Diedrich Roasters IR Series User manual

IR Series

(IR-1, IR-2.5, IR-5, & IR-12)

Installation & Operation Manual

2019

Diedrich Roasters LLC, 850 Hawthorne Ave., Ponderay, ID 83852

Telephone: (208) 904-1989 Toll Free: (844) 343-3742 Fax: (208) 417-1552

Technical Support: support@diedrichroasters.com

PROPRIETARY RIGHTS NOTICE: All rights reserved. No part of this material may be reproduced or transmitted in any form or by

means, electronic, mechanical or otherwise, including photocopy and recording or in connection with any information storage or

retrieval system, without the written permission of Diedrich Roasters, LLC.

Please read all sections of this manual and retain for future reference.

•The completed roaster installation MUST BE INSPECTED for compliance to building

codes in your specific location, and by your local fire inspector PRIOR TO operating

the roaster. Failure to have these inspections performed may void the warranty and

will relieve Diedrich Roasters of any liability associated with the installation and use of

your machine.

•A fire extinguisher should be located close to the roasting system. Consult with your

local fire department for recommendations on suitable fire extinguishers.

•Proper installation, cleaning, and safe operation of the coffee roaster are the owner’s

and operator’s responsibility.

•This roaster is intended for professional use only and is to be operated by qualified

personnel only. Never permit an unqualified person to operate the roaster.

Instructions to be followed in the event the operator smells gas or otherwise

detects a gas leak must be posted in a prominent location. This information can

be obtained from the local gas company or gas supplier.

Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and

maintenance instructions thoroughly before installing or servicing this

equipment.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the

vicinity of this or any other appliance.

DANGER

Avoid contact with hot surfaces.

DANGER

Keep the area around the roaster free and clear from combustibles and maintain

a minimum of 18-inches clearance around the roaster at all times.

Always be aware of the risk of a fire. Fires are caused by failure to maintain a

clean roaster and its exhaust duct system.

Table of Contents

1. SAFEGUARDS.................................................................................................................................1

2. SPECIFICATIONS............................................................................................................................2

3. INSTALLATION INSTRUCTIONS....................................................................................................8

3.1 RECEIVING AND UNPACKING SHIPMENT................................................................................8

3.2 LEVELING.....................................................................................................................................8

3.3 PROXIMITY TO WALLS...............................................................................................................8

4. GAS INSTALLATION.......................................................................................................................9

4.1 SAFETY SHUT-OFF VALVE ........................................................................................................9

4.2 PRESSURE REGULATOR.........................................................................................................10

4.3 PIPE SIZING...............................................................................................................................10

4.4 GAS INSTALLATION..................................................................................................................11

5. ELECTRICAL INSTALLATION......................................................................................................11

6. CYCLONE TO ROASTER CONNECTIONS ..................................................................................12

6.1 ROASTER EXHAUST DUCTING ...............................................................................................12

6.2 INSTALLATION INSPECTION....................................................................................................13

7. OPERATIONS.................................................................................................................................14

7.1 ROASTER PARTS......................................................................................................................14

7.2 AIR FLOW POSITIONS ..............................................................................................................14

7.3 OPERATOR CONTROL PANEL.................................................................................................15

7.4 COMPONENT DESCRIPTION...................................................................................................15

8. INITIAL START-UP ........................................................................................................................16

8.1 LIGHTING THE PILOT BURNER ...............................................................................................16

9. ROASTING .....................................................................................................................................17

9.1 SEASONING THE DRUM...........................................................................................................18

9.2 ROASTING FOR CONSUMPTION.............................................................................................19

9.3 SHUT DOWN..............................................................................................................................21

10. ROASTING LOG ............................................................................................................................21

11. CLEANING......................................................................................................................................22

11.1 EVERY 4 HOURS.......................................................................................................................23

11.2 DAILY..........................................................................................................................................23

11.3 EVERY 40 HOURS.....................................................................................................................23

Page 1 of 23

1. SAFEGUARDS

Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in bordered boxes similar to

the ones below.

CAUTION

WARNING

DANGER

CAUTION

CAUTION boxes contain information about actions or conditions that may cause

or result in a malfunction of your system.

WARNING boxes contain information about actions or conditions that may

cause or result in damage to your system, and which may cause your system to

malfunction.

DANGER

DANGER boxes contain information about actions or conditions that may cause

or result in injury to personnel, and which may cause damage to your system

and/or cause your system to malfunction.

Page 2 of 23

2. SPECIFICATIONS

Description

Unit of Measure

IR-1

IR-2.5

IR-5

IR-12

Roast Capacity Range

lbs

5.29oz / 2.2

1-5.5

1 - 10

1 - 26.4

(minimum batch by

temperature)

kg

150g / 1

.454 / 2.5

.453 - 5

.454 - 12

* Hourly Roast Output

lbs

6.6

16.5

33

79.4

(based on 20 min cycle)

kg

3

7.5

15

36

Roaster Weight Empty

lbs

125

250

880

960

kg

56.8

113.6

400

437

Floor Bearing Weight

lbs

135

265

895

990

with maximum load of

beans

kg

61.4

120.5

407

450

Space Required at

base of roaster

inches

40 x 30

29 x 50

62 x 86

66 x 92

(includes exhaust air

outlet)

centimeters

101.6 x 76.2

73.7 x 127

158 x 219

168 x 234

Input Gas Pressure

“WC

10-12

10-12

10-12

8 - 9

Natural Gas

MBAR

25 - 30

25 - 30

25 - 30

20 –22.4

Input Gas Pressure

“WC

12 - 14

12 - 14

12 - 14

12 - 14

Liquid Propane Gas

MBAR

30 - 34.8

30 - 34.8

30 - 34.8

30 - 34.8

Gas Consumption

BTU/Hour

8000

24000

50000

90000

(maximum rate)

Kilowatts

2.34

6.15

14.65

26.38

Gas Consumption

per roast

BTU/Roast

1685

4195

9795

18675

(estimated rate)

Kilowatts

0.5

1.23

2.9

5.5

Gas Supply Inlet

Diameter (NPT)

inches

½ NPT

½ NPT

½ NPT

½ NPT

Electrical Supply

Volts AC –60 Hz

110

110

110

110

Volts AC –50 Hz

220

220

220

220

Full Load Amperage

110 V AC

2.0

7.2

13

16

230 V AC

1.5

3.1

7

10

Exhaust Duct Air Flow

(50hz-60hz)

SCFM

32-65

113-130

236-290

285-365

(Range depends on air

control position)

m3/h

54-110

192-221

401-493

484-620

Exhaust Duct

Diameters

inches

4

6

8

8

centimeters

10.16

15.24

20.32

20.32

Basic Specifications

Page 3 of 23

IR-1

IR-2.5

Page 4 of 23

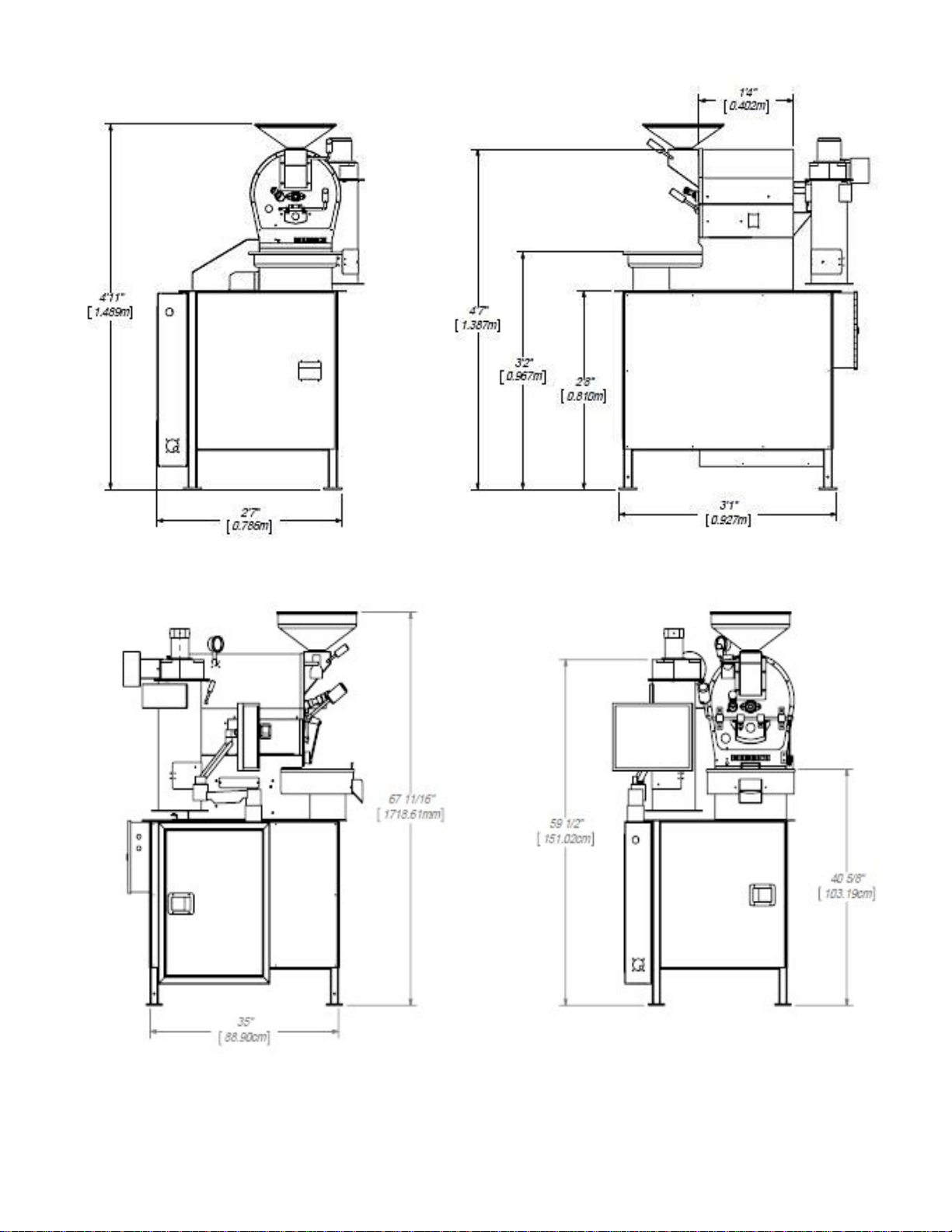

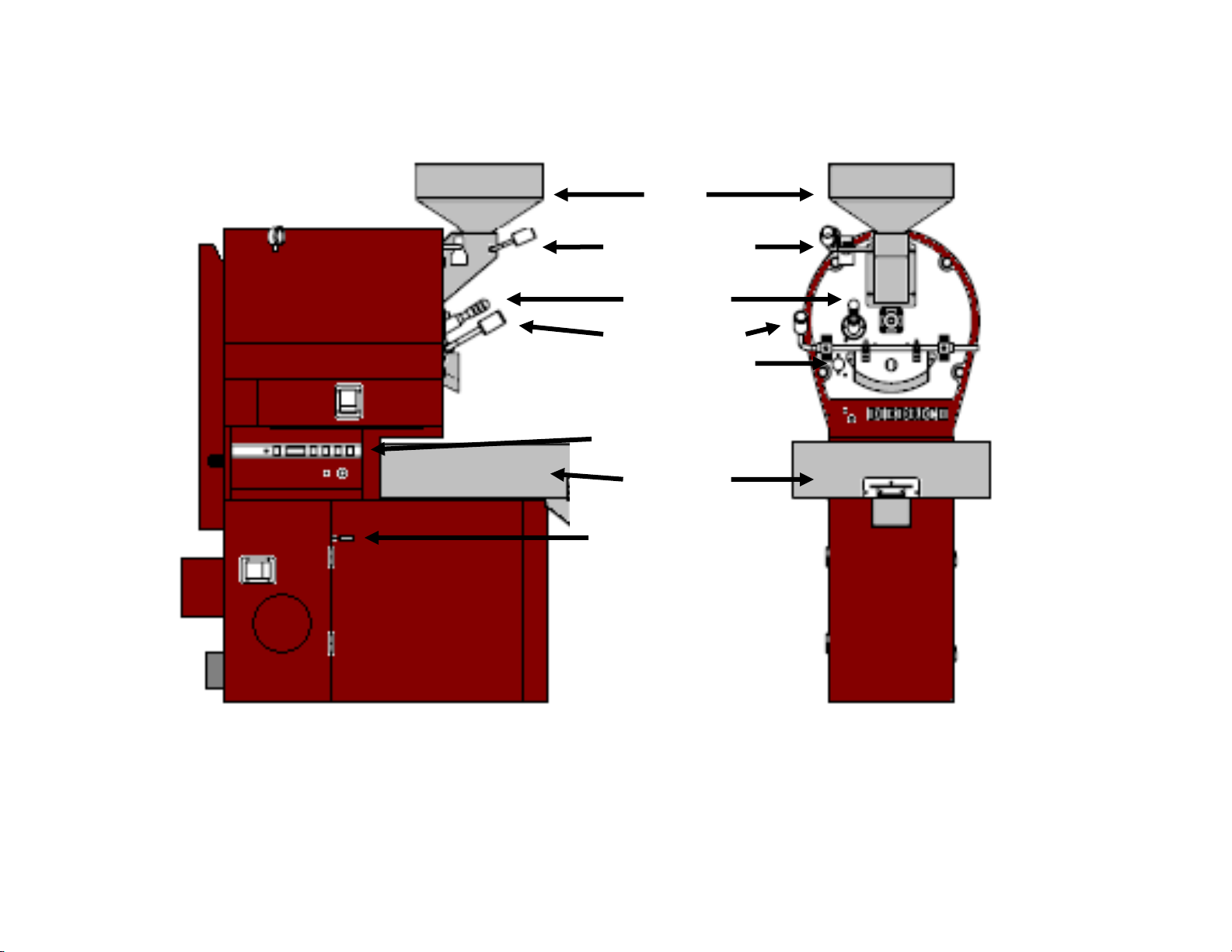

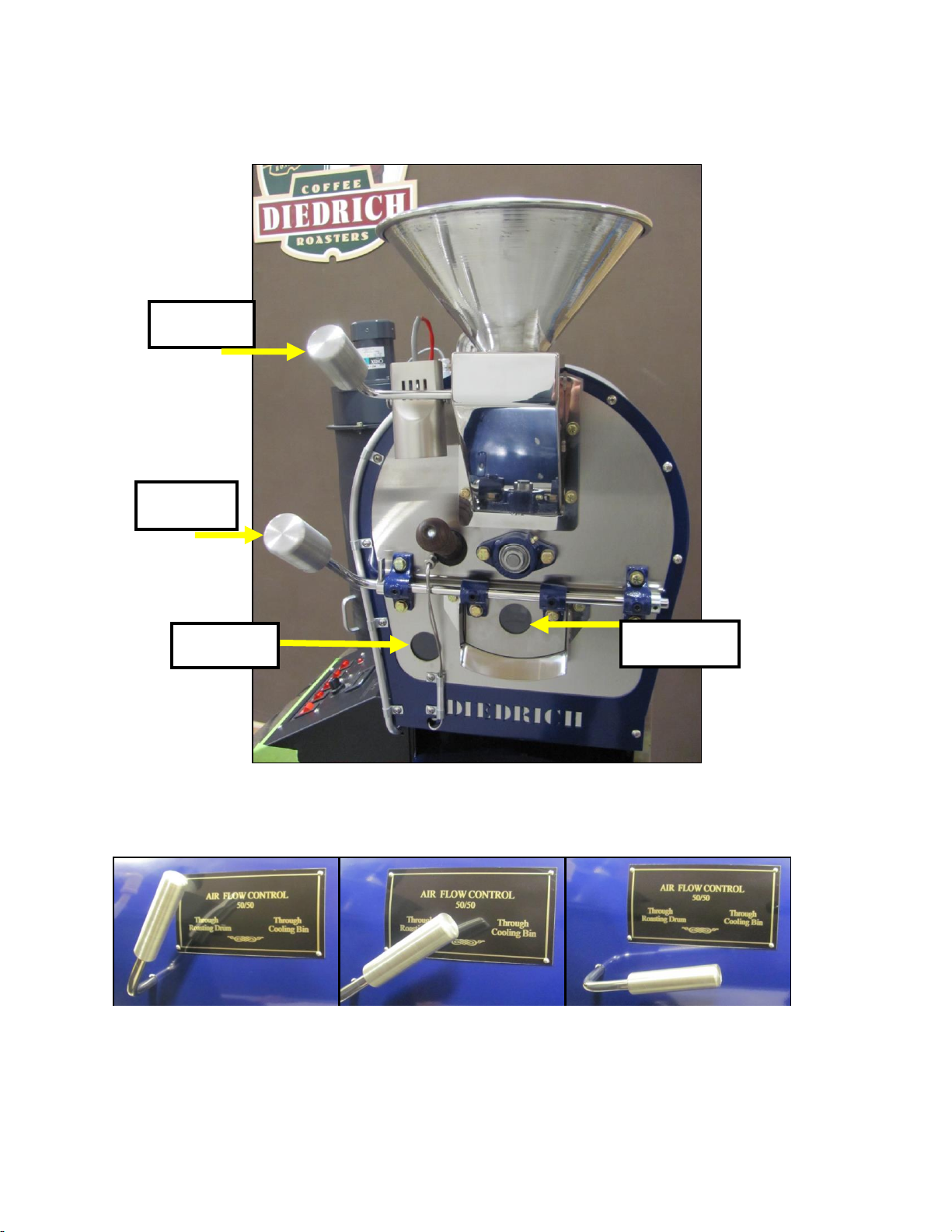

IR-5 & IR-12 Roaster Components

Funnel

Hopper gate handle

Sample trowel

Drum door handle

Burner view window

Operator control panel

Cooling bin

Airflow control handle

Page 5 of 23

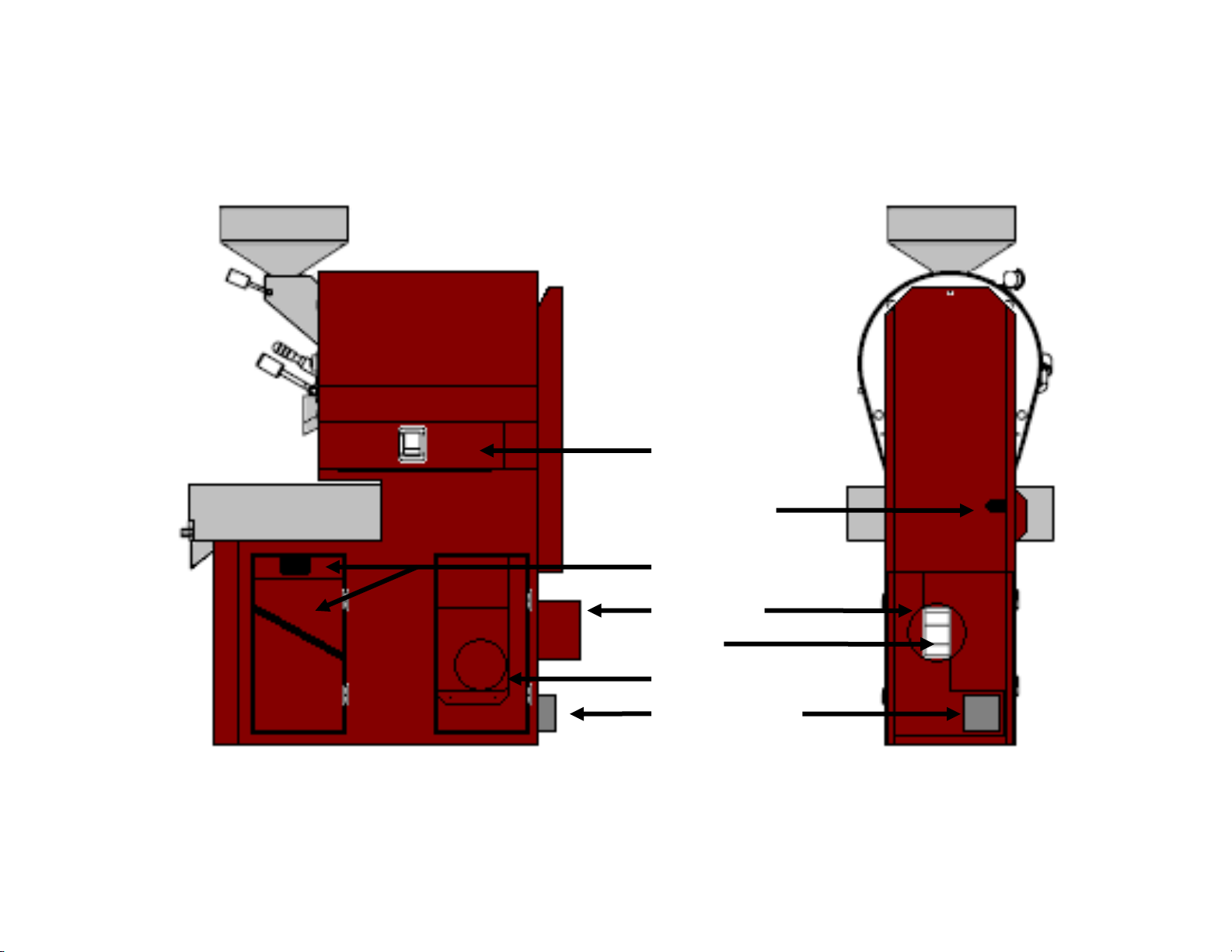

IR-5 & IR-12 Roaster Components

Burner & chaff tray

access door

Gas supply inlet

Cooling bin tray &

chaff compartment

Exhaust outlet

Impeller

Fan shroud

6” x 6” electrical box

Page 6 of 23

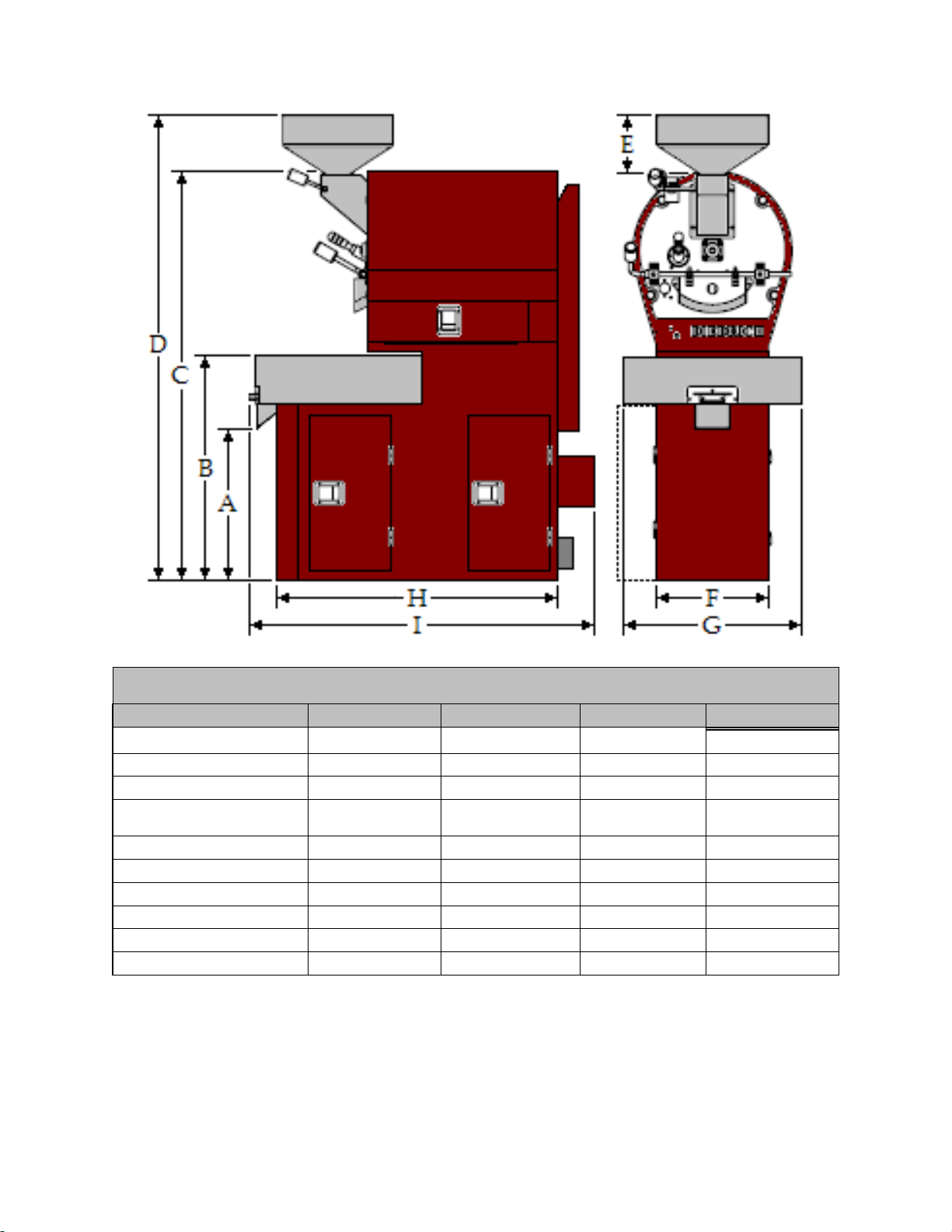

Roaster Dimensions

Inches / Centimeters

IR-1

IR-2.5

IR-5

IR-12

A: Chute Height

NA

8-3/4”/22.22cm

24.5" / 62.2cm

24.5" / 62.2cm

B: Bin Height

32” / 81.28cm

41” / 104.14cm

35.25" / 89.5cm

36.25" / 92.1cm

C: Roaster Height

55” / 139.7cm

59.5”/151.02cm

64" / 162.5cm

66.5" / 168.9cm

D: Roaster Overall Height

with Funnel

59” / 149.86cm

66”/151.02cm

70.5" / 179.1cm

77" / 195.6cm

E: Funnel Height

8” / 20.32cm

8” / 20.32cm

6.5" / 16.5cm

10.5" / 26.7cm

F: Compartment Width

13-1/4”/33.65cm

13-1/4”/33.65cm

18" / 45.7 cm

18" / 45.7cm

G: Cooling Bin Diameter

14-1/2”/36.83cm

16” / 40.64cm

25" / 63.5cm

29" / 73.66cm

G: Overall Width

28”/71.12cm

28”/71.12cm

26.5” / 67.3cm

29" / 73.66cm

H: Compartment Length

37”/93.98cm

37”/93.98cm

42" / 106.7cm

45" / 114.3cm

I: Overall Length

43”/109.22cm

43”/109.22cm

50" / 127cm

55" / 139.7cm

Page 7 of 23

Installation Hook-up Dimensions for Exhaust Duct and Electrical Junction Box

Roaster Models - Dimensions in Inches / Centimeters

IR-1

IR-2.5

IR-5

IR-12

A: Exhaust Air Outlet Height

47”/1193.8

55.5”/1409.7

16” / 44.5mm

16” / 44.5mm

B: Exhaust Air Outlet (Centerline

from back left side)

4”/101.60

6”/152.40

7.5” / 19.1mm

7.5” / 19.1mm

C: Electrical Junction Box Height

9”/228.60

9”228.60

9” / 22.8mm

9” / 22.8mm

D: Gas Inlet

1.55”/3.94

1.70”/4.32

30.5” / 77.5mm

30.5” / 77.5mm

Non-restrictive

exhaust cap

Check with local

codes and duct

manufacturer for

clearances to

walls

Minimum 8” clearance for

access to roaster components

Page 8 of 23

3. INSTALLATION INSTRUCTIONS

3.1 RECEIVING AND UNPACKING SHIPMENT

Upon receipt of your roaster immediately check for crate damage. Do not refuse shipment if damage is

evident. Make notes of damage on the appropriate shipping forms and take photos. Uncrate and look for

damage to the roaster; i.e., dents, scratches or chipped paint, and if found, immediately file a claim with the

appropriate freight carrier.

Locate the roaster where operation and coffee roasting can be observed in natural light or under consistent

light conditions. Natural light is essential for best results when observing the true color changes coffees

undergo during roasting. The use of a full-spectrum fluorescent light to simulate the full color of sunlight is

recommended for consistency in roasting.

After uncrating your roaster, if it becomes evident that movement may be hindered while moving it to its

installation location, detach and remove the cooling bin.

If the roaster is automated, mount the computer monitor onto the arm using the supplied Allen key.

3.2 LEVELING

The floor must meet weight-bearing requirements of local codes. Refer to the specifications chart for floor

bearing weights.

3.3 PROXIMITY TO WALLS

Failure to abide by required clearances will void your Diedrich warranty. No cabinets or storage areas are

to be installed over the roaster or near the ducting.

Make sure all controls, access doors, and inspection panels are accessible and can be opened without

restriction.

ATTENTION

Professional installation is required. Your Diedrich Roaster is designed for ease of installation and

simplicity of operation. Read these instructions completely before starting installation. Your local

building authority should be contacted to obtain local codes and installation requirements before

installing your roaster.

DANGER

Clearance from the roaster to adjacent walls, counters or other appliances must be at

least 18-inches (46 cm) or greater to ensure adequate cooling of the roaster and

adjacent walls.

This roaster MUST be installed on a flat/level, and noncombustible floor.

Page 9 of 23

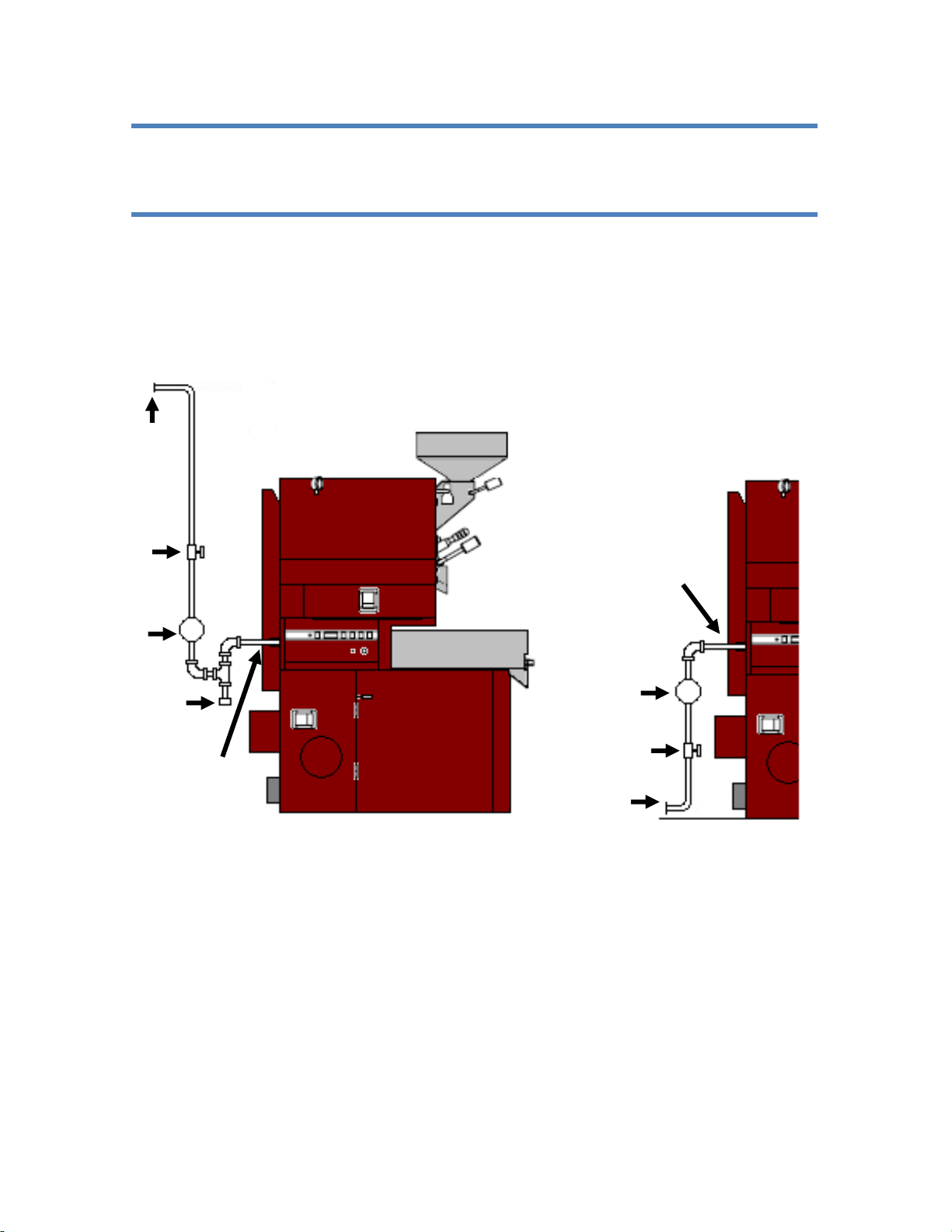

4. GAS INSTALLATION

Gas installation MUST conform to local codes, regulations, and/or laws.

The gas supply line MUST be sized to accommodate the total length of the run and to accommodate any

required elbows. The line MUST be no less than the roaster's inlet size.

A water trap to collect condensation and loose particles should be installed in the gas supply line upstream

from the roaster.

Possible installation of Gas Lines

4.1 SAFETY SHUT-OFF VALVE

A safety shut-off valve MUST be installed in the gas supply line close to the roaster and pressure

regulator and in a location where it can be reached quickly in case of an emergency. The shut-off

MUST be marked to identify it as the gas shut-off.

Gas

shut-off

valve

To gas source

Pressure

regulator

Condensation

trap

Roaster gas inlet

Roaster gas inlet

To gas source

Gas

shut-off

valve

Pressure

regulator

ATTENTION

Use a licensed gas company for the gas line installation.

Page 10 of 23

4.2 PRESSURE REGULATOR

The roaster’s factory installed valve is preset for the BTU requirements of the roaster burners. The

valve in the roaster is not intended to reduce incoming pressure. A pressure regulator MUST be

installed before the roaster to reduce the incoming pressure. Your gas technician will be able

to provide the correct regulator for the specific installation.

Locate the regulator on the incoming gas supply line between the safety shut-off valve and the

roaster’s gas inlet. Diedrich recommends 8 to 14 inches WC (20 – 34.8 mbars) for natural gas and

12 to 14 inches WC (30 –34.8 mbars) for liquid propane at the roaster’s gas inlet. These pressures

are ideal for optimal performance.

NOTE: The manometer on top of the roaster measures the burner manifold pressure and not the

incoming pressure. When the burners are set at maximum gain the manometer should read

approximately 7-inches WC (16 mbars) for natural gas and 11-inches WC (27.4 mbars) for liquid

propane.

4.3 PIPE SIZING

IMPORTANT: When the gas installation is complete have your gas technician check the gas pressure at

the point where the gas line connects to the roaster. The roaster and/or afterburner and any other

appliances connected to the gas line should be running at the full flame setting for this test (See Orifice

Sizes and Testing Specifications table below).

The valve may experience damage if the incoming line pressure to the roaster

exceeds 20-inches WC (50 mbars). An external pressure regulator is required to

limit incoming gas pressure.

Sizing of the gas supply line is critical to the roasters performance. Ensure the gas

supply line is sized in accordance with the maximum BTU demands of the roaster and

any other appliances connected to the gas line.

The roaster must be isolated from the gas supply line by closing the safety shut-off

valve during any pressure testing of the gas supply line.

If the installation has both a roaster and an oxidizer, a separate incoming

pressure regulator MUST be used for each piece of equipment.

Page 11 of 23

Roaster

Gas

Orifice

Max Manifold

Pressure

Inlet Pressure

Gas

Consumption

High Fire Allowable

Range

"WC

mbar

"WC

mbar

BTU/Hr

KW

Plus 5%

Minus 5%

IR-12

LP

1.9mm

11

27

12 - 14

30 - 35

90,000

26

85,500.00

94,500.00

N

35

6

15

8 - 9

20 - 22.5

90,000

26

85,500.00

94,500.00

IR-5

LP

1.45mm

11

27

12 - 14

30 - 35

50,000

15

47,500.00

52,500.00

N

47

7

17

10 - 12

25 - 30

50,000

15

47,500.00

52,500.00

IR-2.5

LP

59

11

27

12 - 14

30 - 35

24,000

7

22,800.00

25,200.00

N

55

7

17

10 - 12

25 - 30

24,000

7

22,800.00

25,200.00

IR-1

LP

64

11

27

12 - 14

30 - 35

10,000

3

9,500.00

10,500.00

N

55

7

17

10 - 12

25 - 30

10,000

3

9,500.00

10,500.00

4.4 GAS INSTALLATION

Before placing the roaster in operation, always check connections for gas leaks with a soapy water

solution or other acceptable method.

Do not remove any labels, warnings or rating plates from the roaster or from its components as this

may void manufacturer's and Diedrich Roaster’s warranties.

5. ELECTRICAL INSTALLATION

Electrical installation must conform to local regulations. Some roasters must be hard-wired (pipe

conduit with grounding wire) from the electrical source to the roaster.

Do not remove any labels, warnings or rating plates from the roaster or from its components as this

may void manufacturer's and Diedrich Roaster’s warranties.

Some automated roasters have the ability to control optional equipment (i.e., loader and/or

destoner. Each of these options will require an additional dedicated circuit separate from

the roaster circuit.

ATTENTION

Use a licensed electrician for the electrical installation.

DANGER

DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS!

DANGER

This roaster must be electrically grounded in accordance with local codes. A

severe shock hazard exists if the electrical source is not grounded or if the

polarity is reversed.

Page 12 of 23

All electrical components supplied in the roaster are grounded electrically to the roaster frame.

6. CYCLONE TO ROASTER CONNECTIONS

(Applies to IR-1 & IR-2.5 ONLY) Connect the blower motor cord as shown in the photo below.

6.1 ROASTER EXHAUST DUCTING

One of the most important aspects of the roaster installation is the use of an approved ducting system. Its

design will greatly affect the performance of the roaster and the product quality. Two considerations when

designing a ducting system are the static pressure and the distance the ducting is to combustible/non-

combustible materials.

All makes of roasters and oxidizers have a blower mounted inside which forces exhaust air into the ducting.

The oils and residues in the exhaust air are flammable. In the event of a ducting/flue fire, the internal duct

temperatures can exceed 1000° F (538°C), which could cause nearby combustible materials to ignite. For

this reason, Diedrich recommends, at a minimum, stainless steel, double wall, positive pressure grease

ducting (UL certified for USA and Canada, or CE for European Union).

•ROASTER: Ducting must be suitable for 1000°F (538°C) continuous and 1400°F (760°C)

intermittent operating temperatures.

•OXIDIZER: Ducting must be suitable for 1400°F (538°C) continuous.

Attach the blower motor cord to the

receptacle on the motor assembly.

DANGER

A safety shut-off must be installed in the electrical supply line near the roaster‘s

junction box where it is easily accessible by the operator.

Page 13 of 23

The exhaust system must be designed to operate with a static flue pressure between negative 0.15”WC

and positive 0.25”WC at the exhaust of the roaster while in operation.

Check local codes to determine the requirements specific to your location.

Designing an exhaust system requires a trained professional to calculate the efficiency of the system and

proper size of duct. The ducting must be of sufficient diameter to accommodate the SCFM (standard cubic

feet per minute) or SCMH (standard cubic meters per hour) of airflow. A licensed Heating, Ventilation, Air

Conditioning (HVAC) professional can assist you with the best ducting layout for your site. Pertinent

information relating to the diameter of the exhaust ducting on the roaster and the maximum exhaust air flow

in SCFM is located in the Basic Specifications table at the beginning of this manual.

When venting your roaster, a direct vertical run is typically the most efficient and cost effective. The design

of the building may dictate the use of 45° or 90° elbows which will put a restriction on the airflow and may

cause unwanted backpressure on the roaster. If spacing permits, use two 45° elbows rather than a 90°

elbow to reduce restriction. A booster fan may be needed to assist air movement if the system is too

restrictive. A qualified ducting contractor/engineer will determine the best design for your specific

installation.

The roaster MUST NOT support the weight of the exhaust system. Ducting must be connected to the

roaster based on the ducting manufacturer’s recommendation.

A properly designed and installed chimney and rain cap is essential to the overall design. Water leaking in

may cause an electrical short or damage the equipment. Your contractor will be able to coordinate with

local jurisdictions for the correct cap. The cap should not have a screen since it will clog with residue of

chaff over time.

Consult the services of a ducting manufacturer to determine the best venting option for your setup. Your

HVAC installer may also have a recommendation or preferred manufacturer. Positive pressure grease

vents are not an off-the-shelf product so plan ahead to compensate for long lead times.

6.2 INSTALLATION INSPECTION

DANGER

DO NOT USE CLASS B OR SPIRAL-WRAP DUCTING UNDER ANY CIRCUMSTANCES.

DANGER

Fires are caused by failure to maintain a clean roaster and its exhaust ducting

system. Regular cleaning of the roaster and exhaust ducting will prevent the

buildup of residues that could cause fire.

ATTENTION

The completed roaster installation MUST BE INSPECTED for compliance to codes and by your local fire

department PRIOR TO OPERATING THE ROASTER. Failure to have these inspections performed will

void the warranty and will relieve Diedrich of any liability associated with the installation and use of our

products.

Page 14 of 23

7. OPERATIONS

7.1 ROASTER PARTS

7.2 AIR FLOW POSITIONS

“Through Roasting Drum” “50/50” “Through Cooling Bin”

Drum Door

View Window

Burner View

Window

Hopper

Gate Handle

Drum Door

Handle

Page 15 of 23

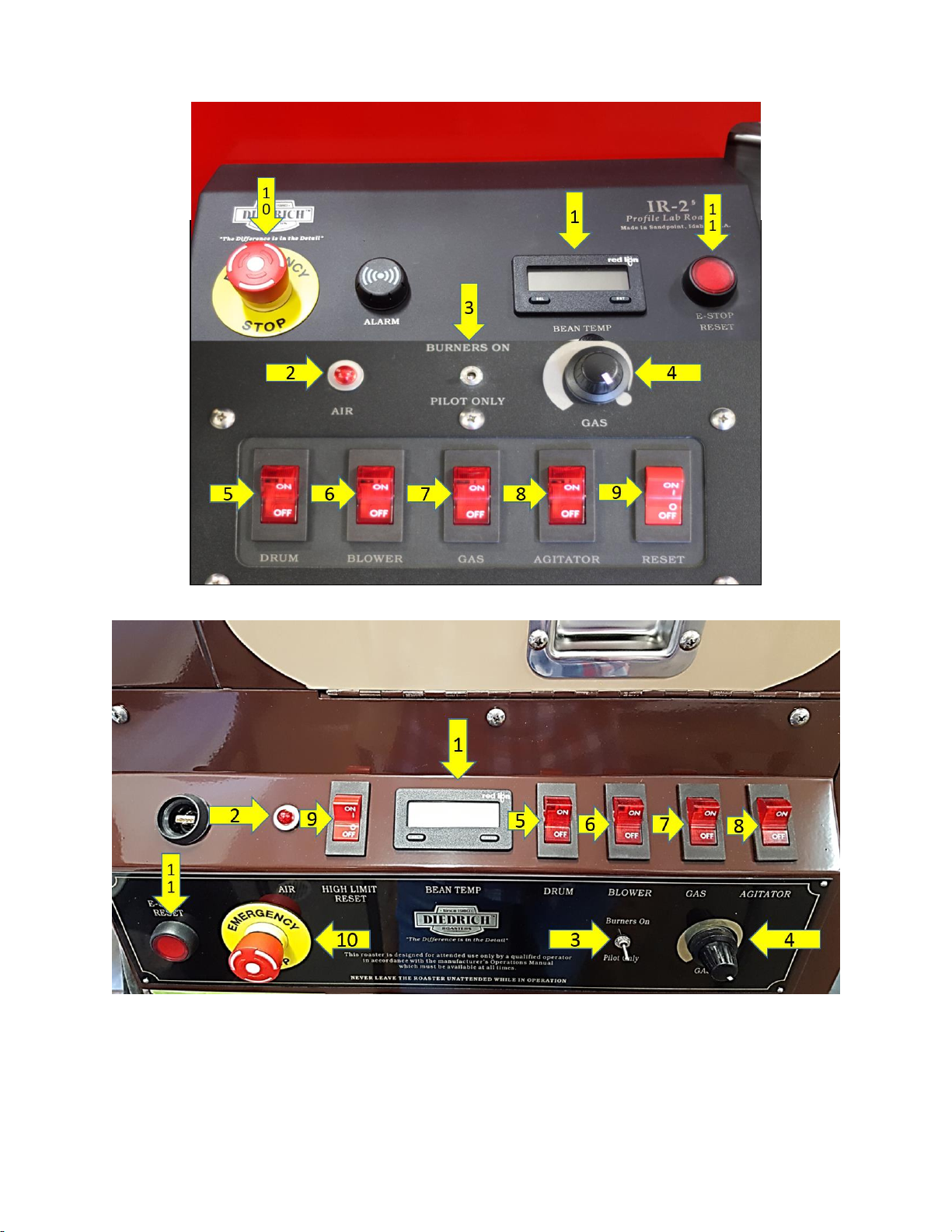

7.3 OPERATOR CONTROL PANEL.

IR-1 & IR-2.5 (Manual)

IR-5 & IR-12 (Manual)

7.4 COMPONENT DESCRIPTION

1. BEAN TEMP display: This is the temperature of the beans in the drum.

2. AIR light: This light may be on or off depending on the model of roaster.

Standard model roasters have a red light. If it is illuminated there is an air flow restriction and the

roaster will not ignite the burners.

Page 16 of 23

Universal model roasters have a blue air light. This light will be illuminated during normal

operation. If it is NOT illuminated there may be a draft in the exhaust ducting and the roaster will

not ignite the burners.

3. Pilot Only/Burners On toggle switch: This switch toggles the main burners on and off. If lower

than the minimum GAS knob setting is required, the operator can turn the main burners off.

4. GAS knob: This knob controls the flame level. The intensity can be viewed through the window

below the sample trowel and gas pressure on the manometer on the top or the roaster.

5. DRUM switch: This switch starts the drum spinning.

6. BLOWER switch: This switch starts the blower fan.

7. GAS switch: This switch turns on the gas.

8. AGITATOR switch: This switch turns on the agitator in the cooling bin.

9. RESET switch: This switch will reset the high limit safety module if the temperature climbs above

485°F (252°C).

10. Emergency Stop: This button is to be pushed in case of an emergency.

11. E-Stop Reset: Push this button to reset the roaster after pushing the “Emergency Stop” (10)

button.

8. INITIAL START-UP

8.1 LIGHTING THE PILOT BURNER

The pilot burner is a small flame which is in between the main burners. It looks like three small

candle flames and can be seen through the view window below the sample trowel.

Follow these steps to ignite the pilot burner: (Numbers ( ) correspond to the picture in section 7.3,

Operator Control Panel above.

1) Ensure the “Pilot Only/Burners On” (3) switch is in the "Pilot Only" position.

2) Verify that the air flow handle in the Cooling Bin position.

3) Confirm that the “GAS” knob (4) is turned all the way to the right (clockwise).

NOTE: Standard model roasters and Universal model roasters have different start-up procedures.

A Standard roaster has a red air light on the control panel a serial number that starts with “S”. A

Universal roaster has a blue air light on the control panel and a serial number that starts with “U”.

ATTENTION

At 475°F (246°C) - the main burner shuts off, but the pilot DOES NOT (No alarm will sound). At 485°F

or 252°C- the alarm will sound and the Excess Temperature limit will shut down the roaster's entire gas

system. You will have to reset the roaster once it has cooled down below the Excess Temperature

limit. To restart the burners, follow the normal start up procedure.

DANGER

A possibility of fire exists if the coffee is not removed from the drum before 500°f

(260c). The coffee may ignite even if the flame was turned off at 485°f (252°c).

ATTENTION

Make sure the “Emergency Stop” button is not engaged before performing the steps below.

Page 17 of 23

4) Lighting the burners:

a) For Standard roasters: (Standard roasters have a serial number which starts with

“S”.)

Turn on the switches in the following order:

•Drum (5)

•Blower (6)

•Gas (7)

NOTE: The igniter will spark until the pilot burner ignites or for a maximum 90 seconds. If the pilot

does not ignite turn the GAS switch (7) “OFF”, wait a minimum of 5 minutes, and then attempt to

relight the appliance.

b) For Universal roasters: Universal roasters have a serial number which starts with

“U”.

Turn on the switches in the following order:

•Drum (5)

•Gas (7)

•Wait for the BLUE air light to come on then turn on the Blower (6) switch.

NOTE: After the roaster will goes through a 30 second purge cycle the igniter

will start to spark. Should the pilot fail to light, shut off the blower and gas

switches, wait a minimum of 5-minutes, and then attempt to reight the

appliance. NOTE The blower MUST stop turning before attempting to

light the roaster again.

5) All roasters: Once the pilot is lit, switch to the "Burners On" (3) position and use the gas control

knob to adjust the flame intensity

NOTE: The first time the pilot ignites extra time may be necessary to allow air to bleed out of the

gas line. Following the ignition of the pilot, two to three minutes may be required to allow the two

infrared burners to ignite for the first time. Watch through the view window for burner ignition.

6) Move the Gas (7) knob to the desired flame setting and monitorthe Bean Temperature Display

(1).

7) Allow the roaster warm to 400°F - 450°F, (204°C - 232°C).

NOTE: If no grinding sounds occur up to 415°F, the initial warm-up is complete and roasting can

begin. If there is a grinding sound, turn “OFF” the drum motor (5) and contact the Diedrich Roasters

Technical Support for instructions.

8) Check the exhaust system for leaks.

NOTE: If leaks are present, the ventilation contractor must be contacted to correct the situation.

9. ROASTING

The instructions below explain the operation of the roaster. They are not an attempt to teach all the

subtleties and proper techniques of roasting the many varieties of coffee beans. Further information on

roasting is available during the Diedrich Roasters roasting seminars.

Average roasting times are from 14 -15 minutes for a light roast and 15-18 minutes for a darker roast,

depending on the source or type of beans. Reducing the burner flame is one of several ways to lengthen

roast times. The temperature of the roasting system (comprised of the coffee beans, roasting drum, and

end plates) reacts slower than the flame adjustments. Do not expect an immediate temperature change

when the heat level is changed. After a short time, the beans and roasting system will show signs of

dissipating heat.

Other manuals for IR Series

1

This manual suits for next models

4

Table of contents

Other Diedrich Roasters Kitchen Appliance manuals