DIG GF100 User manual

INTRODUCTION

Thank you for purchasing the DIG’s Model GF100 Gravity Feed Drip Irrigation Kit. Please take the time to

read through the enclosed instructions and follow them step by step. If you have any questions, please call

our customer service line at 1.800.344.2281.

ABOUT YOUR GF100 KIT

Let your landscape thrive with a slow and precise drip watering kit that connects to a gravity feed barrel

or to an outdoor faucet. DIG’s GF100 kit is a complete kit designed for a low-pressure gravity feed system

for up to 50 plants. The kit includes all the parts needed to install a drip irrigation system to water roses,

vines, shrubs or vegetables, starting from a raised rain barrel with a 3/4″hose thread outet. The kit can also

be used from a garden faucet using the included pressure regulator. Use the following guidelines to design

and install an efcient low-volume irrigation system from a rain barrel that conserves water and promotes

a healthy environmment.L

AMPLE

INSTALLATION

Before you start:

The GF 100 Gravity Feed Drip Irrigation Kit contains all the parts necessary to install a drip system that

starts from a rain barrel or outdoor faucet. Select a 60- to 200-gallon rain barrel (not included) and raise

it above the ground for best results. All of the included threaded ttings are “hose” type, so no Teon tape

is needed to seal the connections, and they should be tightened clockwise until they are only “hand tight”.

The 1/2″poly tubing serves as the main supply line which starts from the faucet at the bottom of the

rain barrel.

DIG CORPORATION THREE-YEAR WARRANTY

DIG CORPORATION warrants these products to be free from defects in material and workmanship for a period of

three years from date of purchase. This warranty does not cover damage resulting from accident, misuse, neglect,

modication, improper installation or subjection to line pressure in excess of 50 lbs. per square inch. This warranty shall

extend only to the original purchaser of the product for use by the purchaser. This warranty shall not cover batteries

or any malfunction of the product due to battery failure. The obligation of DIG CORPORATION under this warranty is

limited to repairing or replacing at its factory this product which shall be returned to the factory within three years after

the original purchase and which on examination is found to contain defects in material and workmanship.

DIG CORPORATION SHALL IN NO EVENT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY

KIND; THE SOLE OBLIGATION OF DIG IS LIMITED TO REPAIR OR REPLACEMENT OF DEFECTIVE PRODUCTS. SOME

STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Unattended use for prolonged periods without inspection to verify proper operation is beyond the intended use of this

product, and any damage resulting from such use shall not be the responsibility of DIG CORPORATION. There are no

warranties which extend beyond the description on the face hereof. In the case of purchase of the product for use other

than, for irrigation purposes, DIG CORPORATION hereby disclaims any implied warranties including any warranties of

merchantability and tness for a particular purpose. In the case of the purchase of the product for personal, family or

household purposes, DIG CORPORATION disclaims any such warranties to the extent permitted by law. To the extent

that any such disclaimer or implied warranties shall be ineffectual, then any implied warranties shall be limited in

duration to a period of one year from the date of the original purchase for use by the purchaser. Some states do not

allow limitation on how long an implied warranty lasts, so the above limitation may not apply

to you. In order to obtain performance under this warranty, the unit must be returned to the factory, along with proof of

purchase indicating original date of purchase, shipping prepaid, addressed as follows:

DIG CORPORATION, 1210 Activity Drive, Vista, CA 92081. Repaired or replaced units will be shipped prepaid to the

name and address supplied with the unit returned under warranty. Allow four weeks for repairs and shipping time.

Repair of damaged units not otherwise within warranty may be refused or done at a reasonable cost or charge at the

option of DIG CORPORATION. This warranty gives you specic legal rights, and you may also have other rights which

vary from state to state.

INSTALLATION INSTRUCTIONS

Gravity Feed

Drip Irrigation Kit

Model GF100

www.digcorp.com

1210 Activity Drive

Vista, CA 92081-8510

Printed in the USA. We at DIG strongly believe in conservation.

Please recycle whenever possible. 082118 REV A 26-035

1.800.322.9146 FAX: 760.727.0282

CONTENTS

(50) 1-GPH Button Drippers

part# W221B

(4) 1/2″Compression Tees

part# C35

(1) 1/2″Compression Coupling

part# C33

(4) 1/2″Compression Elbows

part# C36

(5) Hose End Figure “8”

part# F68B

(10) 1/2″Tubing Holder Stakes

part# R60

(10) 1/4″Barbs

part# H80A

(10) 1/4″Tees

part# H82A

(20) 1/4″Stakes

part# P33B

(10) Goof Plugs

part# G79B

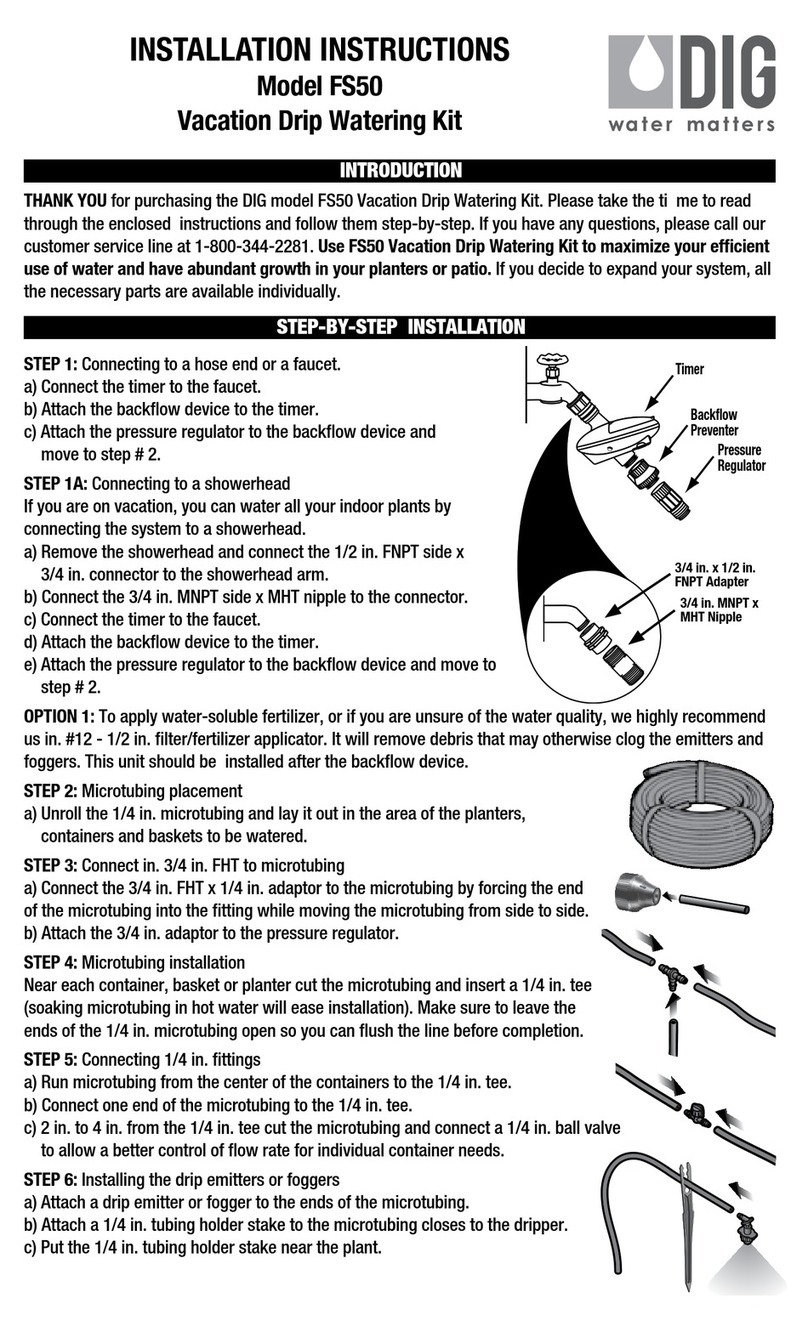

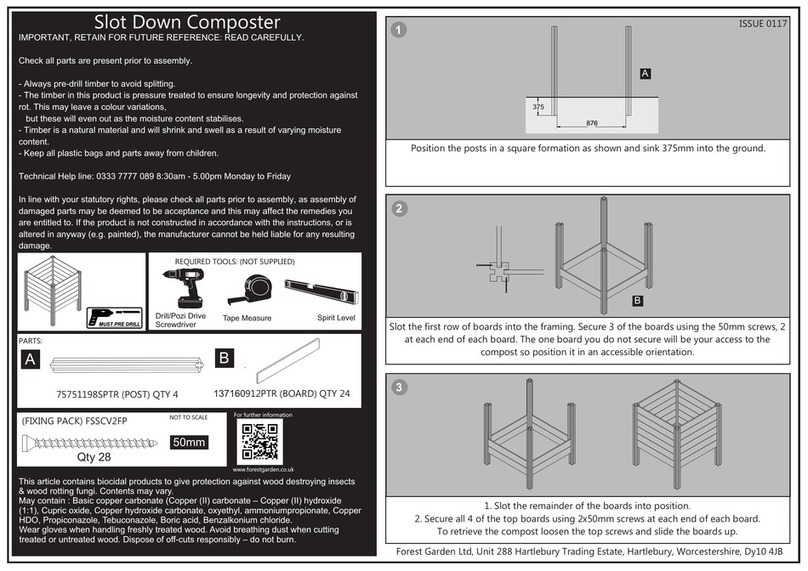

Barrel faucet connections:

Begin the installation at the rain barrel by turning the 3/4″Y hose

end splitter (optional) onto the male threads of the rain barrel faucet.

Then, connect the 3/4″ plastic screen lter with FHT (#D57A) to one

of the splitter outlets; if the splitter is not used, connect the lter

directly to the rain barrel faucet. Next, force the end of the 1/2″poly

tubing into the 3/4″swivel adapter, and then connect the swivel

adapter to the lter outlet by turning it clockwise until hand tight.

Note: If you are connecting this kit to a conventional pressurized outdoor

faucet, install the included pressure regulator (#D46) onto the Y screen-

lter outlet

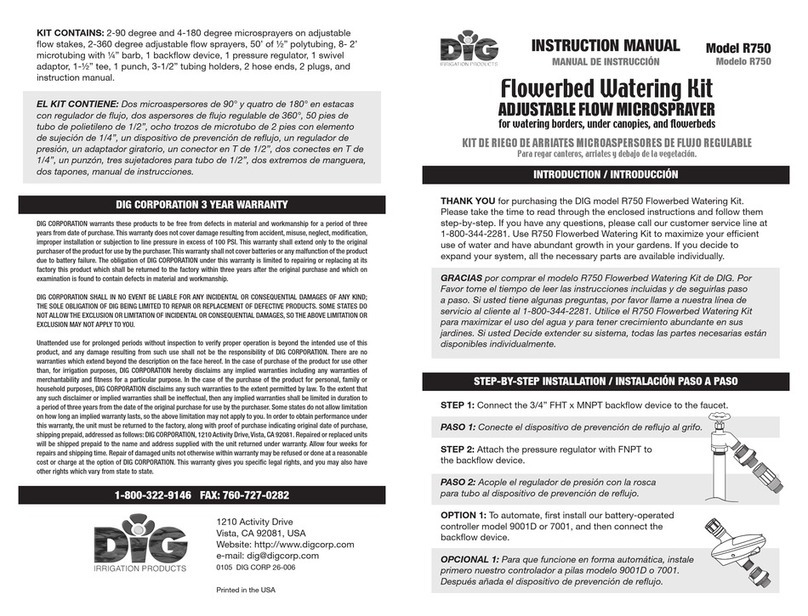

Drip tubing layout:

Before installing the 1/2″poly tubing, uncoil the roll and lay it out

in direct sunlight (if possible) for 30 to 40 minutes. This will make it

more pliable and easier to work into the compression ttings during

installation.

Lay out the 1/2″ poly tubing and run it next to as many plants as

possible. Secure the tubing to the soil with the

1/2″drip tubing stakes. Install the drip tubing in a

gentle S curve to allow for contraction of the 1/2″

tubing at low to high temperatures.

Connect the 1/2″ drip ttings

Use 1/2″tees (part #C35) and elbows (part #C36) throughout the

layout as needed. To install the 1/2″ compression drip ttings, cut

the drip tubing with a hand pruner, being careful to keep dirt from

entering the line. Hold the tting in one hand and the drip tubing in

the other and force the drip tubing into the compression tting by

moving it from side to side.

Note: Open the faucet on the rain barrel and ush out the poly drip

tubing through the ends before installing the drip emitters.

Drip emitter installation:

The drip emitters can be installed along the poly drip tubing at

varying or specic spacings, depending on the layout of the plants. To

ensure high uniformity, take care not to exceed the recommendations

provided in the chart and the kit specications. Drip emitter ow rate

performance will depend on the rain barrel elevation.

To install the drip emitters, use one of the below options:

Option 1: Installing the drip emitters into the 1/2″poly tubing

Insert the drip emitters directly into the 1/2″tubing: Punch a hole

into the side of the poly tubing using the small punch (part #D44).

Snap the barbed side of the drip emitter into the hole after the lines

have been ushed.

Option 2: Installing the drip emitters into the 1/4″micro tubing

Extend the drip emitters using 1/4” micro tubing to reach plants

that are not near the 1/2″poly tubing. First, run a length of micro

tubing from the 1/2″poly tubing to the plant and cut it. Then, insert

a 1/4″barbed connector (part #H80A) into the micro tubing. Punch a

hole into the 1/2″poly tubing and insert the 1/4″barb into the poly

tubing. At the other end of the micro tubing, insert the barbed side

of the drip emitter after the lines have been ushed. Add a stabilizer

stake and secure to the ground.

Initial system start-up

Turn the water on again, ush the line[s], this will ush out any dirt

or debris that may be in the line. Close the end of the poly tubing

with the gure “8” hose end (part #F68B).

Test and inspect the system to identify if there are any leaks in the

drip tubing laterals. If there are any leaks from the barbed ttings or

drip emitters, remove the tting or drip emitters and insert a goof

plug to close the hole. Reinsert the barb tting or drip emitter nearby.

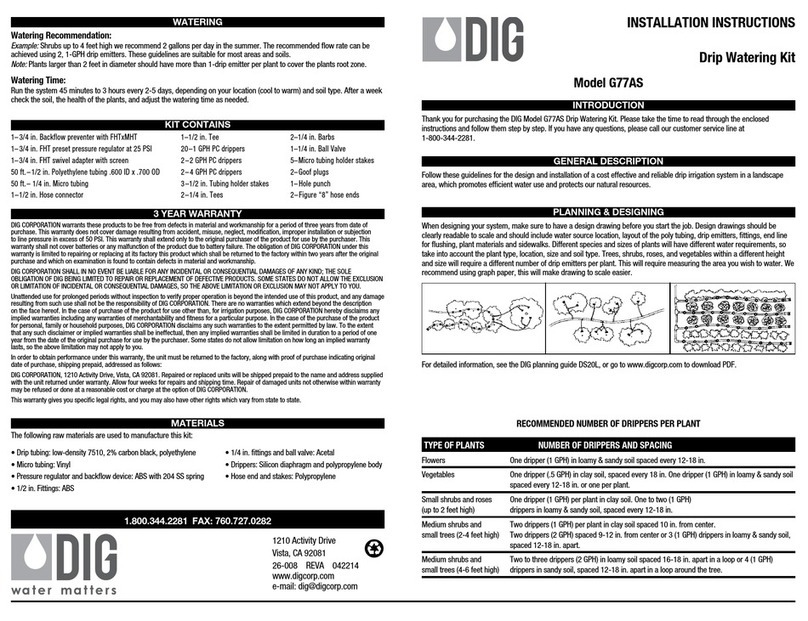

SPECIFICATION

• Operating pressure: 2 to 15 PSI

• Drip emitter ow rates: .5 GPH at 5 PSI,

.8 GPH at 10 PSI, and 1 GPH at 15 PSI (nominal)

• Drip emitter inlet size: 1/4″barb

Rain

barrel

size

Barrel height

above the

drip sytem

Outlet

pressure

Dripper

ow rate

Length

1/2″drip

tubing

# of

drippers

Total ow

rate per 50

drippers

Total ow

rate per 50

drippers

Avg.

barrel

time to

empty

60 gal.

227 L

5 ft 2.16 PSI 0.33 GPH Up to 60 ft 50 16.5 GPH .28 GPM 3.6 h

1.5 m .15 bar 1.25 L/H Up to 18 m 50 62.4 L/H 1.04 LPM 3.6 h

60 gal.

227 L

10 ft 4.33 PSI 0.43 GPH Up to 70 ft 50 21.5 GPH .36 GPM 2.8 h

1 m .30 bar 1.62 L/H Up to 21 m 50 81.4 L/H 1.26 LPM 2.8 h

60 gal.

227 L

20 ft 8.66 PSI 0.72 GPH Up to 80 ft 50 36 GPH .60 GPM 1.67 h

6 m .60 bar 2.7 L/H Up to 24 m 50 136 L/H 2.27 LPM 1.67 h

ABOUT THE GRAVITY FEED SYSTEM

In gravity feed systems, raising the rain barrel above the drip system will allow the system to gain

pressure. For every 1′(30 cm) of elevation above the drip system there is a gain of .433 PSI (.030 bar). If

the rain barrel is raised 10′(3 m) above the drip system, there is a pressure gain of 4.33 PSI (.30 bar) at

the rain barrel bottom or outlet (.433 x 10 = 4.33).

Keep in mind that low pressure such as 4.33 PSI (.30 bar) or less in a drip system will lead to:

1. Limited distance to the layout of the 1/2″or 1/4″drip tubing.

2. Reduction in the drip emitters’ ow rate to considerably below the specied nominal ow rate.

3. A drastic drop in uniformity once a certain length is exceeded.

• Drip emitter outlet side: nipple

• Poly tubing length & size: 100′of

1/2″with .600″ ID x .700″OD

• Micro tubing length & size: 50′ x 1/4″

• Total ow rate for this kit: 32 GPH (.53 GPM)

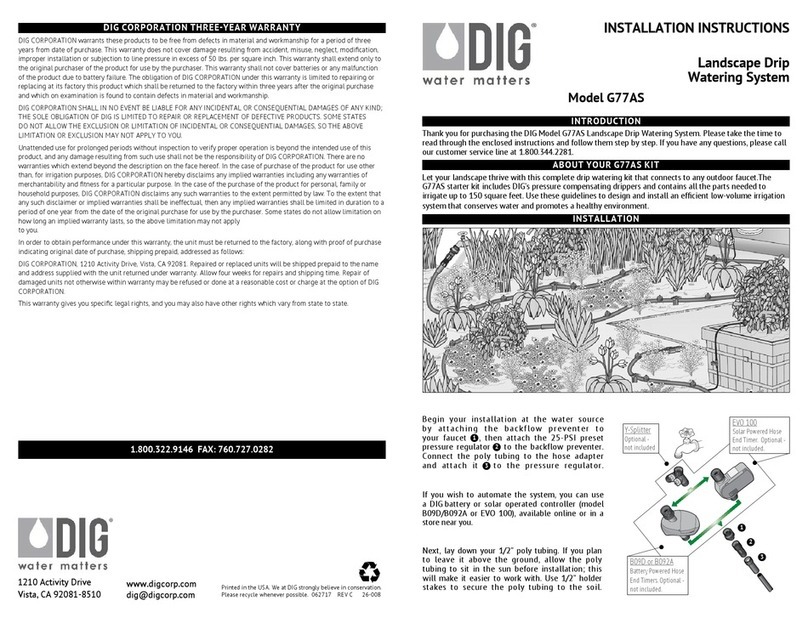

CONTENTS

(1) 100′of 1/2″Black Poly Tubing

with .600″ ID x 700″OD

part# B36

(1) 50′of 1/4″Black Micro Tubing

with .170″ ID x 250″OD

part# B38P

(1) 3/4″Y Hose End Splitter

part# D52

(1) Hole Punch

part# D44

(1) 3/4” Filter with FHT x MHT

part# D57A

(1) 3/4″ MPT x MHT Nipple

part# D49

(1) 3/4″Faucet Adapter

part# C34

(1) 3/4″Pressure Regulator

part# D46

D52

D57A

C34

D46

3/4” Pressure

Regulator

Other DIG Lawn And Garden Equipment manuals