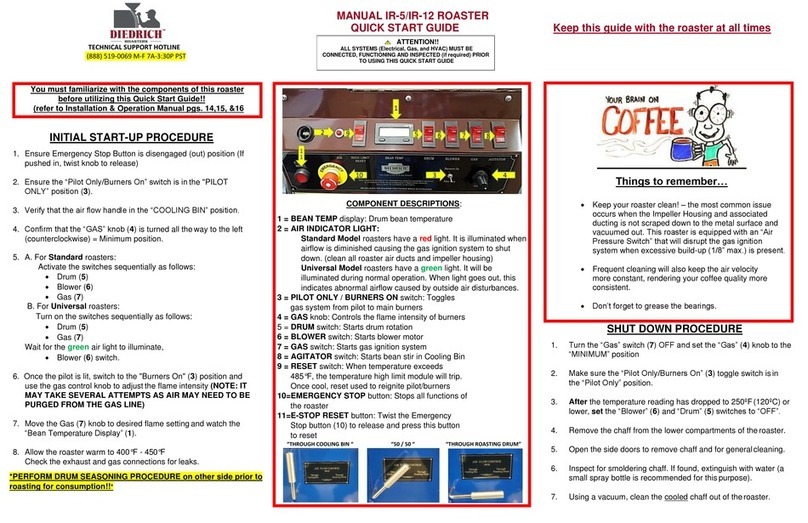

Diedrich Roasters IR Series Configuration guide

IR Series

IR-1, IR-2.5, IR-5, and IR-12

Cleaning, Maintenance & Troubleshooting Guide

2017

Diedrich Roasters LLC, 30620 HWY 200 Ponderay, ID 83852

Telephone: (208) 263-1276 Toll Free: (877) 263-1276 Fax: (208) 265-4584

Technical Support: support@diedrichroasters.com

PROPRIETARY RIGHTS NOTICE: All rights reserved. No part of this material may be reproduced or transmitted in any form or by means,

electronic, mechanical or otherwise, including photocopy and recording or in connection with any information storage or retrieval system, without

the written permission of Diedrich Roasters, LLC.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Please read all sections of this manual and retain for future reference.

•The completed roaster installation MUST BE INSPECTED for compliance to building codes in

your specific location, and by your local fire inspector PRIOR TO operating the roaster. Failure

to have these inspections performed may void the warranty and will relieve Diedrich Roasters

of any liability associated with the installation and use of your machine.

•A fire extinguisher should be located close to the roasting system. Consult with your local fire

department for recommendations on suitable fire extinguishers.

•Proper installation, cleaning, and safe operation of the coffee roaster are the owner’s and

operator’s responsibility.

•This roaster is intended for professional use only and is to be operated by qualified personnel

only. Never permit an unqualified person to operate the roaster.

Instructions to be followed in the event the operator smells gas or otherwise detects a

gas leak must be posted in a prominent location. This information can be obtained

from the local gas company or gas supplier.

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

DANGER

Avoid contact with hot surfaces.

DANGER

Keep the area around the roaster free and clear from combustibles and maintain a

minimum of 18-inches clearance around the roaster at all times.

Always be aware of the risk of a fire. Fires are caused by failure to maintain a clean

roaster and its exhaust duct system.

Table of Contents

1. CLEANING...........................................................................................................................................................2

1.0 Suggested Hand Tools...............................................................................................................................2

1.1 Lubricants Required / Where Used:.........................................................................................................2

2. CLEANING POINTS...........................................................................................................................................2

2.1 Cyclone Chaff & Chaff Collection Compartment....................................................................................3

2.2 Blower Fan...................................................................................................................................................5

2.3 Impeller Compartment (IR-5 & IR-12 ONLY)..........................................................................................6

2.4 Vacuum Sensor Tube.................................................................................................................................9

2.5 Air Flapper................................................................................................................................................. 10

2.6 Cooling Bin................................................................................................................................................ 11

2.7 Infrared Burner Compartment................................................................................................................ 18

2.8 Burner & Drum Tray Access Doors....................................................................................................... 19

2.9 Rear Ducting............................................................................................................................................. 20

2.10 Air Box (IR-1 and IR-2.5 ONLY)............................................................................................................ 22

2.11 Exhaust Ducting....................................................................................................................................... 23

3. MAINTENANCE PROCEDURES.................................................................................................................. 24

3.1 Suggested Hand Tools............................................................................................................................ 24

3.2 Lubricants Required / Where Used:...................................................................................................... 24

3.3 Roasting Drum Drive Chain (IR-2.5 ONLY)......................................................................................... 24

3.4 Lubricate Drum Bearing(s) ..................................................................................................................... 26

3.5 Lubricate Drum Drive Chain (For roasters with chain drive motors ONLY).................................... 27

3.6 Agitator Drive Shaft Coupling................................................................................................................. 27

3.7 Air Flow Control Lever (Manual roasters only).................................................................................... 28

4TROUBLESHOOTING AND FAQ’s .............................................................................................................. 29

Page 1of 31

Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in bordered boxes similar to the ones

below.

CAUTION

WARNING

DANGER

CAUTION

CAUTION boxes contain information about actions or conditions that may cause

or result in a malfunction of your system.

WARNING boxes contain information about actions or conditions that may

cause or result in damage to your system, and which may cause your system to

malfunction.

DANGER

DANGER boxes contain information about actions or conditions that may cause

or result in injury to personnel, and which may cause damage to your system

and/or cause your system to malfunction.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 2of 31

SAFEGUARDS

Proper installation, cleaning and safe operation of the coffee roaster and ancillary equipment is the owner

and operator’s responsibility.

Ensure the coffee roaster is cool to the touch prior to cleaning or servicing.

Wear protective gloves and eyewear when scraping residue off of internal walls and components.

Do not use a water hose or any type of sprayer other than a normal cleaning bottle for the purposes of

cleaning.

At a minimum, the Cleaning & Maintenance Schedule found at the back of this manual should be completed as

directed.

1. CLEANING

1.0 Suggested Hand Tools

•Allen wrench (at a minimum): 3/16”, 3/32”, 5/32”, 1/8”

•Wrenches: 7/16” 5/8”, 1/2”, 5/16”

•Phillips 3-inch screwdriver #2, and #3

•Flathead screwdriver,

•Socket set,

•Slotted screwdriver,

•Nut driver 5/16-inch,

•Grease gun (cartridge type),

•Wire brush,

•Small spray bottle,

•Putty knife (flexible),

•Pry bar

•Small hammer

•Vacuum Cleaner (with reversible airflow)

1.1 Lubricants Required / Where Used:

•High Temperature Food Grade Grease (Available for purchase from Diedrich Manufacturing) / Use on

bearing, agitator, and impeller.

•SAE20 non-detergent oil or sewing machine oil / Use on chain driven motor ONLY,

•WD-40 spray lubricant / Use on hinges.

2. CLEANING POINTS

ATTENTION

All motors are sealed and should not require service.

ALWAYS disconnect roaster at electrical source (at the circuit breaker or safety

shut-off switch) before servicing.

DANGER

Electrical Power MUST be Disconnected and Locked Out.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 3of 31

IR-5/IR-12 Roaster Representation

2.1 Cyclone Chaff & Chaff Collection Compartment

The cyclone and chaff collection compartment’s function is to collect the chaff that separates from the

coffee during the roasting process. These areas fill up quickly and require frequent emptying. Residue will

accumulate on the metal surfaces within the compartment.

Use a wire brush or scraping tool to scrape off any residue, down to bare metal. Diedrich Roasters

recommends cleaning these areas after 4-hours of roasting.

DANGER

Make sure the chaff inside the cyclone and/or chaff collection compartment is

cool to the touch and contains no hot embers before vacuuming. Vacuuming

hot embers may start a fire and/or cause personal injury.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 4of 31

IR-1 & IR-2.5

IR-5 & IR-12

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 5of 31

2.2 Blower Fan

2.2.1 IR-1 & IR-2.5 ONLY

IR-1 & IR-2.5 Blower Fan

2.2.2 Unscrew the two Phillips head screws that secure the duct to the blower housing

2.2.3 NOTE: There may be a line of caulk used to secure the top and bottom parts of the

blower housing. Carefully remove the caulk from the housing. Once the screws have

been taken out, remove the duct from the blower housing.

2.2.4 Remove the four Phillips head screws from the top plate of the blower housing.

2.2.5 Lift the top plate and motor off of the housing.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 6of 31

2.2.6 Being careful to not bend the impeller blades, clean the fan with a wet rag.

2.2.7 Reassemble the blower cover in the reverse order making sure to reapply caulk if

necessary.

2.3 Impeller Compartment (IR-5 & IR-12 ONLY)

CAUTION

Do not spray any kind of liquid directly onto the fan.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 7of 31

2.3.1 Unscrew the two wingnuts securing the impeller cover

2.3.2 Remove the cover from the impeller compartment.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 8of 31

2.3.3 Clean out the set screw holes.

NOTE: Prior to removing the impeller, measure the gap between the impeller and the housing to

ensure the position on the shaft doesn’t change when you reinstall it.

2.3.4 Using a 5/32” Allen wrench, unscrew the set screws (NOTE: It may be necessary to use a

penetrating oil such as Liquid Wrench to assist in removing the set screws.)

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 9of 31

2.3.5 Grab the impeller firmly with both hands and pull it towards you. (NOTE: It may be

necessary to pry the impeller loose using a flathead screwdriver or pry bar depending on

the state of cleanliness.)

2.3.6 After thoroughly cleaning the impeller, apply anti-seize to the motor shaft before

reinstalling it.

2.3.7 Reinstall the impeller on the motor shaft in the same location.

2.3.8 Insert and tighten the set screw on the keystock of the shaft first. This set screw should

be screwed in as tight as possible.

2.3.9 Being careful to not over-tighten the screw, insert and tighten the second set screw that

sits on the round portion of the shaft.

2.3.10 Reinstall the impeller cover and tighten the two wing nuts.

2.3.11 Spin the impeller by hand to make sure it doesn’t interfere with the cover. If there is

interference, a slight adjustment will be required.

2.4 Vacuum Sensor Tube

The vacuum sensor tube (IR-5 & IR-12 –aluminum; IR-1 & IR-2.5 –black plastic) hangs above the

impeller in the blower compartment or in the side of the cyclone if you have one. The tube

connects directly to the vacuum sensor which is monitoring the air pressure in the roaster system

–the sensor does not suck or blow so debris is usually lodged right at the termination point. The

vacuum tube’s purpose is to measure pressure within the impeller compartment. If it is clogged

with oily residue the roaster will fail to ignite. This is a built-in safety feature. The air light on the

switch panel illuminates if the tube becomes clogged.

Example of a dirty sensor tube.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 10 of 31

IR-5/12 Vacuum Sensor Location

2.4.1 Locate the aluminum tube in the impeller compartment.

2.4.2 NOTE: Do not use a vacuum cleaner to clean the tube. If any debris or residue is

evident, clean the inside of the tube using a thin tool or wire to pull the residue through the

tube.

2.4.3 Use a wire brush or scotch-brite pad to clean the outside of the sensor if necessary.

IR-1 IR-2.5

2.4.4 NOTE: Do not use a vacuum cleaner to clean the tube. Use a small pointed object, like

a paperclip, to clean out any debris that may have accumulated in the vacuum tube opening.

2.5 Air Flapper

Vacuum Sensor Tube

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 11 of 31

The air flapper is located in the blower compartment to the top left. As you change your air position

from cooling bin to 50/50 to through the roasting drum, this flapper rotates to direct the air through

a different section of the roaster.

IR-5/12 Air flapper

2.5.1 Scrape the flapper down to metal on all sides.

2.5.2 Scrape the side walls down to help with smooth movement.

2.6 Cooling Bin

The cooling bin’s function is to cool the fresh roasted beans before processing for storage, blending,

packaging, etc. Proper air-flow through the cooling bin is critical to rapidly cool the beans and arrest

any further roast development.

Dirty Cooling Bin Screen

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 12 of 31

2.6.1 IR-1 and IR-2.5

For cooling efficiency and to minimize a fire hazard, the area below the screen must be cleaned.

For roasters without agitators:

2.6.1.1 Lift the cooling bin from the roaster frame by simply lifting the cooling bin up and sliding it

away from the roaster.

For roasters with agitators:

2.6.1.2 Pry off the cap on top of the agitator hub.

2.6.1.3 Using a 3/16” hex key, remove the screw under the cap.

2.6.1.4 Lift the hub to remove the agitator.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 13 of 31

2.6.1.5 Tilt the front edge of the cooling bin up.

2.6.1.6 Slide the cooling bin to the right.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 14 of 31

2.6.1.7 Guide the cooling bin up and over the agitator motor shaft.

2.6.1.8 Use a wire brush or screen cleaning tool to dislodge debris from the screen.

2.6.1.9 Thoroughly clean both sides of the screen (at a minimum of every six months.).

2.6.1.10 Vacuum any chaff from under the cooling bin.

2.6.1.11 Re-install the cooling bin and agitator in the reverse order.

Example of a Clean IR-1 & IR-2.5 Cooling Bin Screen

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 15 of 31

2.6.2 IR-5 and IR-12 Cooling Bin

(NOTE: The agitator arm assembly is held in place by its own weight. There is not a set

screw or bolt securing it to the gearbox shaft.) Place one hand on each side of the

horizontal agitator arm and lift the whole agitator assembly up.

2.6.2.1 Use a wire brush or screen cleaning tool to dislodge debris from the screen.

2.6.2.2 Thoroughly clean both sides of the screen (at a minimum of every six months.).

2.6.2.3 Vacuum any chaff from under the cooling bin.

Place both hands

under the agitator

horizontal shaft and

lift up.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 16 of 31

Reassembly

2.6.3 Apply a lubricant such as food grade grease or anti-seize to the gearbox shaft

2.6.4 Reinstall the agitator on the agitator shaft.

Align the channel on the

shaft with the square key

inside the agitator hub and

push down until the hub is

seated on the Teflon ring.

Apply Anti-Seize to the shaft

before putting the agitator

back in place.

Diedrich Roasters Maintenance, Cleaning & Troubleshooting Guide

Page 17 of 31

Example of a Clean IR-5 & IR-12 Cooling Bin Screen

Other manuals for IR Series

1

This manual suits for next models

4

Table of contents

Other Diedrich Roasters Commercial Food Equipment manuals