Digimet 3000 User manual

DIGIMET ®3000

Vacuum and Pulsation Tester

Operator’s Manual – 4C

Digimet 3000 Version 4.0

L. J. Engineering, Inc.

Digimet 3000 Manual - 4C

January 2009

(Digimet 3000 Complete Pictured)

2

Dear Digimet User:

Thank you for your purchase of the Digimet

3000. It's a very good idea to read the

manual before operating any instrument,

such as your new DIGIMET 3000. Please

remember to read the manual thoroughly at

some point for a complete understanding of

the Digimet and its functions.

Thanks, again.

L. J. Engineering, Inc.

3

INTRODUCTION 6

PHYSICAL CHARACTERISTICS 6

Digimet 3000 Enclosure 6

Display 6

Keypad 6

Vacuum Input 6

Electronic Pulsator Input 7

RS-232 Serial Port (9-Pin) 7

Carrying Case 1 – Standard 7

Carrying Case 2 – Large Model 7

Fittings Supplied 8

SPECIFICATIONS 8

Power 8

Vacuum Input 8

Electronic Pulsation Input 9

Resolution and Accuracy 9

Calibration 9

FUNCTION 9

Auto Shutoff 10

Battery Low Indication 10

Reset 10

Data Display Hold 10

Store/Recall 11

Store 11

Store Graph 12

Recall 12

Print/Upload 13

Timer Stamp 15

Labeling 15

Table of Contents

Limping data 13

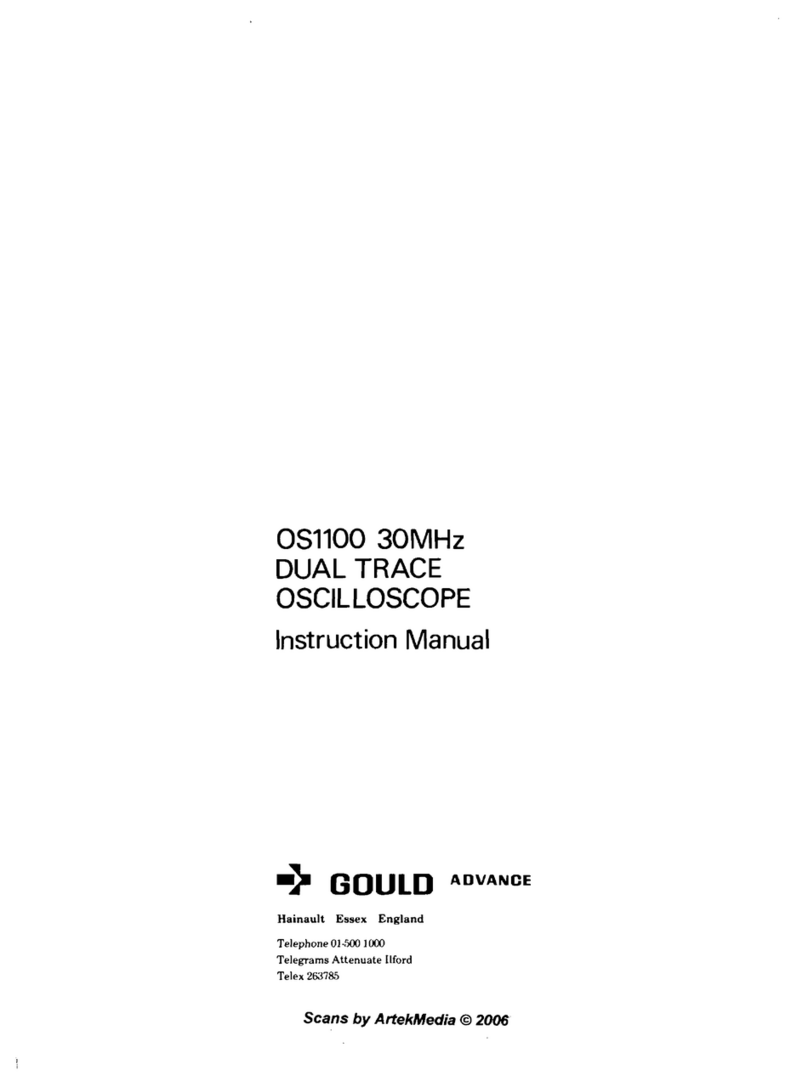

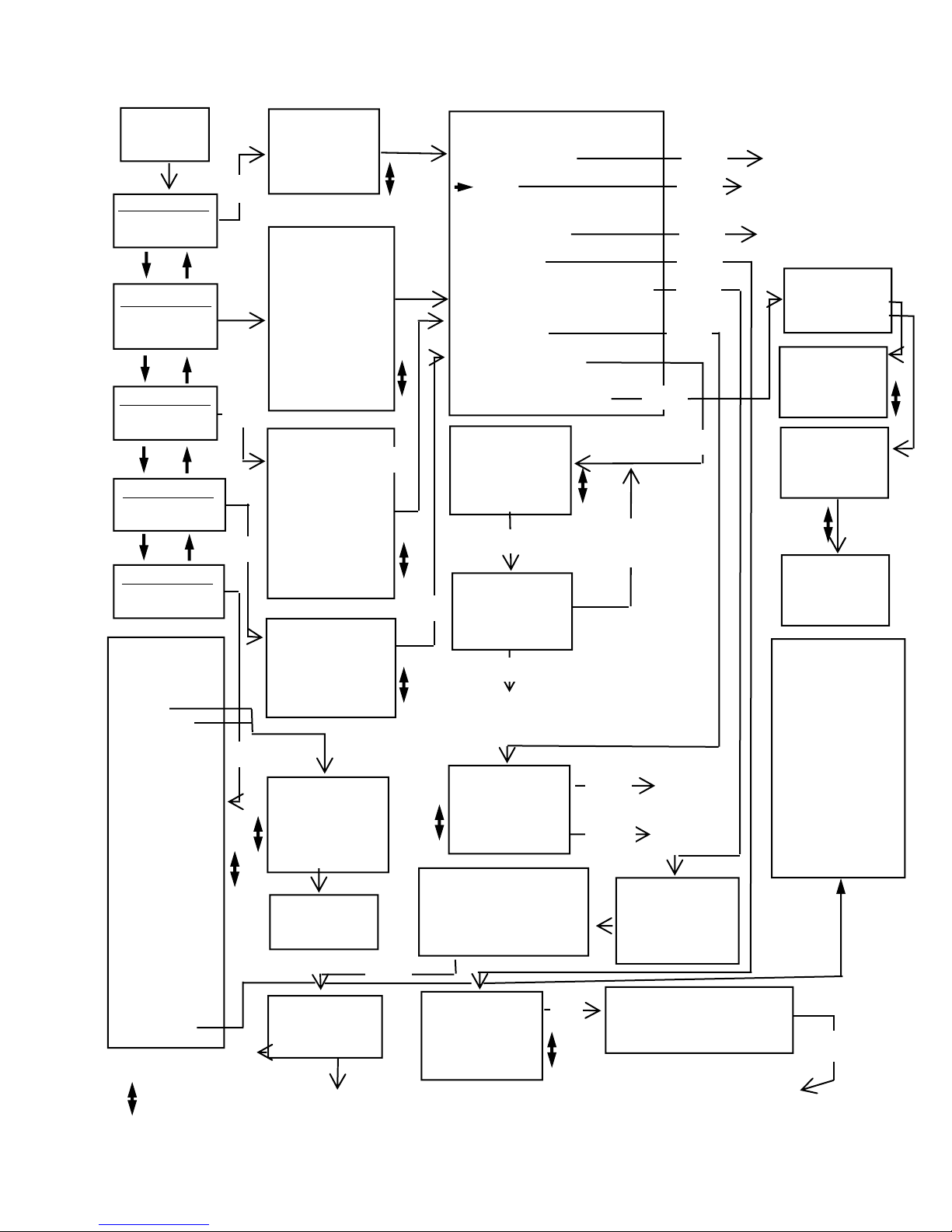

Figure A - Menu Navigation 14

Auto Zeroing 15

MENU & DISPLAY SYSTEM 16

Navigation 16

Display Standards 16

Battery Low Indication 16

Start-up Display 17

Function Menu 17

UTILITY MENU 17

Upload/Print all Data 18

Upload Graphic Data 18

Print Graph 20

Fluctuation Time Frame 20

Liner Collapse Point (LCP) 20

Display Units 20

Type of Pulsation Storage 20

Auto Shutoff 21

Clear Storage Memory 21

DISPLAYS 21

Vacuum Level Function Display 21

Pulsator Ratio Function Display 21

Milk/Rest Ratio Function Display 22

Pulsation-Electronic Function Display 22

Option Menu 23

Store/Recall Menus 23

Store Graph Menus 24

MEASUREMENT FUNCTIONS 24

Measurement Constants 24

Table of Contents (cont.)

Print Limping data 21

Available options – Figure B 22

4

Table of Contents (cont.)

Display Units 25

Type Pulsation 25

Auto Shutoff 25

Vacuum Level Function 25

Vacuum Fluctuation 26

Pulsator Ratio 26

Setting Pulsator Ratio Limits 26

B-Phase Fluctuation 27

Milk/Rest Ratio 28

Pulsation Electronic 29

CALIBRATION 29

Unit Initialization 29

Auto-Zero 29

HARDWARE SPECIFICATIONS 29

Microprocessor 29

Power Subsystem 29

Vacuum Sensing 30

Electronic Pulsation Input 30

DIGIMET PRINTER 30

Digimet Printer Settings 30

Digimet Printer Operations 30

SOFTWARE 31

Computer Requirements 31

DOS program Upload.exe 31

WINDOWS program DigiData.exe 31

Upload Item 32

Viewing Data 32

Notes 32

MENU: 32

Table of Contents (cont.)

File - New 32

File - Open 32

File - Save As 32

File - Set Printer Font 32

File - Print 33

File - Exit 33

Options - Label Data Set 33

Options - Set Com Port 33

Options - Type Pulsation 33

Options - Graphing 33

Options - Set Pulsator Limits 33

Options - View Pulsator Limits 33

View Grid or Standard 33

View Inches Hg or kPa 33

Graph Settings 34

Help 34

Upload item 34

Upload all 35

Upload Graph 35

Display Graph 36

Send to D. Printer (Not Used) 36

Rec. archive data (Not Used) 36

Graph data 36

Saving Files 36

When is Uploading complete? 37

Use of other programs 37

CABLES 37

PARTS LIST 37

5

Table of Contents (cont.)

MISCELLANEOUS 38

Tapping Holes 38

Comparing Electronic and Pneumatic

Pulsation

38

Cleaning 38

Use of Stainless Needle 39

Serial Number 39

Configurations 39

Packing List 39

Trademarks 40

Troubleshooting 40

Default Pulsator Ratio parameter Limits 40

ADDENDUM #1 40B

Viewing pulsator data 40B

Using kPa 40B

Pulsator limits not transferred 40B

Setting Pulsator Limits 40B

Testing data on CD 40B

Contents of CD 40B

Graphs & Printouts 41

Graphs - computer 47

Quick Reference Guide 48

Digimet Printer Instructions (Digimet Complete) 49

Limited Warranty 50

Contact Information 51

6

INTRODUCTION

The Digimet 3000 is a 5-key, hand-held,

battery operated, microprocessor-based

vacuum and pulsation multi-function

testing meter for measuring vacuum level

characteristics and pulsation attributes in a

milking system. The Digimet 3000’s stored

data can be either viewed on its LCD

screen, uploaded to a computer or printed

to the Digimet®Printer.

The Digimet 3000 stores and displays the

following types of information:

• Average Vacuum level

• Maximum Vacuum level until reset by

user

• Minimum Vacuum level until reset by

user

• Fluctuation level with user-set time

frames

• Pulsation ratio with A, B, C and D

phases in percentages and milliseconds

• Evaluation of the B phase - B Fluc

• Maximum and Minimum vacuum per

pulse

• Pulses per minute

• Pulsation Limits can be set for various

pulsation attributes.

• In the Pulsator Ratio Function when

limits are not met or exceeded the value

will blink.

• Unit calculates the Limping Ratio

• Milk/Rest ratio with user-selected Liner

Collapse Point

• Electrical pulsation with On versus Off

time, Maximum & Minimum voltage per

pulse, PPM

• Units measured may be Inches Hg

mercury or kilopascals (kPa)

• Data items can be labeled

• Up to five 10-second graphs can be

saved and later printed or downloaded.

Graphs can be printed to the Digimet

Printer or uploaded to a computer.

• Pulsator data can be stored as single or

dual pulsation.

• User set auto shut-off

PHYSICAL CHARACTERISTICS

Digimet 3000 Enclosure

The Digimet 3000 is enclosed in a durable

black ABS plastic case with dimensions of:

7.50” in length x 4.00” in width x 1.26” in

depth.

Display

The Digimet 3000 has a 16-character by 4-

row LCD dot-matrix display capable of

displaying the alphanumeric character set

plus additional characters (#, etc.). The

display supports the character attribute of

blinking. The front panel includes a

protective clear window to cover the

display.

Keypad

The Digimet 3000 has a front panel

consisting of a durable and washable

plastic face and integrated membrane key

switches, with access for all input

receptacles. The front panel incorporates

the following membrane keys:

The specific functions of these keys are

described in the section titled: MENU &

DISPLAY SYSTEM.

Vacuum Input

The Digimet 3000 has a 1/8” tube

receptacle located on the front panel for

attachment to an external vacuum source,

vacuum line, etc. The vacuum input will

not be damaged by the intrusion of

ON

OFF Menu Enter

7

moisture or liquids, but care should be

taken to prevent this from happening.

If, for example, milk were allowed to

enter the transducer and dry, the

performance of the transducer could be

affected. A filter is provided to keep liquids

from coming into contact with the

transducer. IMPORTANT: THE FILTER

MUST BE USED AT ALL TIMES.

If milk accidentally enters the transducer

area, the transducer should be rinsed with

water. Please refer to the section

Cleaning for further instructions. If milk is

allowed to dry inside the transducer, the

transducer will need to be replaced.

The Acrodisc filter will not allow milk to

pass through it. As long as milk is not

allowed to sit in the filter, milk will not

adhere to the filter membrane. Keeping the

filter clean will allow for repeated use.

Check the filter periodically to determine

whether it has become plugged or

restricted. To do this, check Digimet 3000

readings on one of the pulsation (vacuum)

Functions with and without the filter in

place. If similar readings are obtained then

the filter is not plugged.

The tube that comes out of the Digimet

3000 at the port labeled VACUUM is

connected to a quick-disconnect male

fitting (DM3-16-03). When the Digimet is

not in use, a white plug (DM3-16-06) plugs

the opening of the male fitting. When in

use, attach the Acrodisc filter (DM3-15) to

the male fitting and TIGHTEN. Attach to

the Acrodisc filter a 4’ length of 5/32”

plastic tubing which is used to connect the

Digimet 3000 to the vacuum system. Note:

the 5/32” tubing has a small tube clamp on

the end that connects to the Acrodisc. This

provides for a tighter fit to the smaller 1/8”

slip-fit end of the Acrodisc.

Three methods can be used to connect the

Electronic Pulsator Input

The DIGIMET 3000 has two banana jack

receptacles located on the front panel.

These jacks are located side-by-side with

a distance between them that

accommodates a standard 3/4" double

banana plug or single plugs as provided

with the unit. THE UNIT WILL FUNCTION

PROPERLY WITH EITHER POLARITY

OF INPUT.

RS-232 Serial Port (9-Pin)

This 9-pin serial connector is used to

connect the Digimet 3000 to either the

Digimet Printer or a computer. Cables are

provided. The serial port has a small

plastic dust cover for protection. This port

is labeled Serial.

Carrying Case – Standard

The DIGIMET 3000 padded canvas

carrying case is approximately 9" long x 5"

wide x 3 1/2" deep. Case includes a

compartment for the DIGIMET 3000 with

two inside straps to keep the unit in place,

and an additional compartment for storing

items such as vacuum tubing, banana

plugs, extra batteries, etc. A shoulder strap

is also provided.

Large Carrying Case

The Large Hard Carrying Case is

approximately 15-3/4” x 9-7/8” x 6-7/8”. It

is divided into compartments which

tubing to the vacuum system: 1) A needle

connector and stainless steel needle. Be

sure needle does not become plugged

during use. (See the section Use of

stainless needle.) 2. A “T” fitting is

supplied to accommodate plugging into

the short pulsation air tube without use of

a needle. 3) A 1/4” plastic pipe fitting with

a 5/32” nipple is also provided to tap into

plastic pipe systems, as well as a plastic

pipe plug to be used when the fitting is

8

accommodate the Digimet 3000, the

Digimet Printer, AC wall transformer (for

the printer) and accessories. A shoulder

strap is also provided.

Fittings Supplied with DIGIMET 3000

The Digimet can accommodate two types

of input: 1) vacuum; 2) electrical

pulsation. Fittings are supplied to facilitate

both forms of input.

Vacuum Port – The vacuum port is labeled

VACUUM and consists of a quick-

disconnect male luer fitting (DM3-16-03)

with a white plug (DM3-16-06) attached.

The white plug serves as prevention

against debris entering the vacuum port

when the unit is not in use. A quick

counter-clockwise turn will remove the

white plug from the male luer fitting.

During operation, the vacuum port with its

male luer fitting is attached to an Acrodisc

filter (DM3-15) which is connected to

approximately 4' of 5/32" tubing. A small

hose clamp is provided to secure the hose

to the Acrodisc filter, tightly. Note: the

Acrodisc filters should be used at all

times. To connect the free end of the

tubing to the vacuum system, the user has

several choices: 1) A needle connector

(DM3-Connector) is provided for use with

the stainless needle (DM3-17), which is

inserted into rubber components of the

milking system. (See section

Miscellaneous-Use of stainless needle.)

2) 5/32" nipples may be fitted into the

vacuum system for connecting the 5/32"

tubing. A sample of such a fitting is

provided with your Digimet 3000 (pipe

fitting DM3-PIPE and plug DM3-17-02).

The pipe fitting is a 5/32-27 NPT fitting.

See the section, Tapping holes, for

instructions on tapping holes for this fitting.

3) A pulsator tube adapter “T” fitting

(provided) can be used to check pulsation

line vacuum instead of using the stainless

needle. Connect opposing sides of the “T”

fitting to the short pulsation air tube at the

milk claw and the middle of the “T” to the

Digimet 3000 plastic tubing.

SPECIFICATIONS

This section defines the operating

conditions and performance specifications

which apply to the Digimet 3000.

Power

The Digimet 3000 operates on four AA

alkaline batteries. The Digimet 3000 will

operate for approximately 40 hours before

batteries need to be changed. When the

batteries are low, in the upper right-hand

corner, a “B” will blink, indicating low

battery level. The unit will still function but

the batteries should be replaced. If the

batteries are not supplying sufficient power

for the unit to function properly then the

screen will go blank and the unit will turn

itself off. The battery compartment is

located just behind the LCD display with

the opening on the back side of the unit.

Care should be taken to install batteries

in the proper direction. Data stored in

the Digimet is not affected by turning the

unit off. If the batteries are replaced,

however, they should be replaced within

an hour of removal or storage data will

be lost.

Vacuum Input

In this manual, VACUUM refers to a

differential pressure, with atmospheric

pressure as the reference. Zero vacuum

equates to a zero difference from

atmospheric pressure. Positively

increasing vacuum equates to a

decreasing of pressure relative to

atmospheric pressure (i.e. less than

atmospheric pressure).

9

The Digimet 3000 will accept a vacuum

input with the following characteristics:

Range — 0-18” Hg, equivalent to 0-60.9 kPa

Frequency — 30 -120 Pulses Per Minute,

equivalent to .5-2 Hz

Electronic Pulsation Input

The Digimet 3000 will accept an oscillating

electrical input from 0 volts to +/- 30 DC

volts. Over-voltage protection is provided

for inputs up to 50 DC volts so that the unit

will not be damaged. The electrical input

accommodates up to 40 amps. The

polarity of the input signal is rectified to

guarantee that all voltages are positive. An

internal filter is incorporated to eliminate

sharp voltage spikes that occur during

solenoid switching. DO NOT TOUCH

CONNECTORS TO 110-VOLTS OR 220-

VOLT AC INPUTS.

Resolution and Accuracy

Vacuum Display and Unit Relationships

All vacuum (pressure) measurements will

be displayed according to the selected

Vacuum Display Unit. The available units

are Inches of Mercury (“Hg) and

kilopascals (kPa).

The following provides an orientation to

the equivalency of various pressure units:

1 atm ≈30.0” Hg ≈14.7 psi ≈ 101 kPa

The actual conversion factor used is:

1” Hg = 3.3864 kPa

The following resolutions are used:

Units Precision Display Range Example

“Hg 100ths 18.00 12.05

kPa 10ths 60.9 45.5

The performance specifications for the

various measurement types are defined in

the table below. Specifications are for the

entire operating range of the Digimet

3000, and for a temperature range of 32-

150 degrees Fahrenheit.

Calibration

The Digimet 3000 is factory calibrated. Its

components are designed so that losing

calibration is unlikely, but if the unit is

subjected to harsh environments or

treated roughly, it may need factory

recalibration at some future time. But, as

any electronic instrument, yearly

recalibration is recommended.

FUNCTION

This section describes the operation and

features of the Digimet 3000.

The functions of the Digimet 3000 are

divided into the following areas:

System Functions

Auto Shutoff

Battery Low Indication

Reset

Data Display Hold

Store/Recall

Store Graph

Print/Upload

Limping data

Timer Stamp

Labeling

Auto Zeroing

Measurement Units Resolution Accuracy

Vacuum “Hg 0.01 +/-.06

Vacuum kPa 0.1 +-.2

Time msec 1+-1

PPM ppm 0.1 +-.1

Ratio %0.1 +-.1

Voltage DC Volts .1 +-.3

10

Menu & Display System

Measurement Functions

Vacuum Level

Pulsator Ratio

M/R Ratio

Pulsation Electronic

Utilities

Upload/Print all data

Upload Graph

Print Graph

Fluctuation Time Frame

Liner Collapse Point

Type of Pulsation Storage

Display Units - “ Hg or kPa

Type Pulsation - Dual/Single

Auto Shutoff

Clear Storage Memory

Print Limping Data

Set Pulsator Limits

The measurement Functions are fully

independent from one another. Information

(unless it is “stored”) is not retained when

switching from one Function mode to

another.

Auto Shutoff

The Digimet 3000 provides for automatic

shutoff of the unit after a user selectable

period of time from 0 to 30 minutes of non-

use. This is set in the Utility Menu, item

number eight. See section on Utility

Menu. This feature is designed to

maximize battery life. “Use” of the unit is

defined as presses on the front panel

keys. Each depression of a key will cause

an internal timer to reset to zero. This

timer is continually counting, and when it

reaches the specified time, the Digimet

3000 will shut off. When the Digimet 3000

is auto-shutoff, all currently displayed

information will be lost, the same as if a

user had switched the unit off. (Stored

data is not lost.) When the unit is auto-

shutoff and subsequently turned back on,

it will perform the normal start-up

sequence defined in the section entitled

Start-up Display.

Battery Low Indication

The Digimet 3000 detects when the

battery power is low and displays a

message. The Low Battery indicator is a

blinking “B” in upper right corner of the

screen. See more about the Battery Low

Indication under heading MENU &

DISPLAY SYSTEM.

Reset

The Vacuum Level Measurement function

has the ability to “reset” the Max. and Min.

Vacuum readings. Vacuum Level Min/Max

Reset is further discussed in the section

entitled Vacuum Level Function.

Data Display Hold

The Digimet 3000 has the capability to

“freeze” the data currently displayed, with

the use of the Hold mode. The entire set of

measurements for a Function that is held

will be frozen, including items not visible

within the display window. This allows the

user to scroll through all measurements.

When placed in Hold mode, the Digimet

3000 will continue to sample input and

calculate the measurements for the current

function; however, the display will not be

updated with the current information, but

will display the measurements at the time

the unit was placed in Hold mode. When

accessing the Option Menu to utilize Hold,

within a particular Function, the MENU key

must be pressed. The data that is on the

screen the instant the Menu key is pressed

will be the data held.

When the Digimet 3000 is then placed in

the Continue mode, the display will be

updated with current measurements. This

operation is analogous to a split-time

feature of a stopwatch. The Hold mode is

automatically released when the

measurement Function is exited. For

example, if the unit is in Hold mode within

11

the Vacuum Level measurement Function

and then the Pulsator Ratio Function is

selected, the Pulsator Ratio function will

begin in the Continue mode.

All measurement Functions have the Hold

mode capability.

Store/Recall

The Store/Recall function allows for the

storage of screen data within the Digimet

3000’s memory, and for the recall to the

Digimet display, printing to the Digimet

Printer or uploading to a computer.

Store

The Store function of the Digimet 3000

allows a measurement set to be stored for

later viewing (recall) or uploading (to a

computer) or printing (to the Digimet

Printer). A measurement set contains all

measurement parameters of the Function

being stored plus a label of up to 16

characters or if no label is inputted a timer-

stamp will be associated with the data.

This data is stored into dedicated storage

slots (selected by the user) and remains in

storage even if the unit is turned off and

back on.

Each measurement Function contains a

maximum number of measurement sets

that can be stored, and each slot is

numbered. This means that storage space

reserved for a particular Function cannot

be used by any other Function.

The following storage is provided:

Measurement # Storage Slots

Vacuum Level 10

Pulsator Ratio 60

M/R Ratio 30

Pulsation Electronic 5

Graph Storage 5

Some measurements require a minimum

start-up time before data is displayed (see

section titled MEASUREMENT

FUNCTIONS). This is generally

approximately two or three seconds,

depending on the measurement. If the

required start-up time has not elapsed, the

Store option will not be available, it is

surrounded by < > on the display screen.

If the unit is in the Hold mode the held data

will be stored. Otherwise, the data that is

current at the time Store is selected will be

stored.

When the Store screen appears, choose the

storage slot number where the data is to be

stored. An empty slot has neither a timer-

stamp or a label next to it. The next screen

will allow a label to be attached to the item

being stored. The top of the screen will

indicate “Label Slot 01”. The 01 would

change depending on the number of the slot.

Below this, there will be 16 hyphens

indicating 16 available characters for the

label. The cursor will be all the way to the left

under the first character. Choose characters

for the label by using the up and down arrow

key on the keypad. The up arrow key will

start with A,B,C,D and so on through some

symbols and numbers. The down arrow key

starts with the (space),#,0,1,2 and so on.

Once the character is chosen, press the

Enter key to advance to the next character.

When done with the label press the Menu

key to Save. If the Menu key is pressed

without selecting any characters for a label, a

timer stamp will be associated with the data

stored. This timer-stamp is described in the

section Timer-Stamp. Once the item is

saved, the Option Menu will re-appear.

Store Graph

This option appears in all three of the

pneumatic functions in the Function Option

Menus. The time period for graph length is

12

set at this time from 2 seconds to 10

seconds. Up to five separate graphs from

2 seconds to 10 seconds each, can be

stored. On subsequent store graphs the

unit will remember storage time and will

not need to be changed unless you desire

a different time period. Please note: It is a

good practice to match the fluctuation time

frame - a variable in the Vacuum Level

Function (set in the Utility Menu), with the

store graph time period so the numeric

data printed out on the graphs, matches

the activity of the graph. For example, you

would want to set the Fluctuation Time

Frame to 3 seconds (Utility Menu item #4)

if you wanted a graph period of 3 seconds.

This practice is only applicable for the

Vacuum Level Function. The Fluctuation

Time Frame is not a variable in the other

pulsation functions. Another note

regarding Fluctuation Time Frame and

Graphing time: If the Fluctuation Time

Frame is less than the Graph time, then

the Fluctuation figure, which will print-out

on the graph, will cover the last portion of

the graph which includes the period of the

Fluctuation Time Frame. For example, if

the Fluctuation Time Frame is 2 seconds

and the Graph time is 3 seconds then the

Fluctuation figure will be for the last 2

seconds of the 3 second graph. If the

Fluctuation Time Frame is greater than

the Graph time, then the Fluctuation figure

will be for the time period of the graph. For

example, if the Fluctuation Time Frame is

set for 5 seconds and the Graph time is for

3 seconds, the Fluctuation figure will be for

3 seconds.

When you first enter Store Graph, a

screen will appear with 5 storage slots.

After choosing the slot the next screen will

allow a label. It is not necessary to choose

a label. In the case where no label is

chosen the graph will have a timer stamp

associated with it. When the label screen

is exited, the screen will indicate, Enter for

3 sec. of graph. Up/Down changes.

Menu to exit. (This assumes that 3

seconds is the chosen graph period). Time

can be set from 2 seconds to 10 seconds.

Pressing the appropriate key will either exit

without saving or you will enter the

function in the Recording Mode. In this

mode an Rwill appear in the upper right

corner of the Digimet screen. There is a

short delay before the unit begins Storing

the graph. When the Rbegins to blink,

storing data has begun. The initial delay

allows the readings to stabilize. Note: If

you want to capture a particular

activity, start the activity the moment

the “R” starts to blink.

After the Rstops blinking, storage is

complete. You can now use Print Graph

to graph to the Digimet Printer or use

Upload Graphic Data to upload graph

data to the computer for viewing on the

Computer Screen. Upload Graphic Data

and Print Graph are both options that

appear in the Utility Menu, item 2 and 3.

The reason for these different options is

because the Digimet formats the data

differently depending on the ultimate way

that the data will be viewed.

Recall

Data that has been previously stored may

be recalled for display by the Digimet

3000. The particular measurement set that

will be recalled depends on the current

13

measurement Function. That is, the

Digimet must be in a measurement

Function for this option to be available. If a

slot does not contain any stored data, the

Digimet will not allow selection of that slot

for recall.

When the RECALL screen appears, if

there is stored data in a particular slot,

there will be either a label or a timer-stamp

next to the numbered slot. Only twelve

characters of the label will appear in the

Store screen.

When data is recalled, it is displayed on

the Digimet 3000 display in the same

format as during normal sampling

operation, except that the recall slot

number appears (blinking) at the upper

right corner of the display screen. Both

recalled data and held data can be stored

in multiple slots, allowing the user to “make

a copy”.

Print/Upload

The Print/Upload function allows the user

to Print an individual item to the Digimet

Printer or Upload an individual item to a

computer via a serial port. In order to print,

the Digimet Printer must be connected to

the Digimet 3000 (See section on the

Digimet Printer). The printer cable

supplied with the Digimet Printer has a 25-

pin male serial connector at one end and a

9-pin male serial connector at the other.

The 9-pin end connects to the Digimet

3000 and the 25-pin end connects to the

Digimet Printer. The next step is to supply

the Digimet Printer with power using the

supplied AC wall transformer. Turn the

Digimet Printer “ON”. Press the Enter key

to select Print/Upload. A screen will appear

with storage slots identified along with

either labels or timer-stamps (same as in

Recall). Choose the item to Print/Upload

by selecting the item with the up and down

arrow keys. Select the item by pressing

the Enter key. The next screen will indicate

that the numbered slot with the attached

label will be sent. Press Enter to send,

Menu key to exit without printing or

uploading the item. If there is a loose cable

connection or the Digimet Printer is not

“ON” then an error message “No Clear to

Send” will appear and remain on the

screen. If the “No Clear to Send” remains

on the screen, then press the Menu key to

exit and the connection problem must be

corrected. If all is OK then the item data

will be sent to the Digimet Printer.

The above procedure would be identical

for Uploading an item to the computer

accept for a few differences. To upload,

the supplied 6’ computer cable (supplied

with the Basic Digimet 3000) which has 9-

pin connectors at each end, one is a

female and one is a male connector, must

be used. The male end attaches to the

Digimet 3000 and the other to the

computer. The second difference would be

that the software to upload data from the

Digimet 3000 must be loaded and running

on a computer to complete the upload

procedure. Other than these two

differences the steps for Uploading would

be the same as for Printing. For

information on the software requirements

for uploading data from the Digimet to a

computer, see the section on

SOFTWARE.

Limping data

In versions greater than 3.2, a feature was

added to the Pulsator Ratio Function

called the Limping data.

The difference in the milking ratio of the

right and left sides of the pulsator is

referred to as “limping ratio”. Limping may

be caused by plugged or worn small air

tubes, plugged or leaking pulsator tubing,

14

Figure A - Menu Navigation

Start-up

Screen

FUNCTION MENU

Vacuum Level

FUNCTION MENU

Pulsator Ratio

FUNCTION MENU

M/R Ratio

FUNCTION MENU

Utility Menu

FUNCTION MENU

Pulsation Electronic

VACUUM LEVEL

Ave 0.00 “Hg

Max 0.00 “Hg

Min 0.00 “Hg

Fluc 0.00 / 1s

Enter*

PULSATOR RATIO

A+B 60.2% 699ms

C+D 39.8% 463ms

B Fluc 0.43”Hg

Max/P 10.63”Hg

Min/P 0.00”Hg

A 5.3% 61 ms

B 54.9% 638 ms

C 5.7% 66 ms

D 34.1% 397

ms

Total 1162

-OPTION MENU

Function Menu

Hold

Reset (Only for Vacuum Level

Function)

Store

Store Graph (not for Pulsation

Electronic)

Recall

Print/Upload

Limping data (Only for

Pulsator Ratio Function)

Enter

Back to

Function

Menu

Enter Back to

Function in Hold

Enter Back to

Function

Enter

Menu

*

M/R RATIO

Ratio 63:37

PPM 54.2

Max/P 13.59 “Hg

Min/P 0.02 “Hg

Milk 63.3 %

Milk 701 ms

Rest 36.7 %

Rest 405 ms

LCP 6.50 “Hg

TTime 1106

PULSATION ELEC 01

On 60.4%

Off 39.6%

Max/P 10.2 Volts

Min/P 0.0 Volts

PPM 60.4

* Use Up & Down

Arrow Keys

-UTILITY MENU

1Upload-Print all

Data

2 Upload Graphic

Data

3 Print Graph

4 Fluc. Time

Frame >1 2 3 4

5 10 sec

5 Liner Collapse

Point Equals

LCP= 6.5 “Hg

6 Type Pulsation

>Dual

Single

7 Units

>Inches Hg

kPa

8 Auto Shutoff

30 minutes

9 Clear

Storage

Memory

10 Print limping

data

11 Set Pulsator

Limits

Press Enter to

start graphing

Menu to exit.

RECALL 09:06:14

> 01 BARN #1

02 MILK TRAP

03 08:12:00

Send Slot 01

BARN #1

Enter to send

Menu to exit.

Back to

Function

Menu - back to

Option Menu

To Printer or

Computer then back

to Option Menu

Enter

Enter

Enter

Enter for 3

sec. of graph

Up/Down changes.

Menu to exit.

STORE 09:06:14

01 BARN #1

02 MILK TRAP

03 08:12:00

> 04

Label Slot 09

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Menu to Save.

Enter

Save then To

Option Menu

Menu

PRINT 09:06:14

> 01 BARN #1

02 MILK TRAP

03 08:12:00

Enter

Menu

Back to

Option

Menu

Enter

(Enter to move cursor)

Enter

Enter

Menu

Enter

Enter

Enter

Enter

GRAPH

09:06:14

> M01 BARN #2

V02 MILK TR

P03 08:12:15

GRAPH 01:16:58

> 01 BARN

02 MILK

03

Label Graph 01

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Menu to Save.

Back to function in record mode

Menu to

Exit

Menu

Menu

Menu

Enter

LIMPING

> View one

item

LIMPING

> 01AB Available

02AB Not Avail.

03AB Not Avail.

LIMPING

01AB Limping

0.2 %

1 msec

LIMPING

02AB Not Avail.

(press the down arrow

key for more items)

Set Limits:

Bfluct Max 0-3.00

MaxHiV/Pls 5.5-

16.00

MinHiV/Pls 5.0-15.50

MinVac/Pls 0-4.00

MaxAPhase 20-300

MinAPhase 20-300

MaxBPhase 100-750

MinBPhase 100-750

MaxCPhase 20-500

MinCPhase 20-500

MaxDPhase 100-500

MinDPhase 100-500

Max PPM 20-198

15

as well as the pulsator itself.

When using the Digimet 3000 in the Dual

Storage Mode, pulsator data is stored in

slots labeled 01A, 01B, 02A, 02B ... 30A,

30B. When both the A and B slots are

filled with pulsator data, the Digimet will

calculate the Limping data. The Limping

data is an item which appears in the

Option Menu of the Pulsator Ratio

Function. The Limping data will appear as

a percentage and in milliseconds.

The Digimet 3000 evaluates the A + B

phase of each side of the pulsator and

indicates the difference as a percentage

and in milliseconds. For example, Limping

data would appear as follows:

07AB Limping

0.1 %

2 msec.

The Limping data can be viewed on the

Digimet’s display, printed to the Digimet

Printer or uploaded to a computer for

viewing and/or printing. The printing of

Limping data from the computer is

available on the DigiData program version

3.4 and greater.

Timer Stamp

In conjunction with the Store/Recall

function, a clocking mechanism is built in.

The purpose of this clocking mechanism is

to provide an internal real-time counter

that is used to timer-stamp the stored

measurement data. Unless a label is

chosen the timer-stamp will appear in the

Store, Store Graph, Recall, Print/Upload,

Upload Graph and Print Graph screens.

When an item is printed or uploaded the

timer-stamp in addition to the label, if

chosen, will appear. The clock will

increment every second with a range of

12:00 hours. Thus when the clock reaches

11:59, the next increment will roll the clock

over to 00:00.

Labeling

When storing data or graphs, prior to

storage but after choosing the storage slot,

a screen will appear giving you the

opportunity to label your stored item. You

can use up to 16 characters. Use the up

and down arrows to choose the character/

number/symbol. Press the Enter key to

advance to the next character. Holding the

arrow keys down for more than two

seconds will advance the characters

automatically. When done with your label

pressing the Menu key will exit and save

your data or graph. Exiting, with the Menu

key, without entering labeling will attach a

timer stamp to your data. So, it is not

mandatory to choose a label.

Auto Zeroing

The Digimet 3000 has an auto-zero

capability. Due to temperature variations

which can affect certain components, the

Digimet 3000 is designed to auto zero.

This takes place any time the Digimet is in

the Vacuum Level Function or one of the

pulsation (vacuum) Functions with NO

VACUUM INPUT applied. At this time, the

Digimet displays all zeros for Avg Vac,

Max Vac, Min Vac, and Fluctuation. (Note:

If the unit has just displayed vacuum

readings, it may be necessary to reset

Max Vac before a zero reading is

obtained.) The Pulsation (vacuum)

Functions will appear blank when auto-

zeroed.

Therefore, the following procedure is

recommended: When taking Vacuum

Level of pulsation (vacuum) Function

measurements, periodically take a

reading with no vacuum input to allow

the Digimet 3000 to auto-zero.

16

The Menu key is used to access menus.

The Digimet utilizes "pop-up" menus which

are easily accessed with the Menu key.

Navigation

Navigation through the Digimet menus and

functions is illustrated in Figure A page 14.

Display Standards

The design of the display system follows

some basic standards in order to provide a

consistent user interface.

The top line will always display a title in

capital letters, indicating the purpose of the

current screen. This will either be the name

of a menu or the name of a measurement

Function. This title line does not scroll.

Hold Indicator: For all measurement

Function displays, the top right two character

spaces are designated for indicating that the

unit is in Hold mode. Hold mode is signified

by the presence of a single, blinking

character "H". Sampling or real-time mode

is indicated by the absence of the character

"H".

Recall Indicator: The same two character

spaces (top right) are reserved to indicate

the number of a recalled set of

measurements. The recall function is

described in section titled Store/Recall.

Battery Low Indication

A low battery, as detected by system

circuitry, will be indicated on the display by a

blinking "B" in the display status area (upper

right corner).

The battery low indication (blinking "B") on

the display means the batteries will soon

MENU & DISPLAY SYSTEM

The menu system is navigated via the

front panel keys. The basic menu/function

structure is depicted in Figure A on Page

14. The structure and operation of the

menu/display are designed to provide

easy access to all of the Digimet 3000

features.

The use of the keys is as follows:

These keys are used to scroll the screen.

For menus, these keys are also used to

change the current selection. Once the

bottom of a screen has been reached (or

the last item selected), subsequent

pressing of the down arrow will have no

effect, that is, the screen will not loop back

to the top. Similarly, pressing the up arrow

will have no effect after the top of the

screen is reached. The arrow keys are

also used to change data in the Utility

Menu and to choose letters or characters

for labels. Both to be described in a later

section.

The Enter key is used to make a selection

or a change of some kind. This could be

changing to a new Function, changing a

system parameter, etc. But this key is

always associated with some effect on the

Digimet system.

Enter

Menu

17

expire, causing the unit to cease

functioning. The unit will operate properly

for several hours after the low battery

indicator appears on the screen.

IMPORTANT: STORED DATA IS NOT

LOST WHEN THE BATTERIES EXPIRE

OR ARE REMOVED FOR

REPLACEMENT, ASSUMING THAT

FRESH BATTERIES ARE REINSTALLED

WITHIN AN HOUR.

Start-up Display

Each time the Digimet 3000 is turned on,

the following initial screen will be

displayed:

This start-up screen will be displayed for 5

seconds.

The following screen layout diagrams

(shown on the next couple of pages)

illustrate two ways in which a screen is

scrolled. The first is as a "page." A

screen with a page scroll displays lines in

sets of three (excluding the top line which

does not move). These three-line page

groupings are identified by shading. The

second method of scrolling is a single-line

scroll, in which individual lines are scrolled

continuously (rather than in groups as with

the page scroll).

Function Menu

The Function Menu is the system's main

menu. It allows the selection of a

particular measurement Function or of the

Utility Menu.

After the initial Start-up Display, the

selection on the Function Menu will default

to the first option. Upon selection of an

option from the Function Menu, and

subsequent return to the Function Menu,

the last-selected item will be the default

selecti

Action of Keys

Menu None

Enter Go to selected measurement

Function or Utility Menu

Up arrow Previous item on Function

Down arrow Next item on Function Menu

UTILITY MENU

The Utility Menu allows the user to change

several Digimet settings which include:

•Upload/Print all data

•Upload Graph

•Print Graph

•Fluctuation Time Frame

•Liner Collapse Point

•Type of Pulsation storage

•Display Units

•Auto Shutoff

•Clear Storage Memory

-FUNCTION MENU

1 Vacuum Level

Avg Vac,Min&Max

Fluctuation

2 Pulsator Ratio

ABCD% &ms,Min/P

Max/P PPM

3 M/R Ratio

LCP= 6.50

Max/P Min/P PPM

4 Pulsation-Elec

On/Off PPM

Max Volts DC

5 Utility Menu

Settings for

Functions

LJE,Inc.

Digimet 3000

Ver 4.0 SN:00001

Copyright 2004

18

-UTILITY MENU

1 Upload-Print all

Data.

2 Upload Graphic

Data.

3 Print Graph

4 Fluc. Time

Frame 1 >2 3 4

5 10 sec

5 Liner Collapse

Point Equals

LCP= 6.5 “Hg

6 Type Pulsation

Dual

>Single

7 Units

>Inches Hg

kPa

8 Auto Shutoff

10 minutes

9 Clear

Storage

Memory

10 Print

Limping data

11 Set Pulsator

•Print Limping data

•Set Pulsator Limits

The Utility menu is depicted above:

Action of Keys

Menu Return to Function Menu

Up arrow Previous screen/selection

Down arrow Next screen/selection

Enter Edit the value on the displayed

screen

The > symbol points to the current setting.

The enter key is used to access the

Editing mode, which is indicated by a

blinking "E" in the upper right of the

display. While in Editing mode, the (up

arrow) and (down arrow) keys function to

change the current value. Edit mode may

be exited by either pressing the Enter key

to save any changes, or pressing Menu to

abandon any changes that have been

made in the current setting. The editing of

the various settings is described in the

following paragraphs:

Upload-Print all Data

Pressing the Enter key will initiate

transmission of data to either the Digimet

Printer or a waiting computer. The Digimet

Printer must be on if printing is to take

place otherwise an error “No Clear to Send”

will appear at the bottom of the screen. If

transmission is to a computer then the

receiving program must be up and running.

If not or there is a poor cable connection

between the Digimet and the computer the

same error will appear, “No Clear to Send”.

To exit without sending data to the printer

or computer press the Menu key. Note: If

you get no response from the printer after

attempting to print or data that was sent

appears garbled, turn the Digimet OFF then

ON. If you are using the Digimet Printer,

unplug it. Sometimes resetting either

device by turning OFF then ON or

unplugging, will solve the problem. Data

once stored in the Digimet is not lost even if

an upload fails. The data is securely stored

in the Digimet Memory. To erase stored

memory you would have to Clear Storage

Memory (ninth item in the Utility Menu) or

leave the unit without batteries for more

than an hour. This command will upload or

print to the Digimet Printer all numeric data.

Graphs must be printed or uploaded

separately. See Upload Graphic Data (Item

2 in the Utility Menu) and Print Graph (Item

3 in the Utility Menu).

Upload Graphic Data

This Utility Menu item is used to upload

graphs from the Digimet to a computer.

These graphs are formatted to be viewed

on the computer screen and, ultimately,

they can be printed to the computer’s

printer. They are not intended to be sent

to the Digimet Printer. However, if the

raw data is desired, as shown below,

19

• Press the “Press Digi then Here”

button. Button changes to

“******Uploading.” As uploading is

taking place this button will change to

“*****Still Uploading”. When uploading

is completed the button will say “*Done

Uploading”. The Save Graphic file

window will then appear. Choose a

name for your graph file and be sure it

ends with .dgr.

• Press the OK button in the Save

Graphic files window.

• Your graphic file has been uploaded

from the Digimet and saved as a

computer file.

If, however, the message, “No Clear to

Send” appears and remains, then the

Digimet does not have a good connection

or something is wrong with the hookup. If

this happens, pressing the Menu key will

exit the screen and the connection

problem will have to be solved.

The steps are listed here again for

Uploading graphic data from the Digimet to

the Computer.

1. Connect the 6 foot serial cable to the

Digimet and the computers serial port.

2. Open the Digidata program.

3. Go to the UTILITY MENU item 2

Upload Graphic Data on the Digimet.

4. Press Enter on the Digimet.

5. Choose your Graph to upload on the

Digimet.

6. Press Enter on the Digimet, one time.

7. Press the Upload Graph button on the

Digidata computer screen, the button

will change to “Press Digi then Here”.

8. Press Enter on the Digimet one more

time.

time “Hg

.000 12.00

.008 12.01

.016 12.02

(etc.)

you can Upload Graph Data to the Digimet

Printer. The print-out will include all the

time and vacuum data in numeric form, not

a graph. There are 125 readings made

each second. So, for a two second graph,

the raw data will consist of 250 readings.

After pressing the Enter key, the Graph

storage menu will appear. There are 5

storage slots for graphs. If there are stored

items, the slots will either have a timer

stamp next to the slot number or there will

be a label which would have been put in at

the graphing time. Also, the slot number,

01, 02, 03, 04, or 05 will have either a V for

Vacuum Level, P for Pulsator Ratio or a M

for Milk/Rest Ratio in front of it, to

designate which function the graph

originated from. Once you choose the slot

pressing the Enter key, the next screen will

be “Press Enter to start graphing. Menu

to exit.” At this point, before pressing the

Enter key again, the Digimet 3000 should

be connected to a serial port of a computer

with the 6 foot serial cable provided. The

DOS program or Windows program

provided should be up and running on the

computer in order to accept the uploaded

graph. The following will be the steps to

take utilizing the Windows Program

provided – Digidata. Explanation of

uploading using the DOS program can be

found in the SOFTWARE section.

• Press the Upload Graph button on the

Digidata computer screen, the button

will change to “Press Digi then Here”.

• Press Enter on the Digimet one more

time.

20

9. Press the “Press Digi then Here”

button. Button changes to

“******Uploading.” As uploading is

taking place this button will change to

“*****Still Uploading”. When uploading

is completed the button will say “*Done

Uploading”. The Save Graphic file

window will then appear. Choose a

name for your graph file and be sure it

ends with .dgr.

10. Press the OK button in the Save

Graphic files window.

11.Your graphic file has been uploaded

from the Digimet and saved as a

computer file.

Print Graph

This Utility Menu item is used for printing

graphs to the Digimet Printer. These

graphs are only formatted for the Digimet

printer.

Pressing the Enter key will bring up the

Graph storage menu (same menu as in

Upload Graphic Data). Choose the slot to

print.There are 5 storage slots for graphs.

If there are stored items, the slots will

either have a timer stamp next to the slot

number or there will be a label which would

have been put in at the graphing time.

Also, the slot number, 01, 02, 03, 04, or 05

will have either a V for Vacuum Level, P for

Pulsator Ratio or a M for Milk/Rest Ratio in

front of it, to designate which function the

graph originated from. Once you choose

the slot pressing the Enter key, the next

screen will be “Press Enter to start

graphing. Menu to exit.” At this point,

before pressing the Enter key again, the

Digimet 3000 should be connected to the

Digimet Printer and the Digimet Printer

should be on. Pressing Enter again will

initiate the printing of the graph on the

Digimet Printer.

Fluctuation Time Frame

While in Time Frame Edit mode, the up

arrow key will move the marker to the left

and the down arrow key will move the

marker to the right, indicating the selected

setting. Fluctuation time frame can be set

to 1, 2, 3, 4, 5 or 10 seconds. The

Fluctuation time frame establishes the time

frame for the variable - Fluctuation in the

Vacuum Level Function. The Digimet is

looking for the Max and Min value over the

period set here and outputs that difference

to the display and calls it Fluctuation.

Liner Collapse Point (LCP)

While in the LCP Edit mode, the up arrow

and down arrow keys are used to increase

or decrease the liner collapse point.

Prolonged pressing down of the key will

cause rapid advance of the value. LCP

can be set from 0.0 inches Hg/0.0 kPa to

18.0 inches of Hg/60.9 kPa.

Display Units

While in the Display Units Edit mode, the

up arrow and down arrow keys are used to

position the marker next to the desired

setting. Choices for display units are

Inches Hg and kPa.

Type of Pulsation Storage

Storage slots for the pneumatic functions

of Pulsator Ratio and Milk/Rest Ratio can

be either numbered 1,2,3,4, etc. (Single

pulsation) or 1A, 1B, 2B, 2C, etc. (Dual

pulsation). Use the up and down arrow

Table of contents

Popular Test Equipment manuals by other brands

SEAWARD Electronic

SEAWARD Electronic PAC3760 plus II operating instructions

WT

WT PH 2066UK Installation operation & maintenance

Silverline

Silverline 196602 quick guide

Ocean Optics

Ocean Optics XE-1 Xenon Installation and operation instructions

Precision Rated Optics

Precision Rated Optics TP-P6 manual

Agilent Technologies

Agilent Technologies InfiniiVision MSO6104A Service note